A. INSTALLATION GUIDE –TABLE OF CONTENTS

PAGE 5 / 47 Installation and User guide –ECOROCK 700 to 900 Units –05-12-2016

TABLE OF CONTENTS

1. THE ECOROCK SEWAGE TREATMENT PLANT.................................................................. 6

1.1. General points .........................................................................................................................6

1.2. Sizing ........................................................................................................................................6

1.3. Precautions ..............................................................................................................................6

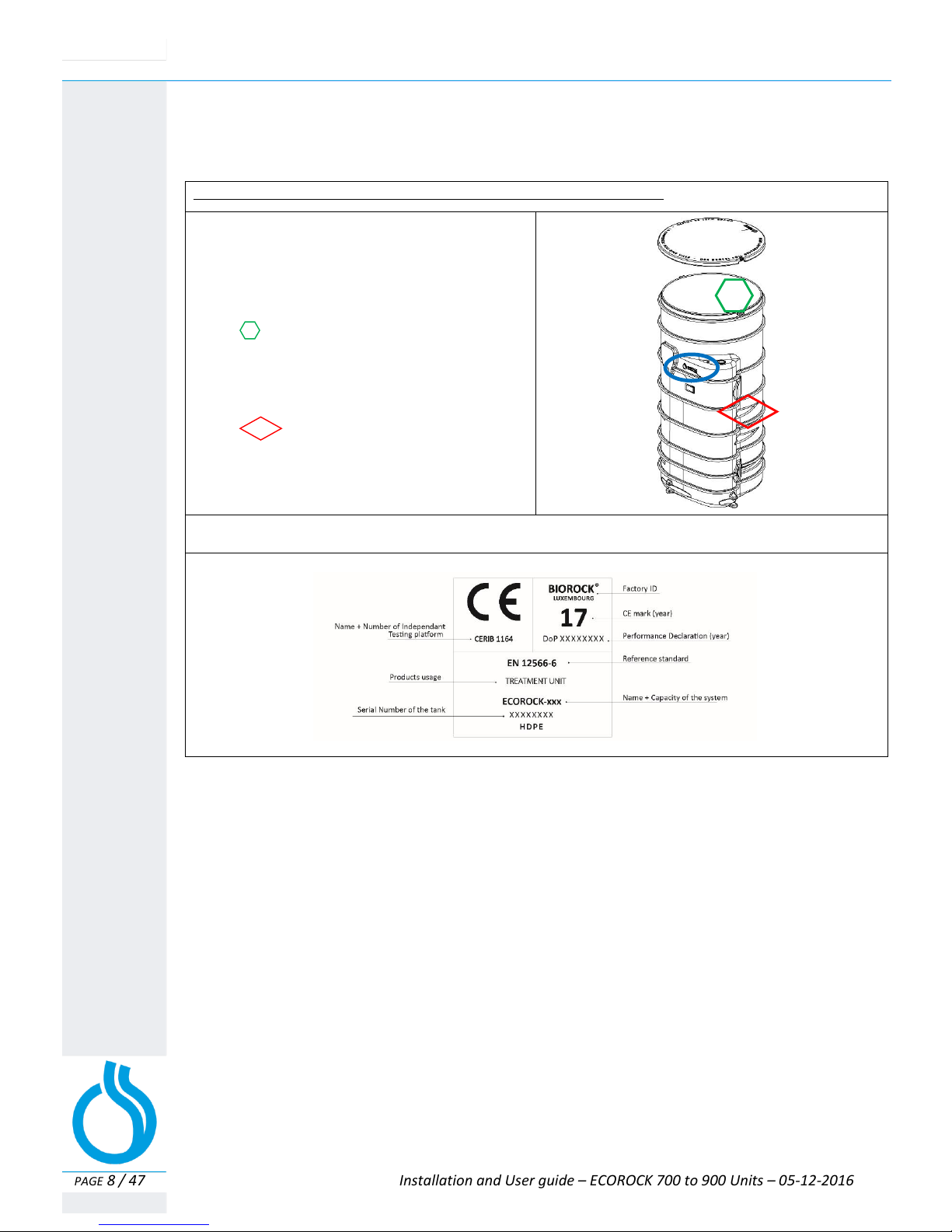

1.4. Identification ............................................................................................................................8

1.5. Handling and transport ............................................................................................................8

2. OPERATING PRINCIPLES OF THE ECOROCK SEWAGE TREATMENT PLANT ....................... 9

2.1. Primary Tank –Operating principle..........................................................................................9

2.2. ECOROCK Treatment Unit –Operating principle....................................................................11

2.3. ECOROCK Treatment Unit –Technical....................................................................................11

3. INSTALLATION LAYOUTS ............................................................................................. 12

3.1 Installation layout n°1.: Gravity discharge (non-electric)......................................................12

3.2 Installation layout n°2.: Pumped discharge (pump after PT) ................................................12

3.3 Installation layout n°3.: Pumped discharge (pump after ECOROCK unit) .............................12

4. INSTALLATION OF THE TANKS .................................................................................... 13

4.1 Principles and constraints of installation works.....................................................................14

4.1.1 Before installation of the complete system.............................................................14

4.1.2 Installation of the Primary Tank .............................................................................14

4.1.3 Installation of the ECOROCK treatment unit ..........................................................15

4.2 Installation in dry ground conditions .....................................................................................15

4.2.1 Installation and digging in dry ground conditions...................................................15

4.2.2 Installation of the Tanks in dry ground conditions..................................................15

4.2.3 Backfilling in dry ground conditions ........................................................................16

4.3 Installation in wet ground conditions.....................................................................................16

4.4 Installation in specific sites.....................................................................................................18

4.4.1 Installation in difficult areas and sites ....................................................................18

4.4.2 Installation in difficult ground conditions ...............................................................18

4.4.3 Backfilling in difficult sites.......................................................................................18

4.5 Installations under roads, courtyards or storage areas..........................................................19

4.6 Other specific cases ................................................................................................................19

4.6.1 Incline too steep ......................................................................................................19

5. VENTILATION AND WATER DISTRIBUTION .................................................................. 20

5.1 Ventilation of the Primary Tank..............................................................................................20

5.2 Ventilation of the BIOROCK® treatment unit .........................................................................21

5.3 Water distribution ..................................................................................................................21

5.4 BIOROCK® media ....................................................................................................................22

5.5 Securing the lids......................................................................................................................23

6. STOPPING AND RESTARTING THE SYSTEM .................................................................. 24

7. CONFORMITY AND WORK COMPLETION .................................................................... 24

8. RECOMMENDATIONS OF USE AND MAINTENANCE .................................................... 24

9. COMPLIANCE WITH REGULATIONS AND STANDARDS .................................................. 24

10. WARRANTY .............................................................................................................. 25