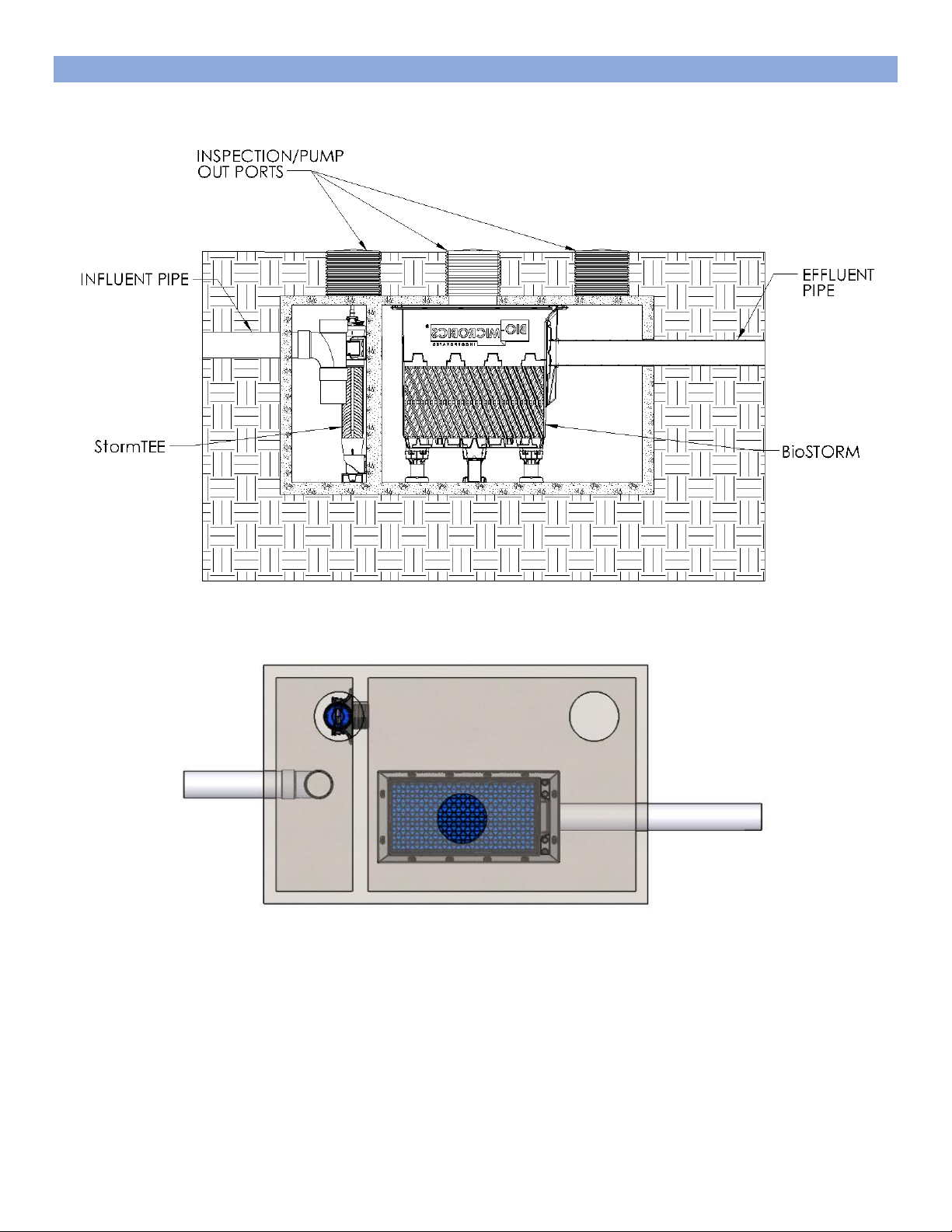

BIO-MICROBICS BioSTORM 0.5 User manual

This manual suits for next models

7

Table of contents

Popular Plumbing Product manuals by other brands

Stern

Stern CSABA Series Installation and maintenance guide

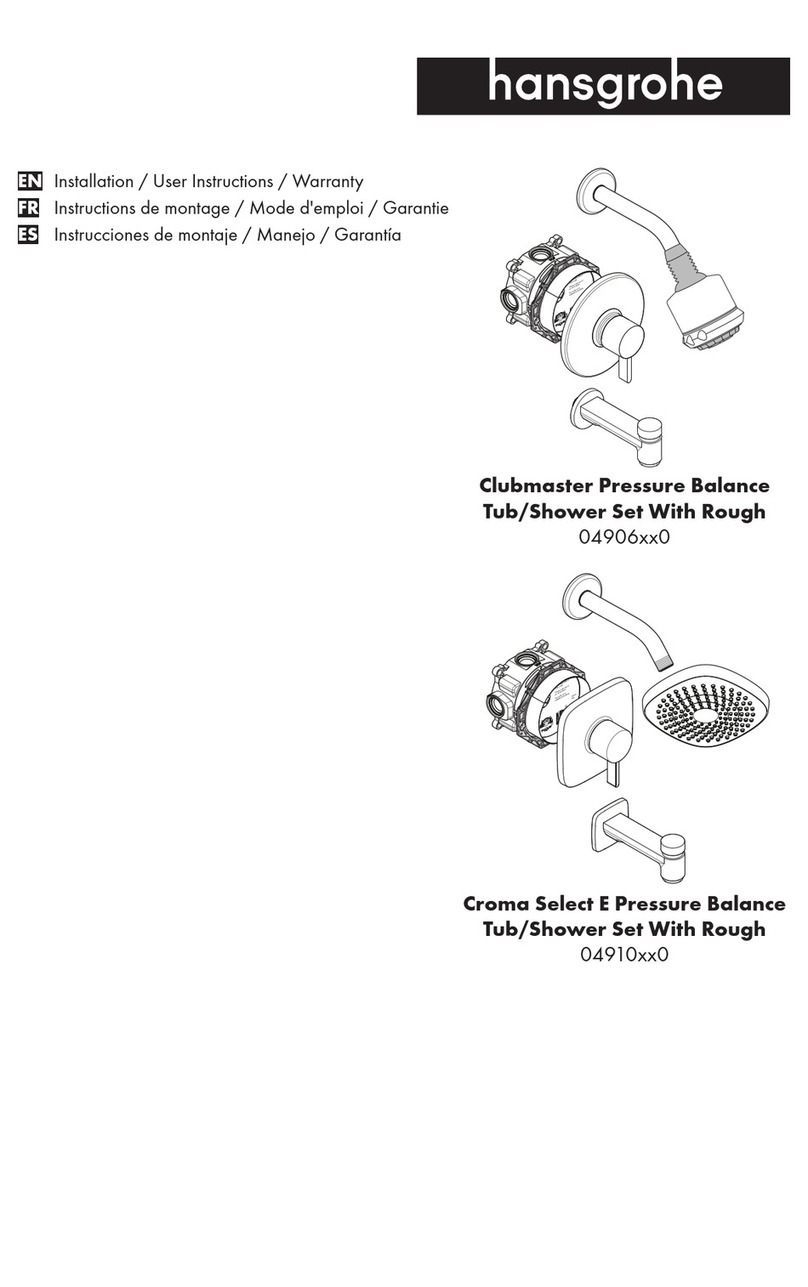

Hans Grohe

Hans Grohe Mondaro 18001 Series quick start guide

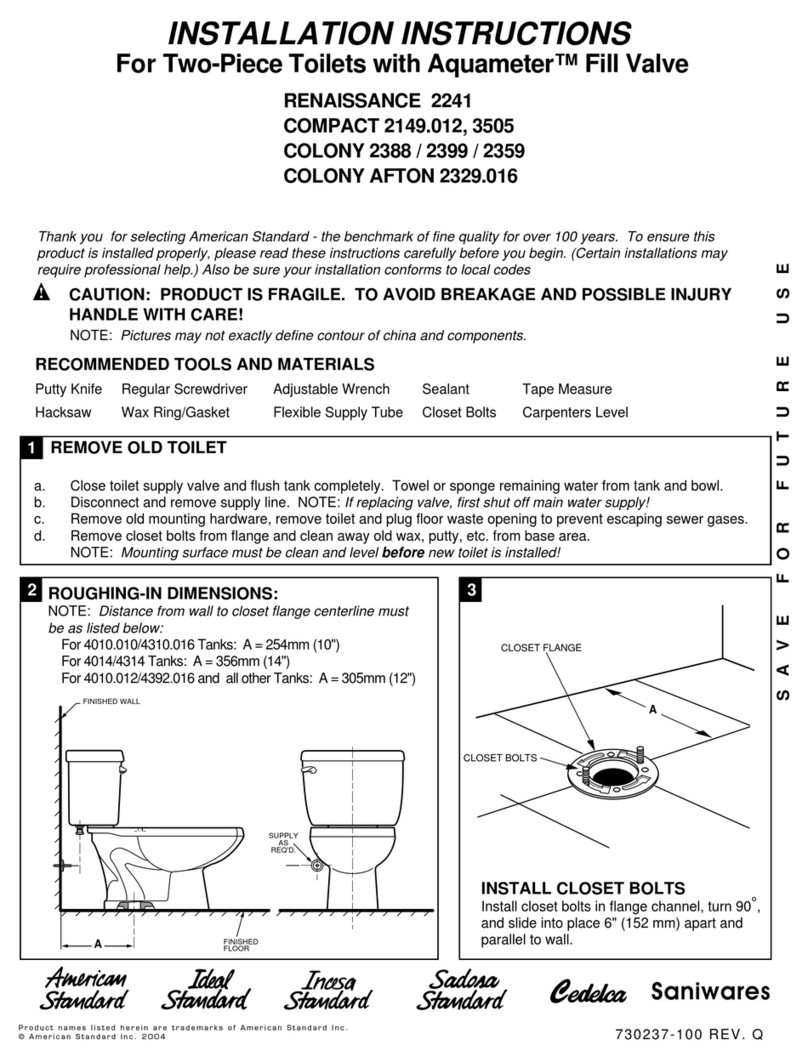

American Standard

American Standard COMPACT 3505 installation instructions

Hans Grohe

Hans Grohe Duo Classic 12401000 Assembly instructions

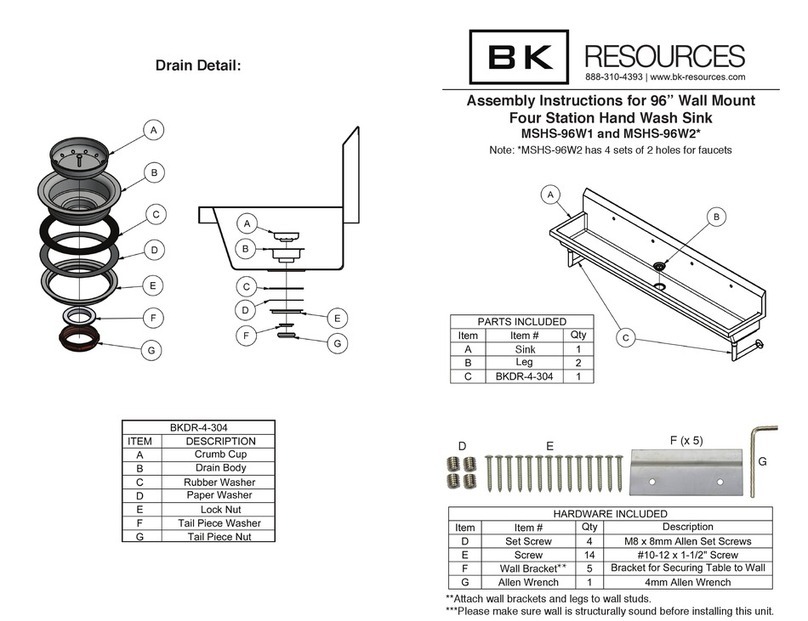

BK RESOURCES

BK RESOURCES MSHS-96W1 Assembly instructions

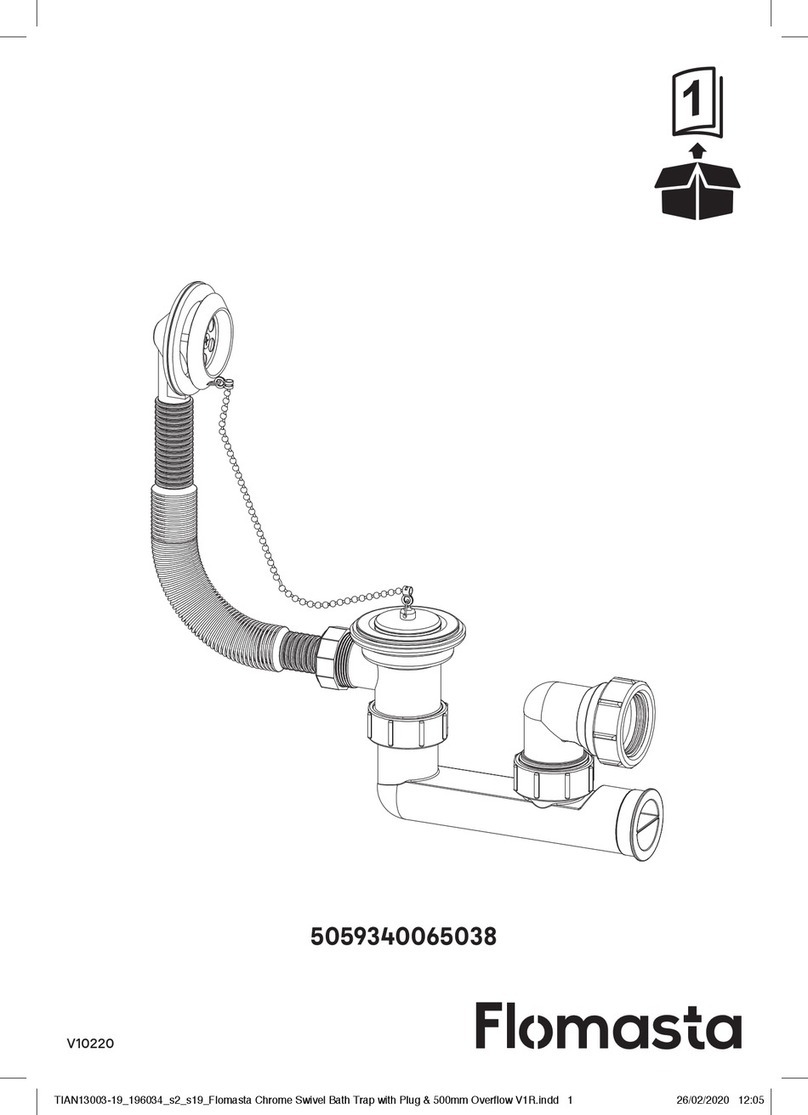

Flomasta

Flomasta 5059340065038 manual

Dynamic Saunas

Dynamic Saunas DYN-5830 owner's manual

Hans Grohe

Hans Grohe Clubmaster 04906 0 Series Installation/User Instructions/Warranty

Sterling

Sterling ClearWater KIRA KIR30 Fitting Instructions and Parts List

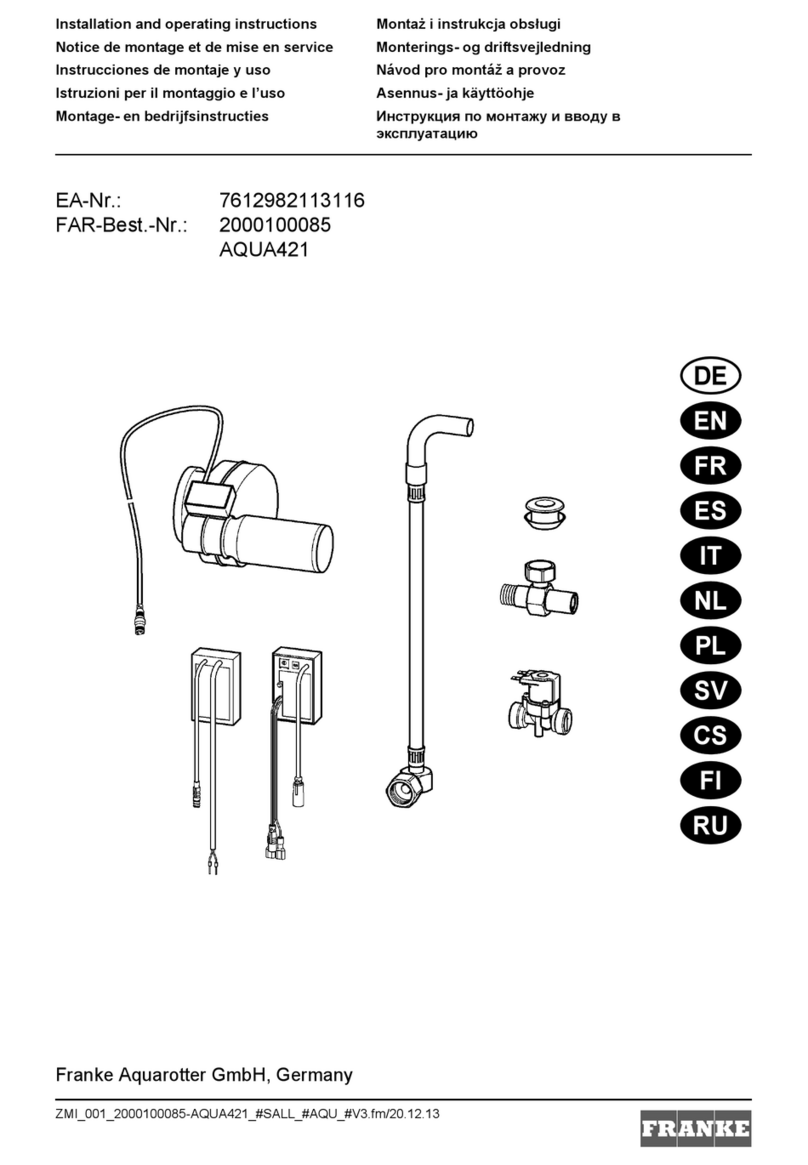

Franke

Franke AQUA421 Installation and operating instructions

Luxart

Luxart Velero VE511TOV Installation

KWC

KWC ERA 810-34 Installation and service manual

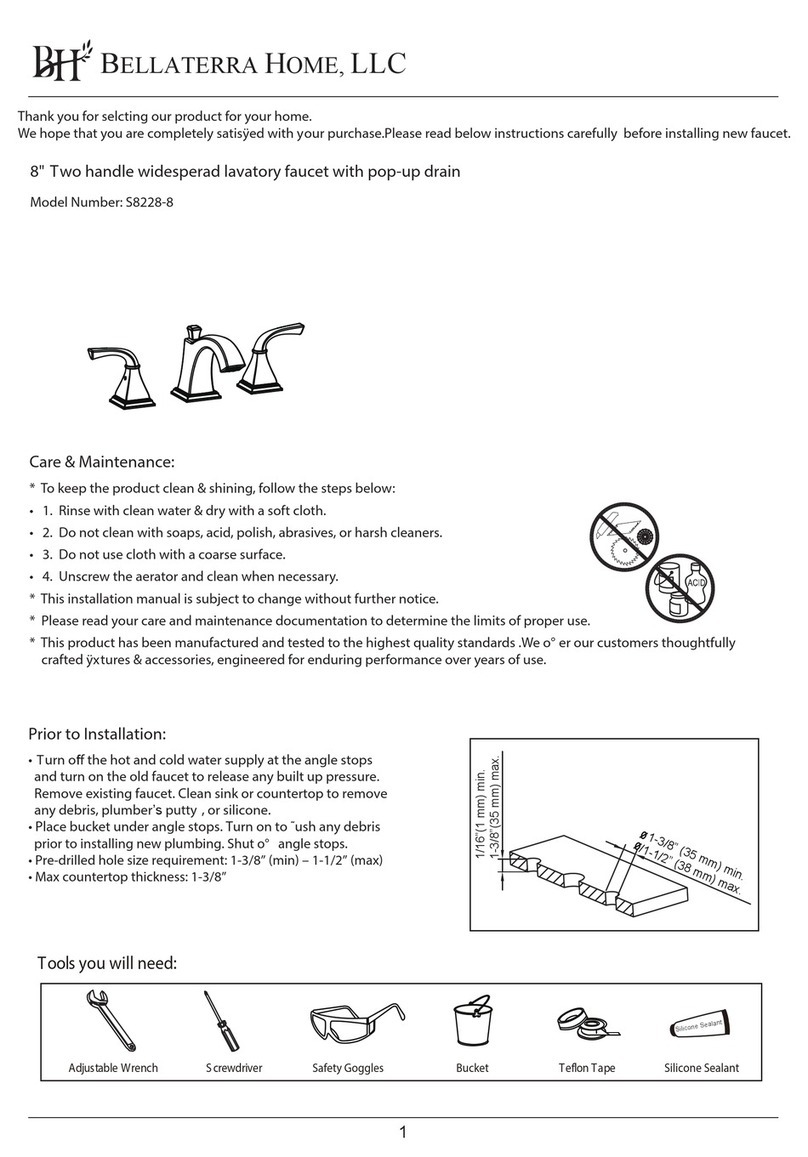

BELLATERRA HOME

BELLATERRA HOME S8228-8 instructions

Hans Grohe

Hans Grohe AXOR Starck 10912000 Instructions for use/assembly instructions

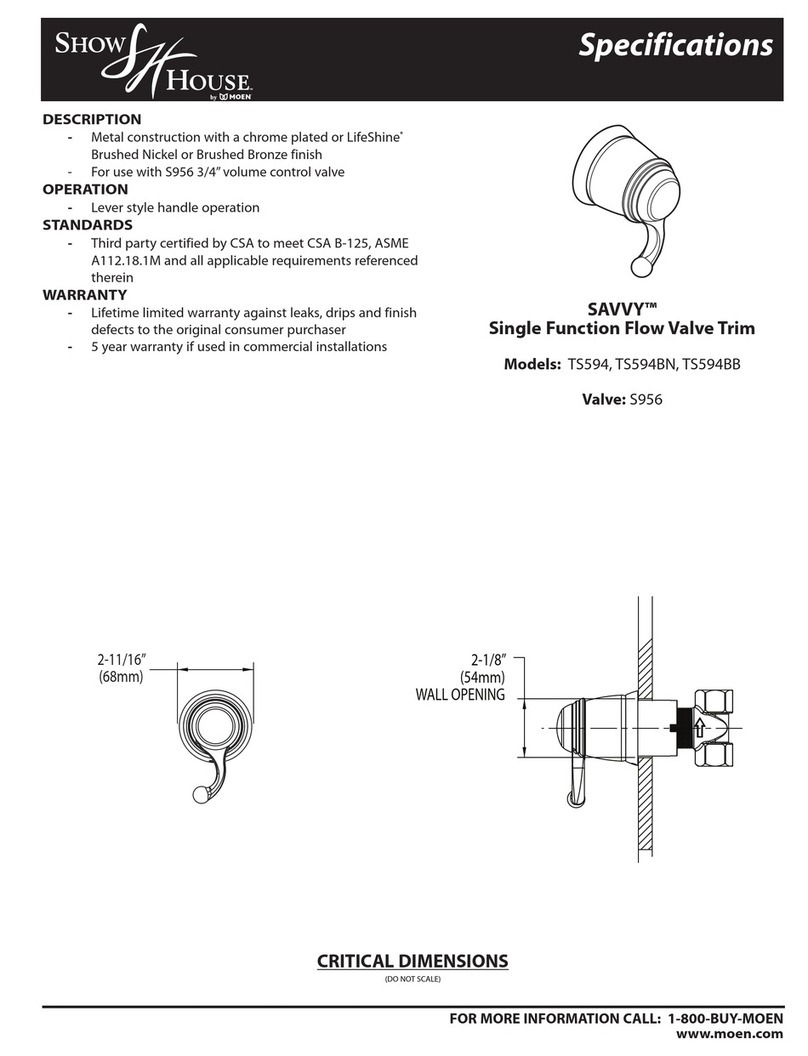

ShowHouse

ShowHouse SAVVY TS594 Specifications

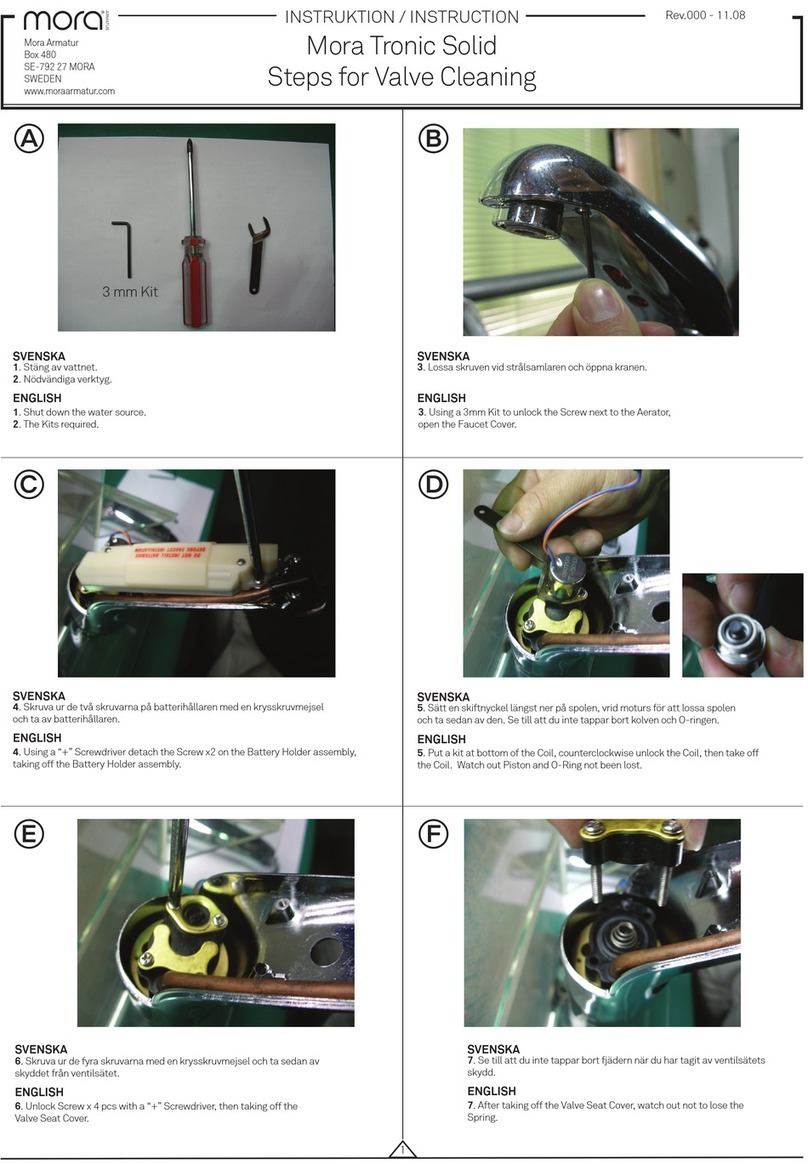

Mora armatur

Mora armatur Tronic Solid instructions

Oxygenics

Oxygenics PawSpa PetJetPro quick start guide

Moen

Moen Antique Bronze 6121AZ Illustrated parts list