For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed

prior to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by

his/her employer.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using cones

and either barriers or tape, available for hire from your

local HSS Hire Shop.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Wear practical, protective clothing,

gloves, footwear and a hard hat.

Avoid loose garments and jewellery that could catch in

moving parts, tie back long hair.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at

your local HSS Hire Shop.

Do not work near flammable gases or liquids, petrol

or paint thinner fumes for example. Keep combustible

materials at a safe distance –at least 5m.

Never use this equipment near overhead power

lines or similar hazards.

Make sure that anyone in the immediate work area

is warned of what you are doing.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

your local HSS Hire Shop.

It is essential to familiarise yourself with the

equipment before starting.

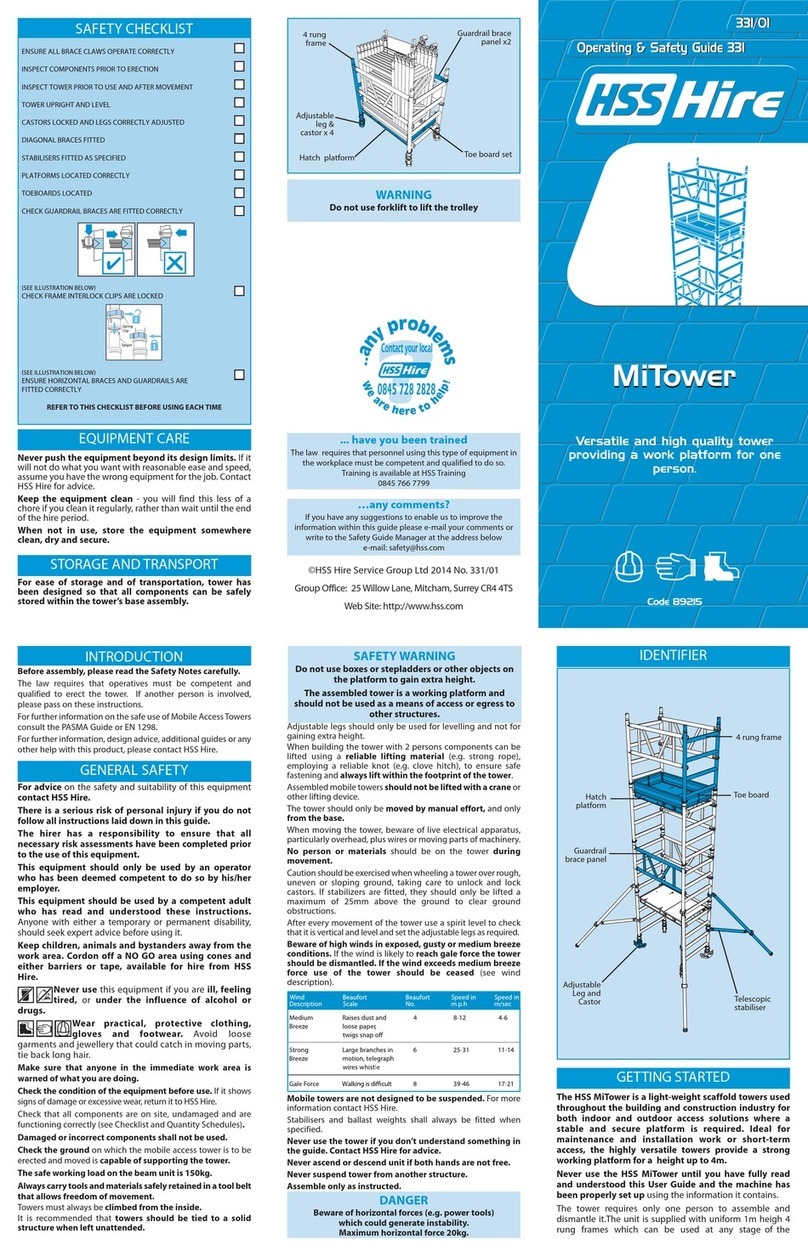

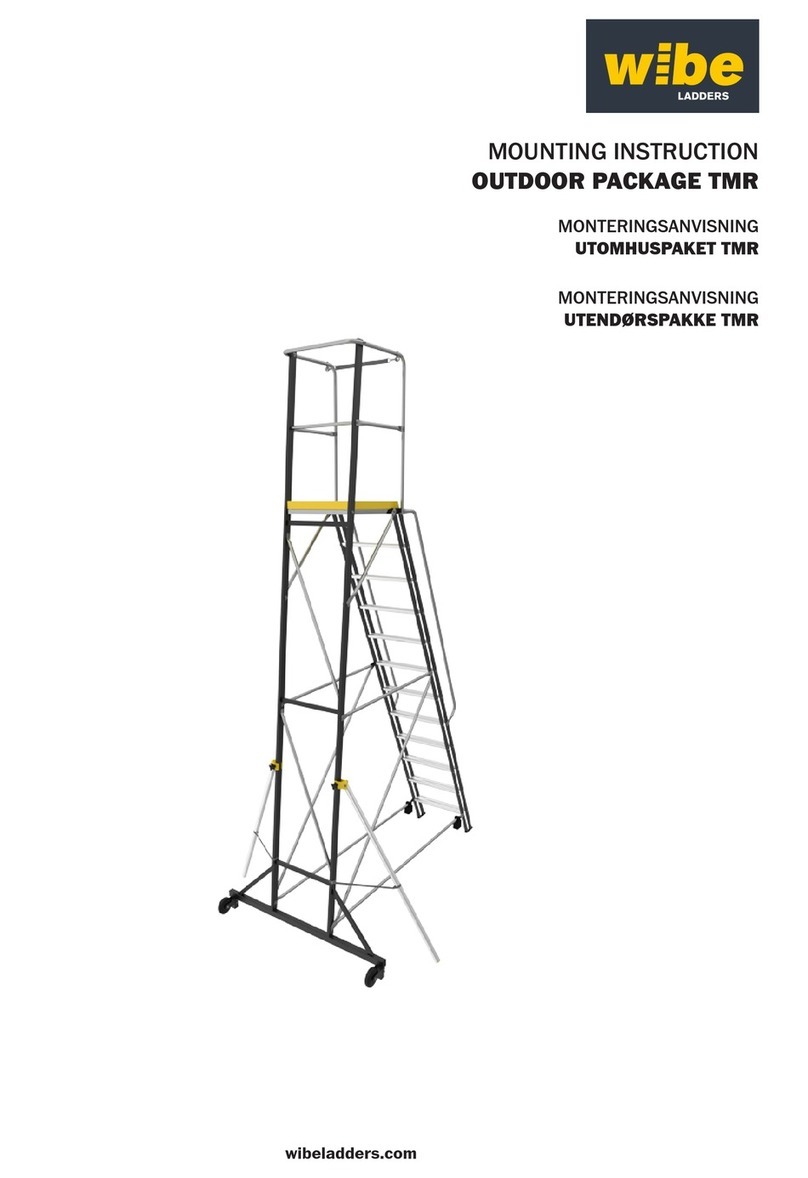

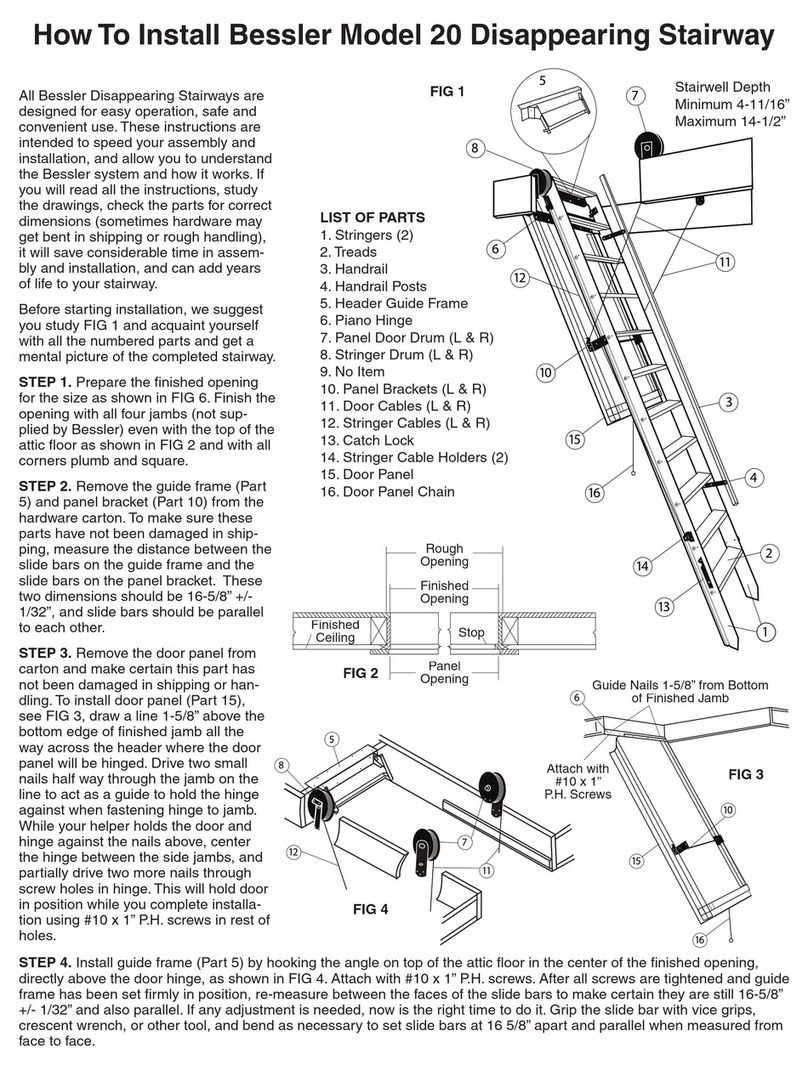

The HSS Span Access Platform must be assembled

before use; it is recommended that two people

assemble the platform.

To assemble the platform, take all the components to the

work area.

Lay the two end supports on the ground, raise the end

support frame so that it is at a 90-degree angle to

the end frame tubes. Lifting the end support base will

also lift the end support braces.

The end support braces have two brace hooks,

when the end support base is at 90 degrees to the

GETTING STARTED

GENERAL SAFETY

end support frame, these will align with one of the

rungs. Affix the hooks to this rung.

When the brace hooks have been fixed to the rungs,

raise the end frame so that it is vertical and stands on all

of its wheels.

Repeat the procedure for the other end support

and place them parallel facing each other.

Fix the clearance brace to the tops of the outer

most set of vertical tubes on the end frame using

the brace hooks. Loosen the coupler holding the

clearance brace diagonals back and secure this to the

vertical of the end frame tube.

Fix the brace hooks to the pivot points on the end

frames.

Raise the end frames to the required working

height, to do this release the four hooks attached to the

end frames and lift the assembly up two rungs. Refit the

hooks to the rungs, repeat the procedure at the other

end support, then repeat at the other end moving the

assembly up in stages to the desired height.

The end support frame forms the guard rail for the

platform and allows you to install the guard rail

before you enter the platform, once the safety rails

are at the required height.

Install the platform ensuring the hooks are secured

over the rungs. The platform hook is equipped with a

spring-loaded pin, which self-locates under the rung.

Climb onto the platform, opening the swing brace(s) on

the end frame to gain access. Install the middle guard

rails, from the inside, using the brace hooks to the

end frame verticals at either side. Open and install

one-piece toeboard set so that it fits snugly around the

platform.

Push the Access Platform to the correct location and

brake all the wheels using the integral wheel

brakes, (see illustration).

The Access Platform is ready to use.

The platform may be located on any rung to give the

optimum working height. The end frame assembly

should be re-located to rest on the same rung as the

platform and provide the correct guard heights.

DO NOT climb onto the platform until it has been

fully assembled.

ENSURE all brace hooks are secure.