AFFIX MALT Series User manual

Assembly Manual

Linked Towers MALT Series

BS1139-6:2014

No: CE/21-22/046

01

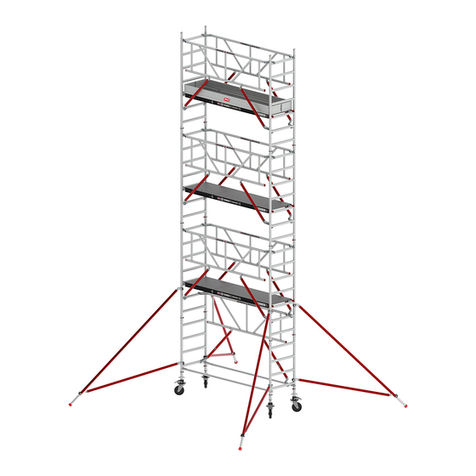

Aluminium LInked Towers

MALT

The AFFIX Linked Tower is a mobile access tower manufactured in our

ISO 9001 accredited facility.

The AFFIX Linked Tower is a mobile access tower manufactured in our

ISO 9001 accredited facility.

This user guide provides you with step by step instructions to ensure your

system is assembled easily and safely, using the 3T (Through the Trapdoor)

method.

This user guide provides you with step by step instructions to ensure your

system is assembled easily and safely, using the 3T (Through the Trapdoor)

method.

BS1139-6 3 7/9 XXXD

WARNING

NEVER FORGET TO TIE

THE STRUCTURE

DESCRIPTION:

Through The Trapdoor (3T) Method:

The 3T method of construction is an approved method of assembly and it minimizes the risk of

a fall from height. The erector can complete an ‘assembly or access’ platform level from which

the ‘next lift’ of frames, braces and platform is added, until the final working height of the tower

is achieved. By following the 3T method, the erector sits through the hatch of the platform with

their feet resting on the frame rungs. In this position the erector can attach the guardrail braces.

Once guard-rails are secured in position the erector can climb onto the platform and continue

constructing the next level.

Compliances:

The Affix MALT Linked Tower structure has been tested and certified to BS1139-6: 2014 by TUV,

India

The Affix MALT Series Aluminium Linked Tower offers customer the flexibility to work on the

long span platform of 7.5 Mtrs Length together by joining two Double Width Towers together

through and additional platform at multiple levels. The MALT Series towers allow the user to

work on longer platform with more workers to work simultaneously. This tower is ideal for use

when work is required to be at multiple levels simultaneously.

The information and instructions included in this manual are provided to help get the best

possible service from your MALT Series Aluminium Linked Tower. This user guide provides you

with step by step instructions to ensure your system is assembled easily and safely, using the

3T (Through the Trapdoor) method.

02

Maximum Safe Working Loads

The safe working load of the tower is 1250 kgs including its own weight.

The maximum safe working load of any individual platform is 250 kgs

evenly distributed.

If the tower is to be used for any specific loading contact

your supplier or the manufacturer, Affix Scaffolding WLL.

RECOMMENDATIONS :

Recommend a minimum of two people to assemble, dismantle and move the platform tower.

Check that all components are on site and in good working order.

Towers must always be climbed from the inside of the assembly using the ladder.

Lifting of components must be done inside the effective base area of the tower.

Damaged components or components from other tower systems must never be used.

Never build linked towers without correctly adopting the suggested stability solution.

Outdoor or Indoor towers must be secured to a building or fixed structure.

Linked towers must never be built as free-standing structures. Suitable tying-in must be used.

Do Not use boxes or steps to gain additional height.

Do Not lift or suspend an assembled mobile tower.

Beware of horizontal loads which can lead to instability of the tower. The Max. side force is 20kg.

Ensure that the assembly location is checked to prevent hazards during assembly or moving

and while working on the tower. Particular attention should be given to the ground condition,

whether level or sloping, obstructions and wind conditions. The ground condition must be

capable of supporting the tower structure.

03USAGE ADVICE

Aluminium Linked Towers

Safety Checklist :Safety Checklist :

Air speed and resultant action to be taken

Mobile towers - 3T Method Checklist

Beufort Scale

01 mph

12 mph

17 mph

25 mph

40 mph

Calm, smoke rises easily upwards No action needed

Cease work

No action needed, keep a watch

If expected, dismantle the tower

If expected, tie tower to a rigid

structure

Moderate breeze, raises dust

Gale force, cannot even walk

Raises loose papers, leaves and small

twigs move

Strong breeze, tree branches bend, unable

to use umbrella

3

4

5

6

Description Air Speed Action to be taken

Ensure all brace claws operate and lock correctly prior to erection

Inspect components prior to use

Tower upright and level

Tower properly tied in to a fixed structure

Diagonal braces fitted

Platforms located and wind-locks on

Toe boards located

Check that the guardrails are fitted correctly

04USAGE ADVICE

WARNING

NEVER STAND ON AN

UNGUARDED PLATFORM

Safe working load on the working platform is 250kgs evenly distributed.

ASSEMBLY PROCESS :

PREPARATIONPREPARATION

Locate the tower, ensuring ground is level.

Check the locking triggers in the bracing hooks such that they are working properly.

Make ready the tying in option.

Sort the braces into horizontal and diagonal braces, the diagonals are slightly longer.

Also note that the braces are differently color coded.

The load on the tower should not exceed 1250 kgs.

The maximum recommended platform height is 9M.

SAFE WORKING LOADS AND HEIGHTS

05

Aluminium Linked Towers

FIRST LEVEL

Insert the Base Jack with the jack

pipe inside the bottom of the tubes

of the 1st level 2 Rung Ladder Frame

and 2 Rung Span Frame.

DO NOT USE Hammer.DO NOT USE Hammer.

Step 1

06ASSEMBLY

Step 2.2Step 2.2

One person should hold the frame in

upright position during this step.

Hook both the bottom 2 Horizontal Braces

horizontally to both the Span frame's vertical

pipes, just above the 1st rung.

Step 2.1Step 2.1

Step 2

SECOND LEVEL

Step 3

Level the structure using a Spirit Level on

the Rungs and the braces.

If adjustment required, adjust using the

adjustable jack.

Step 3.1Step 3.1

Step 4

Step 4.1Step 4.1

07ASSEMBLY

Insert the 2nd level Walk-through Frame

and Ladder Frame into the corresponding

spigots of 1st level Span Frame and

Ladder Frame. For clamping instructions

refer to the Clamping Instructions section

on Page 20.

Step 6

Step 5

Step 5.1Step 5.1

Hook the Diagonal Brace to the 3rd Rung

of the 2nd level Walk-through Frame at

one end and the other end should be hooked

to the 1st Rung of the 2nd level Ladder

Frame on the other side.

Step 5.2Step 5.2

Hook the 2nd Diagonal Brace to the 1st

Rung of the 2nd level Walk-through Frame

at one end and the other end should be

hooked to the 3rd Rung of the 2nd level

Ladder Frame on the other side.

08ASSEMBLY

Hook the Diagonal Brace to the 1st Rung

of the 1st level Span frame at one end and

the other end should be hooked to the 1st

Rung of the 2nd level Ladder frame.

Hook the 2nd Diagonal Brace to the 1st

Rung of the 2nd level Ladder frame at

one end and the other end should be

hooked to the 1st Rung of the 1st level

Span frame.

Step 6.1Step 6.1

Step 6.2Step 6.2

Hook the Intermediate trapdoor platform

on the 2nd Rung of the 2nd level frames.

Make sure the trapdoor is towards the

ladder side.

Step 7

Step 8.1Step 8.1

Hook the lower pair of Horizontal Braces

to the 3rd Rung of both the 2nd level

frames.

Step 8.2Step 8.2

Hook the upper pair of Horizontal Braces

to the 4th Rung of both the 2nd level

frames.

Using the 3T method, standing on the

ladder and leaning back against the edge

of the trapdoor aperture, fit the horizontal

braces as mid rails and guardrails.

Step 8

09ASSEMBLY

Step 7.1Step 7.1

Also hook the Intermediate fixed platform

on the 2nd Rung of the 2nd level frames

beside the trapdoor platform .

Step 7.2Step 7.2

THIRD LEVEL

Step 9

Insert the 3rd level Walk-through Frame

and Ladder Frame into the corresponding

spigots of 2nd level Walk-through Frame

and Ladder Frame. For clamping instructions

refer to the Clamping Instructions section

on Page 20.

Step 10

Step 10.1Step 10.1

Hook the Diagonal Brace to the 3rd Rung

of the 2nd level Walk-through Frame at

one end and the other end should be

hooked to the 1st Rung of the 3rd level

Ladder Frame on the other side.

Step 10.2Step 10.2

Hook the 2nd Diagonal Brace to the 1st

Rung of the 3rd level Walk-through Frame

at one end and the other end should be

hooked to the 3rd Rung of the 2nd level

Ladder Frame on the other side.

10ASSEMBLY

Step 12

Hook the working Fixed Platform on the

2nd Rung of the 3rd level frames. Make sure

the platform is not on the ladder side.

Step 11

Step 11.1Step 11.1

Hook the Diagonal Brace to the 3rd Rung

of the 3rd level Walk-through Frame at

one end and the other end should be

hooked to the 1st Rung of the 3rd level

Ladder Frame on the other side.

Step 11.2Step 11.2

Hook the 2nd Diagonal Brace to the 1st

Rung of the 3rd level Walk-through

Frame at one end and the other end

should be hooked to the 3rd Rung of the

3rd level Ladder Frame on the other side.

11ASSEMBLY

Hook the working Trapdoor Platform on

the 2nd Rung of the 3rd level frames

beside the Fixed Platform. Make sure the

trapdoor is towards the ladder side.

Step 12.1Step 12.1

Step 12.2Step 12.2

Step 13

Step 14

One Tower assembly is now complete

12ASSEMBLY

Step 13.1Step 13.1

Hook the lower pair of Horizontal Braces

to the 3rd Rung of both the frames of 3rd

level on both the sides.

Using the 3T method, standing on the

ladder and leaning back against the edge

of the trapdoor aperture, fit the horizontal

braces as mid rails and guardrails.

Step 13.2Step 13.2

Hook upper pair of Horizontal Braces to

the 4th Rung of both the frames of 3rd

level on both the sides.

Step 16

Hook the lower set of 2 brdige decks (fixed

platforms) to the 2nd rung of the 2nd level

frames on either side

Step 15

Start erecting another tower at a distance

of 2.5 Mtrs from the first tower. Ensure

the Walkthrough Frames of both the

towers face each other.

Repeat Steps 1 to 8 and prepare the other

tower upto the intermediate platform level.

13ASSEMBLY

Step 17

It is safe to remove the safety gates

now from both the sides.

Step 18

Step 18.1Step 18.1

14ASSEMBLY

Hook the lower pair of Horizontal Braces

to the 3rd Rung of both the Walkthrough

frames of both the towers, as Mid rail.

Step 17.1Step 17.1

Hook the upper pair of Horizontal Braces

to the 4th Rung of both the Walkthrough

frames of both the towers, as Guard rail.

Step 17.2Step 17.2

Step 19

Step 20

15ASSEMBLY

Insert the 3rd level Walk-through Frame

and Ladder Frame into the corresponding

spigots of 2nd level Walk-through Frame

and Ladder Frame. For clamping instructions

refer to the Clamping Instructions section

on Page 20.

Step 20.1Step 20.1

Hook the Diagonal Brace to the 3rd Rung

of the 2nd level Walk-through Frame at

one end and the other end should be

hooked to the 1st Rung of the 3rd level

Ladder Frame on the other side.

Step 20.2Step 20.2

Hook the 2nd Diagonal Brace to the 1st

Rung of the 3rd level Walk-through Frame

at one end and the other end should be

hooked to the 3rd Rung of the 2nd level

Ladder Frame on the other side.

Step 21

Step 22

16ASSEMBLY

Step 21.1Step 21.1

Hook the Diagonal Brace to the 3rd Rung

of the 3rd level Walk-through Frame at

one end and the other end should be

hooked to the 1st Rung of the 3rd level

Ladder Frame on the other side.

Step 21.2Step 21.2

Hook the 2nd Diagonal Brace to the 1st

Rung of the 3rd level Walk-through

Frame at one end and the other end

should be hooked to the 3rd Rung of the

3rd level Ladder Frame on the other side.

Hook the working Fixed Platform on the

2nd Rung of the 3rd level frames. Make sure

the platform is not on the ladder side.

Hook the working Trapdoor Platform on

the 2nd Rung of the 3rd level frames

beside the Fixed Platform. Make sure the

trapdoor is towards the ladder side.

Step 22.1Step 22.1

Step 22.2Step 22.2

Step 23

Step 24

17ASSEMBLY

Step 23.1Step 23.1

Hook the lower pair of Horizontal Braces

to the 3rd Rung of both the frames of 3rd

level on both the sides.

Using the 3T method, standing on the

ladder and leaning back against the edge

of the trapdoor aperture, fit the horizontal

braces as mid rails and guardrails.

Step 23.2Step 23.2

Hook upper pair of Horizontal Braces to

the 4th Rung of both the frames of 3rd

level on both the sides.

Hook the upper set of 2 brdige decks (fixed

platforms) to the 2nd rung of the 3rd level

frames on either side

Step 25

Step 26

18ASSEMBLY

Hook the lower pair of Horizontal Braces

to the 3rd Rung of both the Walkthrough

frames of both the towers, as Mid rail.

Step 25.1Step 25.1

Hook the upper pair of Horizontal Braces

to the 4th Rung of both the Walkthrough

frames of both the towers, as Guard rail.

Step 25.2Step 25.2

Remove the temporary safety gate from

both the Walkthrough frames.

Step 27

19ASSEMBLY

Insert the wooden toe-boards in the

toe-board holder slot on all the sides and

insert the wooden toe-board

Step 28

Last, but not the least, follow the tying-in methodology

and instructions provided on page 23 and tie the tower

to a fixed rigid structure before start using it.

Table of contents

Other AFFIX Ladder manuals

Popular Ladder manuals by other brands

KRAUSE

KRAUSE 835239 Assembly and user's manual

Rivers Edge

Rivers Edge CLASSIC XT Operator's manual

Little Giant

Little Giant SafeFrame Instructions for use

Little Giant

Little Giant Classic User instructions

Calspas

Calspas Cal Designs Deluxe Spa Step WOOD118-KD Assembly

Little Giant

Little Giant LOOT BOX quick start guide