BL-Z Stairways conform to DIN 4570, are manufactured from high strength die-cast aluminium alloy

components and have a load bearing of 200kgs. The stairway is ed to a white coated

mul plex backboard (item 12); the height of the special backboard is variable, up to 2000mm high

by up to 1200mm wide.

The stairway is supplied with two heavy-duty counter-balanced springs (item 7), incorporated into

pivot brackets to ensure that the stairway can be raised and lowered with minimum effort.

All BL-Z stairway units are supplied with a telescopic handrail installed. Both sec ons are adjustable

and must be configured by the installer to suit their specific installa requirements. The bo

of the handrail is whereas the top sec n slides within the om sec to extend

and retract when the ladder is opened and closed. The securing screws on the underside of the

handrail fixing brackets should be used to adjust the length of the top se Ensuring that the

handrail doesn’t interfere/conflict with the interior of the hatch box or the roof hatch above, while

also achieving the maximum length possible within the installa

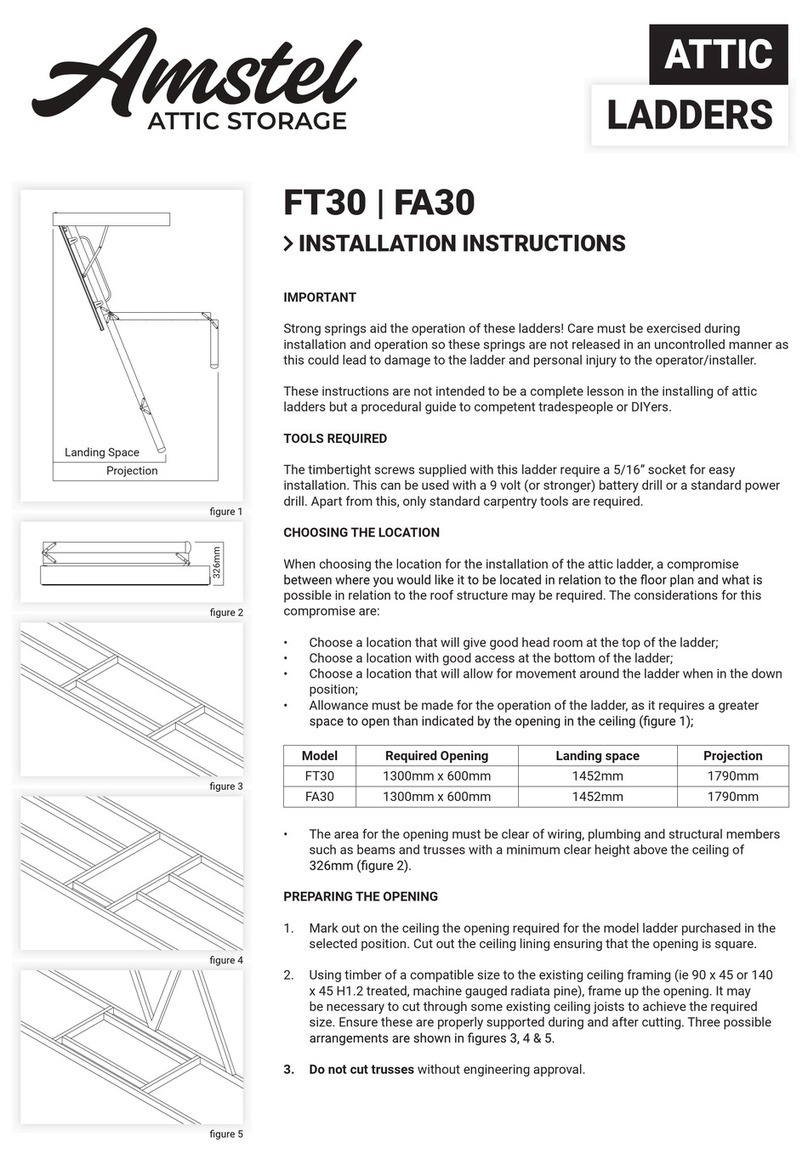

The maximum fixing height from the floor to underside of the backboard is 3390mm. Selec n of

the correct stairway for the floor level to fixing height is determined as follows:

BL-Z 1 stairway supplied with 9 treads, 350mm wide x 140mm deep, to suit a floor to

underside of the backboard height of 2250mm - 2500mm.

BL-Z 2 stairway supplied with 10 treads, 350mm wide x 140mm deep, to suit a floor to

underside of the backboard height of 2501mm - 2790mm.

BL-Z 3 stairway supplied with 11 treads, 350mm wide x 140mm deep, to suit a floor to

underside of the backboard height of 2791mm - 3090mm.

BL-Z 4 stairway supplied with 12 treads, 300mm wide x 140mm deep, to suit a floor to

underside of the backboard height of 3091mm - 3390mm.

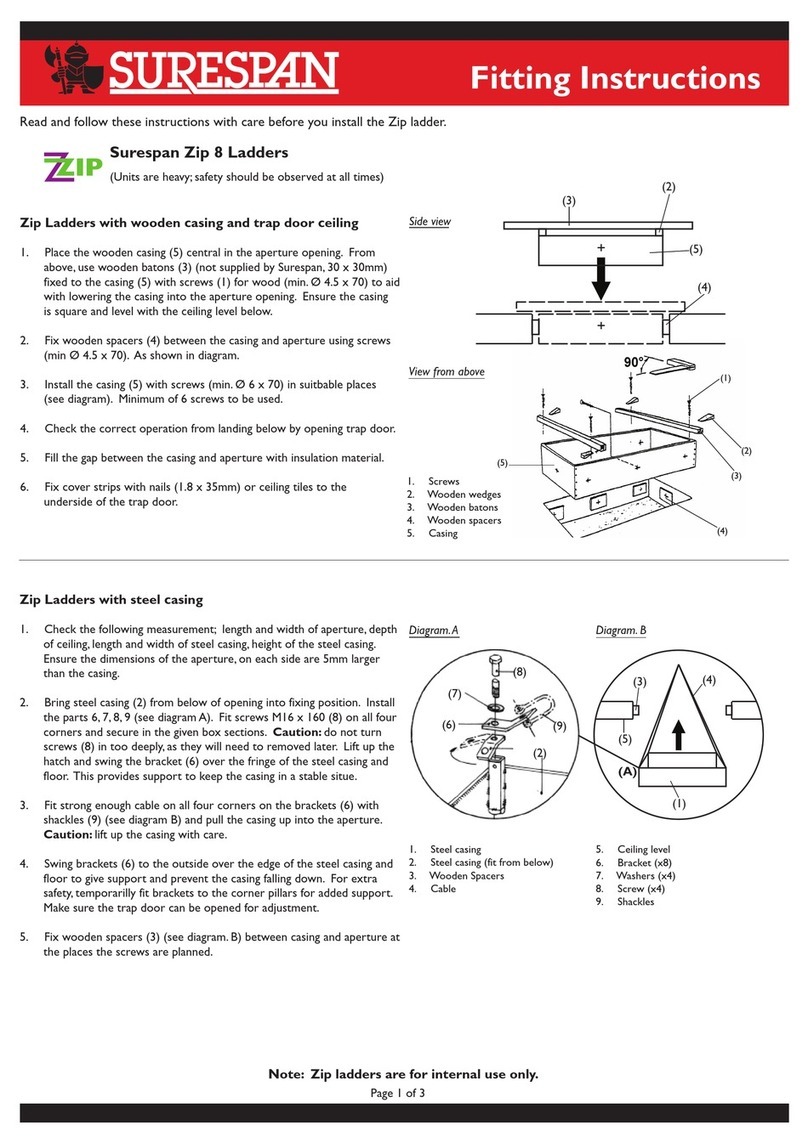

Installing the Stairway

First, check that the correct stairway has been received to suit the actual floor to height as

detailed above.

Please Note: It is not possible to stretch the stairway out to its full length un it has been

fixed in posi on.

Please Note: The stairway must be d in the closed posi n.

We recommend that the backboard is securely fixed to the support structure using a minimum of 6

No. suitable screws (item 10), Ø8mm x 80mm, complete with Ø9mm washers (item 11).

The screws are not included with the stairway, as the correct screws/fixings depend on the actual

surface that the stairway is being fito. Ensure the backboard is fixed to solid structural material.

Once the stairway has been correctly fid, it can then be lowered to the floor surface.

Bilco UK Ltd, Pavilion 7, Fornham Business Court, Hall Farm

I BL-Z BK TS Bilco UK Rev.B 2021

Bilco UK is part of the Access 360 portfolio of Tyman UK and Ireland

Bilco products are designed and fabricated to

consistently high quality standards to ensure

complete customer satisfaction.

BL-Z RETRACTABLE LADDER: INSTALLATION