Bioclimatic PCO Technical Document

OUR MISSION

To design and build quality engineered air cleaning systems

to provide indoor comfort, protect occupants, and ensure the

reliability of critical systems and processes.

Bioclimatic.com

350-AUG-2021

IMPORTANT

Save this Document

for Future Reference &

Warranty Information

Photo Catalytic

Oxidation Series

Installation, Operation

and Maintenance Guide

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 2

1-800-394-3458 350-AUG-2021 Bioclimatic.com

! I M P O RTA NT!

READ THIS BEFORE STARTING INSTALLATION.

DO NOT THROW AWAY THIS GUIDE.

How to Contact Us: If you need help, please contact a

Bioclimatic Air Systems Representative for technical assistance.

For installation you MUST:

■ Always disconnect power to the unit before handling any of the

components.

■ DO NOT connect to the power before the installation is complete and

personnel are aware of the imminent operation.

■ Carefully read this instruction booklet before beginning the installation.

■ Follow each installation or repair step exactly as shown and explained in

this guide.

■ Observe all local, state, national and international electrical codes.

■ Pay close attention to all warnings and caution notices given in this guide.

!CAUTION!

Do not touch while in operation shut off electricity before servicing!

This equipment should be inspected frequently and collected dirt removed from it regularly to prevent excessive

accumulation that may result in flashover or risk of fire.

!MISE EN GARDE!

Ne touchez pas pendant le fonctionnement couper l’électricité avant l’entretien

Cet équipement doit être inspecté fréquemment et la saleté collectée doit être retirée régulièrement pour éviter

toute accumulation excessive pouvant entraîner un contournement ou un risque d’incendie.

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 3

1-800-394-3458 350-AUG-2021 Bioclimatic.com

Table of Contents

01 INTRODUCTION 4

1.1 Disclaimer 4

1.2 Receiving 4

1.3 Storage 4

1.4 Warranty 5

02 PHOTO CATALYTIC OXIDATION PCO 6

2.1 System Structure 7

2.2 PCO Panel 7

2.2 Performance 7

03 GENERAL INSTALLATION 8

3.1 Considerations 8

3.2 Unit Installation 8

3.3 Clearances for Service Access 8

04 MAINTENANCE 9

05 PRODUCT NUMBERS 10

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 4

1-800-394-3458 350-AUG-2021 Bioclimatic.com

01 INTRODUCTION

1.1 Disclaimer

These instructions are submitted with the implicit understanding that:

1. This manual is to guide the user of Bioclimatic equipment in the proper installation, operation and maintenance procedures to

insure maximum equipment life with efficient operation.

2. The customer has assigned competent maintenance and operating personnel to the system described herein and will assume

operational and maintenance responsibility upon start-up of the system.

3. The customer will read and thoroughly examine the foregoing instructions and will notify the seller of any points not fully

understood, points of conflict or error.

4. The customer, in lieu of any notification to the contrary, has read and fully understands the operation of the system and

is aware of the hazards of corrosion, abrasion and fire or explosion and shall take the necessary steps in the operation of

equipment to control such hazards to the maximum extent possible.

5. Start-up assistance or field engineering service provided by B.A.S. shall in no way relieve the customer of responsibility for the

proper operation of the system.

1.2 Receiving

Products leaving the B.A.S. factory are inspected and in satisfactory operating condition. All equipment should be thoroughly

inspected when received. Although all units are properly packaged, rough handling in transit can cause breakage. Any shortage

or damage should be reported at once to the transportation company. Note the damage on the bill of lading before signing

for the shipment. No equipment may be returned to Bioclimatic without written authorization. Returned equipment sent

without authorization will be refused and returned to sender.

All products are shipped F.O.B. (Ex Works, FCA) Bioclimatic warehouse. Responsibility for all equipment passes to the buyer at the

time equipment is loaded onto the carrier’s truck.

1.3 Storage

If the UV or UV lamps are not installed upon delivery, it should be stored in a cool, dry, weather protected location. Do not stack

any other equipment on top of the filters.

Continue on Next page

IMPORTANT: Any modifications to the unit by unauthorized personnel will void factory warranty.

The unit must be installed in accordance with the manufacturer’s instructions to preserve warranty.

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 5

1-800-394-3458 350-AUG-2021 Bioclimatic.com

1.4 Warranty

The seller warrants the equipment against defective workmanship and material for fifteen (15) months from date of factory

shipment or one (1) year from commissioning, whichever occurs first. In the fulfillment of its warranty, the sole obligation of seller

shall be to repair or replace, at its option, F.O.B. its factory, any part or parts which are returned F.O.B. its factory, shipping charges

prepaid, and which after inspection by seller are found to be defective. Buyer shall notify seller of defect in writing, promptly upon

discovery and within the warranty period. This warranty does not cover defects caused by corrosion or normal deterioration; it

does not extend to consequential damage, loss or delay associated with a warranty defect; and it does not cover any cost of labor,

travel, or other expense associated with the repair or replacement of defective parts. Seller assumes no liability for product loss

or other claims whatsoever arising out of the use or application of the equipment in any operations, whether the machine is used

alone or in conjoint use with other equipment or processes. Notwithstanding the foregoing, seller’s warranty obligations with

respect to any items not manufactured by seller shall not exceed the obligations undertaken by the manufacturer thereof under

express warranty to the seller. This express warranty is in lieu of all other warranties of fitness of the machine for any particular

purpose.

There are no other representations, warranty of condition in any respects either expressed or implied, statutory, or otherwise in

contract or tort, other than what is stated above.

The seller shall not be held liable in any way for consequential damages, however caused.

This warranty will not apply if the seller’s equipment has been damaged due to improper installation, alteration, abuse or misuse,

accident, fire, flood, or unavoidable circumstance. Further, this warranty will not apply if repairs, replacements, or alterations are

made by others without the seller’s prior written authorization.

In the event the state in which the equipment is installed does not permit the limitation or exclusion of implied warranties or

conditions under given circumstances, the provisions of this written warranty are in addition to and not a modification of the

statutory warranties and other rights and remedies provided by such laws.

Any modification to original equipment by any company or person other than the manufacturer will serve to cancel and void all of

the seller’s liability under the manufacturer’s warranty. Enclosures containing electronic components are normally sealed by the

manufacturer to prevent unauthorized tampering or adjustments. Only authorized service provides may break seals to complete

calibration or to trouble shoot the unit. Unauthorized tampering or breaking seals will release the seller from any future liability

under the warranty.

Disclaimer: The air purification technologies provided by Clean Air Group are intended to improve indoor air quality. They are

not intended as a replacement for reasonable precautions aimed at preventing the transmission of contaminants, airborne or

otherwise. All persons having access to the serviced premises should comply with applicable public health laws and guidelines

issued by federal, state and local governments and health authorities such as the Centers for Disease Control and Prevention

(CDC). Clean Air Group does not maintain that its products will protect people from all modes of transmission of bacteria, viruses

or other contaminants, and excludes liability for loss or damage arising from any such claims or the consequences arising out of

the application, use or misuse of its products.

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 6

1-800-394-3458 350-AUG-2021 Bioclimatic.com

02 PHOTO CATALYTIC OXIDATION PCO

Photo Catalytic Oxidation or PCO is an effective, environmentally friendly, and low-cost way to remove many harmful and

objectionable contaminants and improve indoor air quality.

The Bioclimatic PCO system is designed to remove many VOCs efficiently and effectively from the air, reduce odors, and

deactivate many microorganisms like bacteria, viruses, and fungi. Air quality is improved by the germicidal effect of the ultraviolet

(UV) light which is an integral part of the system.

Photo Catalytic Oxidation provides multiple air cleaning benefits:

■ Eliminates VOCs

■ Reduces Odors

■ Neutralizes biological contaminants

■ Kills or neutralizes bacteria, viruses, mold, and fungi

■ Enables Energy Savings

A PCO air cleaner uses ultraviolet (UV) light and titanium dioxide (TiO2; a proven efficient, economical, and efficient UV catalyst)

to oxidize and reduce many VOC gases in the air. A catalyst coated surface irradiated with UV light results in a chemical reaction

at the catalytic panel surface. Hydroxyl radicals that are created react with and neutralize volatile organic compounds and kill or

interfere with the life cycle of many viruses and bacteria. Titanium dioxide is proven to be an efficient and economical UV catalyst.

2. PHOTO CATALYTIC OXIDATION (PCO Cleaning Strategies)

Clean Air. We take it for granted and assume that the air we are breathing is healthy, safe and pleasant. Sadly,

that’s usually not the case. Allergens, bacteria, exhaust fumes, industrial chemicals, and thousands of other

pollutants and irritants contaminate our air. Even our own human bio-effluents from crowded public spaces,

schools, commercial buildings, hospitals, casinos, stadiums or other buildings can produce an unpleasant

environment. Bioclimatic can help you create a clean, safe, pleasant environment that can improve health,

productivity, help you generate income, and save on cooling and heating costs.

One of the most recent air cleaning technologies to emerge is Photo Catalytic Oxidation. PCO is an effective,

environmentally friendly and low cost way to remove many harmful and objectionable contaminants and

improve indoor air quality.

The Bioclimatic PCO system is designed to safely and effectively remove many VOCs from the air and improve

indoor air quality and neutralize or deactivate many biologic contaminants like bacteria, viruses, mold and fungi.

Air quality is further improved by the germicidal effect of the ultraviolet (UV) light which is an integral part of

the system. Users of the system may be able to reduce the amount of outside air they need in their HVAC system

while maintaining or improving indoor air quality which leads to significant savings in heating and cooling

energy costs by reducing outside air ventilation.

Photo Catalytic Oxidation provides multiple air cleaning benefits:

•Eliminates VOCs

•Reduces Odors

•Neutralizes biological contaminants

•Kills or neutralizes bacteria, viruses, mold and fungi

•Enables Energy Savings

In its simplest form, a PCO air cleaner uses ultraviolet (UV) light and a titanium dioxide (TiO2) catalyst to

oxidize and reduce many VOC gases in the air. When a surface coated with the catalyst is irradiated with UV

light a chemical reaction takes place at the surface and hydroxyl radicals are formed from water vapor. The

hydroxyl radicals react with and neutralize volatile organic compounds and kill or interfere with the life cycle

of many viruses and bacteria. Titanium dioxide is proven to be an efficient and economical UV catalyst.

Continue on Next page

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 7

1-800-394-3458 350-AUG-2021 Bioclimatic.com

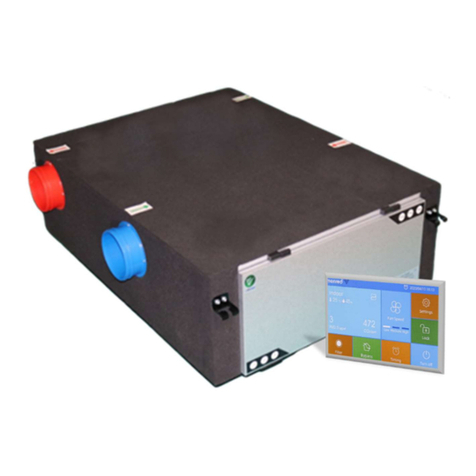

2.1 System Structure

The Bioclimatic PCO system is comprised of UV lamps, photo catalytic panels

with a titanium dioxide coating permanently bonded to the panel. The panels

are designed for optimum air cleaning performance. Each PCO panel is a

matrix coated with titanium dioxide catalyst that is designed to maximize the

amount of irradiated surface area exposed to the air flow. The number, size and

configuration of the components are determined by the size of the system and

the contaminants that need to be removed or neutralized.

The base system contains a pre-filter (required to protect the panel and lamps),

a single array of UV lamps, PCO panels, and high efficiency filters (if included)

to remove any particulate matter. A single stage of UV can irradiate up to two

stages of PCO panels.

UV-C (also known as UVGI) lamps are placed are placed approximately 6” from

the catalytic panel to provide maximum air cleaning efficiency. The lamps

are selected and placed to provide a minimum of 1,100 microwatts per square

centimeter across the front of the catalytic panel.

2.2 PCO Panel

The heart of the PCO system is the photo catalytic panel. The panel is a ¾” deep aluminum honeycomb with TiO2 coating that

is permanently bonded to all surfaces of the panel. The panel structure, size and shape are designed to maximize the system air

cleaning and purification capacity while minimizing airflow pressure drop.

■ Each 24” by 24” honeycomb panel has over 10,000 square inches of catalytically active surface to provide the maximum air cleaning

surface. Panels are available in a variety of sizes to fit different systems configurations.

■ The positions of the panel and lights are optimized to maximize the air cleaning catalytic reactions.

■ The Bioclimatic panel is easy to maintain. The panel does not shed or deteriorate. The only maintenance that may be needed is to

occasionally rinse off any accumulated debris.

■ The panel has no moving parts and the bonded TiO2 catalyst is not consumed by the reaction. Properly maintained, the panel can

provide many, many years of service.

■ The panel’s air cleaning efficiency and low cost make it an extremely and efficient air cleaning solution.

2.2 PCO Panel

Photo catalytic Oxidation is a proven air cleaning technology. Independent test results from around the world confirm that

Bioclimatic’s technology produces profound reductions in air pollutants and contaminants.

■ 93.6% reduction in Viruses and Bacteria

■ 80% drop in VOCs

■ Reduces Ozone and Formaldehyde

■ Low Pressure Drop

2.1 System Structure

The Bioclimatic PCO system is comprised of

UV lamps, photocatalytic panels with a titanium

dioxide coating permanently bonded to the

panel, and high efficiency filtration. The panels

are designed for optimum air cleaning

performance. Each PCO panel is a matrix

coated with titanium dioxide catalyst that is

designed to maximize the amount of irradiated

surface area exposed to the air flow. The

number, size and configuration of the

components are determined by the size of the

system and the contaminants that need to be

removed or neutralized.

The base system contains a pre-filter, a single

array of UV lamps and PCO panels, and high

efficiency filters to remove any particulate

matter. A single stage of UV can irradiate two

stages of PCO panels. For more demanding air

cleaning applications additional stages of catalytic panels and UV lamps can be added as required. Some

specific contaminants require additional cleaning technologies to remove or neutralize them.

Bioclimatic’s engineers will help you design a system to address challenging air cleaning requirements.

UV-C lamps with an optimum germicidal wavelength of 254 nanometers are placed are placed

approximately 6” from the catalytic panel to provide maximum air cleaning efficiency. The lamps are

selected and placed to provide a minimum of 1,100 microwatts per square centimeter across the front of

the catalytic panel.

2.2 PCO Panel

The heart of the PCO system is the photo catalytic panel. The panel is a ¾” deep aluminum honeycomb

with TiO2 coating that is permanently bonded to all surfaces of the panel. The panel structure, size and

shape are designed to maximize the system air cleaning and purification capacity while minimizing

airflow pressure drop.

•Each 24” by 24” honeycomb panel has over 10,000 square inches of catalytically active surface to

provide the maximum air cleaning surface. Panels are available in a variety of sizes to fit different

systems configurations.

•The positions of the panel and lights are optimized to maximize the air cleaning catalytic reactions.

•The Bioclimatic panel is easy to maintain. The panel does not shed or deteriorate. The only

maintenance that may be needed is to occasionally rinse off any accumulated debris.

•The panel has no moving parts and the bonded TiO2 catalyst is not consumed by the reaction.

Properly maintained, the panel can provide many, many years of service.

•The panel’s air cleaning efficiency and low cost make it an extremely safe and efficient air cleaning

solution.

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 8

1-800-394-3458 350-AUG-2021 Bioclimatic.com

03 GENERAL INSTALLATION

Install all UV fixtures and molecular filtration elements per manufacturer’s guidelines.

CAUTION: Never Expose Eyes or Skin to UVC – Read all materials before starting or operating this unit.

3.1 Considerations

Improper installation, adjustment, alteration, service, maintenance, or use can cause fire, electrical shock, or other conditions

which may cause personal injury or property damage. Consult a qualified installer, service agency, or your supplier for information

or assistance. The qualified installer or agency must use factory kits or accessories when installing this product. Refer to the

individual instructions packaged with kits or accessories when installing them. Follow all local codes, wear protective glasses, and

work gloves. Read all instructions thoroughly and follow any warnings or cautions attached to any accessed area. Consult local

building codes and the National Electrical Code (NEC) for all applicable requirements.

WARNING: Before installing or servicing, turn of all power — there may be more than one (1) switch.

3.1.1 All access doors/panels shall have an interlock switch that disconnects the power to the UV sub system upon

opening. The interlock switch should be capable of handling a 20-amp lighting load.

3.1.2 An optional window shall be available for each air handler to allow visual inspection of the System during

operation. The viewing window shall be designed to block UV-C light emissions below the threshold limits

specified by NIOSH and/or ACGIH.

3.1.3 Units shall have a warning label applied to the exterior of each section containing UV-C lights.

3.2 Unit Installation

Typical installation is with a duct connection for the entering and leaving air. It is recommended that duct elbows be avoided

within two diameters of the connections to the unit to assure consistent velocity across the panel(s). Unit should be supported

from the base unless provide with factory installed hangers.

3.3 Clearance for Service Access

A minimum of 3 feet of access on the access door/panel side of the unit or as dictated by local code is required for general service.

For units with UV lamps exceeding 3 feet in length it is advisable to provide more space to allow for easy removal of the lamps.

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 9

1-800-394-3458 350-AUG-2021 Bioclimatic.com

04 MAINTENANCE

The PCO panel itself has no moving parts and no electrical connections. The only maintenance the PCO might require is to rinse

off with water if dust accumulates on the panel. This should be an infrequent occurrence since the prefilters will normally remove

most airborne debris. The upstream filters must be maintained properly and replaced as needed as determined by monthly or

quarterly inspections.

A thin layer of contamination will decrease the effectiveness of the UV lamps. At least quarterly use a lint-free cloth soaked in IPA

(isopropyl alcohol) or methylated spirits. Never touch quartz lamps with bare hands. Natural oily deposits left by fingers and

palms create an opaque mark on the lamp thereby reducing the UV transmission. These marks also cause the quartz to break

down, causing premature lamp failure. Use caution when cleaning near the ends of the lamps excessive pressure may remove or

smear the coating protecting the lamp electrodes.

Operating life of the lamps is 10,000 hours. Check the unit mounted hour meter if included. UV output will diminish even if lamp

appears to be functional. Timely replacement is extremely important for proper function. Lamps must be replaced with the

same type and intensity. To retain maximum UV output, rotate the lamp 90 degrees after each cleaning. This prevents the lamp

from sagging and extends the useful life.

CAUTION: If the lamp has wire connectors, do not rotate beyond 360 degrees in one direction. Constant

rotation in the same direction can cause excessive strain on the wire, and premature failure due to a

dislocated connection.

Installation, Operation & Maintenance Guide Photo Catalytic Oxidation Series 10

1-800-394-3458 350-AUG-2021 Bioclimatic.com

05 PRODUCT NUMBERS*

Photo Catalytic Oxidation (PCO)

PCO CASSETTE PCO121201

PCO-202-CP2 PCO122401

PCO-303-CP2 PCO162001

PCO-304-CP2 PCO162501

PCO-305-CP2 PCO182401

PCO-306-CP2 PCO202001

PCO-406-CP2 PCO202401

PCO-407-CP2 PCO242401

PCO-506-CP2

PCO-507-CP2

PCO-508-CP2

PCO-607-CP2

PCO-609-CP2

PCO-610-CP2

PCO-810-CP2

*If your specific model is not listed please contact the factory at:

1-800-394-3458 for operating instructions, safety information and

replacement parts or service.

This manual suits for next models

23

Table of contents

Popular Fan manuals by other brands

Emerson

Emerson CF552GES00 owner's manual

Home Decorators Collection

Home Decorators Collection GAMALI 56000 Use and care guide

Eldom

Eldom COLUMBIA VAC WGC40N manual

Jocel

Jocel JVT030542 instruction manual

Craftmade

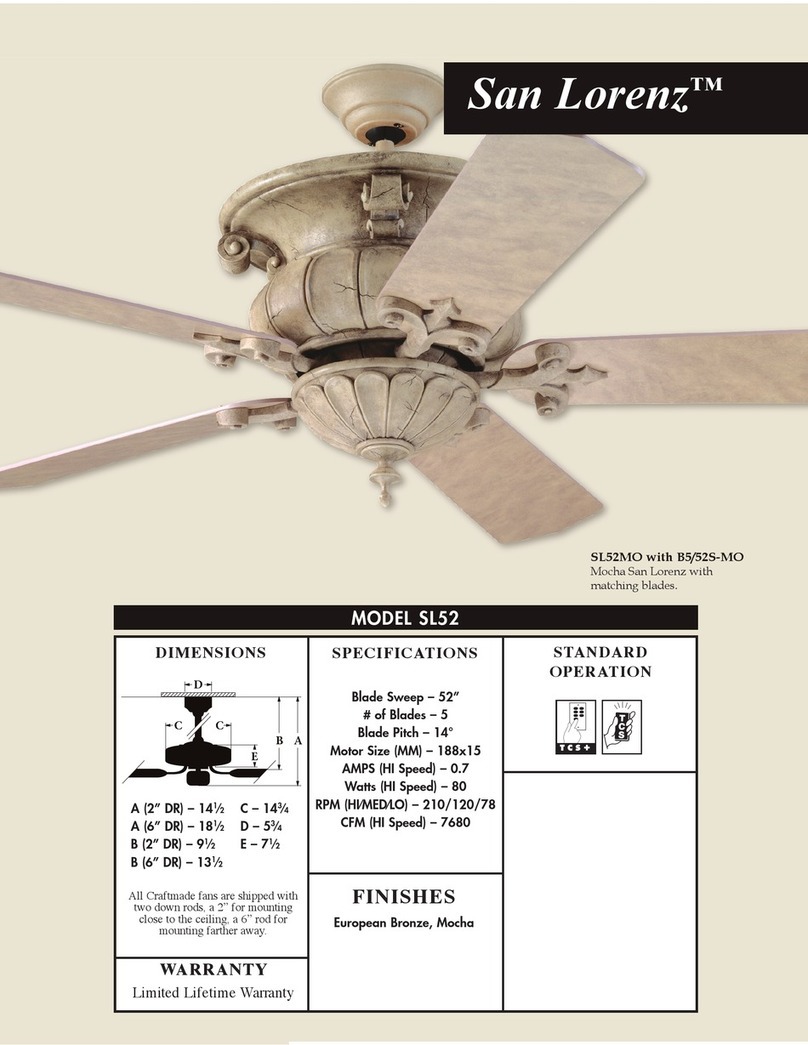

Craftmade San Lorenz SL52 Specifications

Prominence Home

Prominence Home Potomac 51639 owner's manual

Fanimation

Fanimation AIRE DUO LP8066LBN manual

KDK

KDK 17CUH Installation and operating instructions

Hunter

Hunter Piccolo owner's manual

Miele

Miele DA 217-2 Operating and installation instructions

Lifebreath

Lifebreath Pure Performance 120ERV Instalation instructions

SolutionAir

SolutionAir VENTUS 450+ owner's manual