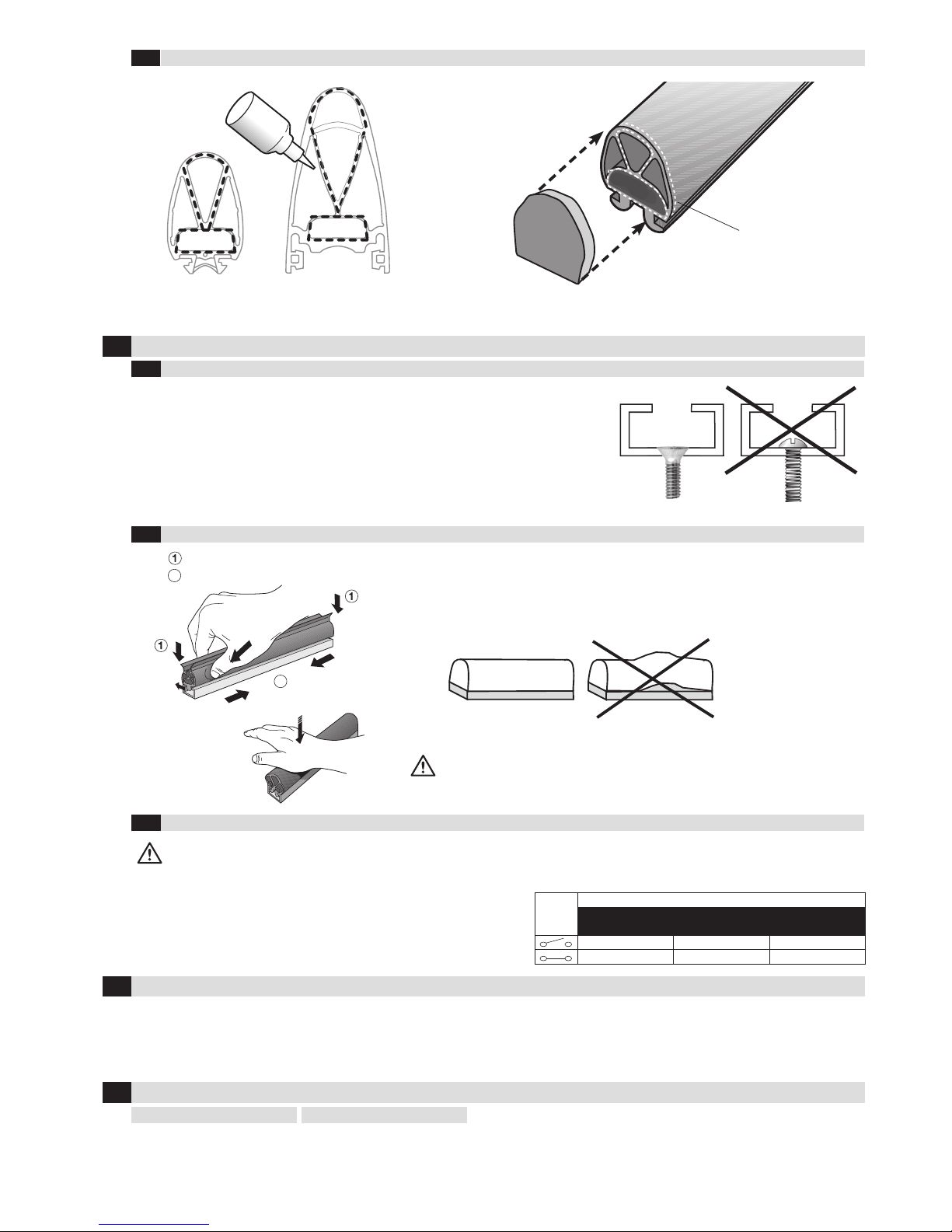

Mounting the rubber prole 4.2

Moisten «click-t foot» rubber proles with a solution of soapy water and press into the

aluminium prole (do not pull in).

To ensure correct functioning of safety edges with a click-t foot, after moun-

ting, the safety edge must be pressed in along its entire length to make sure

the foot engages properly in the aluminium bar.

Otherwise, the safety edge will connect through. Check t of rubber prole in

aluminium strip.

2

2

Final checks4.3

Check the resistance of the safety edge with an ohmmeter.

Notice: The overall safety of the machine and its protection systems

depends on the quality, reliability and correct connection of the inter-

faces.

Warning: Perform a nal functional and visual check of the safety edge. Once mounting is complete, test the safety edge on

the object to make sure it functions correctly. The protection system must also satisfy the force, overtravel and sensitivity

requirements of the standards applicable in the relevant country.

The safety edge is maintenance-free. If damage occurs, such as a brittle or torn rubber prole, non-tight switching chamber, insucient contact

resistance in the activated state (>500 ohms) or similar, the safety edge must be replaced immediately. Please request a new one, remembering

to state the product designation.

Check the resistance of the safety edge with an ohmmeter, referring to the table above.

Maintenance

5

6Contact details

Manufacturer

Bircher Reglomat AG

Wiesengasse 20

CH-8222 Beringen

www.bircher-reglomat.com

Press in prole at both ends

Work from outside inwards

Glueing on the end caps3.3

ES-KLEBER

Attach end caps by applying ES-KLEBER to the points shown and hold in place, applying pressure across the whole area, for approx. 10 seconds.

Note: No end caps on ELE040/081 and ELE040/105

Attaching aluminium strip4.1

Attach aluminium strip to object with countersunk head screws. Recommended hole

spacing 300 mm. Make sure aluminium strip is securely attached to ends of safety edge.

You may have to make holes for the cable to exit.

NB: In the case of 2-panel systems, the two proles should be aligned facing each other.

The same applies to any counter sealing prole.

Notice: If possible, avoid routing the cable through the aluminium prole as it may press

against the switching chamber.

T-foot rubber proles should be pulled into the aluminium.

Any burrs on the aluminium prole must be removed rst.

End pieces

ENEH-8

ENES-8

ENEH-0

ENES-0

ENEH-K...

ENES-K...

8.1 - 8.5 kΩ ∞ ∞

< 500 Ω < 500 Ω < 500 Ω

Mounting the safety edge

4

c

c

Glue

4

Danish seller

Swissdoor ApS

Stenhuggervej 2

DK-5471 Soendersoe

Tlf.: +45 86 28 00 00

www.swissdoor.dk