Bioquell QUBE User manual

©Bioquell UK Ltd (2015). All rights reserved. USER MANUAL

TD069-O&M-001

REVISION 6

Bioquell UK Ltd

52 Royce Close

West Portway

Andover

Hampshire SP10 3TS

T:

F:

E:

W:

+44 (0)1264 835 835

+44 (0)1264 835 836

info@bioquell.com

www.bioquell.com

Page 1 of 80

Aseptic Processing Workstation

USER MANUAL

USER MANUAL

TD069-O&M-001

R.EVISION 5

Rev DescriDtaon Date C.R. o. Oris. chkd. ADDrd

1FIRST I55UE 3oh luly

2013 ]L PM ORC

2Screen navigation, glove & sl€€ve replac€ment added,

Eoad replac€able fu!€s added; Sectron 3.3.1 mov€d to

4.3.2; alarm condltionyactions added to tablei enors th Sept

2013 cR2455 JL PM ORC

3Ugdated al.rm table; ADMIN tunctrons, date & time,

time zone moved to superuisor acc6s; FiE 27 corrected;

updated screenshots; new pressure setpoints function

buttonj connector part nos. tor air Sampler add€d;

erroE corrected; seNice schedule updated,

23 )an

20L4 cR2560

cR2541 JL PM oRc

4additlon of us stenlant labelling notesj Environmental

Monitoring Level 4 opdon; 3,1 advice on positioning unit

added; Fig 20 updated; 3.1.2 advice on power covers

add€d; 3.3 bottle fill, storaqe and documents amended;

4,1.2 Rd 2 bottle holder (hange; 4.5 2 info moved to

product l€aflet 5.3.1 advice corre.ted; 5.3 infomation

amended; 8.2 am€ndedi 8.3 remoy€d, 9 volt free

12 May

2015 cR2689

cR2629 oRc ]H PGB

5Aeration cut-back added, p42, Maintenance penod

cla fied. Alams 40,41,72, 73 & 119 added. QRTP &

QBPM added. Addltionalinfo and trouble shooting on

.h<<-<.n.itivitw ^f H,O. <.nsor p7O

12 Aug 15 cR2889 ORC GK PGB

6Section 6.3 removed, 6.2 coveG all sePice information, 25 Sep 15 cR2971 @c- Ik stb

Bioquell designs, manufactures and supplies as a service a broad range of

bio-decontamination solutions for:

. rooms

. systems and processes

. laboratory equipment

. biomedical equipment

For further information and contact details refet to website

www.Bioquell.com

It is essential that the safety and operating instructions described in this manual

are observed.

These are the originat instructions

The Bioquell QUBE is only to be used by personnel who have been trained

by Bioquelt or their agents on its safe use. If the equipment is used in a

manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

These instructions assume the equipment has been installed in accordance with

the procedure detailed within TD069-IM-001'

oqu

Page 2 of 80

bt ell

USER MANUAL

TD069-O&M-001

REVISION 6

Page 3 of 80

Contents

1SAFETY ................................................................................................6

1.1 Safety Information relating to Hydrogen Peroxide and HPV Cycles.........6

1.1.1 Consumable H2O2bottle labelling symbols explained .....................8

1.2 General Safety Information relating to the QUBE ................................8

1.3 Warning Labels within the QUBE .......................................................9

2DESCRIPTION OF QUBE SYSTEM ........................................................... 10

2.1 Purpose of System ........................................................................ 10

2.2 QUBE Modules.............................................................................. 10

2.2.1 QUBE Hydrogen Peroxide Vapour Module - QHPV........................ 11

2.2.2 QUBE Extension Module - QEXT................................................ 11

2.2.3 QUBE Side Door Module – QSDM ..............................................11

2.2.4 QUBE Material Transfer Device - QMTD...................................... 12

2.2.5 QUBE Open Connection Module – QOCM .................................... 12

2.2.6 QUBE End Modules.................................................................. 12

2.3 Optional Sub-systems.................................................................... 14

2.3.1 Glove Tester........................................................................... 14

2.3.2 Sterility Test Pump.................................................................. 14

2.3.3 Integrated Environmental Monitoring......................................... 16

2.3.4 ‘Tri-Clover’ or Sanitary Connection Port to Chamber.................... 21

2.3.5 Ducted Extract........................................................................ 21

2.3.6 Additional Printer.................................................................... 21

2.4 Configurations.............................................................................. 21

2.5 Control Panel................................................................................ 21

2.6 Lighting ....................................................................................... 21

2.7 Modes of Operation ....................................................................... 22

2.7.1 Processing Mode..................................................................... 22

2.7.2 Bio-decontamination Mode....................................................... 22

3QUBE CONNECTIONS & SET-UP............................................................. 23

3.1 Position ....................................................................................... 23

3.2 Electrical Connections.................................................................... 23

3.2.1 External Electrical Connections ................................................. 23

3.2.2 Internal Electrical Connections.................................................. 25

3.3 Door Control................................................................................. 26

3.4 Hydrogen Peroxide Supply ............................................................. 27

4QUBE OPERATION................................................................................ 29

4.1 The Control Panel Explained ........................................................... 29

USER MANUAL

TD069-O&M-001

REVISION 6

Page 4 of 80

4.1.1 Icons..................................................................................... 29

4.2 Logging ON .................................................................................. 33

4.2.1 Loading the QHPV chamber...................................................... 34

4.2.2 Opening Doors........................................................................ 35

4.3 Bio-decontamination Mode............................................................. 35

4.3.1 Preparing to Start a Cycle........................................................ 35

4.3.2 Loading a Hydrogen Peroxide Bottle.......................................... 37

4.3.3 Running a Cycle...................................................................... 39

4.3.4 Cycle Phases .......................................................................... 39

4.3.5 Aborting a cycle...................................................................... 43

4.3.6 Printouts................................................................................ 44

4.4 Cycle Recipes ............................................................................... 44

4.4.1 Viewing Recipes...................................................................... 44

4.4.2 Pre-Loaded Recipes................................................................. 45

4.4.3 Creation and Editing Recipes .................................................... 45

4.5 Pressure Testing ........................................................................... 47

4.5.1 Chamber Leak Test ................................................................. 47

4.5.2 Glove Leak Testing (optional)................................................... 47

4.6 Operation of the Sterility Test Pump (optional) ................................. 47

4.7 Operation of Active Air Sampler...................................................... 47

4.8 Aseptic Hold................................................................................. 49

5SYSTEM ADMINISTRATION ................................................................... 50

5.1 System Information (only viewable)................................................ 50

5.2 OPERATOR editable functions ......................................................... 51

5.2.1 Set Language......................................................................... 51

5.2.2 Adjust Chamber light intensity.................................................. 51

5.3 SUPERVISOR editable functions ...................................................... 51

5.3.1 Suspending Processing Mode - system use not required............... 51

5.3.2 Door Interlocks....................................................................... 52

5.3.3 Set Time Zone........................................................................ 52

5.3.4 Date and Time........................................................................ 53

5.4 ADMINISTRATOR editable functions................................................. 53

5.4.1 Pressure Setpoints.................................................................. 53

5.4.2 Maximum Aseptic Hold Period................................................... 54

5.4.3 Manage Users......................................................................... 54

6PREVENTATIVE & SCHEDULED MAINTENANCE......................................... 57

6.1 Operator Maintenance ................................................................... 57

USER MANUAL

TD069-O&M-001

REVISION 6

Page 5 of 80

6.1.1 Cleaning ................................................................................ 57

6.1.2 Replacing Gloves .................................................................... 58

6.1.3 Fitting New Sleeves................................................................. 58

6.1.4 Changing the Printer Paper ...................................................... 59

6.2 Scheduled Maintenance ................................................................. 60

7TROUBLESHOOTING ............................................................................ 61

7.1 Alarms & Warnings........................................................................ 61

7.1.1 Alarm Screen ......................................................................... 61

7.2 Troubleshooting............................................................................ 69

8PARTS LIST......................................................................................... 70

8.1 Consumables................................................................................ 70

8.2 Replacement Parts ........................................................................ 70

9SPECIFICATION................................................................................... 71

10 EC DECLARATION OF CONFORMITY.................................................... 74

11 SCREEN NAVIGATION....................................................................... 75

12 GLOSSARY...................................................................................... 77

13 DEFAULT PASSWORDS ..................................................................... 78

United States of America only:

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

—Consult the dealer or an experienced radio/TV technician for help.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 6 of 80

1SAFETY

1.1 Safety Information relating to Hydrogen Peroxide and

HPV Cycles

Safety instructions that must be observed when operating or servicing the

Bioquell QUBE or handling the Hydrogen Peroxide bottles are listed below.

Danger and Warning signs are used where there is a potential hazard to

personnel.

The mandatory symbol is used to describe other safety precautions that

should be followed before operating the equipment.

DANGER – CHEMICAL INJURY HAZARD

HANDLING HYDROGEN PEROXIDE

Wear personal protective equipment including

Eye protection, single use neoprene or vinyl gloves and protective

clothing.

HYDROGEN PEROXIDE LIQUID

can cause burns and blistering to the

skin and tissue damage to the eyes when in contact. HYDROGEN

PEROXIDE VAPOUR can cause irritation to eyes, nose, throat, lungs and

skin and breathing difficulties and coughing.

IN ALL CASES SEEK MEDICAL ADVICE.

ACTION TO BE TAKEN ON EXPOSURE TO HYDROGEN PEROXIDE

EYES Irrigate with sterile water for at least 10 minutes.

LUNGS Remove casualty immediately to fresh air, rest and keep warm.

SKIN Drench with water. If spilled on clothing remove immediately and wash

thoroughly.

MOUTH Rinse thoroughly with water and give plenty to drink. Do not induce

vomiting.

SAFETY OBSERVANCE IS ESSENTIAL WHEN USING THIS EQUIPMENT.

READ THIS SECTION CAREFULLY BEFORE USING THE EQUIPMENT

USER MANUAL

TD069-O&M-001

REVISION 6

Page 7 of 80

SPILLAGES

Mop up with plenty of water and run to waste, diluting at least 20:1.

Always ensure wipes used to mop up spillages are rinsed with cold water

before being put in waste bins; there is a risk of spontaneous combustion

if thrown directly in waste bin containing other materials.

HANDLING HYDROGEN PEROXIDE BOTTLE

Wear protective gloves. Inspect outer bag containing peroxide bottle for

signs of liquid before opening. If any liquid is present in the bag DO NOT

OPEN. Discard safely.

If no signs of liquid in the bag open carefully and remove bottle. Keep

bottle upright at all times.

Handle bottle in accordance with safety data supplied on bottle label and

packaging.

BEFORE RUNNING A CYCLE

Check that all doors and front access windows are closed and seals

inflated.

DURING A CYCLE

·Do not attempt to open the QUBE before the end of the cycle or to

open a QUBE door unless the door switch is illuminated GREEN.

·Observe warnings and alarms displayed on the control panel.

·Do not attempt to disengage or remove the Hydrogen Peroxide liquid

bottle.

AT THE END OF AERATION

Check that the vapour concentration is at, or below, the country’s

Occupational Exposure Limit (OEL) (Long-term exposure limit is 1ppm

and short-term is 2ppm in the UK). In USA: the Permitted Exposure Limit

(PEL) has a Threshold Limit Value (TLV) of 1ppm for eight hours exposure

a day.

IF THE CYCLE ABORTS DURING

GASSING OR AERATION

Check that the vapour concentration is at, or below, the OEL before

opening the QUBE.

If above the OEL run an “AERATION ONLY” cycle in accordance with the

operating instructions until the safe concentration level is reached.

VISIB

LE LIQUIDS

in the enclosure must be treated as concentrated

Hydrogen Peroxide. Observe Hydrogen Peroxide handling precautions

and remove liquid by diluting with water at least 20:1 and wiping up.

EXTERNAL DISCHARGE

of vapours by ventilation from the enclosure to

atmosphere during the aeration period must avoid leakage of Hydrogen

Peroxide vapours within the building.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 8 of 80

1.1.1Consumable H2O2bottle labelling symbols explained

CHEMICAL INJURY

HAZARD Hydrogen Peroxide

liquid is hazardous –

corrosive

CHEMICAL INJURY

HAZARD Hydrogen Peroxide

liquid is harmful and

is an oxidizing agent

RFID This product contains an

RFID tag

Note: Further information relating to safety for the Hydrogen Peroxide is

available from on the MSDS provided with the consumable.

1.2 General Safety Information relating to the QUBE

WARNING – EQUIPMENT DAMAGE

The

QUBE system

, once installed, only require

s

moving forward to enable

cleaning of all sides. If the equipment is to be moved across a threshold or

any substantial distance then it should be completely disassembled and re-

assembled by trained personnel to ensure safe operation once re-

positioned. Cables must not, at any time, be trailed causing a trip hazard.

Ensure supporting feet (x2) are retracted prior to moving any QUBE

system. The weight of the QUBE system is dependent upon the

configuration; however, local manual handling regulations must be adhered

to. To prevent damage to the QUBE do not manoeuvre by handling the front

screen, glove ports or gas strut covers.

Avoid moving the

QUBE system

(or any part thereof)

once a cycle has been

started.

Prior to switching on the QUBE system ensure

all doors are closed.

Operate the equipment strictly in accordance with the Operating

Instructions.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 9 of 80

Major r

epairs or adjustments to the Bioquell

QUBE

should only be made by

a Bioquell Service Provider or those trained to perform such procedures by

Bioquell. Non-routine maintenance performed by unqualified personnel or

installation of unauthorised parts could cause personal injury or result in

damage.

The equipment must be serviced in accordance with the Maintenance

Schedule to maintain safe performance. Potential hazards or failure of

performance may occur if the equipment is not serviced by trained and

authorised personnel. Contact your Bioquell Service Provider to schedule

preventative maintenance or for emergency repairs.

Use of traditional alcohol

sprays and

wipes must be avoided to prevent

damage to the sensitive electrical components within the QUBE system

especially the Hydrogen Peroxide sensor.

Use of paper or other abrasive cloths could potentially damage the QUBE

front screen during cleaning.

Do not cover the top of the QMTD as this could potentially block the filter.

DANGER – PERSONAL INJURY HAZARD

The Bioquell

QHPV

m

odule

weigh

s

approx

.

280

kg

(

617

lbs)

; the QEXT

module approx. 240Kg (529.1 lbs) and the QMTD module approx. 64 kg

(141 lbs). Local manual handling regulations and SOPs must be adhered to

when moving this equipment to prevent personal injury. Assisted

mechanical devices will be required if moving over a threshold or for any

distance.

Take care when moving the Bioquell

QUBE

on inclined surfaces.

Park the Bioquell

QUBE

on flat surfaces only. Secure by

extending the

support feet to stop the unit moving.

Do not tilt the unit over as toppling may occur.

The Bioquell

QUBE

contains electrical connections. Always disconnect the

power supply before gaining access to electrical and pneumatic systems for

inspection or maintenance. Access to these systems should be restricted to

trained personnel; failure to do so may cause an ELECTRICAL INJURY

HAZARD.

1.3 Warning Labels within the QUBE

ELECTRICAL INJURY

HAZARD Only trained personnel

should be accessing the

electrical system

USER MANUAL

TD069-O&M-001

REVISION 6

Page 10 of 80

2DESCRIPTION OF QUBE SYSTEM

2.1 Purpose of System

The Bioquell QUBE is an aseptic processing workstation with integrated HPV

decontamination system. This system can be used for various applications

including: sterility testing; pharmacy compounding, aseptic material transfer and

others that require an aseptic environment. It is a modular system that is

configurable to the Client’s needs.

The QUBE is loaded via the front access window. Dependent upon the application,

the QUBE may be supplied with Bioquell “SafeSort1”, internal racking and rails.

There is a Product Description Sheet for each of the optional accessories available

from Bioquell.

All replacement or serviceable parts are accessible from the front of the QUBE;

thereby allowing it to be positioned against a wall. Key access is required to

components that may present a hazard.

2.2 QUBE Modules

The QUBE system is modular incorporating a QUBE Hydrogen Peroxide Vapour

(QHPV) Module and additional modules dependent upon ordered configuration:

•QUBE Extension Module (QEXT) (max.2)

•QUBE Side Door Module (QSDM)

•QUBE Material Transfer Device (QMTD)

·QUBE Open Connection Module (QOCM)

·QUBE Closed Connection Module (QCCM)

·QUBE Rapid Transfer Port (QRTP)

·QUBE Blank Plate Module (QBPM)

As standard the QHPV Module is supplied without integrated continuous particle

monitoring or active air sampling systems (unless ordered as part of the

configuration). However, it is fitted with the connections for these systems

including having a “Dummy cone” in place.

Figure 1 depicts one typical configuration of a QUBE system. The QUBE is

available as a 1-chamber, 2-chamber or 3-chamber system of various

configurations.

1Bioquell SafeSort is a prescription decontamination system designed for gassing components and

used in hospital pharmacy applications.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 11 of 80

QHPV

module

Figure 1: Typical Configuration of QUBE System

QEXT

module

QMTD

module

2.2.1QUBE Hydrogen Peroxide Vapour Module - QHPV

This chamber incorporates the HPV decontamination system and controls

including the touch screen. Each QUBE system incorporates a QHPV module. The

complete system is controlled via a Control Panel from the QHPV Module. Figure 2

depicts the main features of this module.

2.2.2QUBE Extension Module - QEXT

This module can be positioned either left, right or both sides of the QHPV

chamber. It enables the Operator to continue to ‘work’ on one load whilst

simultaneously decontaminating another load. If the system is configured with

more than one QEXT module then one may be used as an accumulator to store a

load whilst one is being processed and one being gassed.

2.2.3QUBE Side Door Module – QSDM

This module is positioned either on the left hand end, or right hand end, or both

ends of the chambers. It can be used to transfer the load between QUBE

modules, while providing a physical separation between modules allowing the

QHPV unit to run cycles on its own.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 12 of 80

2.2.4QUBE Material Transfer Device - QMTD

This module is positioned either on the left hand end, right hand end, or both

ends of the chambers. It can be used to transfer the load into and/or out of the

QUBE system.

2.2.5QUBE Open Connection Module – QOCM

The QOCM allows for a large open aperture between QEXT modules only, thus

making them into a 4-glove device.

2.2.6QUBE End Modules

The end panels for the QUBE system where a QMTD is not fitted can be one of the

following:

QUBE Closed Connection Module – QCCM

This is a solid end panel

QUBE Rapid Transfer Port – QRTP

This end panel has a 190mm diameter RTP fitted to it. There is a left and a right

hand version ensuring that the RTP always hinges to the back.

QUBE Blank Plate Module – QBPM

The end panel has a circular blank 3mm thick stainless steel sheet, through which

penetrations can be made to suit application.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 13 of 80

Control Panel

Chamber test

point*

Processing

chamber

Stirrer

fans (2x)

Clear front

access window

H2O2Bottle

module

Key access to

components of

pneumatic

system

Figure 2: QHPV Module

Vaporiser outlet

Internal electrical

connections

Environmental

Monitoring

Module

Glove ports

(gloves and

sleeves not

shown)

Printer

Key access to

electrical system

Foot switch for

opening QSDMs

* Mating part is Bioquell part number H03020720 and has a 5/16” (8mm) Hose

barb outlet.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 14 of 80

2.3 Optional Sub-systems

The following sub-systems are not integrated into the QUBE as standard but

available to order as part of the configuration:

2.3.1Glove Tester

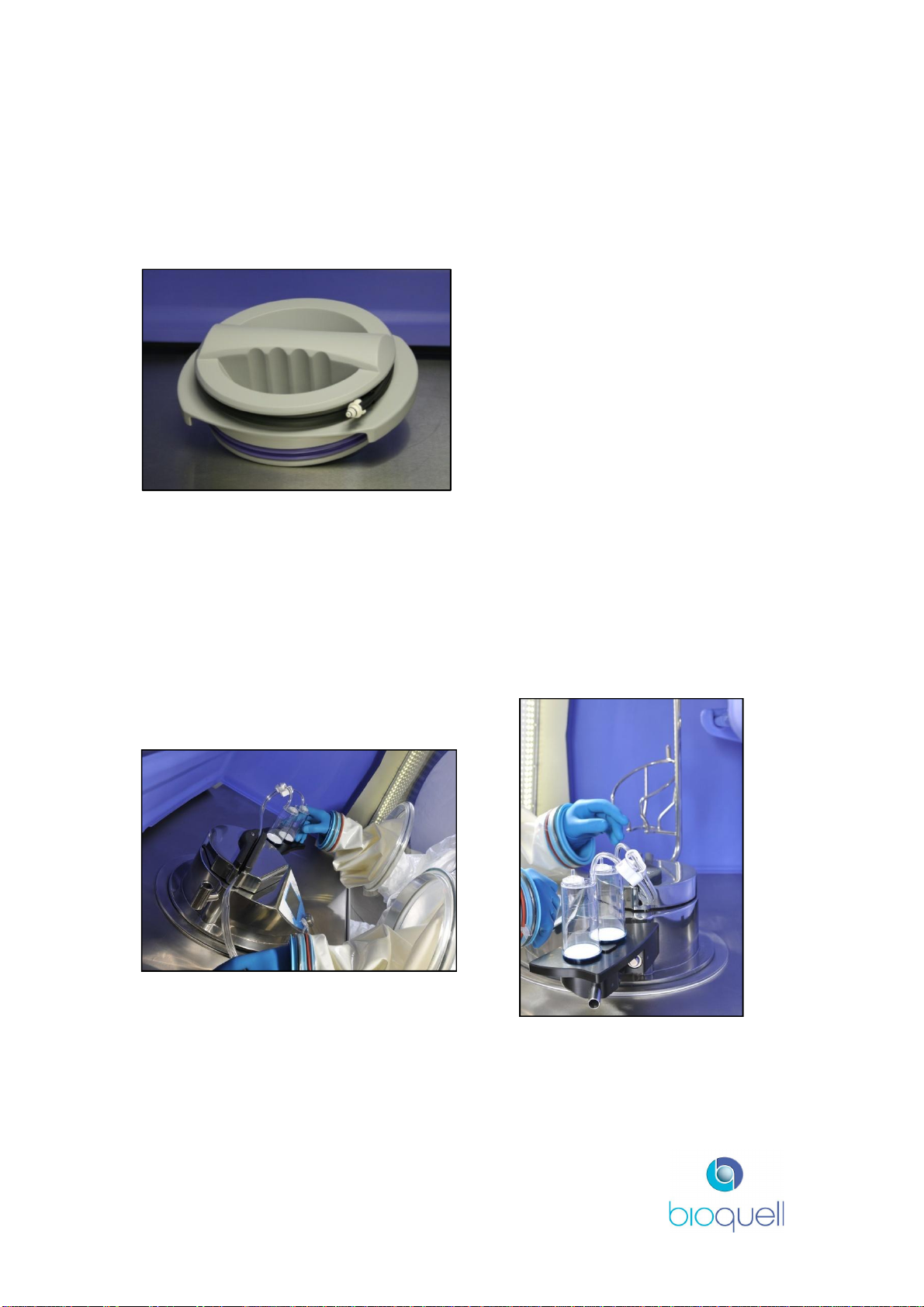

Figure 3: Glove Tester

The Glove Tester (Part No.TD069-5900)

is an accessory that can be supplied

with the QUBE system to enable the

leak testing of sleeves and gloves.

A glove test cannot be performed on a

QUBE module which is being

decontaminated.

For information on how to use the glove tester refer to Instructional Leaflet

TD069-5900_PDS (supplied with glove tester).

2.3.2Sterility Test Pump

The QUBE system has been designed to work with the Merck Millipore SteriTest

Symbio Flex or Equinox Isofit Pump for sterility testing applications. The

“SteriTest” unit is fully integrated into the chamber moulding.

Figure 4: Sterility test unit in use (Equinox shown)

USER MANUAL

TD069-O&M-001

REVISION 6

Page 15 of 80

Sterility Test

Pump (Merck

Millipore

Equinox or

Symbio Flex)

Housing for

SteriTest pump

controller/power

supply and

continuous

particle

monitoring

system. Access

required by

Service

personnel.

Figure 5: SteriTest unit installed

Drain,

passes

through floor

to allow safe

disposal

outside the

unit (see

Fig.6)

Footswitch

operation of

the SteriTest

pump.

Prior to use of SteriTest unit ensure tubing is connected to drain. Connect tubing

as shown in Figure 6.

Figure 6: Push-in connection

USER MANUAL

TD069-O&M-001

REVISION 6

Page 16 of 80

For details on how to use the “SteriTest” pump refer to the Manufacturer’s

Instructions (supplied if part of ordered configuration).

To remove the drain connection press release button and pull out, as shown in

Figure 7.

Figure 7: Removal of drain tubing

It is advisable to execute the scheduled maintenance of the “SteriTest” unit whilst

the QUBE is being serviced. Contact Merck Millipore for scheduling the Servicing

of this unit (refer to Section 6.2 for contact details).

The QUBE may also be supplied with the “SteriTest” pump drain only if a client-

supplied free standing SteriTest pump is installed.

Racking has been designed by Bioquell for this application. This racking is

available in kit form; refer to TD069-6200_PDS for how to assemble.

2.3.3Integrated Environmental Monitoring

2.3.3.1 Level 1 Environmental Monitoring Package

As standard the QUBE QHPV and QEXT chambers have been designed to allow

for Level 1 Environmental Monitoring to be performed. Level 1 Environmental

Monitoring consists of:

·Periodic particle monitoring checks using a portable particle counter

connected to the pre-fitted tube and supplied ISO-Kinetic cone. A blanking

cone is also supplied, to be fitted instead of the ISO-Kinetic cone when

sampling is not taking place. The particle monitor is not supplied by

Bioquell.

·An integral connector inside the chamber can be used to connect to an

Active Air Sampler (see Fig. 21, Item 2), and a coupler is provided (see

Fig. 12) on the QUBE’s right leg to enable connection to the air sampler’s

power device. The Active Air Sampler and power device and settle plates

are not supplied by Bioquell.

·Settle plates and other alternative monitoring methods may be adequate,

as shown in Figure 8.

USER MANUAL

TD069-O&M-001

REVISION 6

Page 17 of 80

Figure 8: Level 1 Environmental

Monitoring System Diagram

Figure 9: Level 1 Environmental

Monitoring System Diagram

ISO-Kinetic cone, blanking cone and integral cable and connectors for Active Air

Sampler are supplied with units. The connectors are specifically for the SAS

Isolator 180 Sampler. If not using a Bioquell-supplied Sampler then a LEMO

connector (LEMO Part No. FGL.2K.302.CLLC55Z) must be fitted to the Sampler.

Cable between sampler and chamber marked with * can be supplied separately

(Bioquell Part No. TD069-0621)

ISO-Kinetic cone

Figure 10: ISO-Kinetic Cone Figure 11: Blanking Cone

Settle plate

Particle

counter

ISO

-

cone

Active Air

Sampler

Air sampler’s

power device

Integral cabling

and connectors

for Active Air

Sampler and its

power device

*

USER MANUAL

TD069-O&M-001

REVISION 6

Page 18 of 80

Connecting the Active Air Sampler

Figure 12: Connecting Active Air

Sampler

Active Air Sampler, location shown, is

plugged into the dedicated connector

within the chamber (refer to Fig. 21,

Item 2)

Keyed bulkhead coupler supplied on

QUBE right leg for attaching the

sampler’s power device.

2.3.3.2 Level 2 Environmental Monitoring Package

The QUBE QHPV and/or QEXT chambers are optionally supplied with an Active

Air Sampler (See Figure 13) to enable Level 2 Environmental Monitoring; the air

sampler is powered and controlled through the QUBE’s touch screen.

Figure 13: Active Air Sampler

The Active Air Sampler has a stainless

steel head. It is permanently placed

within the QUBE and attached through

a dedicated DC supply connector;

labelled thus:

USER MANUAL

TD069-O&M-001

REVISION 6

Page 19 of 80

Figure 14: Level 2 Environmental Monitoring System Diagram

As Level 1, when particle monitoring is to be performed the blanking ISO-Kinetic

cone fitted to the QUBE should be replaced with the supplied ISO-Kinetic cone.

2.3.3.3 Level 3 Environmental Monitoring Package

The QUBE is optionally supplied with an Active Air Sampler and a proprietary

integrated continuous particle monitoring system with integrated vacuum pump.

An ISO-kinetic cone is fitted to the QUBE chamber.

Figure 15: Level 3 Environmental Monitoring System

CONTROLLER

USER MANUAL

TD069-O&M-001

REVISION 6

Page 20 of 80

Sample air is fed continuously to the particle counter monitoring unit via tubing

from the ISO-Kinetic cone. See Figure 15.

Pharmagraph enVigil-PnP logging software is supplied to output and record

results to a PC; the PC is not supplied by Bioquell. Up to 2 chambers can be run

from one software license. Refer to manufacturer’s instructions for use.

2.3.3.4 Level 4 Environmental Monitoring Package

The QUBE is optionally supplied with a proprietary integrated continuous particle

monitoring system with integrated vacuum pump. An ISO-kinetic cone is fitted to

the QUBE chamber. Pharmagraph enVigil-PnP logging software is supplied and

record results to a PC. The PC is not supplied by Bioquell.

An integral connector inside the chamber can be used to connect to an Active Air

Sampler (see Fig. 20, Item 2), and a coupler is provided (see Fig. 12) on the

QUBE’s right leg to enable connection to the air sampler’s power device. The

Active Air Sampler and power device and settle plates are not supplied by

Bioquell.

Figure 16: Level 4 Environmental Monitoring System

Table of contents