BioHorizons INTRASPIN IS220 User manual

Leukocyte- and Platelet-Rich Fibrin

L02065 Rev A AUG 2020

English

Instructions for use: IntraSpin

Español

Instrucciones de uso: IntraSpin

русский

Инструкция по применению: IntraSpin

DEUTSCH

Gebrauchsanweisung: IntraSpin

FRANÇAIS

Instructions d'utilisation: IntraSpin

ITALIANO

Istruzioni per l'uso: IntraSpin

PORTUGUÊS

Instruções de utilização: IntraSpin

Türk

Kullanım talimatları: IntraSpin

简体中文

使用说明:IntraSpin

日本語

使用説明書:IntraSpin

한국어

사용 설명서: IntraSpin

يبرع

IntraSpin

Polskie

Polskie

Polskie

Instrukcja użycia: IntraSpin

čeština

čeština

čeština

češtinaPolskie

Polskie

Návod k použití: IntraSpin

BioHorizons

2300 Riverchase Center

Birmingham, AL 35244 USA

+1-205-967-7880

IntraSpin®, Xpression® & L-PRF® are registered trademarks of BioHorizons; Vacuette® is a registered trademark of

Greiner Bio-One International AG.; Enzymax® is a registered trademark of Hu-Friedy Mfg. Co., LLC.

1 of 31

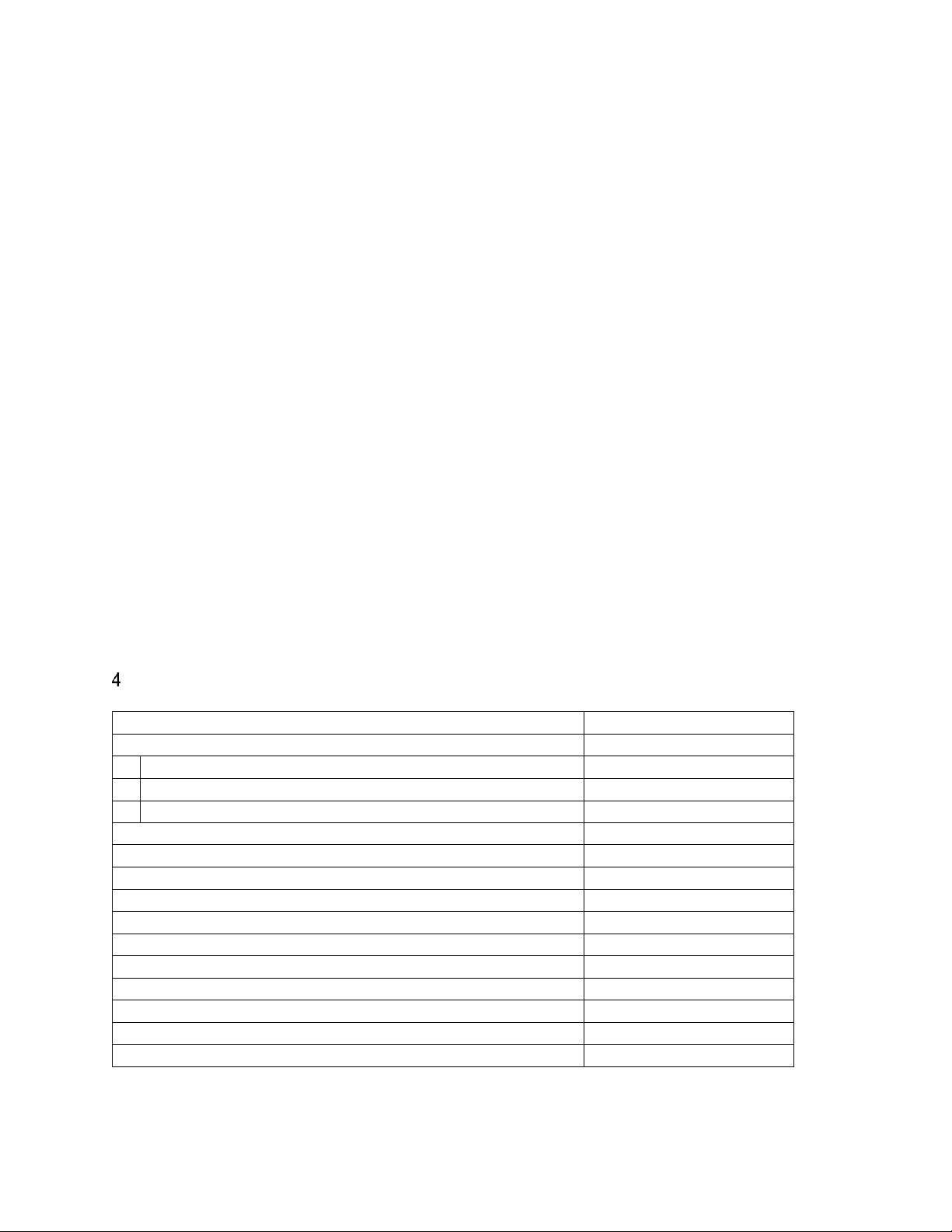

ENGLISH

The symbol table below is for reference only. Refer to product or product packaging label for applicable

symbols.

Symbol

Symbol Description

Caution

Electronic instructions for

use

Manufacturer

BioHorizons products carry

the CE mark and fulfill the

requirements of the

Medical Devices Directive

93/42/EEC

Reference/ article number

Lot/ batch number

Do not re-use

Use-by-date

Sterile by gamma

irradiation

Date of manufacture

Rx Only

Caution: U.S. Federal law

restricts these devices for

sale, distribution and use

by, or on the order of, a

dentist or physician

Symbol

Symbol Description

Home position

Do not use if package is

damaged

Medical Device

Non-sterile

Keep dry

Fragile; handle with care

Temperature limits

This way up

Humidity limits

Warning; Biological hazard

Important note(s)

Separate collection of

electric and electronic

devices.

Authorized representative

in the European

Community

MD

Non-sterile

2 of 31

INDICATIONS FOR USE

The IntraSpin System is intended to be used for the safe and rapid preparation of autologous Leukocyte- and

Platelet-Rich Fibrin (L-PRF) from a small sample of blood at the patient's point of care. The L-PRF is mixed

with autograft and/or allograft bone prior to application to a bony defect for improving handling characteristics.

Observing all information in the Instructions for Use is also a part of the intended use.

CONTRAINDICATIONS

The IntraSpin centrifuge is only meant for the purpose stated in the intended use of the device. Any other

use of the device is considered non-intended. Use of the IntraSpin centrifuge is contraindicated in the

presence of one or more of the following clinical situations: Patients with alcohol addiction or psychiatric

disorders, blood dyscrasias, uncontrolled diabetes, hyperthyroidism, oral infections, malignancies or patients

who have had myocardial infarction within the last 12 months. Patients with systemic diseases that

compromise the immune system, such as AIDS, patients on medications that would compromise healing of

an implant site, patients with a history of poor or noncompliance to oral hygiene procedures.

Patients who are participating in anti-coagulant therapy. These patients are not excluded from the benefits

of PRF, instead the point of care must add additional time to the centrifuge for the separation to be effective

for use.

SAFETY NOTES

▪No claim of warranty will be considered by the manufacturer unless ALL instructions in this manual

have been followed.

▪The operating instructions are a part of the device. They must always be kept readily available. If the

device is set up at a different location, the operating instructions must be provided with it.

▪The centrifuge should be installed on a good, stable base.

▪Before using the centrifuge absolutely check the rotor for firm placement.

▪When the centrifuge is running, no persons, dangerous substances or objects may be within the

safety margin of 300 mm around the centrifuge.

▪Rotors, suspensions and accessories that possess traces of corrosion or mechanical damage or if

their term of use has expired may not be used any longer.

▪The centrifuge may no longer be put into operation when the centrifuging chamber has safety-related

damages.

▪For centrifuges without temperature control, when the room temperature is increased and/or if the

device is frequently used, the centrifuging chamber could be heated up. Therefore, it can't be ruled

out that the sample material might be changed due to the temperature.

▪Before the initial operation of your centrifuge you should read and pay attention to the operating

instructions. Only personnel that has read and understood the operating instructions are allowed to

operate the device.

▪Along with the operating instructions and the legal regulations on accident prevention, you should

also follow the recognized professional regulations for working in a safe and professional manner.

These operating instructions should be read in conjunction with any other instructions concerning

accident prevention and environmental protection based on the national regulations of the country

where the device is to be used.

3 of 31

▪Meeting the country-specific requirements concerning occupational safety with regard to the use of

laboratory centrifuges at the workplaces provided for this purpose by the user is the responsibility of

the user.

▪This centrifuge is a state-of-the-art piece of equipment which is extremely safe to operate. However,

it can lead to danger for users or others if used by untrained staff, in an inappropriate way or for a

purpose other than that it was designed for.

▪The centrifuge must not be moved or knocked during operation.

▪In case of fault or emergency release, never touch the rotor before it has stopped turning.

▪To avoid damage due to condensate, when changing from a cold to a warm room the centrifuge

must either heat up for at least 3 hours in the warm room before being connected to the mains or run

hot for 30 minutes in the cold room.

▪When centrifuging with maximum revolutions per minute the density of the materials or the material

mixtures may not exceed 1.2 kg/dm3.

▪The centrifuge may only be operated when the balance is within the bounds of acceptability.

▪The centrifuge may not be operated in explosion-endangered areas.

▪The centrifuge must not be used with inflammable or explosive materials or materials that react with

one another producing a lot of energy.

▪No biosafety systems are available for this centrifuge.

▪The centrifuge must not be operated with highly corrosive substances which could impair the

mechanical integrity of rotors, hangers and accessories.

▪Repairs must only be carried out by personnel authorized to do so by the manufacturer.

▪In order to offer patients the highest level of clinical safety, IntraSpin products are made with

materials that are biocompatible with human plasma.

▪This product is not authorized for sale in every market and it may not be available in your market.

Please consult with your local representative for additional information.

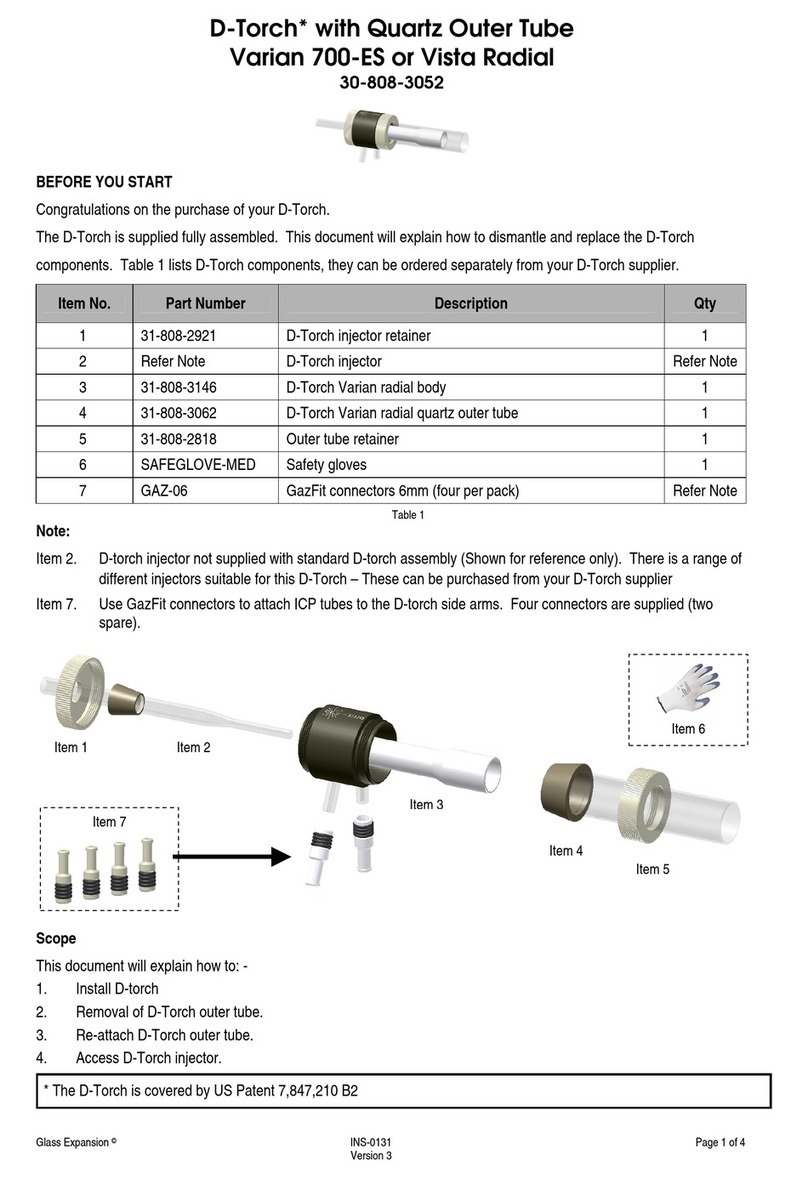

INTRASPIN SYSTEM COMPONENTS

COMPONENT

QUANTITY PER SYSTEM

IntraSpin Centrifuge including:

1

Power Cable

1

Fuse

2

Hex Hand Wrench

1

IntraSpin Blood Collection Tubes –9 ml plastic tubes (single use)

150

Greiner Safety Blood Collection Set + Holder, 21G (single use)

24

Latex Free Tourniquet

1

Test Tube Rack

1

Surgical Curved Scissors

1

Surgical Tissue Forceps

1

Round Stainless-Steel Bowl

1

Rectangular Stainless-Steel Bowl

1

Dual Biomaterial Carrier Spatula

1

Dual Biomaterial Packer

1

Xpression® Box

1

4 of 31

Only verified compatible components for direct use with the IntraSpin centrifuge are recommended and

warranted:

COMPATIBLE PART #

DESCRIPTION

WCT_50 (455006)

IntraSpin White Blood Collection Tubes

BVBCTP2_50 (455385)

IntraSpin Blood Collection Tubes

455092

Tube 9ml Serum Clot activator, red cap (50 pcs)

455001

White Cap 9ml No additive blood collection tube (50 pcs)

BHEXZ (E613)

IntraSpin Hex Key, 110v & 220v

BROTORZ (E3694)

IntraSpin Rotor, 100v & 220v

BPOWER110Z (E1673)

IntraSpin Power Cord, 110v

BPOWER220Z (E1669)

IntraSpin Power Cord, 220v

BTUBEHOLDZ (E872 x 1)

IntraSpin Tube Holder Replacement

BFUSE110Z (E997)

IntraSpin Fuse IS110

BFUSE220Z (E891)

IntraSpin Fuse IS220

BRIEF CENTRIFUGE SETUP

Remove and save transport bolts from bottom of centrifuge.

Attach AC cable and plug into electrical outlet.

Power centrifuge on by using the rocker switch on the back of the device.

Select speed and time: Speed = 2700 & Time = 12:00 min.

Press START.

The centrifuge cover will open automatically at the end of each cycle.

After the first procedure, the timing and speed are recorded in the centrifuge memory unless the settings are

changed.

BLOOD COLLECTION TUBES CAUTIONS AND INSTRUCTIONS

▪Handle all biological samples and blood collection “sharps” (e.g. needles, and blood collection sets)

according to the policies and procedures of your facility.

▪Obtain appropriate medical attention in the case of any exposure to biological samples (e.g. via

puncture injury) due to the possible transmission of HIV (AIDS), viral hepatitis or other infectious

diseases.

▪Discard all blood collection “sharps” in approved biohazard containers.

▪Transferring a sample from a syringe to a tube is not a recommended procedure.

▪If blood is collected through an intravenous (IV) line, follow the policies and procedures of your

institution to ensure that the line has been cleared of IV solution before beginning to fill the blood

collection tubes.

▪Blood clotting accelerant may appear white on the tube surface, which has no effect on the

performance of the tubes. If any other discoloration or precipitates are present in the tube, it should

not be used.

▪Do not use the tubes after the expiration date.

▪Store tubes at 4–25°C (40–77°F).

▪Avoid exposure to direct sunlight. Exceeding the maximum recommended storage temperature may

lead to impairment of the tube quality (i.e. vacuum loss, coloring, etc.).

5 of 31

▪To prevent backflow, place the patient’s arm in a downward position, hold the tube with the cap up,

release the tourniquet as soon as blood starts to flow into the tube, avoid tube contents coming in

contact with cap or end of the needle during venipuncture.

▪Be sure that the following materials are readily accessible before performing venipuncture: all

necessary blood collection tubes, identified labels for positive patient identification of samples,

blood collection needles and holders, alcohol swab for cleansing the puncture site, clean gauze,

tourniquet, adhesive plaster or bandage, approved biohazard container. For protection against

exposure to bloodborne pathogens, appropriate PPE (Personal Protective Equipment) is

recommended (e.g. gloves, laboratory coat, goggles, etc.).

Venipuncture Technique and Blood Sample Collection:

The blood collection must be made as quickly as possible, since there is no anticoagulant in the collection

tubes. The blood sample will begin to coagulate immediately. Wear gloves during venipuncture and when

handling blood collection tubes to minimize exposure hazard. Prior to the blood draw, wipe the top of the

blood tube cap(s) with a disinfectant wipes of your choice. Remove the cover over the valve section of the

needle. Prepare venipuncture site with an appropriate antiseptic. Do not palpate venipuncture area after

cleansing. Place the patient’s arm in a downward position. Remove the needle shield. Perform the

venipuncture with the arm downward and tube cap upper-most. Push the blood collection tube into the holder

and onto the needle valve puncturing the rubber diaphragm of the blood collection tube. Center the blood

collection tubes in the holder when penetrating the cap to prevent sidewall penetration and subsequent

premature vacuum loss. Remove the tourniquet as soon as blood appears in the blood collection tube. During

procedure, always hold the collection tube in place by pressing it with a thumb. This will ensure a complete

vacuum draw. The blood collection tube will fill automatically. If no blood flows into collection tube or if blood

flow ceases before an adequate specimen is collected, the following steps are suggested to complete a

satisfactory collection:

▪Push the blood collection tube forward to ensure the cap has been penetrated.

▪Confirm the correct position of the needle in the vein.

▪If blood still does not flow, remove and appropriately discard the collection tube. Obtain a new

collection tube and push into holder.

▪If the second collection tube does not draw, remove and appropriately discard the needle and the

collection tube. Repeat the procedure.

▪When the maximum volume fill line of the blood collection tube bas been reached, gently remove it

from the holder. Repeat with a second blood collection tube.

▪Gently invert each collection tube immediately upon removing from the holder. Do not shake the

tubes filled with blood sample. Vigorous mixing may cause foaming or hemolysis. Insufficient mixing

or delayed mixing in serum tubes may result in delayed clotting.

Upon completion of blood sample collection, remove the needle from the vein. Activate the safety mechanism

of the needle. Apply pressure to the puncture site with a dry sterile swab until the bleeding stops. If desired,

apply a bandage once clotting has occurred. It is recommended that filled collection tubes, be kept in an

upright position. Once the second blood collection tube is full, remove it and place the first and second tubes

into the centrifuge on opposite locations to counterbalance the rotor. Close the cover of the IntraSpin

centrifuge and press the START button to allow it to spin for 12 minutes.

6 of 31

If more than two tubes of blood are required, please follow this alternative procedure: After the first two tubes

of blood are collected, immediately place them into the IntraSpin centrifuge, opposite from each other to

ensure the centrifuge is properly balanced. Close the cover and press the START button and allow the

centrifuge to run while you collect the remaining tubes of blood. Press the STOP button and allow the

centrifuge to come to a full stop. The cover will pop open; immediately place the remaining tubes in the

centrifuge opposite from each other to ensure proper balance and press the START button to reset and

complete recommended protocol.

Always place the tubes in pairs and place them in opposite positions to balance the centrifuge rotor. The

tubes must always be balanced in the rotor before pressing the START button or this may cause serious

damage to the centrifuge, improper coagulation, and/or separation. If the tubes are not properly balanced,

there will be too much vibration during centrifugation and a poor L-PRF fibrin clot will result.

If you have an odd number of blood samples to centrifuge, then place a tube of the same size as the blood

samples, filled with water to the indicated full line, opposite to the un-paired tube in the rotor. This will allow

for proper balancing of the centrifuge.

Begin centrifugation immediately after collecting the blood samples. Delays affect the blood separation

procedure and result in a poor L-PRF fibrin clot.

L-PRF PREPARATION

After centrifugation, three segments are visible:

1. Upper Segment = platelet poor plasma (PPP).

2. Middle Segment = fibrin clot: L-PRF.

3. Lower Segment= red blood cell clot.

L-PRF fibrin membranes or plugs must be prepared relatively quickly: 0-15 minutes after centrifugation or the

clot will shrink in volume by releasing the trapped serum. After centrifugation, remove the rubber stopper

from each tube. Using the Surgical Tissue Forceps remove the L-PRF clot from the tube. Gently scrape the

red blood cell clot from the L-PRF® fibrin clot just below the union, using the Dual Biomaterial Carrier Spatula,

so that only a minimal, residual amount of red blood cells are attached to L-PRF clot. Place the fibrin clot

onto the Xpression Perforated Tray.

FIBRIN MATRIX PREPARATION

Protocol #1 L-PRF Membrane

Place each of the fibrin clots on the Xpression Perforated Tray. Once all of the fibrin clots are placed,

place the Xpression Compression Plate and Xpression Weighted Cover over the fibrin clots without

exerting any pressure over the clots.

Allow the weight of the cover to slowly press down the fibrin clot while the exudate is filtered to the bottom

of the tray. Do not apply pressure to the weighted cover. Gravitational force on the weighted cover will

gently compress the clot and express the serum from the L-PRF clot without damaging the fibrin network.

7 of 31

Wait at least 5 minutes before removing and using any fibrin membranes. Do not remove any fibrin

membranes until actual time of use. The fibrin membrane may remain in the Xpression Box for a period

of up to 3 hours.

Protocol #2 L-PRF Plug

Place a fibrin clot inside the white plug fabrication cylinder. Use the piston to slowly press the clot inside

the white L-PRF plug fabrication cylinder. Continue to press until the top edge of the piston is flush with

the top edge of the white L-PRF plug fabrication cylinder. With this technique, one will be able to form a

thick, round fibrin plug for the extraction socket. For a single tooth, one L-PRF plug may be sufficient.

Pre-molars may need two L-PRF plugs, and three L-PRF plugs may be needed for molars, depending

on the size of the extraction socket and the size of the fibrin clot created.

The working properties of L-PRF provide an excellent medium for use in combination with

your biomaterial of preference. Utilizing any of the following mixing protocols, the biomaterial

is captured in the fibrin matrix increasing its handling and biologic capacity.

Protocol #3- Biomaterial/L-PRF Mixture

To create a ‘putty like’ mixture that can be gently formed with the biomaterial instrument into the desired

shape and thickness use the following protocol: Gently cut the L-PRF fibrin membrane into small pieces

in a sterile dish with the Surgical Curved Scissors. Add the desired amount of bone graft material.

Thoroughly mix the L-PRF and bone graft material. This mixture can be placed into defects using the

Dual Biomaterial Carrier Spatula.

8 of 31

Protocol #4- Biomaterial/L-PRF Matrix Mixture

Place the predetermined amount of bone graft material into a sterile bowl or tray. Dip the expressed L-

PRF membrane(s) or pieces of the L-PRF membrane into the graft material covering the entire surface

area of the L-PRF membrane with graft material. Alternatively, the graft material may be sprinkled onto

the L-PRF membrane covering the entire surface area with graft material. Note: A wetter L-PRF

membrane may retain slightly more graft material than a dryer L-PRF membrane. The graft material

should cling to the surface of the L-PRF, however, if desired, gently press the graft material onto the L-

PRF membrane. The Surgical Tissue Forceps can be used to place this mixture into the defect.

Protocol #5- Biomaterial Hydration

Add the desired amount of bone graft material into a sterile bowl or tray. Utilize the exudate from the

bottom of the Xpression Collection Tray to hydrate the graft material. Thoroughly mix the exudate and

bone graft material. This mixture can be placed into defects using the Dual Biomaterial Carrier Spatula.

TISSUE REGENERATION KIT CLEANING AND STERILIZATION

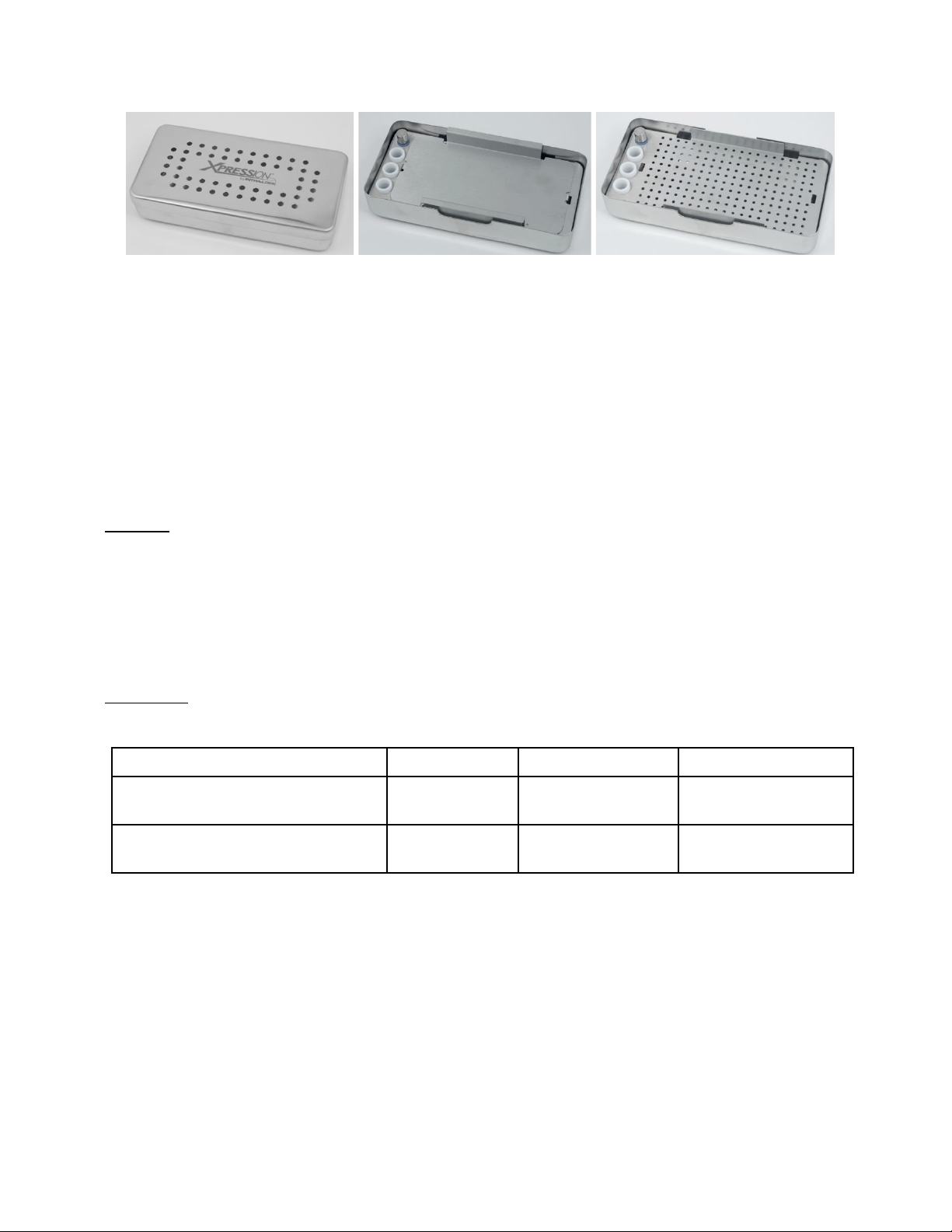

The Xpression Box enables the fabrication of fibrin membranes of constant thickness with ease. The exudate

can be collected from the Xpression Collection Tray, underneath the Xpression Perforated Tray. The

Xpression Box includes L-PRF plug fabrication cylinders and a piston to fabricate L-PRF plugs that easily fit

post-extraction sockets.

9 of 31

Xpression Weighted Cover

Xpression Compression Plate

Xpression Perforated Tray in

Xpression Collection Tray

The Xpression Box and ancillary instruments are NOT supplied sterile. Remove and discard any shipping

material before initial sterilization. Clean and sterilize the Xpression Box and ancillary instruments before

each use.

Disassemble the Xpression Box before each cleaning and sterilization cycle to avoid debris encapsulation,

material discoloration, and/or inadequate drying of components. The L-PRF plug fabrication cylinders and

piston grommet are not intended to be removed from the Xpression Perforated Tray for cleaning and

sterilization.

Cleaning: (1) Remove any visible debris from the Xpression Box components and ancillary instruments using

a soft bristle brush and a broad-spectrum cleaning or disinfecting agent such as Hu-Friedy’s Enzymax® or

equivalent. Rinse thoroughly. (2) Place the Xpression Box components and ancillary instruments in an

appropriately sized container of the same solution and sonicate for 10 minutes. Rinse thoroughly. (3) Rinse

the Xpression Box components and ancillary instruments with isopropyl alcohol to remove any soap residue

and minerals. (4) Blot the Xpression Box components and ancillary instruments with a lint-free towel and air

dry completely. Refer to the labeling of the cleaning agent used for instructions for use.

Sterilization: (1) Place the reassembled Xpression Box and ancillary instruments in an FDA cleared

sterilization bag or wrap. (2) Run through one of the following qualified sterilization cycles:

Sterilization Method

Temperature

Exposure Time

Minimum Drying Time

Pre-vacuum Steam (ANSI/AAMI ST79)

132°C (270°F)

4min

20-30 minutes

Pre-vacuum Steam (UK DoH Health

Technical Memorandum 01-01)

134°C (273°F)

3min

20-30 minutes

Attention! Improper cleaning may lead to inadequate sterilization. Failure to completely dry the Xpression Box

components and ancillary instruments during autoclaving may leave moisture and cause discoloration and

oxidation. The use of hydrogen peroxide or other oxidizing agents will damage the surface of the Xpression

Box components and ancillary instruments. Periodic testing, cleaning, and calibration of the autoclave

equipment is recommended to ensure the unit remains in proper working order.

10 of 31

CENTRIFUGE CLEANING AND MAINTENANCE

The device can be contaminated. Pull the mains plug before cleaning. Centrifuges, rotors and accessories

must not be cleaned in rinsing machines. They may only be cleaned by hand and disinfected with liquids. The

water temperature must be between 20 –25°C. Only detergents/disinfectants with a pH between 5 - 8 and

that do not contain caustic alkalis, peroxides, chlorine compounds, acids and alkaline solutions may be used.

In order to prevent appearances of corrosion through cleaning agents or disinfectants, the application guide

from the manufacturer of the cleaning agent or disinfectant must be considered.

Clean the centrifuge housing and the centrifuging chamber regularly, using soap or a mild detergent and a

damp cloth if required to prevent corrosion through adhering impurities. Ingredients of suitable detergents

include soap, anionic surfactants and non-ionic surfactants. After using detergents, remove detergent residue

by wiping with a damp cloth. The surfaces must be dried immediately after cleaning. In the event of water

condensation, dry the centrifugal chamber by wiping out with an absorbent cloth. Lightly rub the rubber seal

of the centrifuge chamber with talcum powder or a rubber care product after each cleaning. The centrifuging

chamber is to be checked for damage. If damage is found to be relevant to safety, the centrifuge may no

longer be put into operation. In this case, notify Customer Service.

For surface disinfection, if infectious materials penetrate into the centrifugal chamber, it must be disinfected

immediately. Ingredients of suitable disinfectants include ethanol, n-propanol, ethyl hexanol, anionic

surfactants and corrosion inhibitors. After using disinfectants, remove disinfectant residue by wiping with a

damp cloth. The surfaces must be dried immediately after disinfecting.

For removal of radioactive contaminants, the agent must be specifically labelled as being an agent for

removing radioactive contaminants. Ingredients of suitable agents for removing radioactive contaminants

include anionic surfactants, non-ionic surfactants, polyhydrated ethanol. After removing the radioactive

contaminants, remove the agent residue by wiping with a damp cloth. The surfaces must be dried directly after

removing the radioactive contaminants.

ROTOR AND ACCESSORIES CLEANING AND MAINTENANCE

To avoid corrosion and changes to the materials, the rotor and accessories have to be cleaned regularly with

soap or a mild cleaning agent and a moist cloth. Cleaning is recommended at least once a week.

Contaminants must be removed immediately.

Ingredients of suitable detergents include soap, anionic surfactants and non-ionic surfactants. After using

detergents, remove detergent residue by rinsing with water (only outside of the centrifuge) or wipe off with a

damp cloth. The rotor and accessories have to be dried immediately after cleaning. Check the rotor and

accessories weekly for wear and corrosion damage. The rotor and accessories must no longer be used if

they show signs of wear or corrosion. Check the firm seating of the rotor on a weekly basis. If infectious

material should get on the rotor or accessories, they must be appropriately disinfected.

Ingredients of suitable disinfectants include ethanol, n-propanol, ethyl hexanol, anionic surfactants and

corrosion inhibitors. After using disinfectants, remove disinfectant residue by rinsing with water (only outside

of the centrifuge) or wipe off with a damp cloth. The rotor and accessories must be dried directly after

disinfection.

11 of 31

For removal of radioactive contaminants, the agent must be specifically labelled as being an agent for the

removal of radioactive contaminants. Ingredients of suitable agents for removing radioactive contaminants

include anionic surfactants, non-ionic surfactants and polyhydrated ethanol. After removing the radioactive

contaminants, remove agent residue by rinsing with water (only outside of the centrifuge) or wipe off with a

damp cloth. The rotor and accessories must be dried directly after removing the radioactive contaminants.

The rotor may be autoclaved at 121oC/250oF for 20 minutes and dried appropriately. After 10 autoclaving

cycles, the rotor must be exchanged for safety reasons. Autoclaving accelerates the ageing process of

plastics and may cause discoloration. After autoclaving, wait until the rotor has cooled down to the ambient

temperature before using it again. No statement can be made about the degree of sterility.

The period of use of the rotor is limited to 50,000 running cycles (centrifugation runs) or 5 years, whichever

comes first. The maximum permissible number of run cycles can be seen on the rotor. For safety reasons,

the rotor may no longer be used when the maximum allowed number of running cycles (marked on it) has

been reached. The device is equipped with a cycle counter which counts the running cycles (centrifugation

runs).

In case of blood tube fracture, all broken parts and blood are to be completely removed. The centrifuge is to

be thoroughly cleaned as indicated and rubber inserts as well as plastic sleeves of the rotor are to be

replaced.

12 of 31

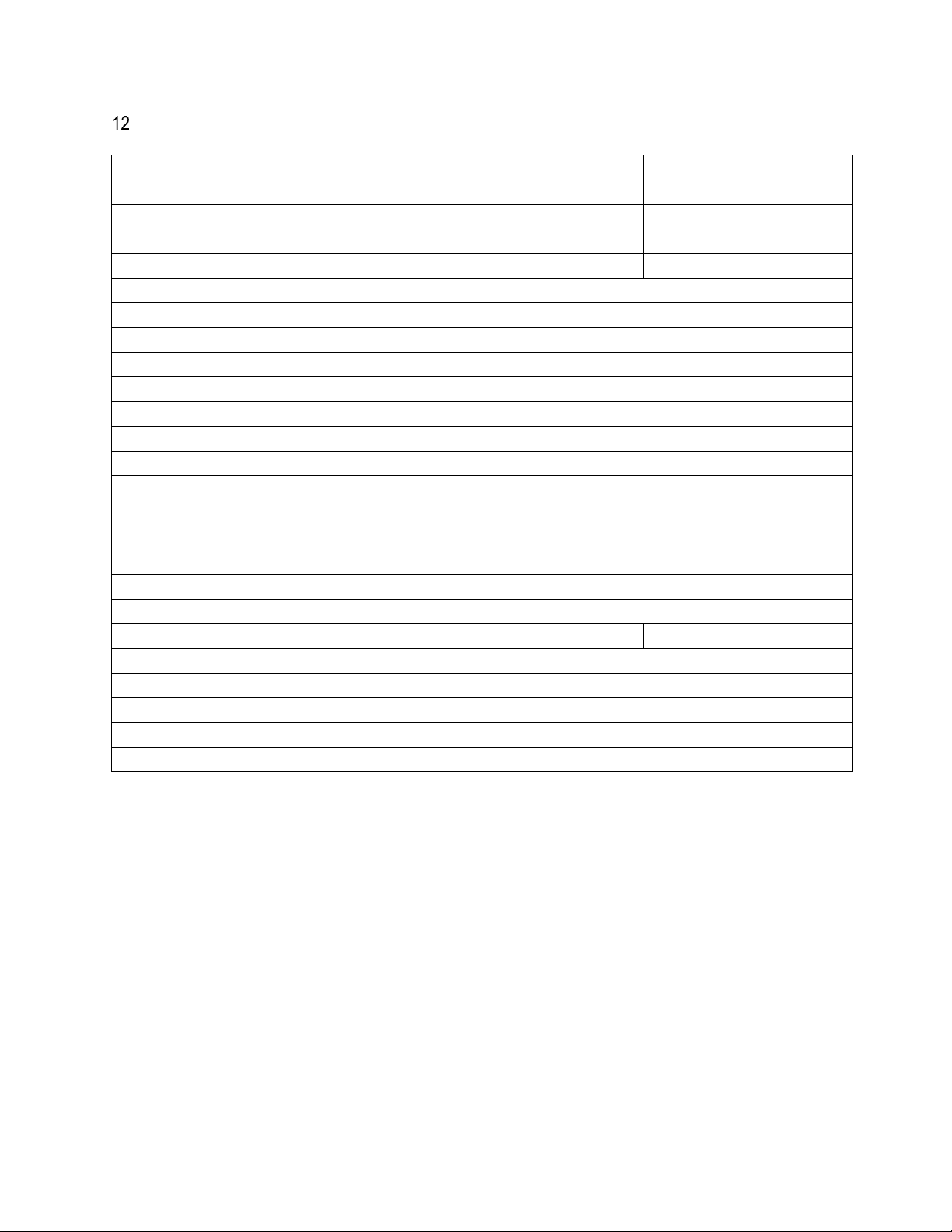

CENTRIFUGE TECHNICAL SPECIFICATIONS

Model Type

IS220

IS110

Mains voltage (10%)

200 - 240 V 1

100 - 127 V 1

Mains frequency

50 - 60 Hz-

50 - 60 Hz

Connected load

100 VA

100 VA

Current consumption

0.5 A

1.0 A

Capacity

8 x 10 ml

Maximum allowed density

1.2 kg/dm3

Maximum Speed (RPM)

6,000

Force (RCF)

3,461

Kinetic energy

750 Nm

Set-up site

Indoors only

Altitude

Up to 2000 m above sea level

Ambient temperature for operation

5°C to 40°C

Relative Humidity for operation

Maximum relative humidity 80% for temperatures up to 31°C,

linearly decreasing to 50% relative humidity at 40°C.

Excess-voltage category

Pollution degree

2

Device protection class

Not suitable for use in explosion-endangered areas.

Emitted interference, Interference immunity

EN / IEC 61326-1, Class B

FCC Class B

Noise level (dependent on rotor)

50 dB(A)

Centrifuge width

261 mm

Centrifuge Depth

353 mm

Centrifuge Height

228 mm

Centrifuge Weight

approx. 9 kg

13 of 31

CENTRIFUGE OPERATING INSTRUCTIONS

It is imperative that the transport securing device, consisting of 2 screws and 2 spacers, be removed. Keep

the transport securing device in a safe place since it must be installed again before transporting the device.

The device may only be transported with the transport securing device installed. To protect the device from

damage during transport, the motor is fixed in place. This transport securing device must be removed when

the device is put into operation.

13.1 INITIAL OPERATION

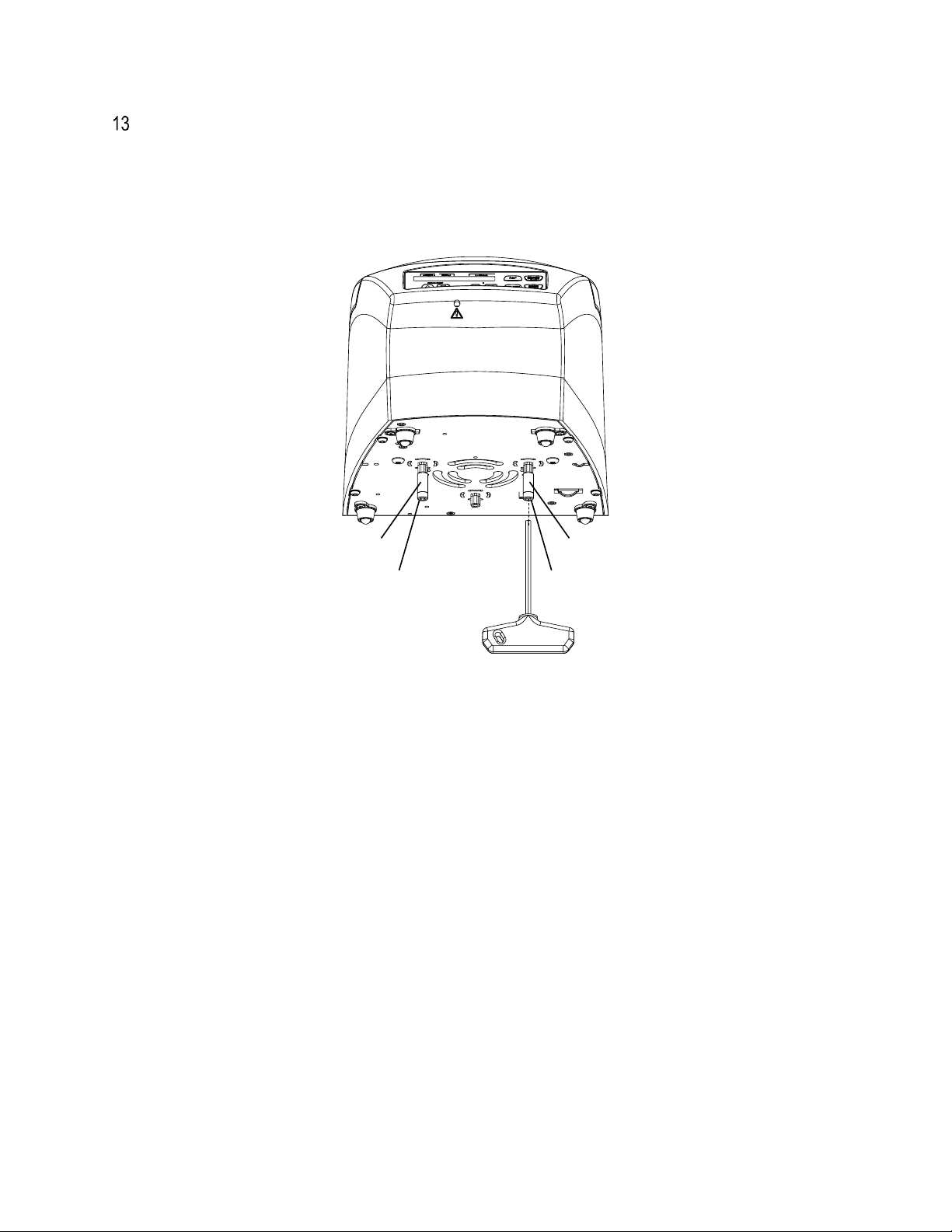

▪Remove the transport securing device from the centrifuge bottom side.

▪Position the centrifuge in a stable and level manner in a suitable place. When the centrifuge is

running, no persons, dangerous substances or objects may be within the safety margin of 300 mm

around the centrifuge.

▪Ventilation openings must not be blocked. A distance of 300 mm must be maintained from the

ventilation slots and openings of the centrifuge.

▪Check whether the mains voltage tallies with the statement on the type plate.

▪Connect the centrifuge with the power cord to a standard mains socket.

▪Switch on the mains switch.

▪The following displays appear on the panel: the centrifuge model type, the software version, and the

last used centrifugation data.

▪If the lid is closed, the message "Open the lid" is displayed. In this case, open the lid to display the

centrifugation data.

13.2 OPENING AND CLOSING THE CENTRIFUGE LID

The lid can only be opened if the centrifuge is switched on and the rotor is stationary. When the cycle counter

is activated, after a centrifugation run, while opening the lid, the remaining number of running cycles

(centrifugation runs) is briefly displayed.

(a)

(b) (b)

(a)

14 of 31

Example:

To open the lid, Press the following key . The lid is unlocked by the motor. indicates lid

unlocked.

Example:

Do not reach with your fingers between the lid and housing. Do not slam the lid closed.

To close the lid, lightly press down the front edge of the lid. indicates lid locked.

Example:

13.3 EMERGENCY UNLOCKING

In the event of a power failure, the lid cannot be unlocked with the motor. Emergency unlocking must be done

by hand. To unlock in an emergency, switch off the mains switch (switch setting "0"). Look through the window

in the lid to make sure that the rotor is at a standstill. Open the lid only when the rotor is at a standstill. Insert

the Allen key horizontally in the bore (A) and turn carefully counterclockwise (to the left) until the lid opens.

CAUTION! Turning the hexagon Allen key in clockwise direction (to the right) may damage the locking

system. Pull the Allen key back out of the bore.

t/min:sRPM>RCF<

STOP

OPEN

t/min:sRPM>RCF<

t/min:sRPM>RCF<

A

15 of 31

13.4 INSTALLATION AND REMOVAL OF THE ROTOR

To remove the rotor, loosen the rotor's clamping nut by turning counter-clockwise with the Allen wrench

(included in delivery) and turn up to the lifting pressure point. After overcoming the lifting pressure point, the

rotor is released from the cone of the motor shaft. Turn the clamping nut until the rotor can be lifted up from

the motor shaft. Lift up the rotor from the motor shaft.

To install the rotor, clean the motor shaft (A) and the bore of the rotor and apply a thin coat of grease to the

motor shaft. Dirt particles between the motor shaft and rotor prevent the rotor from having a perfect seat and

cause it to run unsteadily. Place the rotor vertically onto the motor shaft. When putting on the rotor, the

marking beam (B) on the rotor must be parallel to both surfaces (C) on the motor shaft. Tighten the clamping

nut of the rotor with the Allen wrench (included in delivery) by turning clockwise. Check the rotor to make

sure it is seated firmly.

The rotors must be loaded symmetrically. The blood tubes have to be distributed evenly on all rotor positions.

Rotor evenly loaded

Rotor not evenly loaded

Not permitted!

The blood tubes may only be filled outside of the centrifuge. The maximum filling quantity for the blood tubes

is specified on the tubes themselves and must not exceed the maximum weight listed on the rotor. The

centrifuging vessels may only be filled so far that no fluid can be expelled from them while the centrifuge is

running. When loading the rotor, no liquid may enter the rotor or the centrifuging chamber. In order to maintain

the weight differences within the centrifuge container as marginal as possible, a consistent fill level in the

blood tubes is recommended.

A

B

C

16 of 31

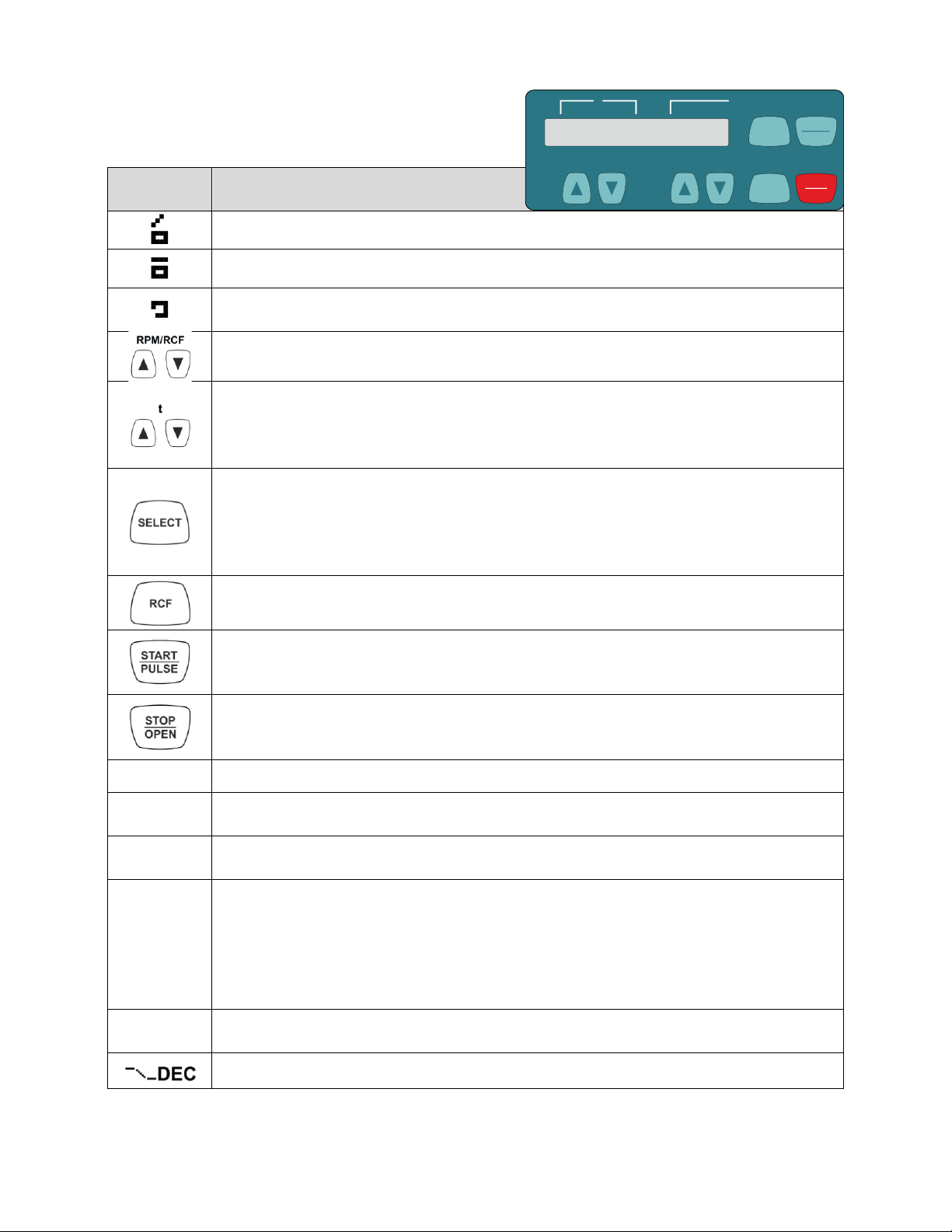

13.5 DISPLAY ELEMENTS DESCRIPTION

Symbol /

Panel Key

Description

Lid unlocked.

Lid locked.

Rotation display. The rotation display lights up, rotating in a clockwise direction, when the

rotor is turning.

To input speed directly. If the key is kept pressed, the value changes with increasing

speed.

To input the runtime directly. Adjustable in steps of 1 second up to a minute, and in steps

of 1 minute starting from 1 minute.

To input the centrifugation parameters. If the key is kept pressed, the value changes with

increasing speed.

To activate individual parameters. Every time the key is pressed, the next parameter is

activated.

Keep the key pressed for 8 seconds to call up the "MACHINE MENU".

In the "Machine Menu", select the menus "->Info", "->Settings" and "Time & Cycles".

To scroll forward in the menus.

To switch between the speed display (RPM) and relative centrifugal force display (RCF).

RCF values are displayed between arrows ><.

To start the centrifugation run.

For short-term centrifugation. Centrifugation is run as long as the key is kept pressed.

To select the menus "->Info", "->Settings" and "->Time & Cycles".

To finish the centrifugation run. The rotor runs down with a pre-selected brake stage.

Pressing the key twice triggers the Emergency Stop.

To unlock the lid.

t/min

Runtime. Adjustable from 1 - 99 minutes, in steps of 1 minute.

t/sec

Runtime. Adjustable from 1 - 59 seconds, in steps of 1 second.

Continuous run "--:--". Set the parameters t/min and t/sec to zero.

RPM

Speed. A number value from 200 RPM to the maximum speed of the rotor can be set.

Adjustable in steps of 10.

>RCF<

Relative centrifugal force. A number value can be set which results in a speed between

200 RPM and the maximum rotor speed. Adjustable in steps of 1.

It is only possible to input the relative centrifugal force (RCF) if the RCF display (>RCF<) is

activated. The relative centrifugal force (RCF) depends on the centrifuging radius (RAD).

After entering the RCF, check to make sure that the correct centrifuging radius has been

set.

RAD/mm

Centrifuging radius. Adjustable from 10 mm to 250 mm, in steps of 1 mm. It is only

possible to input the centrifuging radius if the RCF display >RCF< is activated.

Brake stage. fast = short run-out time, slow = long run-out time.

SELECT

t/min:s

RPM

>RCF<

RPM/RCF t

RCF

STOP

OPEN

START

PULSE

17 of 31

13.6 DIRECT INPUT OF THE CENTRIFUGATION PARAMETERS

The speed (RPM), the relative centrifugal force (RCF), the centrifuging radius (RAD) and the runtime can be

inputted directly with the keys without previously having to press the key. The set

centrifugation parameters are only stored after starting the centrifugation run.

For Speed (RPM):

Example:

Press the key to activate the RPM display (RPM) as needed.

RPM/RCF

Set the desired value with the keys.

For Relative Centrifugal Force (RCF) and Centrifugal Radius (RAD):

Example:

Press the key to activate the RCF display ( RCF ) as needed.

↓

RPM/RCF

Set the desired RCF value with the keys.

↓

t

Set the desired centrifuging radius with the keys as needed.

Runtime:

Up to 1 minute, the runtime can be set in steps of 1 second, and starting from 1 minute, it can only be set in

steps of 1 minute. In order to set the continuous run, the parameters t/min and t/sec must be set to zero. In

the time display (t/min:s), "--:--" appears.

Example:

SELECT

RCF

t/min:sRPM>RCF<

t/min:sRPM>RCF<

RCF

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

Example:

t

Set the desired value with the keys.

t/min:sRPM>RCF<

18 of 31

13.7 INPUT OF THE CENTRIFUGATION PARAMETERS WITH THE "SELECT" KEY

The runtime can be set in minutes and seconds (parameters t/min and t/sec). In order to set the continuous

run, the parameters t/min and t/sec must be set to zero. In the time display (t/min:s), "--:--" appears.

Example:

The relative centrifugal force (RCF) depends on the centrifuging radius (RAD). During the input of the RCF,

the set centrifuging radius is displayed. If no key is pressed for 8 seconds after selection or during parameter

input, the previous values are shown on the display. The parameters must then be entered again. By pressing

the button, the settings will be saved. If several parameters are entered, the key must be pressed

after setting the last parameter. Entering parameters can be cancelled at any time by pressing the key.

In this case, the settings are not stored.

t/min:sRPM>RCF<

START

PULSE

START

PULSE

STOP

OPEN

Example: (RPM) display

Example: (>RCF<) display

Press the key to activate the RPM

display (RPM) or the RCF display

(>RCF<) as needed.

↓

Press the key.

t/min: Runtime, minutes.

↓

t

Set the desired value with the keys.

↓

Press the key.

t/sec: Runtime, seconds.

↓

t

Set the desired value with the keys.

↓

Press the key.

RPM: Speed.

RAD/mm: Centrifuging radius.

It is only possible to display and input

the centrifuging radius if the RCF

display (>RCF<) is activated.

t

Set the desired value with the keys.

RCF

t/min:sRPM>RCF<

t/min:sRPM>RCF<

SELECT

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

SELECT

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

SELECT

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

t/min:sRPM>RCF<

This manual suits for next models

1

Table of contents

Languages:

Popular Laboratory Equipment manuals by other brands

Fresenius Vial

Fresenius Vial OPTIMA PT Operator's guide

Micromeritics

Micromeritics MicroStar 022 installation guide

Genetix

Genetix ClonePix FL Quick setup instructions

Glass Expansion

Glass Expansion D-Torch manual

NI

NI USB-6509 USER GUIDE AND SPECIFICATIONS

IRIS

IRIS Sentinel S-118 Installation instructions & user guide