Birch BP-846M+ User manual

USER’S

MANUAL

THERMAL TRANSFER / DIRECT THERMAL

BAR CODE PRINTER

BP-8410M / BP-846M+ / BP-8463M+

i

Contents

1. Introduction ............................................ 1

Product Introduction ...............................................................................1

2. Operations Overview ..................................... 3

2.1 Unpacking and Inspection ......................................................................3

2.2 Printer Overview ......................................................................................4

2.2.1 Front View ......................................................................................4

2.2.2 Interior view....................................................................................5

2.2.3 Rear View........................................................................................6

2.3 Operator Controls ....................................................................................8

2.3.1 Front Panel Display .......................................................................8

2.3.2 LED Indicators ...............................................................................8

2.3.3 Front Panel Keys ...........................................................................9

2.4 Setting Up the Printer ..............................................................................9

2.5 Installation of Ribbon ............................................................................10

2.5.1 Loading Ribbon ...........................................................................10

2.5.2 Remove Used Ribbon..................................................................13

2.6 Installation of Media ..............................................................................14

2.6.1 Loading Roll Labels.....................................................................14

2.6.2 Loading Fan-fold Labels .............................................................17

2.6.3 Loading Media for Peel-off Mode (Option).................................19

2.6.4 Remove Liner (Option) ................................................................21

2.6.5 Loading Media in Rewind Liner with Label Mode (Option) ......22

2.6.6 Remove Labels from Internal Rewind (Option) .........................24

2.7 Adjustment Knob ...................................................................................25

2.7.1 Print head Pressure Adjustment Knob ......................................25

2.7.2 Print Head Burn Line Adjustment Knob.....................................25

2.8 Using the Keyboard with PS/2 Interface (Optional for

BP-846M+/BP-8463M+ series models) .......................................................27

3. Menu Function ......................................... 28

3.1 Setup Menu Overview............................................................................29

3.1.1-1 Printer Setup (TSPL2)...............................................................30

3.1.1-2 Printer Setup (ZPL2) .................................................................37

3.1.2 Sensor...........................................................................................44

3.1.3 Serial Comm.................................................................................52

ii

3.1.4 Ethernet ........................................................................................55

3.2 File Manager...........................................................................................58

3.2.1 File List .........................................................................................58

3.2.2 Avail. Memory...............................................................................59

3.2.3 Del. All Files..................................................................................59

3.3 Diagnostics ............................................................................................60

3.3.1 Print Config. .................................................................................60

3.3.2 Dump Mode ..................................................................................61

3.3.3 Rotate Cutter ................................................................................62

3.4 Language................................................................................................62

3.5 Service ....................................................................................................63

3.5.1 Initialization ..................................................................................63

3.5.2 Mileage Info. .................................................................................64

4. Diagnostic Tool......................................... 65

4.1 Start the Diagnostic Tool.......................................................................65

4.2 Printer Function (Calibrate sensor, Ethernet setup, RTC setup………)

.......................................................................................................................66

5 Setting Ethernet by Diagnostic Utility (Optional for

BP-846M+/BP-8463M+ models) ...............................67

5.1 Using USB interface to setup Ethernet interface ................................67

5.2 Using RS-232 interface to setup Ethernet interface............................68

5.3 Using Ethernet interface to setup Ethernet interface .........................69

6. Troubleshooting ........................................ 71

6.1 Common Problems ................................................................................71

6.2 Mechanism Fine Adjustment to Avoid Ribbon Wrinkles ....................75

7. Maintenance ........................................... 77

1. Introduction

1.1 Product Introduction

Thank you very much for purchasing BIRCH BP-846M+ and BP-8410 series bar code

printer. This printer is designed with die-casting aluminum chassis and print mechanism,

metal cover with large clear media view window, which ensuring to work for the extreme

and heavy duty industrial environment and applications.

With back-lit graphic LCD display, printer status can be managed easier and operated

more user friendly. The moveable sensor design can accept wide range of label media.

All of the most frequently used bar code formats are included. Fonts and bar codes can

be printed in any one of the four directions. This printer is built-in the high quality, high

performance MONOTYPE IMAGING® True Type font engine and one CG Triumvirate

Bold Condensed smooth font. With flexible firmware design, user can also download the

True Type Font from PC into printer memory for printing labels. Besides the scalable

font, It also provides a choice of five different sizes of alphanumeric bitmap font, OCR-A

and OCR-B fonts. By integrating rich features, it is the most cost-effective and high

performance printer in its class!

2

CAUTION

1. HAZARDOUS MOVING PARTS IN CUTTER MODULE. KEEP FINGER AND OTHER BODY

PARTS AWAY.

2. THE MAIN BOARD INCLUDES REAL TIME CLOCK FEATURE HAS LITHIUM BATTERY

CR2032 INSTALLED. RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN

INCORRECT TYPE.

3. DISPOSE OF USED BATTERIES ACCORDING TO THE MANUFACTURER INSTRUCTIONS.

3

2. Operations Overview

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping.

Please carefully inspect the packaging and printer upon receiving the bar code printer.

Please retain the packaging materials in case you need to reship the printer.

Unpacking the printer, the following items are included in the carton.

One printer unit

One Windows labeling software/Windows driver CD disk

One quick installation guide

One power cord

One USB interface cable

If any parts are missing, please contact the Customer Service Department of your

purchased reseller or distributor.

4

2.2 Printer Overview

2.2.1 Front View

1. LED indicators

2. LCD display

3. Front panel buttons

4. Paper exit chute

5. Lower front cover

6. Printer right side cover

1

2

3

4 6

5

5

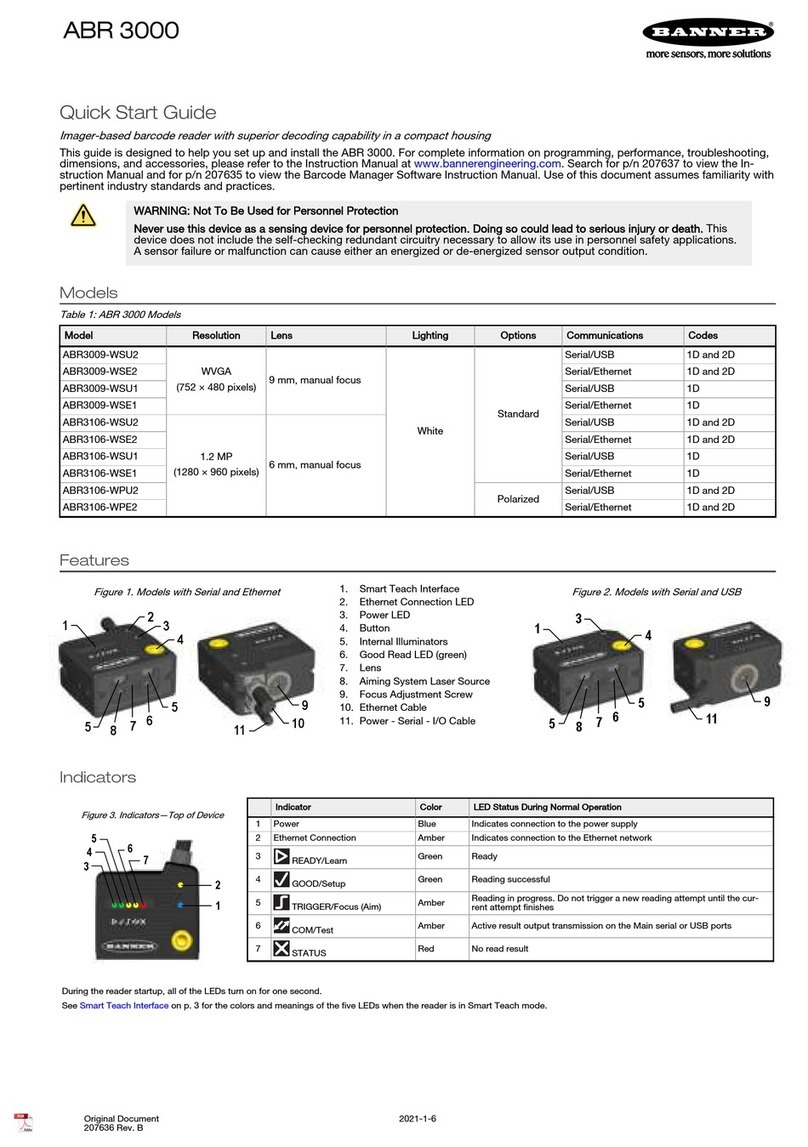

2.2.2 Interior view

1. Ribbon rewind spindle

2. Ribbon release button

3. Ribbon guide plate

4. Print head

5. Platen roller

6. Print head release lever

7. Media guide bar

8. Label roll guard

9. Label supply spindle

10. Ribbon supply spindle

11. Damper

12. Label guide

13. Z axis mechanism adjustment knob

14. Print head pressure adjustment knob

15. Print head secure screw

16. Ribbon sensor

17. Media sensor

5

8

7

10

9

6

11

4

12

3

1

2

13

14

15

17

16

6

2.2.3 Rear View

1. Fan-fold paper entrance chute

2. Centronics interface

3. USB interface

4. RS-232C interface

5. Power jack socket

6. GPIO interface

*7. SD card slot

8. Ethernet interface

9. PS/2 interface

10. Power switch

* Recommended SD card specification.

SD card spec SD card capacity Approved SD card manufacturer

V1.0, V1.1 128 MB SanDisk, Transcend

V1.0, V1.1 256 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 512 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 1 GB SanDisk, Transcend, Panasonic

V2.0 SDHC CLASS 4 4 GB

V2.0 SDHC CLASS 6 4 GB SanDisk, Transcend, Panasonic

V1.0, V1.1 microSD 128 MB Transcend, Panasonic

1

3

5

4

2

10

6

7

8

9

Note:

1. SD card slot, Ethernet interface and PS/2 interface are standard

interfaces for BP-8410M models, but optional for BP-846M+ /

BP-8463M+ models.

2. GPIO interface card includes SD card slot, Ethernet and PS/2

interfaces. So GPIO interface is an factory option for BP-8410M, but a

dealer option for BP-846M+ / BP-8463M+ models.

7

V1.0, V1.1 microSD 256 MB Transcend, Panasonic

V1.0, V1.1 microSD 512 MB Panasonic

V1.0, V1.1 microSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 microSD 4 GB Panasonic

V2.0 SDHC CLASS 6 microSD 4 GB Transcend

V1.0, V1.1 miniSD 128 MB Transcend, Panasonic

V1.0, V1.1 miniSD 256 MB Transcend, Panasonic

V1.0, V1.1 miniSD 512 MB Transcend, Panasonic

V1.0, V1.1 miniSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 miniSD 4 GB Transcend

V2.0 SDHC CLASS 6 miniSD 4 GB

- The DOS FAT file system is supported for the SD card.

- Folders/files stored in the SD card should be in the 8.3 filename format

- The miniSD/microSD card to SD card slot adapter is required.

8

2.3 Operator Controls

2.3.1 Front Panel Display

2.3.2 LED Indicators

LED Status Indication

Off The printer power is turned off

On The printer power is turned on

On Printer is ready

Blinking Pause

Downloading data into printer.

Off Printer is ready

On "CARRIAGE OPEN" or “CUTTER ERROR”

Blinking "NO PAPER", "PAPER JAM" or "NO RIBBON"

LCD display

LED indicators

Front

p

anel buttons

9

2.3.3 Front Panel Keys

Keys Function

1. Enter the menu

2. Exit from a menu or cancel a setting and return to the previous menu

Pause/Resume the printing process

Advance one label

Scroll up the menu list

Scroll down the menu list

Enter/Select cursor located option

2.4 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the provided USB cable.

4. Plug the power cord into the AC power cord socket at the rear of the printer, and

then plug the power cord into a properly grounded power outlet.

10

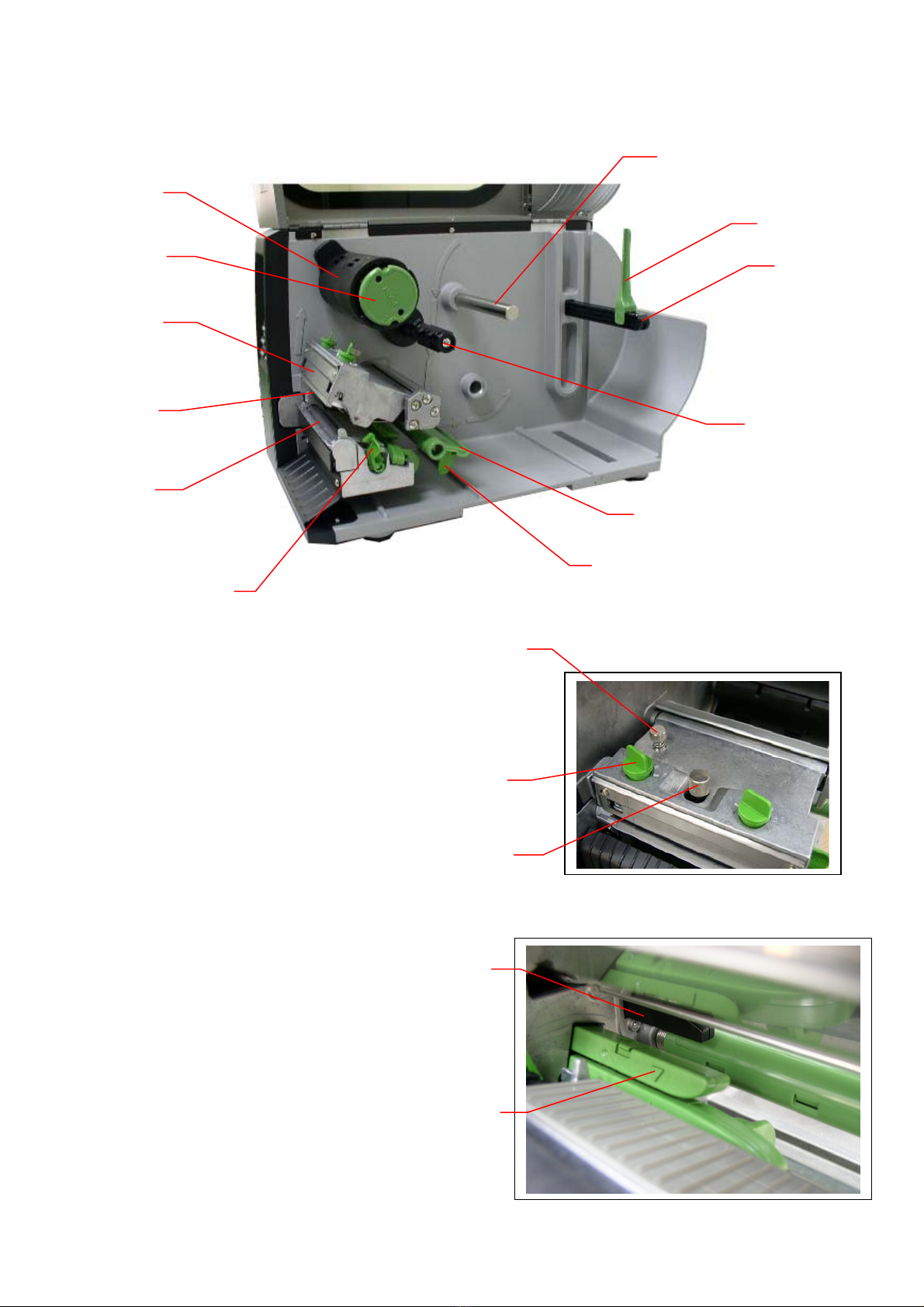

2.5 Installation of Ribbon

2.5.1 Loading Ribbon

1. Lift open printer right side cover.

2. Push the print head release lever to open the print head mechanism.

3. Install the ribbon onto the ribbon supply spindle.

4. Thread the ribbon through the ribbon sensor slot and then through the open space in

between print head and platen.

11

5. Wrap the ribbon onto the ribbon rewind spindle. Keeping the ribbon flat and without

wrinkles.

6. Wind the ribbon clockwise about 3~5 circles onto the ribbon rewind spindle until it is

smooth and properly stretched.

7. Close the print head mechanism making sure the latches are engaged properly.

Ribbon

sensor

Ribbon

12

Loading path for ribbon

13

2.5.2 Remove Used Ribbon

1. Break the ribbon between ribbon guide plate and the ribbon rewind spindle.

2. Push the ribbon release button to release the ribbon on the ribbon rewind spindle.

3. Then, slide off the ribbon from ribbon rewind spindle.

14

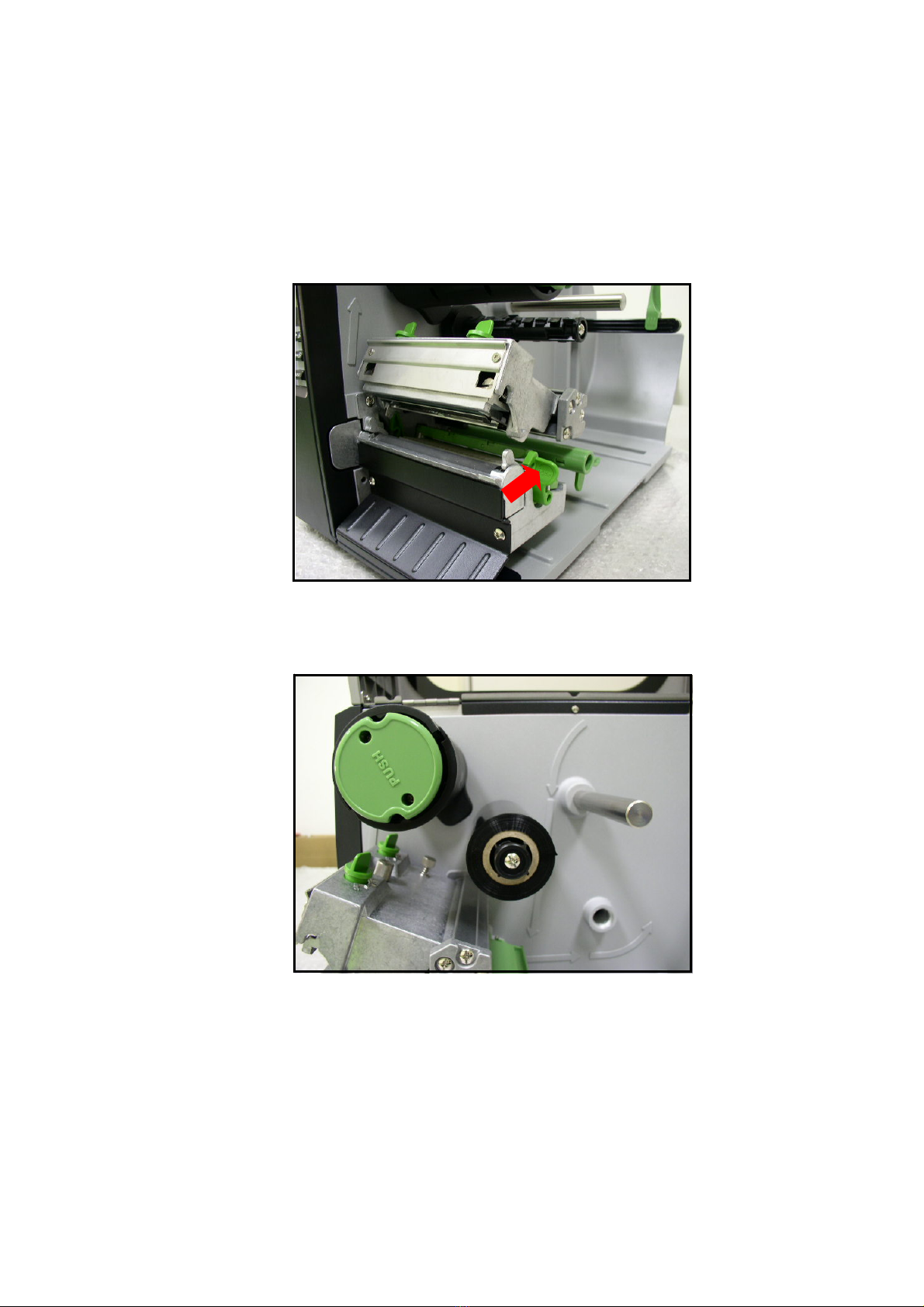

2.6 Installation of Media

2.6.1 Loading Roll Labels

1. Lift open printer right side cover.

2. Push the print head release lever to open the print head mechanism.

3. Move the label roll guard horizontally to the end of label spindle then flip down the

label roll guard.

4. Place the roll of media on the label supply spindle. Flip up the label roll guard. Move

the label roll guard horizontally to gently fit the width of label roll.

15

5. Pull label roll leading edge forward through the media guide bar, damper, media

sensor and place the label leading edge onto the platen roller.

6. Adjust the label guide to fit the width of the label.

Media guide bar

Damper

Label guide

Media sensor

Media sensor

Internal rewind

(Option)

16

7. Close the print head mechanism making sure the latches are engaged properly.

8. Using the LCD panel set the media sensor type and calibrate the selected sensor.

(Please refer to section 3.1.2)

Note: Please calibrate the gap/black mark sensor when changing media.

Loading path for roll labels

17

2.6.2 Loading Fan-fold Labels

Fan-fold media feeds through either the bottom or rear external label entrance chute.

1. Lift open printer right side cover.

2. Push the print head release lever to open the print head mechanism.

3. Insert the fan-fold media through the bottom or rear external label entrance chute.

4. Pull fan-fold label leading edge forward through the media guide bar, damper media

sensor and place the label leading edge onto the platen roller.

5. Adjust the label guide by sliding to fit the paper width.

6. Close the print head mechanism making sure the latches are engaged properly.

7. Set the media sensor type and calibrate the selected sensor. (Please refer to section

3.1.2)

Note: Please calibrate the gap/black mark sensor when changing media.

Loading path for fan-fold labels

This manual suits for next models

2

Table of contents

Other Birch Barcode Reader manuals

Popular Barcode Reader manuals by other brands

SICK

SICK CLV61 DualPort Series technical information

SICK

SICK CLV63 Series technical information

Leuze electronic

Leuze electronic BCL 8 Series Original operating instructions

Symbol

Symbol 3366 Quick reference guide

TLC

TLC Datalogic Gryphon GM4100 Series Programming guide

Honeywell

Honeywell Voyager 9520/40 quick start guide