Bimba OLE Series Instruction manual

Original Line Electric Actuator,

Motor, and Driver Quick Start

Manual

Please read this manual carefully

before implementing your

Original Line Electric Actuator

Contents

1. Actuator-only Models ..................................................................... 2

Installing your motor

2. Actuator and Motor Models ............................................................ 3

Motorspecicationsandwiringdiagram

3. Actuator, Motor, and Driver Models ............................................... 6

a. Mount your drive ..................................................................... 6

b.ConnecttheDCpowersupplytothedriver............................ 7

c. Connect the motor to the driver .............................................. 7

d.Setrotaryswitchformotorselected ....................................... 8

e. Adjust running and idle current ............................................... 8

f. Setloadinertia........................................................................ 9

g. Select step resolution ............................................................. 9

h.Applypowerandrunselftest ............................................... 10

i. Connect input signals ........................................................... 10

j. FAULT output ........................................................................ 13

k. Set step pulse type ............................................................... 14

l. Steppulsenoiselter ........................................................... 14

m.Technicalspecications........................................................ 15

n. Alarm codes .......................................................................... 16

Troubleshooting Guide and FAQ ..................................................... 17

Original Line Electric Actuator,

Motor, and Driver Quick Start

Manual

1

CongratulationsonpurchasinganOriginalLineElectricactuatorfrom

Bimba. Our OLE actuators are designed, built, and tested to provide the

longestlife,greatestdurability,highestspeed,andgreatestthrustper

dollar.Welookforwardtoservingyourelectricactuatorneedswiththe

same responsiveness and engineering expertise you are accustomed to

receivingforourpneumaticproducts.

EveryOLEactuatorisbackedbyaone-yearwarranty.Extendittoatwo-

yearwarrantybyregisteringonourwebsiteat

www.bimba.com/pdf/OLEwarrantyregistration.pdf.

1. Actuator-only Models

Installing your motor

a. Remove plug to provide access to coupler.

Table 1

No Motor

Option Number Allen Key Size Torque

(in-lbs)

OLE-75 5/64" 3.8

OLE-150 3/32" 8

OLE-35013/32" and 5/64" 8 and 3.8

b.Turntheactuatorcouplersotheclampscrewisalignedwiththe

accesshole.Loosencouplersetscrewusingallenkey.Allenkey

sizesareidentiedinTable1.

2

1OLE-350couplershavetwoclampscrews.Tightenthe3/32”

clampscrewfirst.

Table 2

Actuator Size Screw Torque

75 #8-32 12 in-lbs.

150 #8-32 12 in-lbs.

350 #10-24 35 in-lbs.

c.Mountmotortoactuator,slipshaftintocoupler.Securemotorto

actuatorusing4screwsprovided.Allenkeysizesandtorquevalues

areprovidedinTable2.Becarefulnottoturnthecoupler.

d.Tightencouplerclampscrewsomotorshaftissecured(referto

Table1fortorquespecication).Thecouplerclampsaroundthe

circumferenceofthemotorshaft.Theorientationofanyatonthe

shaftdoesnotmatter.Replacecoupleraccessplug.

2. Actuator and Motor Models

All Bimba step motors use the same

8-wirewiringcolorcodeconvention,as

shownbelow.

Warning:Besurepowerisoffbefore

connecting or disconnecting the motor.

Table 3

Frame Winding

Connection

Min. Holding

Torque(oz-in) Volts Amps Ohms mH Rotor Inertia

(oz-in2/g-cm2)

17

Parallel 62.3 2.9 1.7 1.7 2.5 0.44/82

Series 62.3 5.6 0.85 6.6 10.0 0.44/82

Unipolar 43.9 4.0 1.2 3.3 2.5 0.44/82

23

Parallel 269.1 2.1 4.2 0.5 1.7 2.51/260

Series 269.1 4.2 2.1 2.0 6.8 2.51/260

Unipolar 191.2 3.0 3.0 1.0 1.7 2.51/260

34

Parallel 1260 2.72 5.6 0.48 5.4 15.0/2750

Series 1260 5.43 2.8 1.9 21.6 15.0/2750

Unipolar 906 3.88 4.0 0.97 5.4 15.0/2750

SpecicationsforBimba8-lead1.8degreestepmotorsareprovidedin

Table 3.

3

!TightenthecouplerclampscrewtothetorquevalueinTable1.

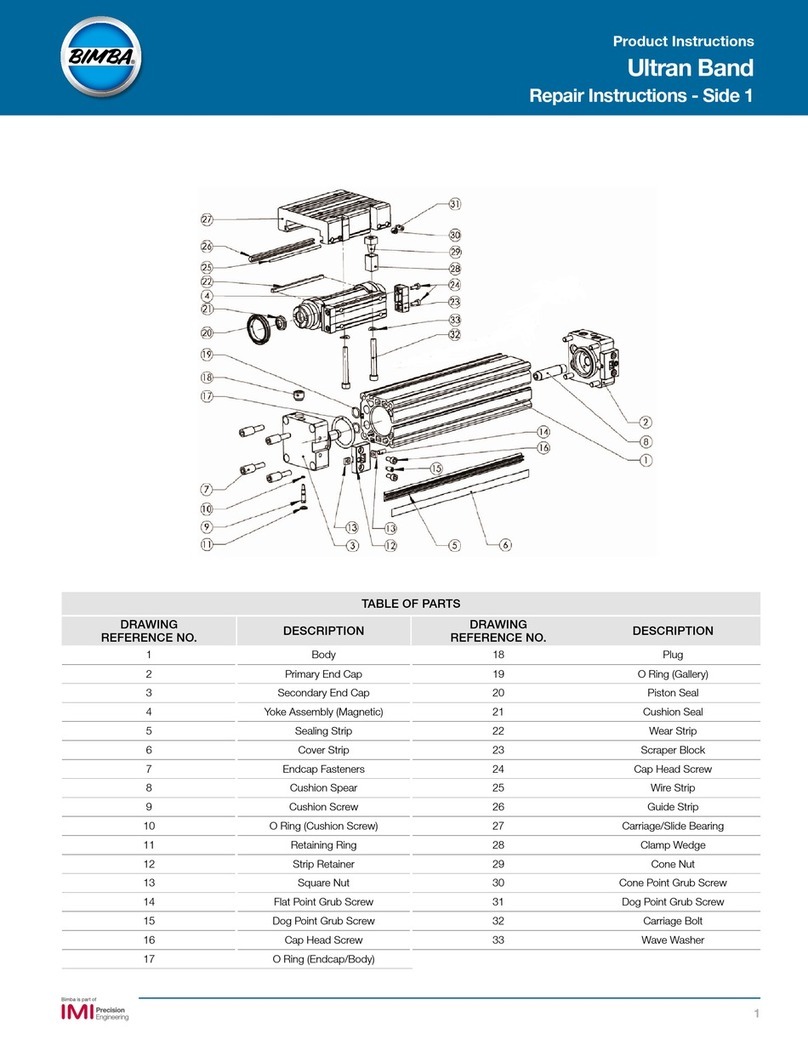

Figure 1

$

$²

% %²

6HULHV

$

$²

% %²

Orange

Org/Wht

Blk/Wht

Black

Red Red/

Wht Yel/

Wht

Yellow

Orange

Org/

Wht

Blk/Wht

Black

Red

Red/Wht

Yel/

Wht

3DUDOOHO

Yellow

Table 4

Encoder Specications

17 and 23 Frame Motors

34 Frame Motor

PowerInput 5 V DC, 100 mA Max. 5 V DC, 160 mA

Resolution 2048 pulses per rev. 2000 pulses per rev.

Output High 2.4 V DC Min. 2.5 V DC Min.

OutputLow 0.5 V DC Max. 0.5 V DC Max.

OperatingFrequency 300 kHz Max. 500 kHz Max.

Operating Temperature -10 to 100°C-30 to 115°C

Enclosure Rating IP40 IP40

Table 5

Wire Color Function

Blue Channel A

Blue/Black Channel A-

Green Channel B

Green/Black Channel B-

Yellow Index

Yellow/Black Index-

Red +5VDCinputpower

Black Encoder ground

Brown

Not used

Brown/Black

Gray

Gray/Black

White

White/Black

Ifyouhaveorderedyouractuatorwithamotor/encodercombination,the

encoderspecicationsarelistedinTable4.

4

Encoderconnectionsfor17and23framesteppersareidentiedin

Table5.Theseencodershave20-inchyingleadsforconnectiontoyour

closed loop controller.

Table 6

Pin No. Wire Color Function

1Yellow Channel A

2Yellow/White Channel A-

3 Blue Channel B

4 Blue/White Channel B-

5 Orange Index

6 Orange/White Index-

7 Green

Not used

8 Green/White

9Brown

10 Brown/White

11 White

12 Gray/White

13 Red +5VDCinputpower

14 Black Encoder ground

15 Gray Drain/shield

5

Encoderconnectionsforthe34framestepperareidentiedinTable6.

Thecableprovidedhasyingleadswhichcanbeconnectedtoyour

controller.

You will need:

Motor & Power Supply

Connector

Run Current, Idle Current

Steps/rev, Inertia, Self Test

Input & Output

Signals

Motor Selector

Status LEDs

Table 7

Driver Power

Supply

Voltage

Bimba

Motor

Parallel

Current

Draw

Parallel

Current

DrawMax

.

24VPower

Supply

Amperage

48VPower

Supply

Amperage

Max

Amps per

Phase

DRV-4 24-48 17frame 1.7 3.4 4 2 4.5

DRV-8 24-75 23frame 4.2 8.4 8 4 7.8

DRV-8 24-75 34frame 5.6 11.2 12 6 7.8

3. Actuator, Motor, and Driver Models

• AnOLEactuatorwithmotorattached.

• Asmallatbladescrewdriverfortighteningtheconnectors.

• Wires - 18 to 20 gage recommended

• Wire cutter/stripper

• AnappropriateDCpowersupply.

a. Mount your drive

Mountthedriveusing#6screws.

Installingonametalsurface

(recommended)helpsdissipateheat.

Forcedairowfromafanisalso

good practice.

6

TheDRV-4acceptspowersupplyvoltagesfrom24to48VDC,whilethe

DRV-8acceptspowersupplyvoltagesfrom24to75VDC.Thecurrent

demandwillneverexceeddoublethemotorcurrent(seeTable3,Amps

column).However,theDRVwillconvertahighvoltagelowcurrentpower

supplyintoalowervoltagehighercurrentpowersupply.A24V4Asupplywill

performsimilarlytoa48V2Asupply.UseTable7belowasaguideline.

!

Warning:Donotapplypoweruntilallconnectionsaremade.

!

Useunregulatedpowersupplieswithoutovervoltageprotection

toavoidproblemswithregenerationduringrapiddeceleration.

b. Connect the DC power supply to the driver -- Do not

apply power

I.Makesurethepowersupplyisnoton.ConnectV+andV-fromthe

powersupplytotheV+andV-terminalsofyourdriver.

II. Ensure a proper earth ground connection by

usingthescrewontheleftsideofthechassis.

Ifusinganexternalfuse,werecommendthe

followingin-linewiththeV+connection:

DRV-4:3AG,4amp(Littlefuse313004P)

DRV-8:3AG,6.25amp(Littlefuse3136.25P)

c. Connect the motor to the driver

orange+blk/wht

black+org/wht

red+yel/wht

yellow+red/wht

A+ A- B+ B-

ConnectOLEeightleadmotorsinparallel,asshownbelow.Ifusingamotor

fromanothersource,pleaserefertoyourmotorspecsforwiringinformation.

AmotorwiringdiagramisshowninFigure1.

!

Warnings:

• Donotinstallwhereambientairismorethan104°F.

• Donotinstallwherethereisnoairow

• Donotinstallwheredrivecangetwet.

• Donotinstallwhereelectricallyconductivematerialcanfallon

the driver.

• Drivesmustbemountedatleastone-halfinchapart.

!

Warning:Observeproperpolaritywhenconnectingwires.

!

Warning:Neverconnectordisconnectthemotorwhenpoweris

applied.

7

e. Adjust running and idle current

d. Set rotary switch for the motor selected

(This is normally set by the factory for the motor specied.)

Switch1and2settherunning

current to 70%, 80%, 90%

or100%ofthemotor’s

rated maximum current.

1 2

100%

1 2

90%

1 2

80%

1 2

70%

4

50%

4

90%

Switch4setstheidlecurrent

toeither50%or90%ofthe

selected running current.

Factory default is 90%.

Bimba Motor

Frame Option Code Setting

17frame P1, E1, Y1, Z1 5

23frame P2, E2, Y2, Z2 8

34frame P3, E3, Y3, Z3 F

• Use 100% position in most ap-

plications (factory default)

• Uselowersettingsforselflock-

ingthreads(OLE12,16,and

20leads).

• Uselowersettingstoreduce

motor temperature

• Usehighersettingsforfullhold-

ingtorque

Turntherotaryswitchtothenumberthatrepresents

the motor you have. This sets current and anti-

resonancesettingsforoptimumperformance.

8

!

• Uselowersettingduring

initial setup to avert

accidental damage

• Uselowersettingstoaddress

safetyissues

• Uselowersettingstoreduce

motor temperature

Switch3choosesbetween

twoloadinertiaranges.

Thisinformationisusedinthe

anti-resonanceconguration.

f. Set load inertia

g. Select step resolution

3

5-10X

3

0-4X

• Valuesaremultiplesofrotor

inerta(seeTable3)

• Use 0-4x for smaller leads and

shorter strokes (factory default)

• Use5-10xforlongerleadsand

greater loads

• 5-10xmayreduceperformance.

The 200µ and 400µ settings use microstep emulation to provide smooth

rotationatlowspeeds.Microstepemulationimpartsaslightdelaytothe

motion.Ifthisisnotacceptable,usethenon-ltered200or400settings.

567

20000

567

12800

567

5000

567

2000

567

400

SMOOTH

567

400

567

200

SMOOTH

567

200

µµ

Thereare4microstepresolutionstochoosefromaswellasfullandhelp

step

• 200

• 200µ(microstepemulation)

factorydefault

• 400

• 400µ(microstepemulation)

• 2000

• 5000

• 12800

• 20000

9

h. Apply power and run self test

TheDRV-4andDRV-8havebuiltinSelfTestfunctions.

Whenswitch8ismovedtotheONposition,the

drivewillautomaticallyrotatethemotorbackand

forth,twoturnsineachdirection.Thisfeaturecan

beusedtoconrmthatthemotoriscorrectlywired,

selectedandoperational.Factorydefaultis“OFF.”

8

ON

8

OFF

SELF TEST

The drives have three inputs:

• STEP:ahighspeeddigitalinputforsteppulsecommands,5-24voltlogic

• DIR:ahighspeeddigitalinputforthedirectionsignal,5-24voltlogic

• EN:a5-24Vinputforcommandingtheremovalofpowerfromthemotor

Table 8

Pulses per

revolution

Degrees per

step

Pulse frequency re-

quired for 300 RPM

Pulse frequency re-

quired for 3000 RPM

200 1.8 1,000 Hz 10,000 Hz

400 0.9 2,000 Hz 20,000 Hz

2000 0.18 10,000 Hz 100,000 Hz

5000 0.072 25,000 Hz 250,000 Hz

12800 0.028 64,000 Hz 640,000 Hz

20000 0.018 100,000 Hz 1,000,000 Hz

Microsteppingprovidessmoothestrotation.However,afastersteppulse

rate(frequency)isrequiredforagivenRPMasshowninTable8below.

i. Connect input signals

10

STEP+

STEP–

DIR–

EN+

EN–

FAULT+

FAULT–

DIR+

inside drive

220 pF

STEP+

STEP-

220 pF

DIR+

DIR-

Motor & Power Supply

Connector

Run Current, Idle Current

Steps/rev, Inertia, Self Test

Input & Output

Signals

Motor Selector

Status LEDs

STEP and DIR inputs can be converted to STEP CW and STEP CCW by

movingtheinternaljumperS3.Fordetailedinstructions,gotoStep“K”of

this section.

Refertotheillustrationbelowforidenticationofstep,direction,and

enableinputsonthedriverscrewterminalblocks.

Connection Examples: STEP & DIR

Connecting to indexer with Sourcing Outputs

STR

COM DIR-

DIR DIR+

STEP-

STEP STEP+

Indexer

with

Sourcing

Outputs

Connecting to Indexer with Differential Outputs

(ManyHighSpeedIndexershaveDifferentialOutputs)

Connecting to Indexer with Sinking Outputs

STR

+5V OUT DIR+

DIR DIR-

STEP+

STEP STEP-

Indexer

with

Sinking

Outputs

STR

DIR+ DIR+

DIR- DIR-

STEP+

STEP-

STEP+

STEP-

Indexer

with

Differential

Outputs

DRV

DRV

DRV

11

Connecting another drive to EN

(Whenoutputcloses,inputcloses)

Connecting an NPN Type Proximity Sensor to an input

(Whenproxsensoractivates,inputcloses)

STR

EN-

EN+

Si drive

OUT+

OUT–

5-24

VDC

Power

Supply

-

+

STR

NPN

Proximity

Sensor

EN-

EN+

output

+

–

12-24

VDC

Power

Supply

-

+

Connecting a PNP Type Proximity Sensor to an input

(Whenproxsensoractivates,inputcloses)

STR

PNP

Proximity

Sensor

EN+

output

+

–

EN-

12-24

VDC

Power

Supply

-

+

Connecting an Input to a Switch or Relay

STR

switch or relay

(closed=logic low)

EN-

EN+

5-24

VDC

Power

Supply

-

+

Connection Examples: EN

DRV

DRV

DRV

DRIVE

DRV

The 5-24 V EN input disables power to the motor.

12

j. FAULT output

TheDRVdrivesfeatureadigitalFAULToutput.Thisoutputclosestosignala

faultcondition.

ThisoutputcanbeusedtodriveLEDs,relaysandtheinputsofotherelec-

tronicdeviceslikePLCs.The“+”(collector)and“-”(emitter)terminalsofthe

outputtransistorareavailableattheconnector.Thisallowsyoutocongure

theoutputforcurrentsourcingorsinking.Diagramsofeachtypeofconnec-

tionfollow.

Sinking Output

STR

5-24 VDC

Power Supply

+ –

Load

FAULT-

FAULT+

!

PLC

STR

5-24 VDC

Power Supply

+ –

FAULT-

FAULT+

IN

COM

Sourcing Output

Driving a Relay

STR

FAULT-

FAULT+

1N4935 suppression diode

5-24 VDC

Power Supply

+ –

relay

DRV

DRV

DRV

Do not connect the output to more than 30 VDC.

The current through the output terminal must not exceed 80 mA.

13

k. Set step pulse type

Mostindexersandmotioncontrollersprovidemotioncommandsinthe“Step

andDirection”format.TheStepsignalpulsesonceforeachmotorstepand

thedirectionsignalcommandsdirection.However,afewPLCsuseadiffer-

enttypeofcommandsignal:onesignalpulsesonceforeachdesiredstepin

theclockwisedirection(calledSTEPCW),whileasecondsignalpulsesfor

counterclockwisemotion(STEPCCW).Thedrivescanacceptthistypeof

signalifyouremovethecoverandmovejumperS3fromthe“1-2”positionto

the“1-3”position.Factorydefaultisthe1-2position.Asyoucanseeinthe

image,thejumperterminals(2,1,3)andS3andS4designatorsareprinted

inwhiteonthecircuitboard.

l. Step pulse noise lter

Electricalnoisecancausethedrivetothinkthatonesteppulseistwoor

more pulses, resulting in extra motion and inaccurate motor and load posi-

tioning.Tocombatthisproblem,thedriveincludesadigitalnoiselteronthe

STEPandDIRinputs.Thedefaultfactorysettingofthislteris150kHz.

Ifyouareoperatingthedriveathighspeedswithstepratesabove150kHz,

removethecoverandmovejumperS4fromthe150kHzposition(1-3)tothe

2MHzposition(1-2)asshownbelow.

Yourmaximumpulseratewillbethehighestmotorspeedtimesthesteps/

rev. For example, 40 revs/second at 20,000 steps/rev is 40 x 20,000 = 800

kHz.Pleaseconsiderthiswhendecidingifyoumustincreasethelterfre-

quency.

14

Jumper S4: noise lter

Shown in 1-2 position

Jumper S3: step pulse type

Shown in 1-2 position

m. Technical specications

15

Amplier

DigitalMOSFET.20kHzPWM.Suitablefordrivingtwo

phaseandfourphasestepmotorswithfour,sixoreight

leads.

Supply voltage:

DRV-4

24-48 VDC

Under voltage alarm: 20 VDC

Overvoltageshutdown:60VDC

DRV-8

24-75 VDC

Under voltage alarm: 20 VDC

Overvoltageshutdown:85VDC

Motor current:

0.5to7.8amps/phasepeakofsine(DRV8)

0.25to4.5amps/phasepeakofsine(DRV4)

Digital Inputs

Optically isolated, 5 - 24V logic. Sourcing, sinking or

differentialsignalscanbeused.

Minimum“on”voltage:4VDC.

Maximum voltage: 30 VDC.

Input current: 5 mA typ at 4V, 15 mA typ at 30V.

Fault Output

Photodarlington, 80 mA, 30 VDC max. Voltage drop: 1.2V

max at 80 mA.

Physical

1.3x3.0x4.65inches(33x75.5x118mm)overall.10.8

oz(305g)includingmatingconnectors.

Ambienttemperaturerange:0°Cto40°C.

Mating Connectors

Motor/powersupply:PCDP/NELV06100(PhoenixContact1757051),

includedwithdrive.

Signals:PCDP/NELVH08100(PhoenixContact1803633),includedwith

drive.

n. Alarm codes

Intheeventofadrivefaultoralarm,thegreenLEDwillashoneortwo

times,followedbyaseriesofredashes.Thepatternrepeatsuntilthealarm

is cleared.

Code Error

solid green no alarm, motor disabled

flashing green no alarm, motor enabled

flashing red configuration or memory error

1 green, 4 red power supply voltage too high

1 green, 5 red over current / short circuit

1 green, 6 red open motor winding

2 green, 3 red internal voltage out of range

2 green, 4 red power supply voltage too low

16

17

Troubleshooting Guide and FAQ

Problem:Actuatordoesnotmovewhenstepmotorisenergized.

Solution:Stepmotorwindingsmaybeshorted.UseanOhmmeterto

measuretheresistancebetweenpairsofwindings(shouldbeinnite)

andbetweentheleadsofeachwinding(shouldbethesameforeach

winding).Useyourmotor’swiringdiagramtoidentifythecorrectleads.

Ifwindingsareshorted,themotormustbereplaced.

Problem:Actuatoroperationisstiff,seemstobebinding.

Solution:Checkfordentsonthebodytube,motorendbell,anddam-

agetothesquarerod.Iftherearesignsofvisibledamage,theactuator

ormotororbothmayneedtobereplaced.Dentsonthemotorshaftor

endbellsmaycausetherotortoseizeorrub,producingbindingandstiff

operation.WhilethenutoftheOLEactuatorisself-lubricating,rodlubri-

cations is recommended at regular intervals. Use Bimba HT-99 grease.

Problem:CanIuseswitcheswithmyOLEforendofstrokesensing?

Solution: All OLE actuators have magnetic pistons. OLE actuators can

usethesameswitchesasOriginalLinepneumaticcylinders.Refertothe

Bimbacatalogforswitchrecommendations.

Problem: The motor gets hot.

Solution:Stepmotorstendtorunhot(theactualmaximumcasetem-

peratureis80°C).However,themotorshouldnotgettoohottotouch.

Ifitisoverheating,thedrivecurrentmaybesettoohigh.Allstandard

OLEstepmotorsare8-wiremotors.RefertoTable3inthismanualfor

requireddrivecurrentlevels.Alsoconsiderdutycycle;reduceeitherthe

runningcurrent,idlecurrent,ordutycycle.Instructionsforadjustingidle

and running current are provided in section 3.e.

Problem:Themotorisnotproducingenoughtorqueoritstallsatlow

speeds.

Solution:Ifthemotorpreviouslyranwell,checktheresistanceofthe

windings.UseanOhmmetertomeasuretheresistancebetweendiffer-

entwindings(shouldbeinnite)andbetweentheleadsofeachwinding

(shouldbethesameforeachwinding).Useyourmotor’swiringdiagram

toidentifythecorrectleads.Ifwindingsareshorted,themotormustbe

replaced.

Iflackoftorqueisobservedattheinitialstartupwithaloadanddesired

speedsarenotreached,checkconnectionsbetweenthemotoranddrive

and check drive settings.

18

Inspectthemotorandrotatetheshaftwhenthemotorisnotconnected.If

youfeelanyrubbingorthereareanydentsonthemotor,thereisprob-

ably an alignment problem and the motor may need to be replaced.

Iftherotorwasremovedfromthestator,itcouldhavebeendemagne-

tized.Themotorwouldneedtobereplaced.

Ifyoustillcannotsolvetheproblem,thesizeofyourpowersupply(volt-

ageoutput)mayneedtobegreater.Whenastepmotorrotates,itacts

likeageneratorpumpingvoltage(backEMF)backintothedrive.Back

EMF rises as motor speed and inductance increase and can cause a stall.

Thesolutionistoeitherchangefromaseriestoaparallelconnection

(seriesconnectionsquadrupleinductance)oruseapowersupplywitha

higher output voltage.

Problem: Themotordoesn’tproduceanyholdingtorque.

Solution: Makesurethatlinepowerison,thedriveispoweredup,and

the motor phases are connected correctly to the drive.

Problem:Themotor(actuator)oscillatesbackandforthatlowspeeds.

Solution: Thisisduetoresonance,commonbetween1-4rps.Ifthisis

observedwithnoload,addaloadtothemotor(theloadwilldampenout

resonance).Changingfromfull-steptohalf-stepormicrosteppingwillalso

solve resonance problems.

Step and Direction Drives

Note:Pleasereadyourmanualrstbeforeandduringyoursetup.Bimba

manuals, available at www.bimba.com/OLE/manuals, are short, to the

point, and comprehensive.

Problem:Thedrive’spowerLEDdoesnotilluminatewhenpowerisap-

plied.

Solution:Checkthefuseandreplaceifnecessarywithoneoftheextra

fusesincludedwithyourdrive.Ifyouhavenofusesorcontinuouslyblow

fuses,callBimbaTechnicalSupport.Checkyourpowersupplytobesure

it is not providing an excessively high voltage to the drive.

Problem: The motor runs then suddenly dies. The connections are cor-

rect.

Solution:Turnoffpower.Refertoyourmotorwiringdiagram.Discon-

nectthemotor.Usinganohmmeter,measuretheresistancebetweenthe

A+ and A- and B+ and B- terminals. The reading should be in the mega-

Ohms.Ifresistanceislow,theH-bridgeisdamagedandthedrivemust

bereturnedonaRGA(ReturnedGoodAuthorization).Iftheresistanceis

normal,inspecttheboardforanyvisibledamagetothecomponentsand

checkthemotorforashortcircuitinthewindings.

Problem: Themotordoesnotmovewhenastepsignalissenttothe

drive.

Solution: Iftheenableinputison(lowwithrespecttoa5-24voltsignal),

itwilldisablethemotor.Donotconnectanythingtotheenableinputif

there is no reason to disable the motor.

Problem: Themotorwillnotrunslowenoughwithapotentiometercon-

nectedtomydrive(ithasaninternaloscillator).

Solution:Somedrives’internalpotentiometerscannotbeadjustedto

zerospeed.Checkthespecicationsinthemanualthatcamewiththe

drive.

Problem:Atstartup,themotordoesnotrunalthoughthewiringiscor-

rect.

Solution:Makesurethatdipswitchesandjumpersaresetproperly.

Readyourdrivermanualcarefully.

Problem:Systemnotworkingproperly.

Solution: Troubleshootbyreplacingthedriveandseeiftheproblem

persists.Pleasereadyourdrivemanualbeforeandduringyoursetup.

Bimbamanuals,conciseandcomprehensive,areavailablefordownload

atourwebsite,www.bimba.com.

18

This manual suits for next models

6

Table of contents

Other Bimba Controllers manuals

Popular Controllers manuals by other brands

ROTOR

ROTOR Pakscan quick start guide

LOVATO ELECTRIC

LOVATO ELECTRIC ADXL 0030 600 installation manual

ABB

ABB Relion 670 series installation manual

SOLE

SOLE LR-OL Quick installation guide

Rain Bird

Rain Bird ESP-LXD Installation, programming & operation guide

industrie technik

industrie technik TH-xxxSx1 Series user manual