BIO-MED DEVICES IC-2A User manual

BIO-MED DEVICES

IC-2A

ADULT INTENSIVE CARE VENTILATOR

SERVICE MANUAL

CATALOG #8011A

PRICE $35.00

REV. 122606

BIO-MED DEVICES, INC.

61 SOUNDVIEW ROAD, GUILFORD, CT 06437 (203) 458-0202

www.biomeddevices.com

TABLE OF CONTENTS

WARRANTY ................................................................................................................... 1

WARNING, CAUTIONS, AND NOTES ........................................................................... 3

WARNINGS................................................................................................................. 3

CAUTIONS .................................................................................................................. 4

NOTES ........................................................................................................................ 4

I. DESCRIPTION......................................................................................................... 8

INTRODUCING THE IC-2A VENTILATOR.................................................................. 8

Controls, Indicators and Connectors............................................................................ 8

Modes of Operation ..................................................................................................... 9

SPECIFICATIONS AND LIMITATIONS....................................................................... 9

II. FUNCTIONAL DESCRIPTION .............................................................................. 11

OPERATING MODES ............................................................................................... 11

LOGIC GATE............................................................................................................. 15

III. INSTALLATION AND OPERATION .................................................................. 17

INSTALLATION ......................................................................................................... 17

IC-2A VENTILATOR SET-UP.................................................................................... 19

IC-2A FINAL CHECKOUT ......................................................................................... 19

OPERATING PROCEDURE...................................................................................... 23

IV. MAINTENANCE INSTRUCTIONS ..................................................................... 29

GENERAL MAINTENANCE ...................................................................................... 29

PREVENTIVE MAINTENANCE................................................................................. 29

V. TESTING AND CALIBRATION ............................................................................. 31

INITIAL LOGIC PRESSURE TESTS ......................................................................... 31

FAIL-SAFE CUTOFF VALVE CALIBRATION............................................................ 32

DEMAND CIRCUIT CALIBRATION........................................................................... 33

MAXIMUM PRESSURE CALIBRATION.................................................................... 35

PEEP/CPAP CALIBRATION ..................................................................................... 36

TIMING CALIBRATION ............................................................................................. 37

FLOW RATE CALIBRATION..................................................................................... 38

PRESSURE GAUGE CALIBRATION ........................................................................ 39

VI. PARTS LISTS .................................................................................................... 40

1

WARRANTY

BIO-MED DEVICES, INC. expressly warrants to the PURCHASER, this Ventilator to be

free from defects in material and workmanship for a period of one (1) year from the date

of purchase. BIO-MED DEVICES, INC. will repair or, at its option, replace any part or

all of this Ventilator which fails to conform to this warranty at no cost to the purchaser

FOR MATERIALS AND LABOR. The warranty does not apply to the patient circuit and

hoses supplied with the instrument nor does the warranty cover abuse or misuse of the

instrument, or damage due to unauthorized servicing.

BIO-MED DEVICES, INC. will pay any shipping charges required in repairing or

replacing any part or all of this Ventilator within three (3) months from the date of

purchase. Thereafter, shipping charges will be paid by the PURCHASER.

THIS WARRANTY IS EXPRESSLY MADE IN LIEU OF THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED.

This warranty shall become null and void if the Ventilator is opened, otherwise tampered

with, or if repairs are attempted by the PURCHASER, or if the Ventilator is operated by

anyone other than trained and duly qualified medical personnel, or if the “Warranty

Registration Card” is not returned within four (4) weeks of the date of purchase to:

BIO- MED DEVICES, INC.

61 Soundview Road

Guilford, CT 06473

Tel: (203) 458-0202

Fax: (203) 458-0440

2

HOW TO USE THIS MANUAL

This manual is intended to provide an easily useable source of reference that will assist

you in operating and maintaining the BIO-MED DEVICES’ IC-2A Ventilator. This

manual is configured in six sections, each of which will support a general understanding

of the IC-2A Ventilator and provide specific maintenance and service instructions. A

complete Table of Contents, List of Illustrations, and List of Tables are included to help

you locate any item of information or procedure in the manual.

3

WARNING, CAUTIONS AND NOTES

SAFETY PRECAUTIONS

This system presents no hazardous when operated properly. However, the following

safety rules should be observed when operating the system:

• Read this manual carefully and follow all recommended procedures.

• Always turn off the equipment prior to performing any maintenance.

FOR YOUR INFORMATION

WARNING - Signifies a procedure or condition that could cause bodily injury if

performed improperly.

CAUTION- Signifies a procedure or condition that could damage the equipment if

performed improperly.

NOTE- Signifies a procedure or condition that requires your special attention.

WARNINGS

• No flow-restricting device (e.g., flowmeter, throttling valve) should be placed in

the supply line. A flow-restricting device interferes with the operation of the

pneumatic logic and may render the time cycling inoperative which can endanger

the health of the patient.

• In no case should a supply pressure less than 35 or over 80 psi be connected to

the IC-2A Ventilator as it will cause malfunction of the ventilator which will

endanger the health of the patient.

• To ensure the health of the patient, pressure alarms must always be used

whenever the IC-2A Ventilator is used unattended.

• No device should ever be connected to the exhalation valve line. Malfunction

may result which could endanger the health of the patient.

• The supplies must be regulated 50 psi sources without flow restricting devices

(e.g., flowmeter, needle valve, etc.). This ensures proper operation and safety of

the patient.

• Whenever the IC-2A Ventilator is turned off, disconnect the patient before turning

the Ventilator back on, in order to avoid erroneous breaths and possible harm to

the patient.

• It is essential, with the triggered demand flow of the IC-2A, that the inspiratory

effort be properly adjusted to assure that the patient can obtain gas.

• Bio-Med Devices cannot be held responsible for any failure to adhere to the

recommendations set forth in this manual.

• Because this is a CE marked device, it must never be modified without prior

expressed written consent from Bio-Med Devices.

4

CAUTIONS

• Hose fittings should be hand-tightened to avoid damage to fittings.

• The gas supply should be clean and dry.

• Never connect a water supply to these fittings.

• Do not attempt to repair the demand valve. Its assembly is highly critical and

must be performed at the factory.

NOTES

• In the SIMV mode, it is essential that the INSPIRATORY EFFORT control be set

so that the patient can trigger the machine at all times.

• The pressurized tanks should be fitted with regulators adjusted to 50 ±5 psi.

• Any intensive care ventilator circuit may be used with the IC-2A Ventilator

including a configuration using both inspiratory and expiratory hoses. Any

exhalation valve may be used. It should be noted that the IC-2A is supplied with

a patient circuit (part number 8002A). The maximum pressure limit and

maximum PEEP pressure are calibrated using this exhalation valve. If another

valve is used, there may be a difference in the maximum pressure limit and

maximum PEEP pressure attainable, depending on the area ratios of the

exhalation valve used.

• The IC-2A Ventilator does not have an internal oxygen blender.

• During IPPV an assist control breath will cause response of both the CYCLE and

DEMAND indicators. A control cycle will activate only the CYCLE indicator.

• In the SIMV mode, it is unnecessary to add an external constant flow source due

to the triggered demand flow system. It is necessary, however, that the

INSPIRATORY EFFORT control be properly adjusted at all times to assure

proper operation.

• The MAX. PRESSURE control must be turned off (fully clockwise) in the CPAP

mode.

• Do not over-tighten the supply fittings with a wrench, as they could be damaged.

• Do not use the logic supply regulator to decrease the logic supply pressure.

Auto-cycling is not to be confused with the regular timed cycling controlled by the

inspiratory and expiratory settings. Auto-cycling can be detected by a very short

or non-existent expiratory time and also by the activation of the DEMAND

indicator at the beginning of an inspiratory cycle without a vacuum being applied

to the patient circuit.

5

FIG. 1-1 IC-2A Ventilator

6

BIO−MED DEVICES, INC.

GAUGE

PRESSUREMAX. PRESSURE

PATIENT

HOSE

GUILFORD, CT U.S.A.

100% O

EXHALATION

2

VALVE

SUPPLY

PATIENT GAS

SUPPLY

LOGIC GAS

CAUTION:

THE CIRCUIT WILL NOT

PRESSURIZE WITH THIS

KNOB AT THE FULL CW

POSITION.

50±5 PSI

345±34.5 kPa

30 LPM MAX. FLOW 82 LPM MAX. FLOW

345±34.5 kPa

50±5 PSI

AIR/OXYGEN

WARNING:

CLEAN, DRY 50±5 PSI REGULATED SOURCES OF MEDICAL GRADE OXYGEN & AIR

MUST BE USED OR MALFUNCTION CAN RESULT. OXYGEN CONCENTRATION OF

POWER SUPPLY GAS AND/OR ALTITUDE AFFECT TIMING ACCURACY. CONSU LT

THE INSTRUCTION MANUAL FOR CORRECTION FACTORS.

CAUTION:

FEDERAL LAW RESTRICTS THIS DEVICE TO SALE BY OR ON THE ORDER OF A

PHYSICIAN.

BEFORE OPERATING THIS INSTRUMENT, READ THE INSTRUCTION

MANUAL THOROUGHLY. PARTICULAR ATTENTION SHO ULD BE GIVEN

TO THE USE OF THE DEMAND MODE.

REF

SN

DATE OF MFR.

I

N

C

R

E

A

S

E

!

0086

FIG. 1-2 IC-2A Ventilator (Rear View)

7

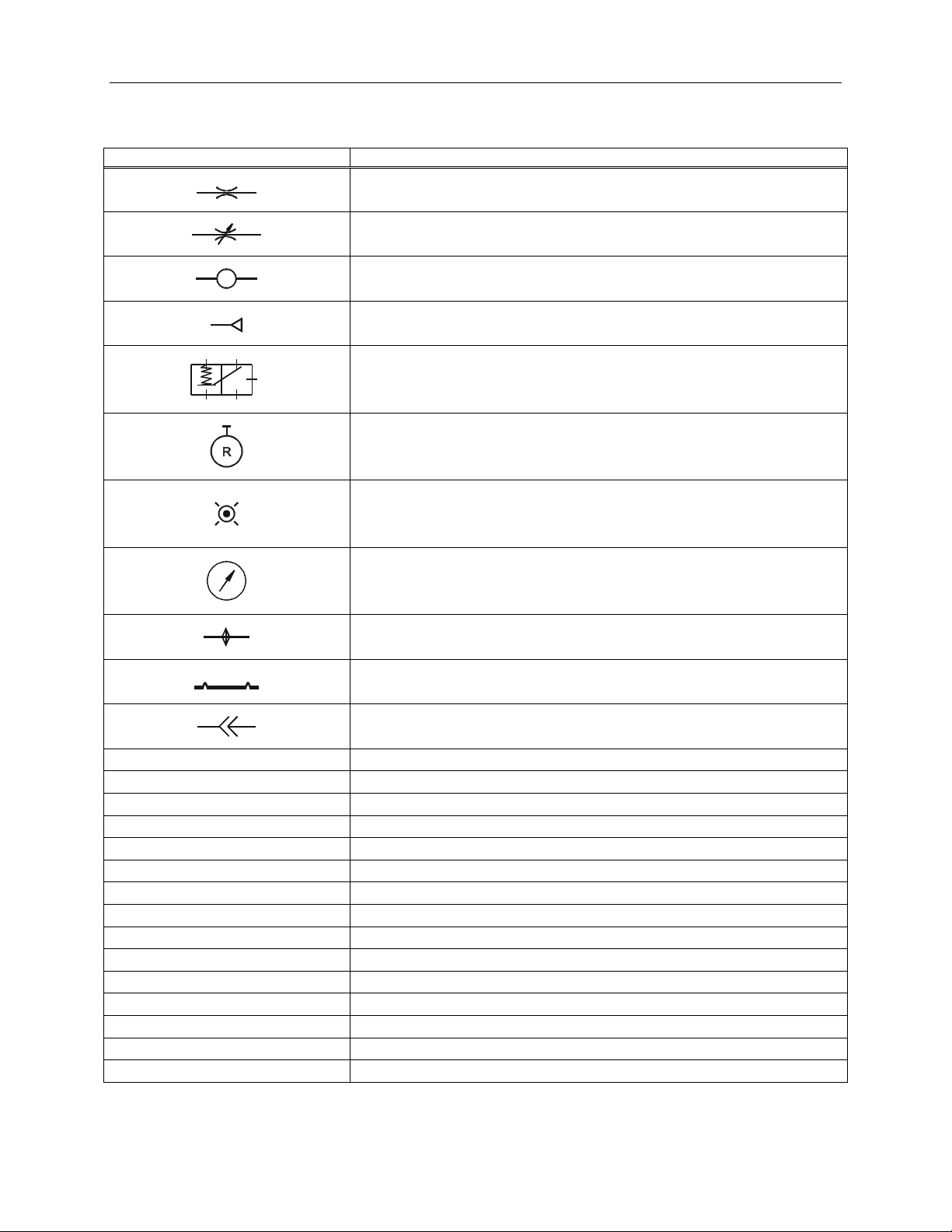

SYMBOLS AND ABBREVIATIONS

Special symbols and abbreviations are used in this manual and are listed here to

provide an easy reference for maintenance personnel.

SYMBOL/ABBREVIATION DEFINITION

Orifice, Resistor, or Restrictor

Variable Orifice, Variable Resistor, Variable Restrictor, or

Needle Valve

Volume Capacitor

Regulated Gas Supply

13

5

42

Logic Gate

Pressure Regulator

Indicator

Pressure Gauge

Filter

Diaphragm

Removable Connector

BK Black

BL Blue

BN Brown

CL Clear

GR Green

OR Orange

RD Red

VI Violet

WH White

YL Yellow

CPAP Continuous Positive Airway Pressure

IMV Intermittent Mandatory Ventilation

IPPV Intermittent Positive Pressure Ventilation

PEEP Positive End Expiratory Pressure

SIMV Synchronized Intermittent Mandatory Ventilation

8

I. DESCRIPTION

INTRODUCING THE IC-2A VENTILATOR

The IC-2A Ventilator (Figure 1-1) is a highly sophisticated, precision, pneumatic, life

support device, built to rigid specifications.

The IC-2A Ventilator is designed for respiratory support of adult patients both in a

health-care facility and during transport. It can be operated within volume or pressure

limits and has a wide range of inspiratory/expiratory time ratios (I/E). Its compact

lightweight design permits hand-carrying or attachment to a stand thus facilitating

uninterrupted support during transport.

The IC-2A Ventilator is compatible with masks and endotracheal and tracheotomy

tubes. It is gas-powered using either a portable pressurized tank or wall outlet providing

50 psi oxygen or air. It is non-electric, presents no shock hazard and features a

constantly self-purging case. Miniature pneumatic logic control elements produce high

reliability due to negligible frictional wear. The IC-2A Ventilator is compatible with

standard accessories: humidifier, oxygen blender, oxygen analyzer, pressure alarm

and patient circuit.

Controls, Indicators and Connectors

a. Front Panel – Table 1-1 lists the IC-2A Ventilator front panel controls and

indicators and their functions. Refer to Figure 1-1.

b. Top and Back Panel Controls and Connectors – Table 1-2 lists the IC-2A

Ventilator top and back panel controls and connectors and their functions.

Refer to Figure 1-2.

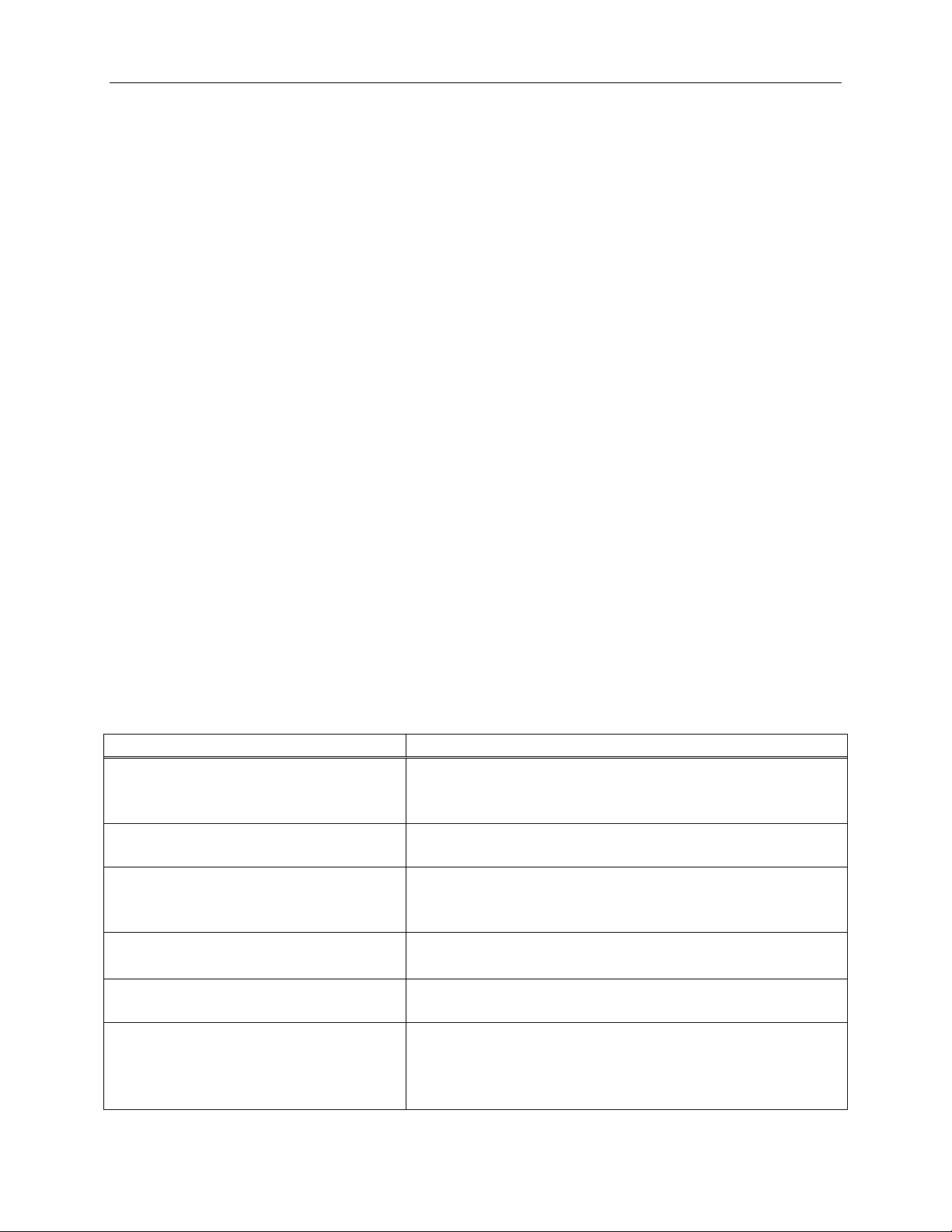

Table 1-1. IC-2A Ventilator Front Panel Controls and Indicators

Control or Indicator Function

CYCLE/MANUAL CPAP switch Two-position toggle switch for selecting non-cycling

(Manual CPAP) or time-cycled (CYCLE) modes of

operation

INSPIRATORY TIME control Rotary control for setting inspiratory time in time-

cycled modes; calibrated from .4 to 2 seconds.

EXPIRATORY TIME control Rotary control for setting expiratory time in time-

cycled modes; calibrated from .5 to 4 seconds and

may be set to 45 seconds or more in IMV range.

FLOW RATE control Rotary control for setting flow rate; calibrated from

20 to 75 lpm.

INSPIRATORY EFFORT control Rotary control for adjusting patient trigger

sensitivity

PEEP/CPAP control Rotary control for setting PEEP level when

CYCLE/MANUAL CPAP switch is set to CYCLE or

for setting CPAP level when CYCLE/MANUAL

CPAP switch is set to MANUAL CPAP

9

NORMAL/SIMV switch Two-position toggle switch for selecting normal

time-cycled mode (NORMAL) or SIMV mode

(SIMV)

OFF/ON switch Rotary switch for controlling main power to the

fluidic logic

MANUAL button Momentary action push button for manually

controlling inspirations

Pressure Gauge Analog gauge indicates proximal airway pressure;

calibrated from –10 to +120 cmH20

CYCLE indicator Activates to indicate any time-cycled inspiratory

period

DEMAND indicator Activates to indicate any cycle initiated by patient

breathing effort or backup timer

Table 1-2. IC-2A Ventilator – Top and Back Panel Controls and Connectors

Control or Indicator Function

Max. Pressure Control Rotary control for setting upper pressure limit for each cycle

Logic Gas Supply

100% O2 connector

A DISS oxygen fitting for connecting to source of clean, dry,

50±5 psi oxygen in order to power logic

PATIENT GAS SUPPLY

Connector

DISS, oxygen fitting for connection to source of clean, dry,

50±5 psi supply of patient breathing gas mixture

PATIENT HOSE

Connector

22mm (15mm inside) connector for attaching main patient

hose

EXHALATION VALVE

Connector

Powers the exhalation valve

PRESSURE GAUGE

Connector

Connects to pressure line T-adapter to provide proximal

airway pressure

Modes of Operation

The IC-2A Ventilator operates in the following modes:

a. Time Cycled, either volume or pressure limited, with or without Positive End

Expiratory Pressure (PEEP).

1. Intermittent Positive Pressure Ventilation (IPPV)

2. Synchronized Intermittent Mandatory Ventilation (SIMV)

b. Continuous Positive Airway Pressure (CPAP)

c. Manual

SPECIFICATIONS AND LIMITATIONS

Table 1-3 lists the specifications and limitations of the IC-2A Ventilator.

10

Table 1-3. IC-2A Specifications and Limitations

Specification/Limitation Range

Logic Oxygen Clean, dry, medical grade 50 ±5 psi oxygen

Patient Supply Clean, dry, oil-free, 50 ±5 psi patient breathing gas

mixture

Inspiratory Time (Calibrated*) 0.4 to 2.0 seconds

Expiratory Time (Calibrated*) 0.5 to 4.0 seconds (variable to 45 seconds or more,

uncalibrated, in the IMV range)

*INSPIRATORY and EXPIRATORY TIME controls are calibrated at sea level and 20°C using USP

oxygen. Changes in barometric pressure, altitude changes, or use of diluted oxygen will affect time

calibration.

Table 1-3. IC-2A Specifications and Limitations (continues)

Specification/Limitation Range

Rate 1-1/3 to 66 bpm

SIMV Backup Rate 4-2/3 to 6-3/4 bpm

I/E Ratio Infinitely Adjustable

Flow Rate (Calibrated) 0 to 75 lpm

Tidal Volume 0 to >3000 ml

PEEP/CPAP 0 to 25 ±5 cmH2O

System Pressure Gauge -10 to +120 cmH2O; ±3% full scale accuracy

Visual Indicators Cycle; Demand

Two-Way Relief Valve Internally installed valve opens above 120 ±20 cmH2O or

below -4±1 cmH2O

Adjustable Maximum

Pressure Valve

0 to 120 cmH2O

Inspiratory Effort

Sensitivity Range

-0.5 to –10.0 cmH2O

Logic Gas Consumption 12 LPM (approx.); varies with control settings; higher

pressure increases consumption

Dimensions 3-3/8” X 6-1/8” X 10-1/4”

(8.57 X 15.56 X 26.14 cm)

Weight 9 lbs approx. (4.1 kg)

Storage Temperature: 32° to 122°F (0°to 50°C)

Operating Temperature: 14° to 122°F (10°to 50°C)

11

II. FUNCTIONAL DESCRIPTION

INTRODUCTION

Figure 2-1 presents a schematic view of the IC-2A Ventilator. Figure 2-2 presents the

logic system. Refer to the list of symbols and abbreviations at the front of the manual.

OPERATING MODES

Intermittent Positive Pressure Ventilation (IPPV)

In the IPPV mode the IC-2A Ventilator acts as a controller or assist/controller. The

following control switch settings are required:

Switch Setting

CYCLE/MANUAL

CPAP

CYCLE

NORMAL/SIMV NORMAL

A pilot valve, operated by the timing signal from the fluid logic, opens for the time set by

the INSPIRATORY TIME control. This allows the gas to flow at a rate set by the FLOW

RATE control. The exhalation valve pressurizes, closing the exhalation port and thus

ensuring that all gas is directed to the patient.

Since the gas supply is a high pressure source and the pressure reached in the patient

is relatively low, the flow rate remains constant and independent of changes in patient

pressure.

a. Volume Limited. The pressure developed in the system depends on the total

compliance and the column of gas delivered. If the adjustable pressure limit

is set higher than the pressure that is reached, then no gas is dumped to

atmosphere and the ventilator is volume limited. In this mode the tidal volume

(VT) is the product of inspiratory time (TI) and flow rate (VI),

VT=TIX VI

In this mode the pressure limit is normally set to 10cm H2O above the pressure attained.

It then acts as an upper-level fail-safe. If patient resistance or compliance causes a

significant increase in pressure, the pressure will be limited at the preset level. When

this occurs the ventilator is no longer volume limited since some gas is dumped to

atmosphere and therefore the tidal volume is unknown.

b. Pressure Limited. Whenever the pressure reached within the patient circuit is

equal to the maximum pressure limit established using the MAX PRESSURE

control on the rear panel, the excess gas is dumped to atmosphere and the

unit is operating in a pressure-limited mode. The Ventilator may be used

continuously in the pressure-limited mode by setting the maximum pressure

and adjusting the inspiratory time and flow rate to give a large enough volume

of gas per breath to ensure that the preset pressure level is reached on each

cycle. When the pressure limit is reached, it is held until the end of

inspiration, thus producing a plateau-type pressure waveform.

12

Fig. 2-1 IC-2A Schematic Diagram

LEGEND

4 Pressure Gauge Line Connector

5 Pressure Gauge

11 Flow Rate Control Valve (panel control)

12 OFF/ON Control Valve (panel control)

13 Patient Hose Connector

15 Logic Gas Supply 100% O2 Connector

16 Exhalation Valve Line Connector

17 Patient Gas Supply Connector

22 Two-way Relief Valve

23 Logic Supply Filter

31 Pilot Line Variable Resistor

32 Pilot Valve

33 Fail-safe Cutoff Valve

35 Patient Supply Regulator

36 Logic Supply Regulator

42 Pressure Gauge Variable resistor

51 Patient Circuit Manifold

13

Fig. 2-2 IC-2A System Logic Diagram

LEGEND

1 CYCLE/MANUAL CPAP Toggle Valve (panel switch)

2 MANUAL Button

3 CYCLE Indicator

4 Inspiratory Time Needle Valve (panel control)

6 Demand Indicator

7 PEEP/CPAP Needle Valve (panel control)

8 NORMAL/SIMV Toggle Valve (panel switch)

9 Expiratory Time Needle Valve (panel control)

10 Demand (inspiratory effort) Valve (panel control)

16 Exhalation Valve Line

19 Max. Pressure Needle Valve (panel control)

24 Inspiratory Time Variable Resistor

25 Expiratory Time Variable Resistor

27 Fail-safe Variable Resistor

28 PEEP/CPAP Variable Resistor

29 Maximum Pressure Variable Resistor

31 Pilot Line Variable Resistor

41 Demand Valve Variable Resistor

43 Inspiratory Time Capacitor

47 Expiratory Time Capacitor

52 Feedback Resistor

53 Backup Timer Variable Resistor

54 Delay Line (with Delay Capacitor)

55 Backup Timer Capacitor

14

The lowest rate attainable in the IPPV mode is established by the backup timer which is

6 breaths/min.

Synchronized Intermittent Mandatory Ventilation (SIMV)

The IC-2A Ventilator provides a unique, triggered, demand-flow system for the addition

of a constant flow source. It eliminates the need for a check valve flowmeter, bag etc.

The EXPIRATORY TIME control is set in the IMV range allowing the patient one or

more spontaneous breaths between the machine assisted breaths.

NOTE: In the SIMV mode it is essential that the INSPIRATORY

EFFORT control be set so that the patient can trigger the machine

at all times.

When the NORMAL/SIMV switch is set, in the SIMV position, while the ventilator cycles

with each inspiratory effort, the pressure builds up in the patient circuit only after the end

of the expiratory time. This is achieved by pressurizing the exhalation valve only after

patient-triggered breath at the end of the expiratory time (assisted breath). At the end of

the expiratory time the machine waits for the next inspiratory effort and, therefore, when

the assisted breath is provided it is synchronized to the patient’s breathing effort. In the

SIMV mode, in the event no patient inspiratory effort is sensed for a period of ten

seconds, a backup time provides a backup breath. Every time an inspiratory effort is

sensed, whether for a spontaneous or an assisted breath, the backup timer is reset.

The interval between assisted breaths may still be set to the maximum expiratory time

of at least 45 seconds.

Each time the machine is cycled it provides gas flow to the patient even when the

exhalation valve is unpressurized. If the inspiratory time and flow rate are set in a way

that provides more gas than needed by the patient, the excess passes to atmosphere.

Should that patient require more gas during a spontaneous breath than is provided, and

if a negative pressure is still being generated (following the termination of the inspiratory

period), another inspiratory period (and as many more as necessary) will be initiated,

thus providing as much gas as required. The patient may exhale at any time during

spontaneous breathing since the exhalation valve is unpressurized. It is, however,

desirable to set the flow rate and inspiratory time to give a tidal volume as close to the

spontaneous tidal volume as possible. With this triggered demand flow system, it is

only necessary to trigger the unit initially. The IC-2A then provides a bolus of gas equal

to the inspiratory time multiplied by the flow rate. Unlike other systems it is not

necessary to maintain a constant negative pressure of several cmH2O during each

spontaneous breath. This eliminates the oscillations observed in other systems at low

flow rates and makes possible the use of normal bubble-type humidifier with the bubbler

in place. Note that during the spontaneous breaths, even though the exhalation valve is

not pressurized, there may be a buildup of 3 to 5 cmH2O pressure depending on flow

rate set. This is due to slight resistance of the exhalation valve at high flow rates.

Positive End Expiratory Pressure (PEEP)

The PEEP/CPAP control applies a constant pressure to the exhalation valve which may

be adjusted to give a pressure in the patient circuit from 0 to 25 cmH2O.

15

The PEEP/CPAP control is operative in all modes of operation, The INSPIRATORY

EFFORT control may be set to compensate for the PEEP/CPAP pressure level in the

patient circuit. Whenever the PEEP/CPAP level is changed, the INSPIRATORY

EFFORT control should be readjusted.

Continuous Positive Airway Pressure (CPAP)

When the CYCLE/MAUAL CPAP switch is placed in the MANUAL CPAP position, the

function of the IC-2A Ventilator is very similar to the SIMV mode. In the CPAP mode,

and inspiratory effort triggers the flow if a volume of gas equal to inspiratory time

multiplied by flow rate. However, in this mode the high pressure is not applied

intermittently to the exhalation valve. Only the PEEP/CPAP control is operative. The

PEEP/CPAP control may be turned fully clockwise thus applying zero pressure to the

exhalation valve. In this way the ventilator may be used to administer, on demand, gas

of a preset oxygen concentration at ambient pressure. In both the SIMV and CPAP

modes there may be a momentary fluctuation of a few cmH2O pressure demanding on

the flow rate, inspiratory time, system compliance, and gauge response.

In this mode, turn the EXPIRATORY TIME control to maximum (fully clockwise) and

place the NORMAL/SIMV switch in the SIMV position. This prevents false cycling and

helps to reduce gas consumption. It is also advisable, for added safety, that the MAX.

PRESSURE control be turned fully clockwise when using the CPAP mode,

Manual Mode

The manual mode can be used for hyperventilating before suctioning, sighing the

patient, or synchronizing with chest compressions for cardiopulmonary resuscitation.

The MANUAL button is inoperative until CYCLE/MANUAL CPAP switch is switched to

the MANUAL CPAP position. The inspiration time is set with the INSPIRATORY TIME

control. Press the MANUAL button long enough to each cycle to set the inspiratory timer

and then release the button. The inspiratory period then lasts as long as the time set

with the INSPIRATORY TIME control. The tidal volume is then equal to the inspiratory

time multiplied by flow rate (volume limited).

If the MANUAL button is held in for a time greater than the preset inspiratory time, then

inspiration lasts during the entire time that the MANUAL button is pressed. In this case

the volume delivered is unknown. The Pressure Gauge may be observed as an

indicator of degree of ventilation. By using the PEEP/CPAP control it is possible to

ventilate manually with PEEP. The MAX. PRESSURE control may also be used in

manual mode to pressure limit each breath.

LOGIC GATE

The Logic Gate contains a floating assembly comprised of two diaphragms connected

by a pair of precision shoulder pins. Switching is accomplished as each diaphragm

covers and uncovers its associated nozzle. This process causes the assembly to move

0.032 inches. There are no sliding parts in the Logic Gate ensuring long life and

trouble-free operation.

16

The five Logic Gate ports are generally used as follows:

Ports 1 and 2 Switching Signals

Port 3 Output Signal

Ports 4 and 5 Supply or Exhaust

Pressure to Ports 1 and 2 actuate a diaphragm assembly allowing either Port 4 or 5 to

connect with Port 3. With no input on either Port 1 or 2, Ports 5 and 3 are

interconnected. An input to Port 1 switches the diaphragm assembly causing Port 5 to

close and Port 4 to open resulting in a connection between Ports 4 and 3. Equal

pressures on both Ports 1 and 2 allow the spring to keep the diaphragm assembly in a

position where Ports 5 and 3 are connected.

Figure 2-3 illustrates the physical aspects of the Logic Gate in a cutaway view and also

provides a functional view.

1534 215

3

4

2

Fig. 2-3 Logic Gate, Cutaway & Schematic Views

17

III. INSTALLATION AND OPERATION

INSTALLATION

Unpacking

When received, the instrument should be immediately unpacked and checked to see

that all component parts have been received, and that there is no apparent damage.

If the IC-2A was shipped directly to you and damage due to shipment is found, notify the

carrier at once. Only you, the consignee, can make a claim against the carrier for

damage in shipment.

If you received the equipment from a Bio-Med Devices dealer, return it to the dealer for

adjustment.

The following items are shipped as part of the IC-2A equipment. Check to assure that

all items have been received.

• IC-2A Intensive Care Ventilator

• 2 complete disposable Patient Circuits, BMD part #8002A

• 1 10 ft. supply hose with female DISS oxygen fittings, BMD #1010

• 1 high pressure oxygen wye, BMD part #8005

• 2 supply elbow adapters; male to female DISS oxygen

• Mounting bracket

• Instruction manual and warranty card

• Test lung, BMD part #1020

Equipment Required

All equipment required for use with the IC-2A Ventilator is supplied with the instrument,

except for the gas supply. No special tools are needed.

It is convenient to have a test lung (part number 1020) available when setting the

ventilator parameters.

Supply Gas

The supply gas is normally from pressurized tanks(s) or a wall source of medical or

therapy grade oxygen and/or air.

NOTE: The pressurized tanks should be fitted with regulators adjusted to

50

±

5 psi.

18

WARNING: No flow restricting device (e.g. flowmeter, throttling

valve) should be placed in the supply line. A flow-restricting device

interferes with the operation of the pneumatic logic and may render

the time-cycling inoperative which can endanger the health of the

patient.

The IC-2A will operate with a supply pressure outside of the 50 ±5 psi range, but the

accuracy of the settings may be impaired.

WARNING: In no case should a supply pressure less than 35 or over

80 pi be connected to the IC-2A Ventilator as it will cause

malfunction of the ventilator which will endanger the health of the

patient.

Mounting Bracket

The supply mounting bracket may be installed on any column up to 1-1/2 inches in

diameter.

Ancillary Equipment

Other standard equipment which may be used with the IC-2A Ventilator at the option of

the user includes:

a. Oxygen Blender. Any oxygen blender that provides sufficient flow rates at

constant pressure may be used. Models with supply disconnect alarms are

recommended. The oxygen blender connects to the PATIENT GAS SUPPLY

connector.

b. Humidifier. Any adult intensive care humidifier intended for use with a

ventilator may be used. It is connected in-line in the main patient hose. Due

to the unique triggered demand flow system of the IC-2A Ventilator, a bubble

tower, if present in the humidifier used, may be left in place without adversely

affecting operation.

c. Pressure alarms. A high-low pressure alarm may be connected to the

pressure gauge line or main patient hose.

WARNING: To ensure the health of the patient, pressure alarms must

always be used whenever the IC-2A Ventilator is used unattended.

d. Rate – I/E Ratio Monitor. This monitor may be connected, if desired, to

simplify use of the IC-2A Ventilator by supplying readout of rate and I/E ratio.

It connects in the same way as the high-low pressure alarm.

e. Spirometer. Any spirometer may be used to verify the tidal volume

administered by the IC-2A Ventilator.

WARNING: No device should ever be connected to exhalation valve

line. Malfunction may result which could endanger the health of the

patient.

Other manuals for IC-2A

1

This manual suits for next models

1

Table of contents

Other BIO-MED DEVICES Medical Equipment manuals

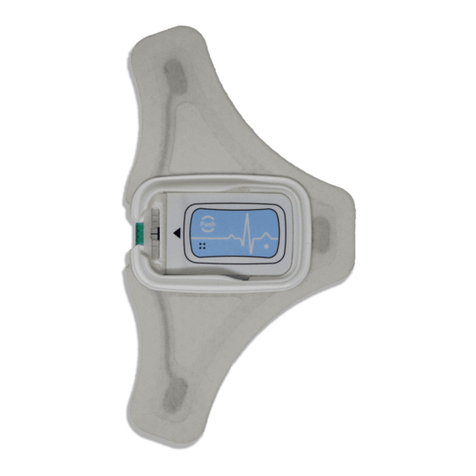

Popular Medical Equipment manuals by other brands

elektron eye technology

elektron eye technology Henson 9000 manual

Dräger

Dräger Cato Instructions for use

Fluke Biomedical

Fluke Biomedical medTester 5000C Operators Operator's manual

Happy Electronics

Happy Electronics STRESSLOCATOR user guide

Activ8rlives

Activ8rlives PulseOximeter2 manual

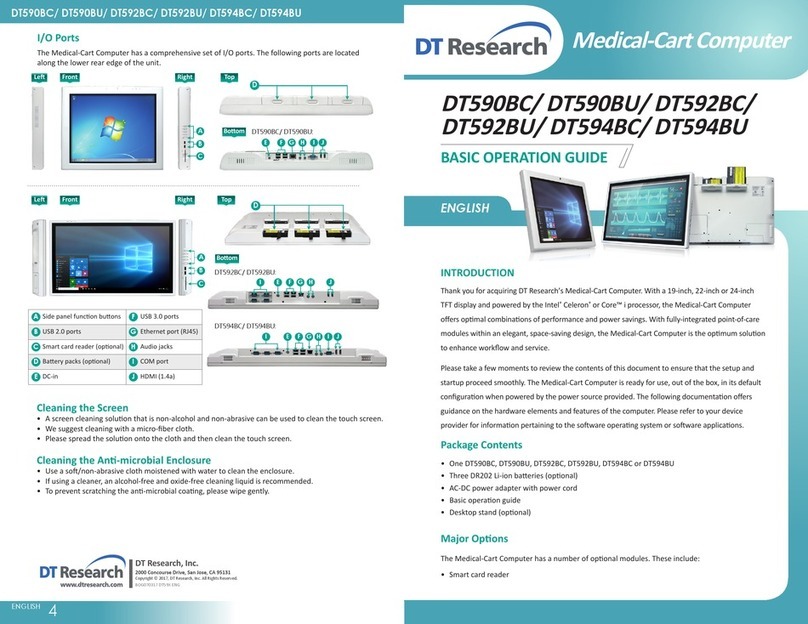

DT Research

DT Research DT590BU Basic operation guide