Biometra Whatman WT16 User manual

Mini Rocking Platform WT16

230 V Order-No. 042-500

115 V Order-No. 042-590

Mini-Tumbling Table WT17

230 V Order-No. 042-600

115 V Order-No. 042-690

Manual

August 2004

!! Warning !!

Please read these instructions carefully

before using this apparatus!

Biometra GmbH

Rudolf-Wissell-Str. 30

D-37079 Göttingen Service Department

Postfach 1544 Rudolf-Wissell-Str. 14-16

D-37005 Göttingen D-37079 Göttingen

Tel: ++49 – (0)5 51 / 50 68 6-0 Tel.: ++49 – (0)5 51 / 50 68 6-10 or -12

Fax: ++49 – (0)5 51 / 50 68 6-66 Fax.: ++49 – (0)5 51 / 50 68 6-11

internet: http://www.biometra.de

1

1.0 Intended Uses And Specifications

Unpack the Mini Rocking Platform WT16 or Mini Tumbling Table WT17 carefully.

Examine for signs of damage and check the contents against the packing list.

Notify BIOMETRA or your local BIOMETRA distributor immediately if you discover any

damage or item discrepancies.

Save all packing material if damage is found.

Do not attempt to operate this device if physical damage is present.

Read the complete instruction manual thoroughly and make sure that every user of the

mixer/shaker has also read the instructions thoroughly before putting the equipment into

operation.

Keep the instruction manual where it can be consulted by all users.

If, after reading the instruction manual, you still have any questions concerning the

installation, operation or maintenance of the mixer/shaker, please contact BIOMETRA or

your local BIOMETRA distributor.

2.0 Packing List

The following individual and accessory part are supplied. Compare the contents of the

shipment gbefore discarding the packing materials. We recommend keeping the original

packing for future transport or storage purposes.

Item Quantity

Mini Rocking Platform WT16 1

or

Mini Tumbling Table WT17 1

Instruction manual 1

Power cable 1

3.0 Specifications

2

Standing area 320 x 350 mm

Unit weight approx. 8 kg

Area of shaking platform 260 x 290 with non-slip, removable rubber pad with

raised edge.

Ambient temperature 0 °C to 50 °C at 80 % relative humidity. Suitable for

use in gassing and incubating cabinets.

Power input 30 W

Voltage / frequency 230/240 V, 50/60 Hz

Protection class IP30

Drive electronically controlled capacitor motor with

overheating cut-out

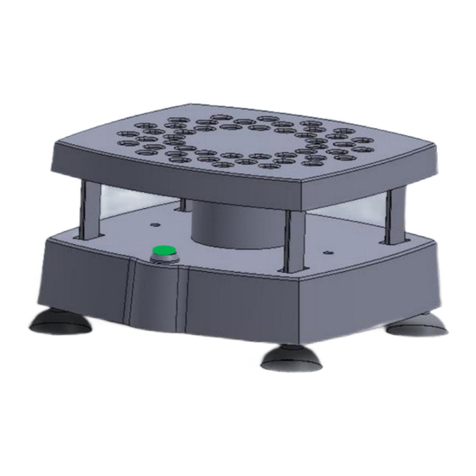

Mini Rocking Platform WT16 - for mixing with gentle rocking motion

Rocking frequency 2 - 50 cycles/min

Angle of inclination 5 ° / 10 °

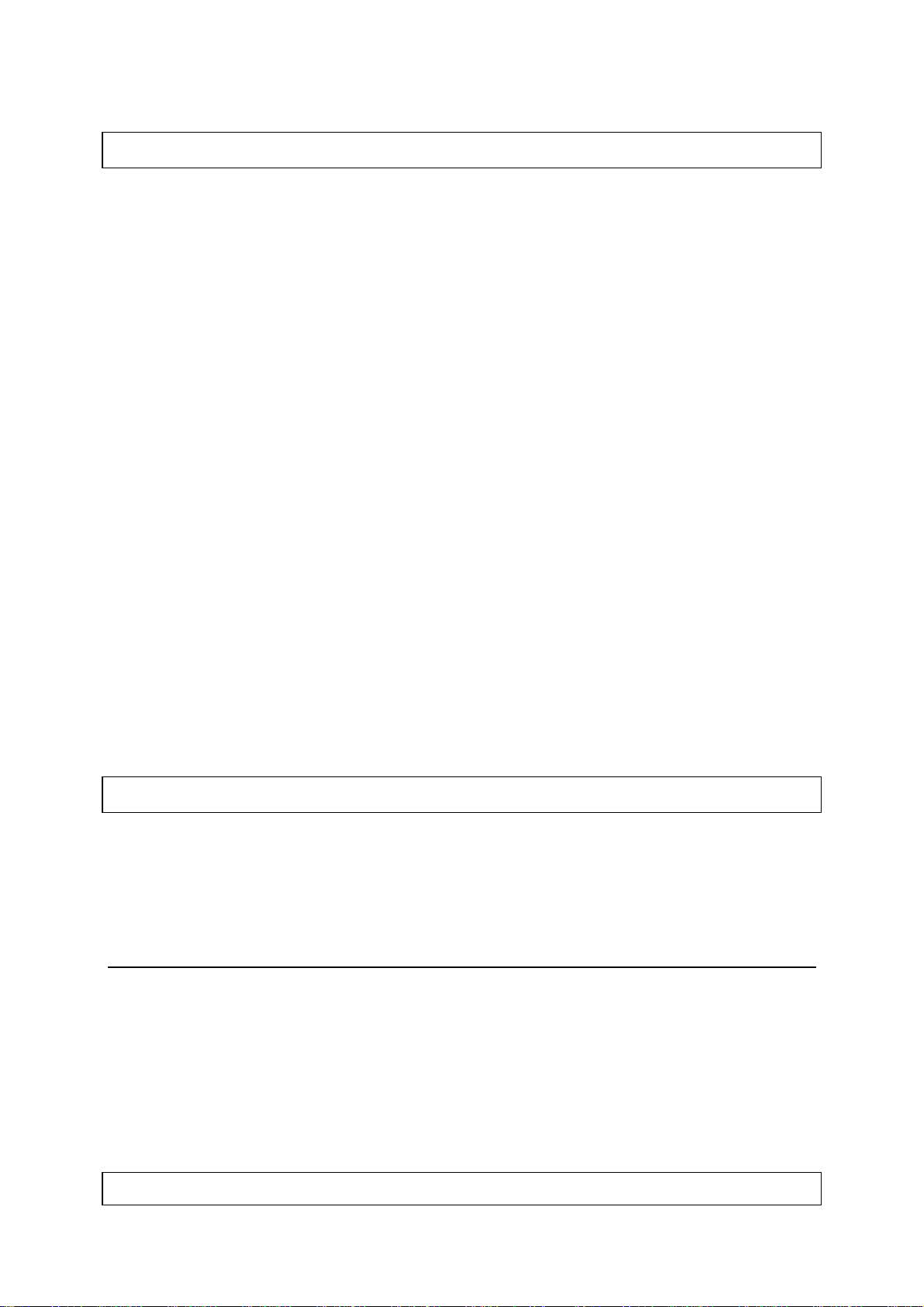

Load capacity 5 kg static; see Figure 1 for limitations with

eccentric loading

Mini Tumbling Table WT17 - for mixing with gentle asymmetrical motion

Asymmetric cycle frequency 2 - 50 cycles/min

Angle of inclination 5 ° (optional 10 °)

Load capacity 5 kg static; see Figure 1 for limitations with

eccentric loading

All mixers/shakers are designed for continuous operation.

3

Fig. 1:

Mini Rocking Platform WT16 / Mini Tumbling Table WT 17

max. eccentric loading

0,0

1,0

2,0

3,0

4,0

5,0

0 20 40 60 80 100 120 140

Distance from centre (mm)

Weight (kg)

Fig. 2

Mini Rocking Platform WT16 / Mini Tumbling Table WT17

Speed steps

0

10

20

30

40

50

012345678910

Rocking / Tumbling Frequency

(

1/min

)

Speed steps

4

4.0 Safety Instructions

Before you connect up the power cable to the mains supply, check that:

the voltage and frequency of the mixer/shaker conforms with the line

voltage (the voltage rating of your mixer/shaker is printed on the

nameplate).

the power switch is set to "0" and the control knobs have all been turned

counterclockwise up to the stop. This will prevent spills due to sudden,

overly vigorous shaking.

The mixer/shaker is not protected for use in explosive atmospheres. Be careful when

using it close to flammable and explosive substances.

The laboratory table must be strong and have a flat and non-slip surface.

Before you start up the mixer/shaker, make sure that the vessel (process medium) is

secure and cannot slip.

Take precautions to prevent attachments or vessels colliding with other objects on

the laboratory table during the shaking operation.

To guard against splashing and spills, close the shaking vessels carefully. When you

work with open vessels, select the shaking frequency accordingly.

To prevent unintentional violent shaking, it is always advisable to start with a low

shaking frequency and to increase it gradually in small steps until you reach the

shaking effect you want.

Always place single vessels at the centre of the platform. When working with several

vessels, always distributed them evenly over the platform.

Consult the load curves whenever you work with high loads and high shaking

frequencies.

Observe the pertinent safety regulations when working with

hazardous media.

Make allowance for the angle of inclination when using tall vessels .

5

5.0 Installation in the Laboratory

Use the supplied power cable to connect the mixer/shaker to the mains supply.

The appliance connector socket is at the rear.

The mixer/shaker is protected by bipolar fuses. The fuses are located in the housing of the

appliance connector socket and can be reached from the outside. The fuse rating is printed on

the plate.

For a description of how to operate your mixer/shaker, turn to the section "7.0 Operating the

mixers/shakers" and look up your particular model variant.

When working with low shaking frequencies, you can place flat vessels, e.g. Petri dishes, on

the platform without an additional fixture.

This mixer/shaker is fitted as standard with a EURO plug (DIN 49441 CEE 7/VII 10/16 A

250 V). For North America it comes with a US standard plug (NEMA Pub. No. WDI-1961

ASA C 73.1 - 1951 page 8 15A 125 V).

To connect the mixer/shaker to a different mains system, you must use an authorized adapter

or you must have an electrician replace the supplied plug with a suitable 3-pin plug

authorized for your mains system. In its delivered condition the mixer/shaker is earthed! If

you replace the original plug, make sure that the protective earth conductor of your

mixer/shaker is connected to the new plug.

Note the following colour codes if you ever use a different power cable or make any changes

to the power cable supplied:

GREEN/YELLOW = protective earth conductor (PE)

BLUE = phase (N)

BROWN = phase (L)

IN THE UNITED KINGDOM IT IS COMPULSORY TO USE AN APPROVED

STANDARD 13 A PLUG IN CONFORMANCE WITH BS 1363 (3-PIN PLUG).

6

6.0 Assembly and Description

All BIOMETRA models of this series are stable and rugged shakers and mixers for maximum

performance. They have been developed specially for the shaking and mixing of substances

for scientific purposes in laboratories. Control knobs are neatly arranged at the front for

convenient operation.

With the delivered models there are no shaking frequency limits provided if they are loaded

centrally as recommended.

Mini Rocking Table WT16

The Mini Rocking Table WT16 is used for the shaking of vessels - particularly flasks,

bottles and dye pans - with a gentle rocking motion.

Vessels are placed on the rubber pad that is supplied with the mixer/shaker.

The rubber pad is easy to replace.

Vessels must be secured to the shaking platform in central position and evenly spaced.

Shaking frequency is adjustable from 2 to 50 cycles/min. See Figure 2 for scale values.

The angle of inclination is 5° or 10°, depending on the model..

Mini Tumbling Table WT17

The Mini Tumbling Table WT17 is used for the shaking of vessels - particularly flasks,

bottles and dye pans - with a gentle asymmetrical motion.

Vessels are placed on the rubber pad that is supplied with the mixer/shaker.

The rubber pad is easy to replace.

Shaking frequency is adjustable from 2 to 50 cycles/min. See Figure 2 for scale values.

The angle of inclination is 5° or 10°, depending on the model.

7.0 Operation

The following controls are situated on the front panel from right to left

2-pole power switch with green illuminated rocker (1/0)

Speed control knob (Speed)

Use the power switch to turn the mixer/shaker on. Use the speed control knob to set the

shaking frequency you require. For exact shaking frequency settings, consult the graph

provided for each model.

7

8.0 Dismantling, Transportation and Storage

DISMANTLING

1. Switch off the mixer/shaker and remove the plug from the socket-outlet.

2. Remove all items of equipment from the vicinity of the mixer/shaker so that it can be

dismantled without difficulty.

3. Remove all vessels from the mixer/shaker. Dismantle any accessories.

TRANSPORTATION AND STORAGE

To prevent damage, it is best to store and transport the mixer/shaker and its components in

their original packaging or other suitable container. Close the packaging with adhesive tape.

Store the mixer/shaker in a dry place.

CAUTION: Guard the instrument from impact and vibration during transport.

9.0 Routine Cleaning and Maintenance

Clean the housing and surface of the mixer/shaker with a damp cloth (mild suds).

IMPORTANT: Never clean the mixer/shaker with chlorine bleach, detergents based on

chlorine, scouring powder, ammonium, cleaning wool or agents with

metallic constituents. This would cause damage to the sensitive surface

of the equipment.

The mixer/shaker has no wearing parts and requires no maintenance. If your BIOMETRA

product ever needs to be repaired, you should enlist the services of a specialist who has been

authorized by BIOMETRA to carry out such work. Contact your local BIOMETRA dealer or

get in direct touch with BIOMETRA.

8

10.0 Service

Should you have any problems with this unit, please contact our service department or your

local Biometra dealer:

Biometra GmbH

Service Department

Rudolf-Wissell-Straße 14 - 16

D-37079 Göttingen

Phone:++49 – (0)5 51 / 50 68 6- 10 or 12

Fax: ++49 – (0)5 51 / 50 68 6 -11

e-mail: biometra.service@whatman.com

If you would like to send the unit back to us, please read the following return

instructions.

Instructions for return shipment

•Return only defective devices. For technical problems which are not definitively

recognisable as device faults please contact the Technical Service Department at

Biometra.

•Use the original box or a similarly sturdy one.

•Label the outside of the box with “CAUTION! SENSITIVE INSTRUMENT!”

•Please enclose a precise description of the fault, which also reveals during which

procedures the fault occurred, if possible.

•Important: Clean all parts of the instrument from residues, and of biologically

dangerous, chemical and radioactive contaminants. Please include a written

confirmation that the device is free of biologically dangerous and radioactive

contaminants in each shipment. If the device is contaminated, it is possible that

Biometra will be forced to refuse to accept the device.

•The sender of the repair order will be held liable for possible losses resulting from

insufficient decontamination of the device.

•Please enclose a note which contains the following:

a) Sender’s name and address,

b) Name of a contact person for further inquiries with telephone number.

9

Equipment Decontamination Certificate

To enable us to comply with german law (i.e. §71 StrlSchV, §17 GefStoffV and §19 ChemG) and to

avoid exposure to hazardous materials during handling or repair, will you please complete this form,

prior to the equipment leaving your laboratory

COMPANY / INSTITUTE ___________________________________________________________________

ADDRESS _______________________________________________________________________________

TEL NO _______________________________ FAX NO_______________________________

E-MAIL __________________________________________________________________________________

EQUIPMENT Model Serial No

__________ __________

__________ __________

__________ __________

__________ __________

If on loan / evaluation Start Date: ________ Finish Date ________

Hazardous materials used with this equipment

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Method of cleaning / decontamination

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

The equipment has been cleaned and decontaminated:

NAME ________________________________ POSITION ___________________________

(HEAD OF DIV./ DEP./ INSTITUTE / COMPANY)

SIGNED ______________________________ DATE _______________________________

PLEASE RETURN THIS FORM TO BIOMETRA GMBH OR YOUR LOCAL BIOMETRA

DISTRIBUTOR TOGETHER WITH THE EQUIPMENT.

PLEASE ATTACH THIS CERTIFICATE OUTSIDE THE PACKAGING. INSTRUMENTS WITHOUT

THIS CERTIFICATE ATTACHED WILL BE RETURNED TO SENDER.

10

11.0 Notes

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

______________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

_______

11

EU - Konformitätserklärung

EC - Declaration of Conformity

Göttingen, den 20. 08. 2004

im Sinne der EG-Richtlinie über elektrische Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen 73/23/EWG

following the EC directive about electrical equipment for use within certain limits of voltage 73/23/EEC

und / and

im Sinne der EG-Richtlinie für die elektromagnetische Verträglichkeit 89/336/EWG.

following the EC directive about the electromagnetic compatibility 89/336/EEC .

Hiermit erklären wir, daß folgende Wipptische und Taumel-Wipptische

Herewith we declare that the following Rocking Platforms and Tumbling Tables,

Typ: Mini-Wipptisch WT16

type: Mini Rocking Platform WT16

Best.-Nr. / Order No. 042-500, 042-590

Typ: Mini-Taumel-Wipptisch WT17

type: Mini Tumbling Table WT17

Best.-Nr. / Order No. 042-600, 042-690

den grundlegenden Anforderungen der

corresponds to the basic requirements of

EG-Niederspannungsrichtlinie 73/23/EWG und der

EC low voltage directive 73/23/EEC and the

EG-Richtlinie über die elektromagnetische Verträglichkeit 89/336/EWG entsprechen.

EC directive about the electromagnetic compatibility 89/336/EEC .

Folgende harmonisierte Normen wurden angewandt:

The following harmonized standards have been used:

EN 61326:1997 + A1:1998 + A2:2001 + A3:2003

EN 61000-3-2:2000 EN 61000-3-3:1997 + A1:2001

EN 61010-1:2001

...........................................................

Dr. Jürgen Otte

Quality Manager

Formular 006

,

Ver. 03

12

Warranty

This laboratory instrument is produced with the highest practical standards of materials,

workmanship, and design. The design and manufacture of parts have been conceived with one

purpose - to produce units which will give satisfactory service.

Biometra GmbH guarantees this unit to be free from defects in materials or workmanship

under normal use or service for 24 month from date of shipment. If, during this time, this unit

proves defective in materials or workmanship, Biometra GmbH will repair or replace it free

of charge if returned to us prepaid. This guarantee does not cover damage in transit, damage

caused by carelessness, misuse or neglect, or unsatisfactory performance as a result of

conditions beyond our control; or consequential losses as a result of failure of our product.

___________________________________________________________________________

Biometra GmbH

Rudolf-Wissell-Str. 30

D-37079 Göttingen Service Department

Postfach 1544 Rudolf-Wissell-Str. 14-16

D-37005 Göttingen D-37079 Göttingen

Tel: ++49 – (0)5 51 / 50 68 6-0 Tel.: ++49 – (0)5 51 / 50 68 6-10 or -12

Fax: ++49 – (0)5 51 / 50 68 6-66 Fax.: ++49 – (0)5 51 / 50 68 6-11

e-mail: biometra.info@whatman.com e-mail: [email protected]

internet: http://www.biometra.de

This manual suits for next models

5

Table of contents

Other Biometra Laboratory Equipment manuals