BILT HARD TL-PW-336 User manual

TABLE OF CONTENTS

Introduction............................................................................................................................................................................3

Safety Rules ...........................................................................................................................................................................4

Safety Symbols ...........................................................................................................................................................4

Safety Instructions ......................................................................................................................................................4

Pressure Washer Features....................................................................................................................................................7

Pressure Washer Parts Assembly........................................................................................................................................7

Pressure Washer Parts List ..................................................................................................................................................7

Assembly..............................................................................................................................................................................10

Packing List............................................................................................................................................................... 10

Unpacking................................................................................................................................................................. 10

Attaching Foot Assembly..........................................................................................................................................11

Install Handle. ...........................................................................................................................................................11

Attaching Upper and Lower Gun Hooks.................................................................................................................... 11

Attaching Accessory Hook .........................................................................................................................................11

Attaching Spray Gun.................................................................................................................................................12

Adding Engine Oil and Fuel ....................................................................................................................................... 13

Operation ..............................................................................................................................................................................15

How to Start Pressure Washer..................................................................................................................................15

How to Turn Off Pressure Washer.......................................................................................................................... 16

How to Use Spray Gun..............................................................................................................................................16

Using Spray Nozzle .................................................................................................................................................. 17

How to Apply Detergent...........................................................................................................................................17

Maintenance .........................................................................................................................................................................18

Pre Operation Steps..................................................................................................................................................18

After Each Use.......................................................................................................................................................... 18

Maintenance Schedule..............................................................................................................................................18

Changing Oil.............................................................................................................................................................19

Engine Maintenance .................................................................................................................................................19

How to Store ............................................................................................................................................................20

Troubleshooting...................................................................................................................................................................21

Warranty ...............................................................................................................................................................................22

SAVE THIS MANUAL FOR FUTURE REFERENCE

This manual contains important information regarding safety, operation, and maintenance.

Thank you for ordering our product. If you have any issue, please email it and your order ID to [email protected] or

call (888)680-2849

INTRODUCTION

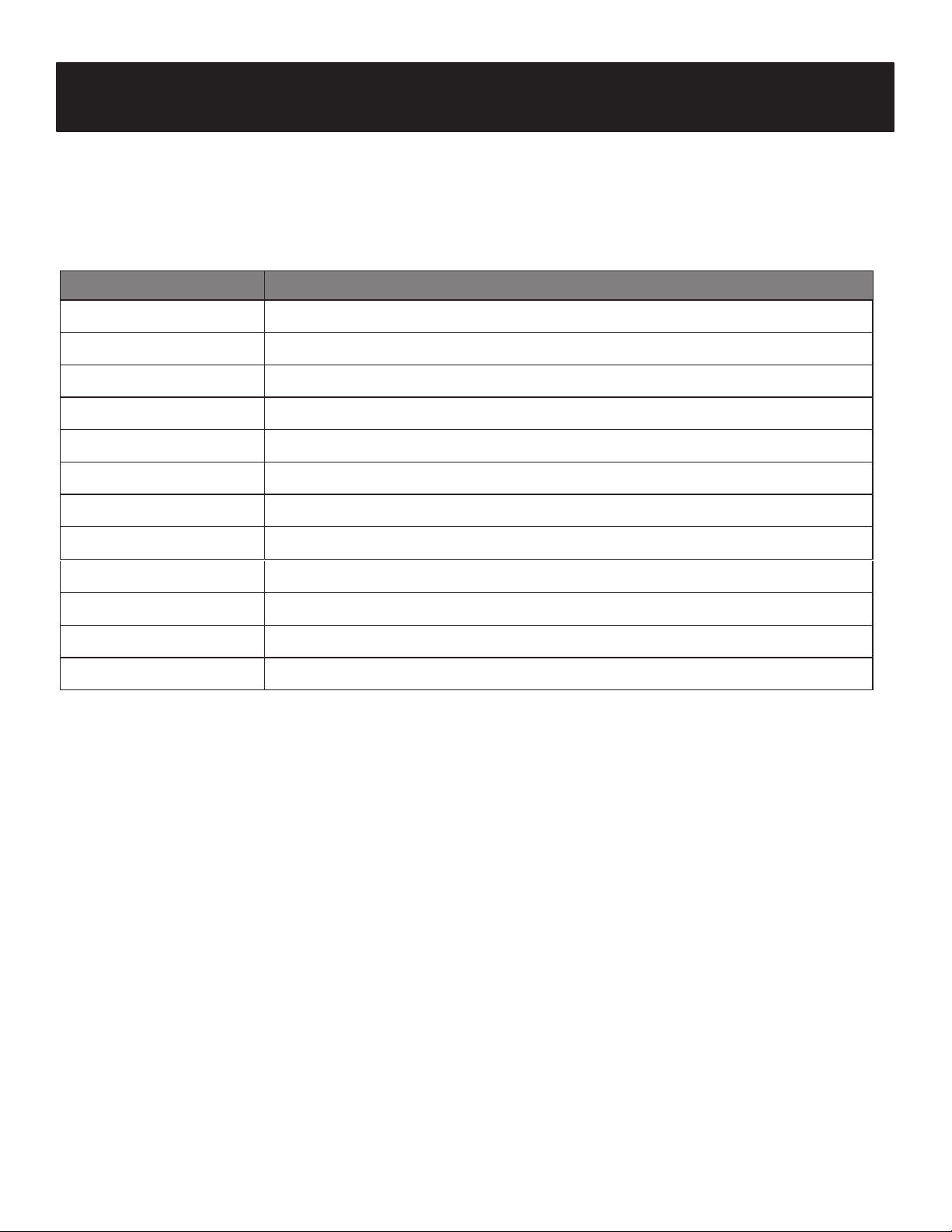

Specications TL-PW-336

Pressure - PSI 3300

Flow Rate - (GPM)2.6

Water Temperature (oF/oC) 104/40 Max

Hose Length (ft) 25

Soap Tank Capacity (L) 1.2

Nozzles 0o, 15o, 25o, 40o, Soap

Engine Displacement 212cc

Spark Plug Type F7TC

Fuel Capacity (L) 3.6

Recommended Oil 10W30

Oil Capacity (L) 0.6

On/O Switch Yes

4

SAFETY RULES

Safety Symbols

Indicates a potentially hazardous

situation which could result in

serious injury or death if not avoided.

Indicates a potentially hazardous

situation which could result in

damage to equipment orproperty.

Safety Instructions

The manufacturer cannot anticipate every possible hazardous circumstance that the user may encounter. Therefore, the

Warning!s in this manual, on tags, and on affixed decals are not all-inclusive. To avoid accidents, the user must understand

and follow all manual instructions and use commonsense.

WARNING!

Do not operate indoors or in a confined space preventing dangerous carbon monoxide gas

from dissipating.

•

•

•

•

Carbon monoxide gas is a poisonous, odorless gas that can cause headache, confusion, fatigue, nausea, fainting,

sickness, seizures, or death. If you start to experience any of these symptoms, IMMEDIATELY get fresh air and seek

medical attention.

Never use indoors, in a covered area, or in a confined space, even if doors and windows are open.

When working in areas where vapors could be inhaled, use a respirator mask according to all of its instructions.

WARNING!

Never spray near a power source such as an electrical outlet. Making contact with

a power source could cause an electric shock or burn.

WARNING!

Read and understand this manual in its entirety before operating this pressure washer.

Improper use of this pressure washer could result in serious injury or death.

Slippery surface

Risk of explosion

Risk of electric shock

Hot surface

Eye protection

WARNING!

CAUTION!

5

SAFETY RULES

WARNING!

•

death.

•

on the unit before starting the engine.

•

Never smoke while operating or fueling this unit.

•

•

•

•

•

When adding or draining fuel, unit should be turned off for at least 2 minutes to cool before removing fuel cap. If unit

has been running the fuel cap is under pressure, remove slowly.

To keep fuel from spilling, secure unit so it cannot tip while operating or transporting.

When transporting unit, disconnect the spark plug wire and make sure the fuel tank is empty with the fuel shutoff valve

turned to the off position.

WARNING!

Pressure washer can create puddles and slippery surfaces.

•

Never wear sandals, always wear protectivefootwear.

•

Operate pressure washer from a level and stablesurface.

•

Do not operate from a ladder, scaffolding, or uneven surface as recoil from spray gun could cause you tofall.

•

Use both hands to control spray gun to control recoil.

•

Do not over-extend yourself in attempt to reach a little further.

WARNING! Moving parts can catch on clothing, jewelry, and hair.

•

Do not wear loose clothing or gloves.

•

Remove jewelry or anything else that could be caught in moving parts.

•

Tie back or wear protective head covering to contain long hair.

WARNING!

To reduce the risk of injection, injury or possible amputation, never direct water pressure

towards people or pets.

•

The high pressure stream of water produced can cut through skin and underlying tissue. Never squeeze the trigger or

point the spray gun at other people, animals, plants, or fragile objects such as glass, even if the engine is stopped.

•

This unit is not a toy. Keep unit away from children and pets.

•

Do not leave spray gun unattended while unit is running.

•

Make sure the spray gun, nozzle, and accessories are attached correctly.

•

Never attempt to repair high pressure hose, alwaysreplace.

•

Never attempt to repair leaks with sealant, always replace O-ring orseal.

•

Never attempt to connect or disconnect hose from pump or spray gun while system is pressurized.

•

Always release water pressure from unit every time you stop the engine.

Table of contents