Table of Contents iii

Copyright notice ...................................................................................................................... ii

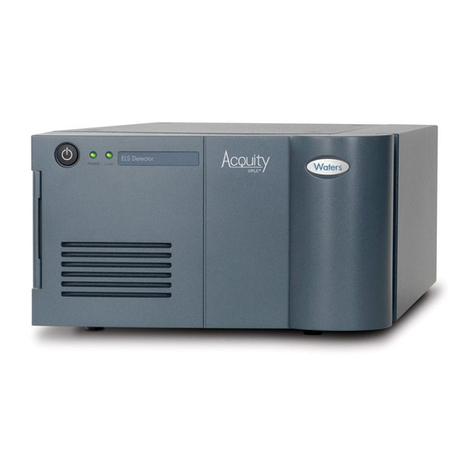

Overview

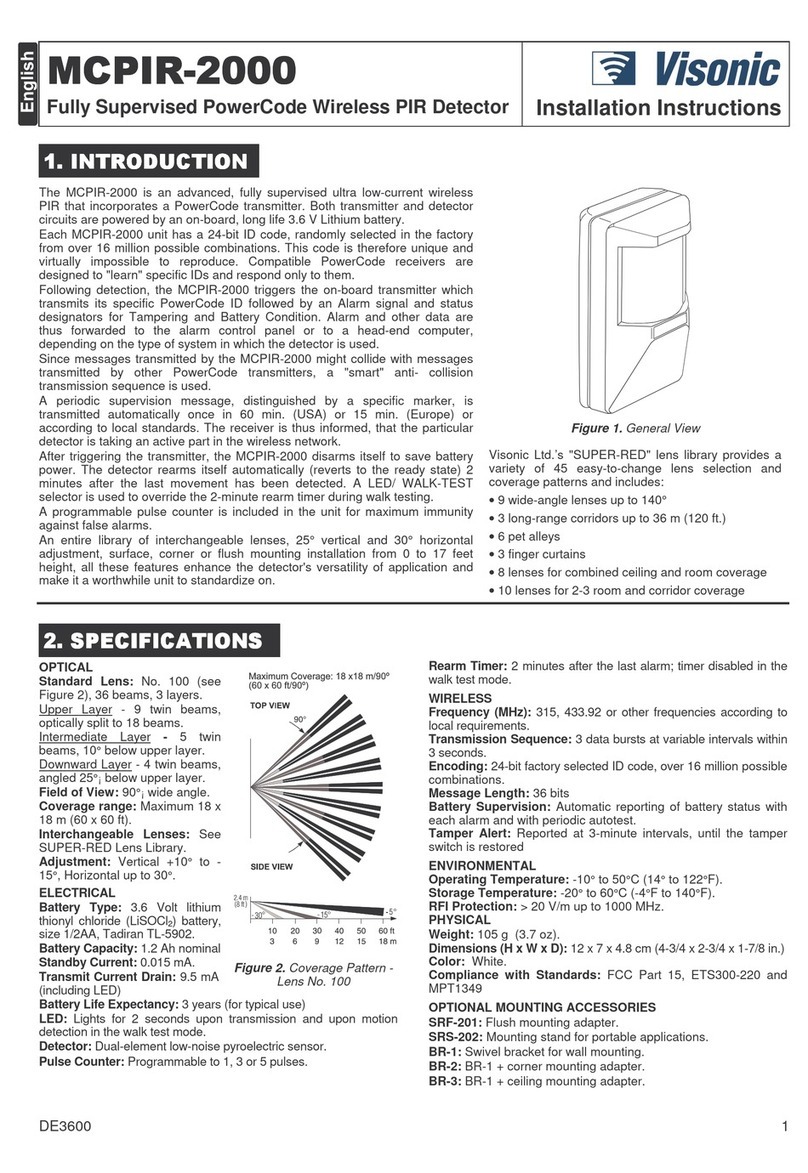

Detector optics .................................................................................................................... 1

Calculating absorbance....................................................................................................... 4

Flow cell operating principles ............................................................................................ 6

Detector capabilities ......................................................................................................... 16

Preparing the detector ......................................................................................................... 17

Installing the detector .......................................................................................................... 18

Plumbing the detector .......................................................................................................... 21

Installing the multi-detector drip tray ............................................................................... 24

Making Ethernet connections ............................................................................................. 25

I/O signal connector.......................................................................................................... 26

Connecting to the electricity source ................................................................................... 26

Starting the detector ............................................................................................................ 27

Monitoring detector LEDs................................................................................................ 29

About the detector control panel....................................................................................... 30

Using a cuvette ...................................................................................................................... 31

Shutting down the detector ................................................................................................. 34

Maintaining the detector ..................................................................................................... 34

Contacting Waters technical service ................................................................................. 34

Maintenance considerations.............................................................................................. 35

Proper operating procedures ............................................................................................. 36

Maintaining the leak sensor .............................................................................................. 37

Replacing the detector’s leak sensor................................................................................. 42

Maintaining the flow cell.................................................................................................. 44

Replacing the lamp ........................................................................................................... 49

Reading lamp energy ........................................................................................................ 52

Replacing the fuses ........................................................................................................... 52

Table of Contents