10

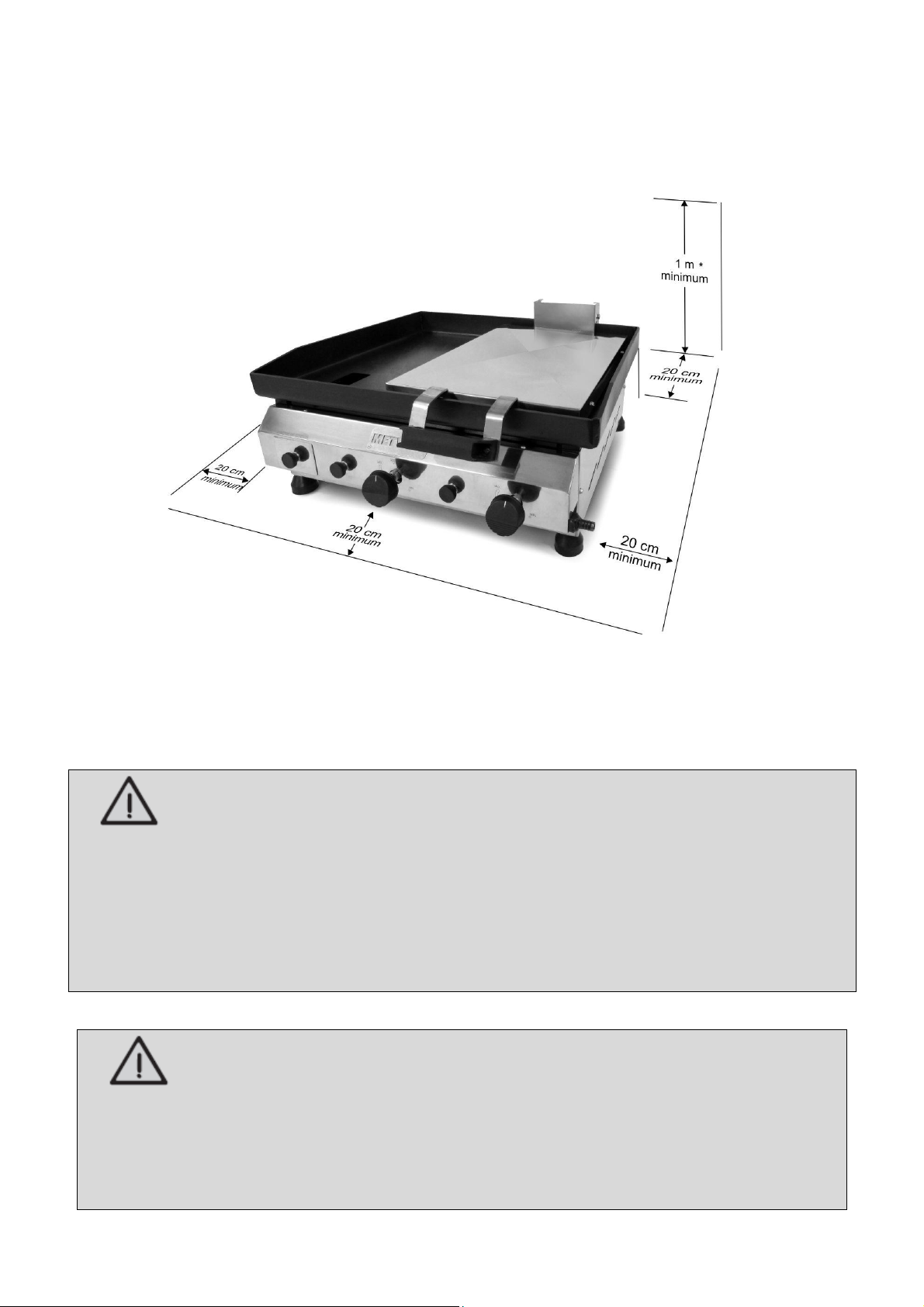

3.2 Installation of LPG Gas - Recommendations and Care

Verify that the location where the equipment will be installed is aired and in accordance with

the Regulations for the Prevention of Risks at Work and Safety at Work in Machinery and Equipment

(Regulatory standard NR-12 for Brazil or according to the regulatory standard in force in your

country), and periodic inspections by a technician are recommended to ensure that its components

are in good condition.

ATTENTION!

The arrangement of the equipment should be in an airy place, but without airflow, thus

avoiding the thus preventing the flames from being burned out, causing gas leakage.

The gas installation should be carried out by a qualified technician for this function and

observing the safety regulations.

The equipment must be installed with the following recommendations and items described

below, BUT NOT PROVIDED WITH THE EQUIPMENT:

• Gas canister - 02 cylinders with a minimum mass of 13 kg (code P13) of LPG (liquefied petroleum

gas) will be required for this equipment. The cylinder shall conform to standard ABNT 8460. Check

the product warranty seal. If you have violated, do not install.

• Pressure Regulator or Gas Valve - use only low pressure regulator (2.8Kpa) and with certification,

inscription in relief NBR 8473. When installing the regulator, turn the boiler to the right until it locks

firmly. Never use tools to perform this operation.

• Hose - The model with INMETRO certification includes NBR 8613 recording, made of transparent

PVC plastic with a yellow stripe. The BIMG fry plates are made with a connection for ½ "hoses. The

hose must not cross or be embedded in walls, and should not make any kind of seam (welding or

gluing). Secure ends only with proper clamps. Never use wires or tapes. Always check the life of the

hose.

IMPORTANT

In addition to the instructions in this manual, it is also recommended to follow the

manufacturers instructions for gas cylinders, pressure regulators (gas valves) and gas

hoses, as these items do not accompany the equipment.

ATTENTION!

Replace the pressure regulator every 5 years or when it is defective.

Always use the gas cylinder in an upright position. Never turn, throw or tilt the cylinder, as

the gas may flow in the liquid phase, canceling the function of the pressure regulator, which

can cause serious accidents.

Never install the can next to heated surfaces, and keep the gas conductive hose shielded

from heat to avoid melting resulting in a fire or other accidents.