Page 6

© ITW Inc 2007

about 100ml (4 fluid oz) of solvent into

the air intake port of the motor. Rotate

the motor by hand in both directions for a

few minutes.

8. Re-connect the airline and cover the

exhaust port with a cloth. Apply low

pressure 0.7bar (10psi) and re-start the

motor. Run until no more traces of

solvent can be seen.

9. The motor should be running smoothly. If

not, then a re-build may be required (see

QS-4016 Replacement of Parts).

REPLACEMENT OF

PARTS

QS-5012-CE Replacement of parts

(see Figs 5 & 6)

Before attempting any MAINTENANCE of

agitators on pressure feed tanks, the tanks

must be relieve of pressure as stated

previously.

1. Turn off and disconnect the mains air

supply hose with the air adjusting valve

(65).

2. Loosen the upper clamp screw (61) and

remove the air motor and gearbox

assembly.

3. Separate the motor and gearbox by

loosening locking screw (91).

4. Remove the spacer (94) and key (95)

from the motor shaft.

5. For the Air motor refer to QS-4016 Air

motor section.

Gear box

1. Remove the oil fill plug (88) or cover

plate (84) and drain gear box lubricant.

2. Disassemble the gearbox by removing

the cover (84), withdraw the gear shaft

(86) and washer (85).

3. Withdraw the worm gear (93) .

4. Inspect the seal (90) for signs of wear,

leaks or damage. Only remove if it needs

replacing.

5. Clean the seal housing and remove any

burrs or contaminants. These could

distort the new seal during fitting.

6. Inspect the gear shaft assembly (86) for

wear grooves, burrs or contamination of

seal sealing area on the shaft diameter.

If the seal sealing area is damaged the

shaft must be replaced.

7. Inspect all other parts for signs of wear,

chipping or other damage. Replace

damaged or worn parts.

8. If the oil seal (90) is being replaced,

check the new seal carefully for damage

before installing. Use an arbour press to

press the seal in. Use a close fitting tool

to the casting bore diameter to avoid

damaging the seal. Make sure the seal

lip is towards the bottom of the bore.

Press in squarely into the bore to avoid

warping. Check that the seal is fully

seated in the bottom of the bore.

9. Reassemble gear box in the reverse

order. Use new gaskets (87 and 92).

When re-fitting the air motor, slide

spacer (94) and fit key (95) before

engaging the motor to the gearbox.

Apply thread locking compound to the

locking screws (91) and tighten to 6.8

Nm (60 lbins). Refill the gearbox with oil

(SAE 10) as per previous section.

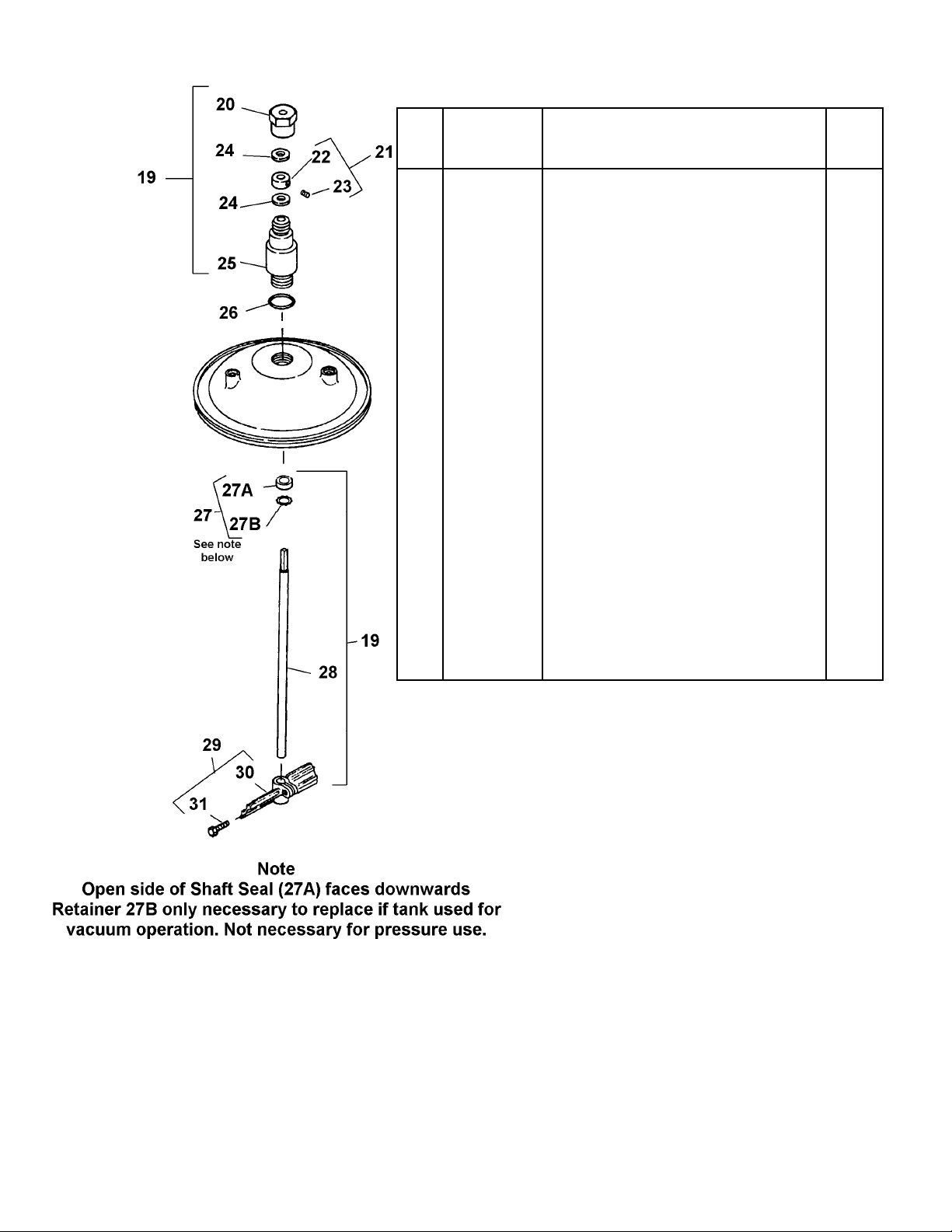

QMS-431-CE, 433-CE and 434-CE

Agitator Replacement of parts (see

Fig. 7)

Before attempting any MAINTENANCE of

agitators on pressure feed tanks, the tanks

must be relieve of pressure as stated

previously.

1. Remove lid from pressure feed tank.

2. Remove paddles by loosening screw(s)

(31).

3. Unscrew retaining nut (20) and remove.

4. Hold the shaft (28), loosen set screw

(23) on the collar (22). The collar (22)

and washers (24) can now be removed.

5. The shaft can now be withdrawn from

the bearing housing (25). Be careful with

the shaft seal (27) as any burrs or dried

paint could damage the lip seal.

6. If the O ring (26) is to be replaced,

unscrew and remove the bearing

assembly (25).

7. Examine the Shaft seal (27A) for any

damage. If it needs replacement, prise

out the retaining clip (27B), then the seal

(27A). Take care not to damage the seat

in the bearing housing (25).

8. Check the size of the oilite bearings in

the housing (25) for wear. These are

15.6mm when new. Replace when the

size is 15.9mm (0.626”) or greater.

9. Take a new seal (27A) and apply a small

amount of water or oil to the outside to

lubricate the fitted O ring.

10. Place the seal in the housing (25) O ring

first with the grooves facing outwards.

Press the seal in making sure it is seated

fully in the housing.

11. Clean the O ring groove in the housing

(25) and make sure the seating surface

on the tank lid is clean. Place the O ring

(26) in the groove and lightly lubricate it

with water or light oil. Screw the housing

(25) into the lid and fully tighten with a

spanner.

12. Take the shaft (28) and insert the

paddle end into the top of the housing

(25) and feed through, taking care when

feeding through the Shaft seal (27A).

13. Hold the shaft (28) with the groove about

12mm from then top of the housing (25)

and slip thrust washer (24) then collar

(22) over the end. Align the set screw

(23) in the collar (22) with the groove

and tighten. Fit 2nd washer (24).

14. Screw on retainer nut (20) onto the

bearing housing (25) and tighten with a

spanner.

15. Slide paddle(s) (29) over the shaft and

position as shown in Fig. 2 in the

installation section.

16. Re-fit the drive motor QS-5012-CE as

per installation section.

QMS-430-CE and

PT-428-CE/PT-419-CE

Replacement of parts (Figs 8 & 9)

Before attempting any MAINTENANCE of

agitators on pressure feed tanks, the tanks

must be relieve of pressure as stated

previously.

1. Turn off air supply with the air adjusting

valve (21) and disconnect the main air

supply hose.

2. Remove Lid from pressure feed tank.

3. Remove propeller (55).

4. Loosen screws (49) and remove retainer

(32A), Shaft (54) with the propeller (55).

5. Loosen screws (34A) or (49) and Air

motor (33) or (35) can be withdrawn from

the housing (34) or (48).

6. For replacement of parts procedure for

the Air motor see section for QS-4016

below. Some of the references are

different but the procedure is the same.

7. Examine the Seal (50) for damage or

wear. Only remove if it needs replacing.

8. Take a new seal (50A) and apply a small

amount of water or oil to the outside to

lubricate the fitted O ring.

9. Place the seal in the housing (34) O ring

first with the grooves facing outwards.

Press the seal in making sure it is seated

fully in the housing.

10. Replace the Air motor and shaft

assembly in reverse order.

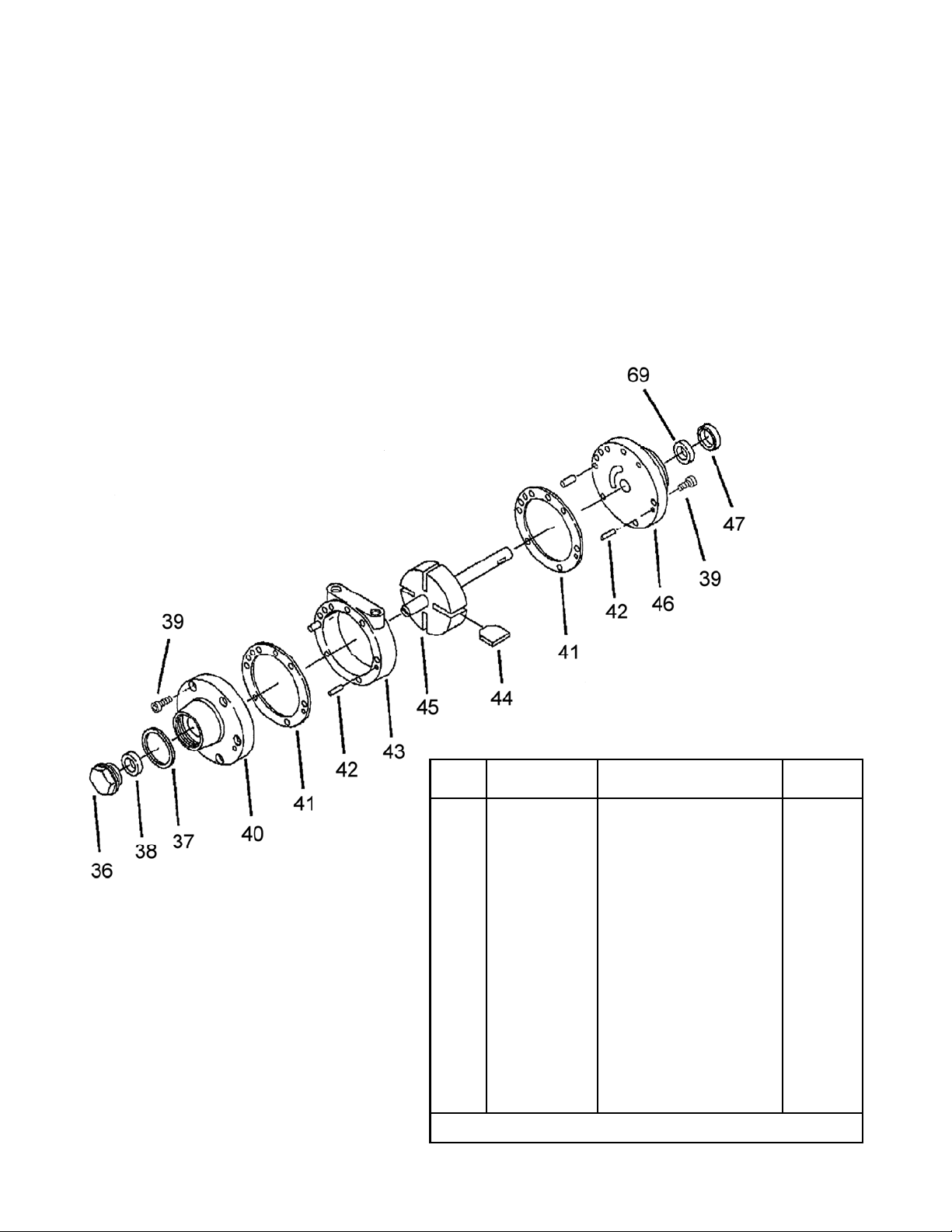

QS-4016 Air Motor Replacement of

parts (for QS-5012-CE)

1. Remove the end cap (36) or (64) for

QMS-430-CE.

2. Remove dead end plate bolts (39).

3. Remove dead end plate (40). Use a

puller, do not use screwdriver to remove

the end plate.)

4. Remove the dowel pins (42) from the

body and push back into end plate (40)

until flush or just below the machined

surface of the dead end plate. Remove

rotor (45) using an arbor press.

5. Remove vanes (44).

6. Remove shaft seal (47) and bearing (38)

or (69) from drive end plate (46) and

bearing (38) from dead end plate (40).

Do Not remove drive end plate bolts or

drive end plate (46).

7. Clean parts. Check for scoring on the