Bindicator Mark-4 User manual

IOM

Mark-4™/GP-4™Yo-Yo™

Installation & Operation Manual

LBY180112 Rev. B

O

Or

rd

de

er

r

f

fr

ro

om

m:

:

C

C

A

A

B

Br

ri

ig

gg

gs

s

C

Co

om

mp

pa

an

ny

y

622 Mary Street; Suite 101; Warminster, PA 18974

Phone: 267-673-8117 - Fax: 267-673-8118

www.cabriggs.com

Mark-4TM/GP-4TM Yo-YoTM

Installation & Operation Manual

CONTENTS

I. HANDLING & STORAGE....................................................................................................................... 1

Inspection and Handling

Disposal and Recycling

Storage

II. GENERAL SAFETY................................................................................................................................ 2

Authorized Personnel

Use

Misuse

III. PRODUCT DESCRIPTION .................................................................................................................... 3

Function

Applications

Features

TechnicalSpecications

Approvals

IV. MECHANICAL INSTALLATION ............................................................................................................. 6

Guidelines

General Installation

Remote Display Unit Installation

V. ELECTRICAL INSTALLATION ............................................................................................................... 7

General Safety

Disconnect Requirements for Permanently Installed Equipment

Protective Earth Ground

Guidelines

Set Sensor Address

Figure 1. Wiring for Multiple Unit-To-Remote Display

Figure 2. Board Layout - Sensor Address Location

Figure 3. Board Layout

Figure 4. Single Unit-To-Remote Display Wiring

VI. SET-UP ................................................................................................................................................ 11

Lines of Display

Operating Mode Functions

Program Mode Functions

To Program a Sensor

Settings Menu

Denitions&MenuDescriptions

VII. MAINTENANCE ................................................................................................................................... 19

Preventative Maintenance

Replacement Parts

VIII. TROUBLESHOOTING ......................................................................................................................... 20

IX. DIMENSIONAL DRAWINGS................................................................................................................ 22

SAFETY SYMBOLS

WARNING:

IDENTIFIES CONDITIONS OR PROCEDURES, WHICH IF NOT FOLLOWED,

COULD RESULT IN SERIOUS INJURY. RISK OF ELECTRICAL SHOCK.

CAUTION:

IDENTIFIES CONDITIONS OR PROCEDURES, WHICH IF NOT FOLLOWED,

COULD RESULT IN SERIOUS DAMAGE OR FAILURE OF THE EQUIPMENT.

1

www.bindicator.com

LBY180112 Rev. B

I. HANDLING AND STORAGE

SAVE THESE INSTRUCTIONS

INSPECTION AND HANDLING

Do not dispose of the carton or packing materials.

Each package should be inspected upon receipt for damage that may have occurred due to mishandling during

shipping. If the unit is received damaged, notify the carrier or the factory for instructions. Failure to do so may

void your warranty. If you have any problems or questions, consult Customer Support at 1-800-778-9242.

DISPOSAL AND RECYCLING

This product can be recycled by specialized companies and must not be disposed of in a municipal collection

site. If you do not have the means to dispose of properly, please contact Bindicator for return and disposal

instructions or options.

STORAGE

If the device is not scheduled for immediate installation following delivery, the following steps should be observed:

1. Following inspection, repackage the unit into its original packaging.

2. Select a clean dry site, free of vibration, shock and impact hazards.

3. If storage will be extended longer than 30 days, the unit must be stored at temperatures between

32º and 158º F (0º to 70° C) in non-condensing atmosphere with humidity less than 85%.

Mark-4TM/GP-4TM Yo-YoTM

CAUTION: DO NOT STORE A NON-POWERED UNIT OUTDOORS FOR A PROLONGED PERIOD.

2

www.bindicator.com

LBY180112 Rev. B

II. GENERAL SAFETY

AUTHORIZED PERSONNEL

Allinstructionsdescribedinthedocumentmustbeperformedbyauthorizedandqualiedservicepersonnel

only. Before installing the unit, please read these instructions and familiarize yourself with the requirements and

functions of the device. The required personal protective equipment must always be worn when servicing this

device.

USE

The device is solely intended for use as described in this manual. Reliable operation is ensured only if the

instrumentisusedaccordingtothespecicationsdescribedinthisdocument.Forsafetyandwarranty

reasons,useofaccessoryequipmentnotrecommendedbythemanufacturerormodicationofthisdeviceis

explicitlyforbidden.Allservicingofthisequipmentmustbeperformedbyqualiedservicepersonnelonly.This

device should be mounted in locations where it will not be subject to tampering by unauthorized personnel.

MISUSE

Improper use or installation of this device may cause the following:

• Personalinjuryorharm

• Applicationspecichazardssuchasvesseloverll

• Damagetothedeviceorsystem

If any questions or problems arise during installation of this equipment, please contact the Customer Support

at 800-778-9242.

3

www.bindicator.com

LBY180112 Rev. B

III. PRODUCT DESCRIPTION

FUNCTION

The Bindicator®Yo-Yo™is a sensor that is mounted to the top of a vessel and measures the distance to the

product in the tank. This is done by lowering a weight to the surface of the product, while measuring the amount

of cable used. When the weight contacts the material, the unit senses the loss of weight. The motor reverses

and automatically returns the weight to its home position, sealing the weight against a bellows assembly in the

bottom of the sensor housing. The cable is measured while traveling in both directions and the readings are

compared. If these measured distances do not agree, the sensor automatically takes another measurement

reading. A microprocessor located on board has the ability to convert this measured distance to “level of

product” or “volume/weight of product” in the vessel. This value is communicated via RS-485 MODBUS to the

remote display or ORBTM. The signal may also be transmitted via 4-20 mA to other equipment.

APPLICATIONS

Bindicator Yo-Yo sensors provide level measurement in most dry bulk solid materials, liquid/solid interfaces, and

liquids at atmospheric pressure. These sensors can be used for measurement of materials with temperatures of up

to 200° F (93° C). Please consult the Bindicator Applications Department if this device will be used in material with

temperatures above 200° F (93° C).

Locatingthepropermountinglocationonthetopofthetankisimportant.Whenllingbulkmaterialsintoavessel,

a positive angle of repose (mound up) is created. When emptying, the angle of repose may become negative. In a

round,centerll-and-dischargevessel,thepointthatbestaveragesthisangleofreposeislocatedat1/6the diameter

of the tank (or 1/3the radius) from the outside wall.

The Yo-Yo sensor, like any other plumb bob device, drops a weight into the vessel. If the material in the vessel buries

this weight, the sensor will become inoperative. Therefore, it is not recommended that readings be taken when there

isachancetheweightwillbeburied.Thiscouldoccurwhenthevesselisbeinglledordischarged.

If material is sticky and will eventually build up on the weight, this will cause the weight to become stuck at its home

position inside the standpipe. In order to avoid this, a tare stop is available. The tare stop will still seal against the

bellows when in the “home” position, but the weight is left suspended below the standpipe. If build-up does occur on

the weight, it will not become stuck because it never enters the standpipe.

Considerationshouldbegiventoairowcharacteristicsinthevesselwhenthereisnoproductmovement.The

internal dynamics of bulk solids storage vessels can vary drastically. If your vessel includes air movement equipment

thatcontinuouslyltersormovesair,thiscouldcauseproblemswiththeweightwhenitisdroppedintothevessel.Air

currents can cause the weight to swing or spin as it is being lowered or raised inside the vessel. If the weight spins,

it can create knots in the cable. Knots in the cable could hinder the movement of the weight as it is being retracted,

or on the next measurement when it is lowered. A swinging weight can be the cause of inaccurate readings or can

abrade and eventually cut the cable as a result of rubbing on the edge of the standpipe at the top of the vessel.

4

www.bindicator.com

LBY180112 Rev. B

FEATURES

TheYo-Yoisthemostapplicationexibleandinterconnectionexiblesensortodate.Thissensorprovides

both RS-485 MODBUS communications and an isolated, reversible 4-20 mA output. It can be cycled using a

momentary contact closure such as a spring-loaded push button; or from the remote display by selecting 1 of up

to 99 sensors and requesting a measurement; or by requesting the measurement via computer either on-site or

off-site.

• Resolution

• Isolated4-20mAOutput

• RS-485(Modbus)Communication

• AutomaticCycleTimer

• RemoteMeasurementRequest

• RemoteDisplay

TECHNICAL SPECIFICATIONS: MARK-4/GP-4 YO-YO

FUNCTIONAL

Operating Power 115 VAC or 230 VAC

Power Consumption

50/60 Hz, 32 watts (operating), 4 watts (quiescent);

with heater add 10 watts

Operating Temperature 32º to 120º F (0º to 49º C);

with heater -31º to 120º F (-35º to 49º C)

Output MODBUS, Analog 4-20 mA optically

isolated (user sourced) into 600 ohms max

PERFORMANCE

Repeatability 0.8 in (2 cm)

Measurement Span Up to 100 ft standard

Automatic Timer From 2 to 9999 minutes (approx. 1 week)

PHYSICAL

Mounting 3” NPT

Conduit Entry GP-4: 2 each 3/4” NPT,

Mark-4: 3 each 3/4” NPT

Air Purge Connection 1/4” NPT

Enclosure Material GP-4: Minlon®frame, low density polyethylene cover

Mark-4: Polyester coated cast aluminum

Enclosure Rating GP-4: NEMA 4

Mark-4: NEMA 4/7/9

Shipping Weight GP-4:13 lbs (6 kg)

Mark-4: 26 lbs (12 kg)

OPTIONS

Motor Heater

Yo-Yo Display

ORB

5

www.bindicator.com

LBY180112 Rev. B

TECHNICAL SPECIFICATIONS: DISPLAY/PROGRAMMER

FUNCTIONAL

Operating Power Powered from Yo-Yo sensor (9-24 VDC); With optional heater, 120/240 VAC required

Operating Temperature

-4° to 158° F (-20° to 70° C); With optional heater: -40° to 158° F (-40° to 70° C)

PHYSICAL

Communication RS-485 MODBUS, Optional Integral Modem

Sensors Up to 99

Display 4 lines by 20 characters, Backlit LCD Display

Keypad NEMA 4X soft-touch

Enclosure NEMA4Xmoldedberglasspolyester

PERFORMANCE

Wiring Requirements Belden®9842, 4 wire shielded cable

Wiring Distance 4000 ft max

Speed 115 Kbps

Protocol MODBUS

Interface RS-485

Internal Modem Optional 56 K Modem

APPROVALS

Mark-4

FM (US) - XP Class I, Division I, Groups C and D; T5, Ta= 60º C

DIP Class II, III, Division I, Groups E, F, and G; T5, Ta= 60º C; Type 4

CSA - Class I, Groups C and D; Class II, Groups E, F and G; Class III; Type 5; Type 4

ATEX

GP-4 FM (US) - General Purpose

CE

6

www.bindicator.com

LBY180112 Rev. B

IV. MECHANICAL INSTALLATION

WARNING: REMOVE POWER FROM THE UNIT bEFORE INSTALLING, REMOVING OR MAKING

ADjUSTMENTS.

GUIDELINES

- Shouldnotbeclosetoanyllpoint.

- To ensure material does not get into the enclosure, it is recommended that the unit be placed where an

air purge is available.

- Sensing weights should weigh between 20 - 25 oz (567 - 709 g)

- The standard plastic weight and spike require additional weight to reach recommended weight; it is

recommendedthattheweightbelledwiththesamematerialthatisinthevessel.

- Forround,centerll,centerdischargingvessels,itisrecommendedthatmountingshouldbelocatedat

a point approximately 1/3of the vessel radius from the vessel wall.

- For other types of vessel shapes, contact Customer Support for assistance in determining ideal

mounting locations.

GENERAL INSTALLATION

1. Determine location of where sensor should be on the top of the tank.

2. Insert unit into the tank with weight going into the vessel.

3. Mount the unit to the top of the vessel using a 3” NPT nozzle or pipe nipple extended vertically from the

top.

NOTE: Due to how the weight is retracted, for the Digestible Bottle Weight a 12 in. (30.5 cm) nozzle is

recommended; for the Stainless Steel Bob Weight a 3 in. (7.62 cm) nozzle is recommended. Other weights do

not need additional considerations.

4. Securetheunittothemounting/ange.

5. Proceed to Electrical Section for wiring instructions.

REMOTE DISPLAY UNIT INSTALLATION

1. Determine location of display – should be mounted where it can be easily read by user.

2. Install feet on enclosure, tightening at the desired angles for mounting location.

3. Hold the enclosure against the wall in the desired location and mark the positions of the mounting holes.

Place the enclosure in a safe location.

4. Drill the mounting holes into the wall.

5. Attachtheenclosuretothewallusinghardware(providedbythecustomer)thatwillsecureitrmlyin

place.

6. Proceed to Electrical Section for wiring instructions.

7

www.bindicator.com

LBY180112 Rev. B

V. ELECTRICAL INSTALLATION

WARNING: REMOVE POWER FROM THE UNIT bEFORE INSTALLING, REMOVING, OR MAKING

ADjUSTMENTS.

GENERAL SAFETY

When using electrical equipment, you should always follow basic safety precautions, including the following:

• Theinstallationandwiringofthisproductmustcomplywithallnational,federal,state,municipal,and

local codes that apply.

• Properlygroundtheenclosuretoanadequateearthground.

•

Do not modify any factory wiring. Connections should only be made to the terminals described in this section.

• Allconnectionstotheunitmustuseconductorswithaninsulationratingof300Vminimum,ratedfor

221ºF(105ºC),aminimumammabilityratingofVW-1,andbeofappropriategaugeforthevoltageand

currentrequired(seespecications).

• Donotallowmoisturetoentertheelectronicsenclosure.Conduitshouldslopedownwardfromtheunit

housing. Install drip loops and seal conduit with silicone rubber product.

DISCONNECT REQUIREMENTS FOR PERMANENTLY INSTALLED EQUIPMENT

A dedicated disconnecting device (circuit breaker) must be provided for the proper installation of the unit. If

independent circuits are used for power input individual disconnects are required. Disconnects must meet the

following requirements:

• Locatedincloseproximitytothedevice

• Easilyaccessibletotheoperator

• Appropriatelymarkedasthedisconnectforthedeviceandassociatedcircuit

• Sizedappropriatelytotherequirementsoftheprotectedcircuit(Seespecications)

GUIDELINES

• Suppliedpowertosensorsshouldbecleanandfreeofinterference.

CAUTION: THE COMMUNICATIONS AND/OR 4-20 MA WIRING SHOULD NOT BE RUN IN THE SAME

CONDUIT AS THE AC SUPPLY WIRING. TWO SEPARATE 3/4” CONDUIT OPENINGS ARE PROVIDED

FOR THIS REASON.

8

www.bindicator.com

LBY180112 Rev. B

• IfwiringmultipleYo-Younitstothesameremotedisplay.Wireunitstoeachother,thenaddtheremote

display at the end of the line. Do not wire individually or in the middle. (See Figure 1.)

Figure 1. Wiring for Multiple Unit-To-Remote Display

• TherecommendedcommunicationcableisBelden#9842(2-pair,AWG24)orequivalent.Usingthis

cable will allow a network distance up to 4000 ft (1219 m). The communications wiring, which consists of

communication and DC Power to remote display, is polarity sensitive.

WARNING: WIRING POWER INTO THE COMMUNICATION TERMINALS WILL RESULT IN

PERMANENT DAMAGE TO THE ELECTRONICS. DOUBLE CHECK ALL COMMUNICATIONS WIRING

BEFORE POWERING ANY SENSOR. DAMAGE CAUSED BY INCORRECT WIRING WILL VOID THE

WARRANTY.

• Eachsystem/networkmusthavetwo(2)EndofLineResistors(EOLR);oneoneachendofthe

communication cable. All sensor boards and the display have embedded resistors that introduced into

the circuit via the EOLR jumper. See Figures 2 and 3.

• Apull-upresistorisrecommendedforcommunicationlinesgreaterthan1,000ft(305m).Twoorthree

pull-up resistors can be used at various points for long lines, place them one quarter of the cable length

away from each end of the network so that each pull-up resistor takes care of half the length of the cable

from its middle.

SET SENSOR ADDRESS

Allsensorsareshippedfromthefactorywithaddress#01.

• Determinethesensoraddressforeachunit-eachsensorMUSThaveauniqueaddressbetween01and

99 inclusive.

Note: One Sensor must have an address of 01 or unit will not communicate with the system.

• Ifmorethanonesensorwaspurchased,ornewsensorsarebeingaddedtoanexistingnetwork,the

sensors will need to be individually addressed.

• Onceaddressswitcheshavebeenset,thesensormustbere-initializedbypressingtheresetbuttonon

board or by turning the power to the sensor off and back on again.

9

www.bindicator.com

LBY180112 Rev. B

Figure 2. Board Layout - Sensor Address Location

Figure 3. Board Layout

A

B

INHIbIT FEATURE (A)

Shorting these terminals or closing the circuit inhibits the sensor from taking a measure; regardless of what

method the measurement is requested. The inhibit feature should be used to ensure the weight does not get

buriedbymaterialduringthellingprocessofthevessel.Multiplewaystousethiscontactclosuresetting;

another device, PLC, or single switch.

MEASURE FEATURE (b)

The Yo-Yo level measuring device also allows the connection of a PLC digital output to request a reading of each

sensor. This is a momentary contact closure. Recommended “start pulse” is 500 milliseconds.

10

www.bindicator.com

LBY180112 Rev. B

CAUTION: VOLTAGE ACROSS THESE TERMINALS, SUPPLIED FROM THE SENSOR BOARD, IS

5 VDC. DO NOT PROVIDE EXTERNAL POWER TO THE INHIBIT AND MEASURE TERMINALS.

PROVIDE A DRY CONTACT ONLY

Figure 4. Single Unit-To-Remote Display Wiring (with additional sensors) (Units built after October 2003)

This drawing applies to all

units using board P/N RAD230007 Rev H and later

and built after October 15th 2003.

11

www.bindicator.com

LBY180112 Rev. B

VI. SET UP

LINES OF DISPLAY

Line Description

Top Sensor address and name

Second Measurement in units selected and percentage full or empty

Third Display mode

Fourth Status of the displayed sensor

S e n s o r 2 5 H D P o l y m e r

1 2 3 4 5 6 7 L b s 1 0 0 . 0 %

M A T R I A L M O D E

S E N S O R I S N O R M A L

OPERATING MODE FUNCTIONS

Button Function

Left/Right Arrow

UsedtoscrollthroughtheYo-Yobeingmodiedorprogrammed;max.numberofunitsis99

Measure Take an immediate manual measurement

PROGRAM MODE FUNCTIONS

Button Function

Arrows Use to scroll through menu or move cursor to desired location

Enter Accept displayed value

ESC Push to go back to previous menu; to get to Main Menu – continue to push until it is

reached on the screen

Program Push to start set-up of unit

12

www.bindicator.com

LBY180112 Rev. B

It is recommended that the following characteristics are determined before the start of programming. The

chartbelowcanbeusedforreference,addmorecolumnsasnecessary.Denitionsandrequirementsforeach

Function are listed below.

Sensor Address

Sensor Name

Units

(Check

one per

sensor)

Distance Feet

Meters

Engineering

Cubic Feet

Cubic Meters

Pounds

Kilograms

Gallons

Liters

Parameters

Tank Height

Full Distance

Empty Distance

Max. Move

Distance

Cone Height

Full Scale Value

Auto Timer

On/Off

Timer Setting

in Mins.

Air Space or

Material Mode

20 mA Full or

20 mA Empty

Jumper Settings

End Of Line

Resistor

Pull-Up

Resistor

Figure 5. Tank Parameters Reference Note: While in Programming Mode,

no information is transferred

between the remote display and

the other Yo-Yo sensors; for this

reason there is an automatic timeout

period. If no keys are pressed for

one minute, the remote display will

exit the Programming Mode without

saving changes and return to the

Operating Mode.

13

www.bindicator.com

LBY180112 Rev. B

TO PROGRAM A SENSOR

1. Press left/right arrow keys in Operating Mode section of the key pad to move to the desired sensor

address. Holding a key down will scroll through the sensors quickly.

Note: One sensor must have an address of 01 or unit will not communicate with the system.

2. Push Program on the key pad.

3.

Enter the password. Password is 1936 – the system does not allow changes to the password at this time.

4. Press ENTER.

5. Use the arrow buttons to place the asterisk (*) beside the desired selection and press ENTER. To move

back press ESC.

Note: After one minute, unit will revert back to previous settings; can be used if mistake has been made to

reset.

Note: For a multiple sensor system, all sensors need to be enabled individually.

SETTINGS MENU

• SetUnits

- Units

- Distance Units

- Engineering Units

• SetTankParameters

- Tank Height

- Tank Full Distance

- Tank Empty Distance

- Maximum Move Distance

- Cone Height

- Full Scale Value

• DisplayMode

- Material

- Air

• Set4-20mAMode

• SetAutotimerMode

- Autotimer Time

• SetSensorName

• En(able)/DisableSensors

• Save&Quit

14

www.bindicator.com

LBY180112 Rev. B

TAKING A MEASUREMENT

Multiple methods can be used to take a measurement with the Yo-Yo, automatically or manually. The Yo-Yo level

sensor also has the ability to offer a variety of remote measurement options.

USING THE REMOTE DISPLAY (IMMEDIATE MEASURE)

The Remote Display is capable of monitoring up to 99 sensors.

1. Press left/right arrow keys in Operating Mode section of the key pad to move to the desired sensor

address. Holding a key down will scroll through the sensors quickly.

2. Press the Measure key in the Operating Mode section of the key pad. The initial indication should read

“Starting Measure” followed by “Sensor is Measuring”

3. When the measurement is complete, the reading will be updated. Status should read “Sensor is

Normal”.

AUTO-TIMER MEASUREMENT

Please use caution when using this feature; sending the sensing weight to the material surface should not be

donewhilethevesselislling.ItisstronglyrecommendedtousetheInhibitFeaturewhenAuto-timerison.See

Electrical Section for details.

1. Press left/right arrow keys in Operating Mode section of the key pad to move to the desired

sensor address. Holding a key down will scroll through the sensors quickly.

2. Push Program on the key pad.

3.

Enter the password. Password is 1936 (The system does not allow changes to the password at this time.)

4. Press ENTER.

5. Use the arrow buttons to place the asterisk (*) beside ‘Set Auto-timer Mode’ and press ENTER.

6. Use arrows to set time (duration period can range from from once every 2 minutes to 9999 minutes

(approximately 1 week).

7. Press ENTER. The Yo-Yo will now automatically take measurements as requested.

15

www.bindicator.com

LBY180112 Rev. B

USING THE ORb

1. Device should be wired to the ORB; see Electrical Section.

2. Login to the ORB normally. NOTE: User permissions have to be set to allow for measurements;

see ORB Installation & Operator Manual for detail to change individual permissions.

3. Locate the desired silo on home page screen.

4. Click ‘Measure’

USING A PLC

1. Device should be wired to accept PLC communication; see Electrical Section.

2. Reference the Modbus to Yo-Yo Guide (Part Number LBY180113) for commands.

DEFINITIONS & MENU DESCRIPTIONS

SET UNITS

• UNITS

This item determines if the sensor will display linear distance units in feet or meters, or in engineering

units(volume/weight).IfEnglishunitsareselectedonthismenu,alltankdenitiondistanceswillbe

edited using feet. If metric units are selected, all distances will be edited using meters.

When engineering units are selected in conjunction with a cone height greater than 0, the displayed

value and the 4-20 mA output are linearized. This linearization assumes a center discharge cone below a

round, straight sidewall silo.

Note: When selecting any engineering unit, the Full Scale Value (the amount of material that corresponds to

the Tank Full Distance) must also be specied.

16

www.bindicator.com

LBY180112 Rev. B

Distance Units

Feet (Default is one decimal place.)

Meters (Default is two decimal places.)

Engineering Units (Default is no decimal places.)

Pounds

Kilograms

Gallons

Liters

TANK PARAMETERS

Thismenudenesthetankdimensions.AlldistancesexceptConeHeightaretakenfromthehomepositionof

thesensor.Thermwareallowstheusertoenteronlythefollowingpossibilities:

Tank Height > = Maximum Move Distance > = Tank Empty Distance

Tank Empty Distance > Tank Full Distance > = 0

Tank Height > Cone Height > = 0

Maximum Move Distance > = (Tank Height/2)

• TANKHEIGHT

This parameter is the distance from the GP-4 Yo-Yo sensor home position to the bottom of the tank. The

default value is 75 ft. (22.86 m) and the range is from 3.3 ft. (1 m) to 199.9 ft. (60.93 m).

Note: Standard cable length is 100 ft. (30.48 m). DO NOT program a value greater than this length unless a

special storage wheel with an extended length of cable has been provided with the sensor.

The tank height value must be greater than or equal to the Maximum Move Distance and Tank Empty

Distance. Therefore, setting this value to less than 75 ft. (22.86 m) will automatically reduce the value of

the Tank Empty Distance and Maximum Move Distance to the same value.

• TANKFULLDISTANCE

This parameter is the distance from the GP-4 Yo-Yo sensor home position to the level of material

where the tank is considered full. This parameter also determines the 20 mA output point when 20 mA

represents a “full” vessel. If 20 mA represents an empty vessel, the Tank Full Distance is also setting the

4 mA point. The default value for the Tank Full Distance is 0. The range is from 0 ft. (0 m) to 1,999.9 ft.

(60.93 m).

• TANKEMPTYDISTANCE

This parameter is the distance from the GP-4 Yo-Yo sensor home position to the point where the tank

is considered empty. This parameter normally determines the 4 mA output. The default value is 75 ft.

(22.86 m) and the range is from half of the Tank Height parameter to 199.9 ft. (60.93 m).

• MAXIMUMMOVEDISTANCE

This parameter is the maximum travel distance from the GP-4 Yo-Yo sensor home position. This

parameter is used to limit the sensor form traveling through the discharge of the tank or into discharge

equipment such as screw conveyors. When the GP-4 Yo-Yo sensor reaches this travel distance it will

This manual suits for next models

2

Table of contents

Popular Security Sensor manuals by other brands

PCB Piezotronics

PCB Piezotronics ICP W105C02/038AG020AC Installation and operating manual

DoCash

DoCash mini IR user manual

Niko

Niko Swiss Garde 360 DALI Secondary A-Comfort high ceiling... installation instructions

DSE

DSE AN-RMP1 owner's manual

Niko

Niko DALI-2 BMS user manual

Waters

Waters ACQUITY UPC2 Overview and maintenance guide

Tunstall

Tunstall Fall Detector user guide

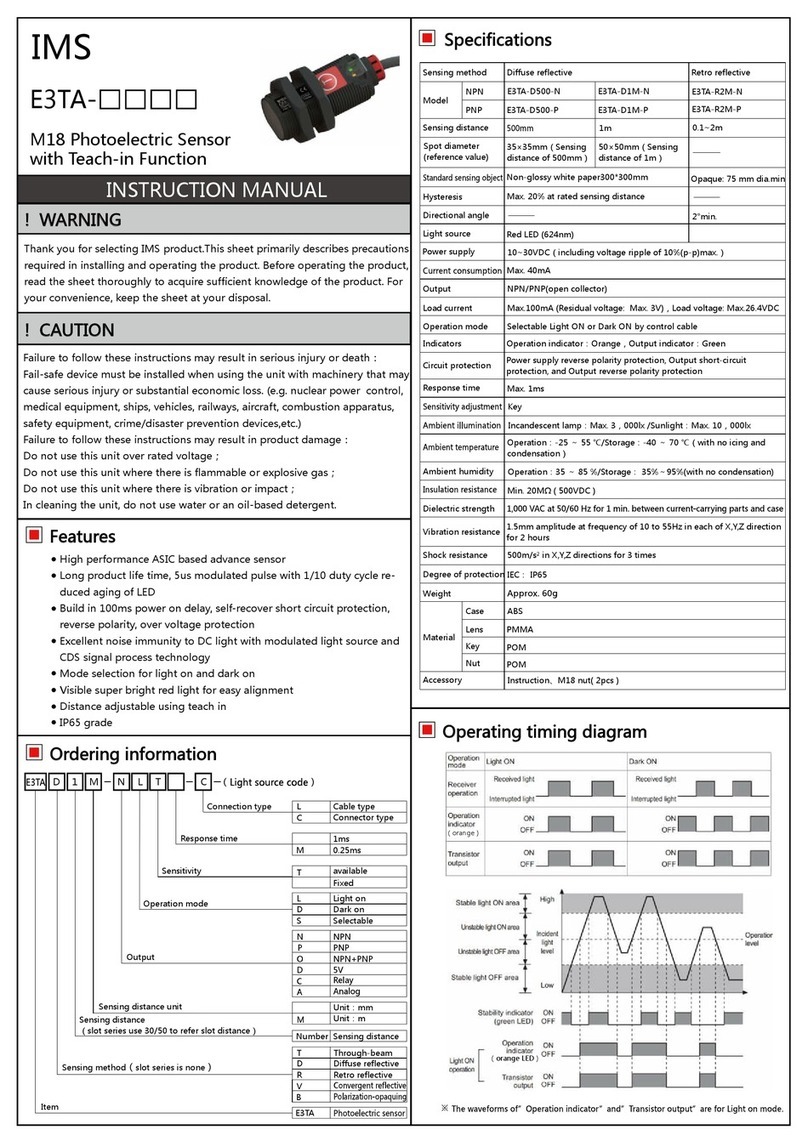

IMS

IMS E3TA Series instruction manual

CPS

CPS Leak-Seeker II Operation manual

Siemens

Siemens FS720 Series Quick reference for components / pin assignment

Kompernass

Kompernass BA 105 A1 operating instructions

Honeywell

Honeywell Ex-Or MLS Installation and commissioning instructions