Birch BX-211 User manual

Table of contents

1. Introduction……………………………………...1

1.1 Safety & caution………...……………….1

1.2 FCC warning..…………...……………. ...2

1.3 Labeling…………………...…………….. 2

2. General Description ..................................... 3

2.1 Product Description ............................. 3

2.2 Illustration ........................................... 3

3. Installation ................................................... 4

3.1 Unpacking .......................................... 4

3.2 Mounting ............................................ 4

4. Configuring .................................................. 6

4.1 Preface ............................................... 6

4.2 Changing Scanner Settings with

Programming Codes ........................... 6

4.3 Changing Scanner Settings with Utility

Tool .................................................... 7

4.4 Factory Default Settings ...................... 7

5. Operating Settings ........................................ 8

5.1 Scanning Triggering ............................ 8

5.2 Time Out .......................................... 10

5.3 Good Read Mode ............................. 11

5.4 Buzzer Beep Tone ............................ 11

5.5 Good Read Duration ......................... 12

5.6 Bad Read Message Settings ............. 13

6. Imager Settings .......................................... 14

6.1 Imager Mode .................................... 14

6.2 Firmware Version .............................. 14

7. Programming Codes .................................. 15

7.1 Factory Default ................................. 15

7.2 RS232 Parameters (for BX-211) ........ 16

7.3 USB Parameter (for BX-211) ............. 21

7.4 Decoding Selection ........................... 22

7.5 Australian Post Settings .................... 29

7.6 Aztec Settings................................... 29

7.7 BPO Settings .................................... 30

7.8 Canada Post Settings ....................... 31

7.9 Codabar Settings .............................. 31

7.10 Codablock Settings ........................... 33

7.11 Code 11 Settings .............................. 34

7.12 Code 39 Settings .............................. 34

7.13 Code 93 / Code 93i Settings .............. 36

7.14 Code 128 / GSI-128 Settings ............. 37

7.15 DataMatrix Settings ........................... 39

7.16 Dutch Post Settings .......................... 39

7.17 EAN /UPC Parameters Settings ........ 40

7.18 GS1 Composite Settings ................... 43

7.19 GS1 DataBar Settings ....................... 45

7.20 Infomail Settings ............................... 45

7.21 Interleaved 2 of 5 Parameters ........... 46

7.22 Japan Post Settings .......................... 47

7.23 Matrix 2 of 5 Settings ........................ 47

7.24 MaxiCode Settings ............................ 48

7.25 MicroPDF417 Settings ...................... 49

7.26 MSI code parameters Settings........... 49

7.27 PDF417 Settings ............................... 50

7.28 Planet settings .................................. 52

7.29 Plessey Code Parameters ................. 53

7.30 Postnet Settings................................ 53

7.31 QR Code Settings ............................. 54

7.32 Standard 2 of 5 Settings .................... 54

7.33 Sweden Post Settings........................ 55

7.34 Telepen Settings ............................... 55

7.35 TLC 39 Settings ................................ 56

7.36 Miscellaneous Parameters ………..... 57

7.37 Preambles and Postambles…...…..... 57

Appendixes .................................................... 59

A. Readable Symbologies ..................... 59

B. Technical Specifications .................... 60

C. Scan Map ......................................... 62

D. Test Symbologies…………………….. 63

1

1. Introduction

Thank you for purchasing this brand-new designed 2D

imager hand held barcode scanner.

This is a cutting-edge gun-type Area Imaging barcode

scanner which is designed specifically for government

administration, custom control, shipping industry and

etc.That adds on more user friendly functions and has

replaceable cable that makes it more easily to be

operated by the customers.

This high performance gun-type scanner provides the

customer with the most cost effective solution in the

market. It is perfectly suitable and definitely the best

choice for you.

1.1 Safety & caution

1) Please read the following safety statement carefully.

2) Please preserve this user manual for reference

sometime.

3) Before cleaning the device, the users must cut off

all AC power. Do not use liquid or spray type of

detersive to clean the device. Please use dampish

cotton cloth to clean the device.

4) The outlet must set nearby the device for

connecting power easily.

5) Keep the device dry to avoid short circuit.

6) During installation you must fix the equipment at

solid table to avoid damage caused by falling.

7) Before inserting power please ensure the voltage is

healthy to the equipment.

8) For safety please tie wire well and don’t put

anything on the wire.

9) If you don’t use this equipment for long time,

please cut off the power to avoid damage from

surge power.

10) Don’t spray any liquid on this scanner because it

may cause a fire or short circuit.

11) Please do not open the equipment. For safety only

the qualified serviceman can open the equipment.

12) If there are the following situations please contact

with the qualified serviceman to check this

equipment.

2

13) The damage of wire or pin of power supply.

14) Some Liquid infiltrate into the equipment.

15) The equipment has been exposed to wet

environment.

16) The equipment can’t work well.

17) The equipment has any obvious damage, making

the device working abnormally.

18) Don’t storage the device at the temperature lower

than -20°C (-4°F) or higher than +70°C (158°F) to

avoid any damage.

1.2 FCC warning

This equipment complies with the requirements in

Part 15 of FCC.

Any operation must comply with the conditions

below:

1) The equipment will not cause any severe

interference.

2) The equipment can avoid any interference from

environment.

Statement:

This product is classified as B class product.

In environment this product may cause some

interference. In this situation the user may do

something to avoid interference.

1.3 Labeling

BX-211 serial

3

2. General Description

2.1 Product Description

BX-211 is a high performance wire 2D imager barcode

scanner supporting liner, area imager barcode

scanning and picture capture.

This device is very easy to configure by this manual,

you can set up by scanning all necessary programming

codes one time that meet applications, the settings are

directly saved permanently, and all settings can be

disabled after scan reset factory default.

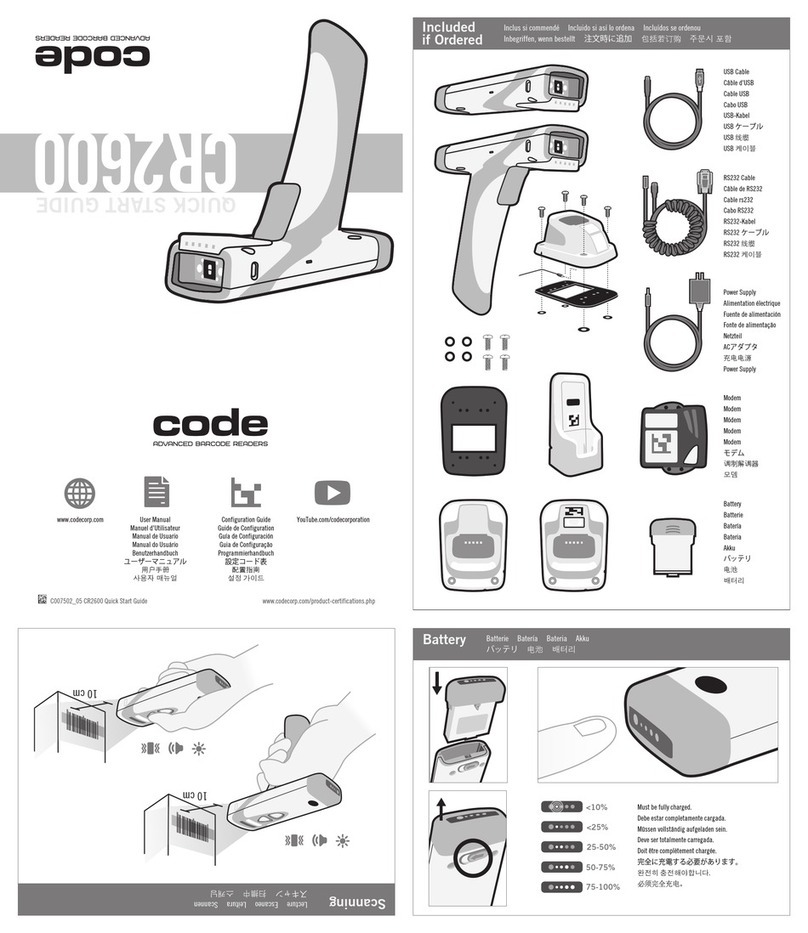

2.2 Illustration

BX-211 Series

4

3. Installation

3.1 Unpacking

1) Take device and its accessories out of the box.

2) Remove the packing material.

3) Check the standard shipment packing list to make

sure you have received all of the items ordered.

BX-211 series

- 2D Imager Scanner

- Power Adaptor (if applied)

- Communication Cable

- Quick Start Guide

4) Visually inspect the device and accessories for any

evidence of physical damage.

5) If anything is missing or appears to be damaged,

immediately contact your dealer.

ATTEN

T

ION:

Store the packing material and boxes: it should

be used whenever the device is transported for

servicing.

3.2 Mounting

Once you have unpacked all components, you can

start installing the device as below steps:

BX-211 2D Imager Barcode Scanner

1) Connect the supplied communication cable at the

bottom side of the scanner and you will hear a

“click” when the connection is made.

2) Turn off the host system.

3) Connect the communication cable to Host system.

4) Connect the Power supply (if needed) to Power

cable inlet. And plug the power supply into the AC

outlet.

5) Turn on the host system.

5

USB Driver

In case you will use the device with USB virtual com

port emulation, please contact with your dealer and

download the correct USB driver for virtual com port.

Since it is necessary to install the USB driver on

your Host system and operate correctly between the

device and your system.

Switching Cable

Before removing the cable from the scanner, it’s

recommended to turn off the power of the host

system and the power supply has been

disconnected from unit.

1) Find the small “Pin-hole” on the bottom of the

unit.

2) Use a bended regular paperclip and insert the

tip into the hole.

3) You will hear a “click”, then gentle on the strain-

relief of the cable and it will slide out of the

scanner.

Skip resistant pad position

6

4. Configuring

4.1 Preface

How to configure this device: The Barcode

Programming Feature gives the possibility to change

the scanner settings with use programming codes.

4.2 Changing Scanner Settings with

Programming Codes

You can setup your device by scanning all necessary

programming codes for parameters that meet

applications. After these scans, the device will save

directly and permanently. To go back to the factory

default settings, just scans the programming code

factory default.

In order to change the scanner settings please follow

the sequence below:

1) Power-up the scanner.

2) Change scanner settings by scanning any of the

programming code that meet applications.

An Example:

For changing the Baud rate to 38400 only scan the

programming code that represents this.

After reading a valid programming code the scanner

will give a High beep and the green led indicator will

lights on.

At any moment, you can stop your programming and

read programming code factory default to go back to

default.

7

4.3 Changing Scanner Settings with

Utility Tool

Manufacturer has setup this scanner with the most

common used programming codes, it could be

possible that you need more advanced settings to use

the scanner without any problems into your application.

In this case you can setup your scanner by using the

advanced Utility Tool. This tool can be used with the

following operation systems: Windows98,

Windows2000, Windows XP en Windows Vista.

This Utility Tool can be delivered on request. Please

contact your dealer

4.4 Factory Default Settings

The factory default settings are shown with * and bold

in the followings sections

The readable and default enable symbologies list,

please see Appendixes A.

8

5. Operating Settings

5.1 Scanning Triggering

<Level>

A reading session begins (lighting and decode

processing on) when beam is activated and stops

when beam is deactivated.

Continuous Scanning

When the scanner is turned on a continuous reading

session begins (lighting and decode processing on).

Pulse

A reading session begins when beam is activated and

stays on until a period of inactivity lasting the time

specified by the timeout.

After the timeout, the scan engine turns off.

Continuous + Flashing

When the scan engine is turned on, a reading session

begins (no need to activate the beam).

After a period of inactivity lasting the time specified by

the timeout, the scan engine starts flashing, checking

for a barcode to be read.

When a barcode is detected, the lighting automatically

turns on and stays on until another period of inactivity

(timeout).

After the timeout the scan engine starts flashing again.

9

Level + Flashing

This mode allows you the switch between level and

flashing mode.

When the scanner is turned on it is in flashing mode

(see flashing mode for explanation).

You can automatically switch to level mode by

activating the beam line.

After a period of inactivity lasting the time specified by

the timeout the scan engine switches back to flashing

mode.

Flashing

Flashing mode allows power up the lighting and

decoding are on (no need to activate the trigger line)

and after a period of inactivity lasting the time specified

by the trigger timeout, the scanner starts flashing,

checking for a bar code to be read.

When a bar code is detected, the lighting and decoding

automatically turn on and stay on until another period

of inactivity (timeout), after the timeout the scanner

starts flashing again.

Autostand

This mode allows you to switch from Flashing trigger

mode to Level trigger mode.

Autostand begins in flashing mode: At power up the

lighting and decoding are on (no need to activate the

trigger line) and after a period of inactivity lasting the

time specified by the trigger timeout, the scanner starts

flashing.

To switch to Level trigger mode activate the trigger line

(press the trigger).

When in Level trigger mode, after a period of inactivity

lasting the time specified by the trigger timeout, the

scanner switches back to flashing mode.

10

Toggle

This mode allows lighting and decoding toggle when

the trigger line is activated.

First trigger activation = lighting and decoding on,

second trigger activation = lighting and decoding off.

Presentation

This mode allows power up lighting and decoding are

on. After a period of inactivity lasting the time specified

by the trigger timeout, the lighting turns off or is

dimmed. When a new bar code is presented the

lighting and decoding restart and stay on until another

period inactivity.

5.2 Time Out

<2 sec>

4 sec

6 sec

11

5.3 Good Read Mode

When active, the scan engine stops the reading

session after a successful decoding.

Note: This parameter is NOT used with continuous and

continuous + flashing modes.

<Active >

Not Active

5.4 Buzzer Beep Tone

5.4.1 Beep Tone Setup

<High >

Medium

Low

5.4.2 Good Read Beeps

<One Beep >

Two Beeps

None

12

5.4.3 Beep Duration

60 msec

<80 msec>

200 msec

Off

5.4.4 Timing

<During Transmission>

Before Transmission

After Transmission

5.5 Good Read Duration

5.5.1 Good Read Led Duration

<80 msec >

0.5 sec

13

1 sec

Off

5.5.2 Error Beep

<On >

Off

5.5.3 Setup Beep

<On>

Off

5.6 Bad Read Message Settings

<Default = "NOREAD" >

Active

<Not Active >

14

6. Imager Settings

6.1 Imager Mode

You can set the best reading performance depends on

the environment, your used application and type of

barcodes.

Linear mode for decode 1D Barcodes.

Area mode for decode 1D and 2D barcodes.

Area mode allows you to set the position of the BX-211

in any direction regardless of the orientation of the

barcode, and perform a good read on 1D and 2D

barcodes.

Linear mode allows you to increase your decoding

speed while scanning 1D barcodes. But, you need to

position the beam across all bars in the 1D barcode.

<Area imager>

Linear imager

1D and 2D Codes, Bright Environment

1D and 2D Codes With

Reflective Surface

6.2 Firmware Version

Display the firmware version of the scanner, please

scan below barcode.

Firmware Version

15

7. Programming Codes

7.1 Factory Default

The default RS232 settings are 57600 baud, 8 data

bits, and no parity.

The factory default settings are shown with bold

< > in the following pages.

7.1.1 To set the scanner parameters to factory

default

Set factory default

Reset all configuration parameters to their factory

default setting. After this reset you must select all

required parameters that meet applications.

16

7.2 RS232 Parameters

7.2.1 Baud Rate

75

150

300

600

1200

2400

4800

9600

19200

38400

<57600>

115200

17

128000

230400

256000

460800

7.2.2 Data Bits

Data Bits 7

<Data Bits 8>

7.2.3 Stop Bits

<Stop Bits 1>

Stop Bits 2

7.2.4 Parity

<None>

Even

Odd

Table of contents

Other Birch Barcode Reader manuals