ENGGA EVC300i User manual

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

1. INTRODUCTION

2. ENVIRONMENTAL

3. TECHNOLOGY SPECIFICATION

The EVC300i Voltage Regulator is thyristor base to control the DC exciter field power of conventional

50 or 60 Hz brushless generators. The AVR circuitry includes under speed and over load protection

features. Excitation power is derived directly from the generator terminals.

-30 to 80°C (-22 to 176 F)

-40 to 80°C (-40 to 176 F)

Less than 2800 meter

<90%

2.1. Operating temperature:

2.2. Storage temperature:

2.3. ALTITUDE:

2.4. RELATIVE HUMIDITY:

Sensing Input

Power Input

Voltage Adjust Range

Field Resistance

Voltage Regulation

Output Voltage

Output Current

Terminal V - V for 220 Vac

Terminal V - V for 400 Vac

Voltage: 180 to 250 Vac

Frequency: 50 Hz or 60 Hz

180 - 300 Vac, 300 - 520 Vac

< 1%

Maximum 90 Vdc @ 240 Vac

Maximum continuous: 6.3 A @ 240 Vac

10 second forcing: 10 A @ 240 Vac

220

380

Recommend 9 - 24

±

Ω

Paralleling

Voltage Buildup

External Volts Adjustment

Thermal Drift

Analog Voltage Input

Current Compensation

Dimensions

Weight

Internal burden and adjustment for 0 to 10%

droop at 1 A, 0.8 PF, (from external CT)

4Vac, 30 Hz

At least 10% with 100k ohm 1 watt trimmer

0.05% per ‘C’change in AVR ambient

In : 1A Input

Not Less than 10 % @ P.F. = 0.8

122 mm L x 93 mm W x 38 mm H

300 10g

±

±5VDC, adjustable output voltage is no less than

2% for 1VDC (i.e. for ±5VDC it come out to be

±10%)

±

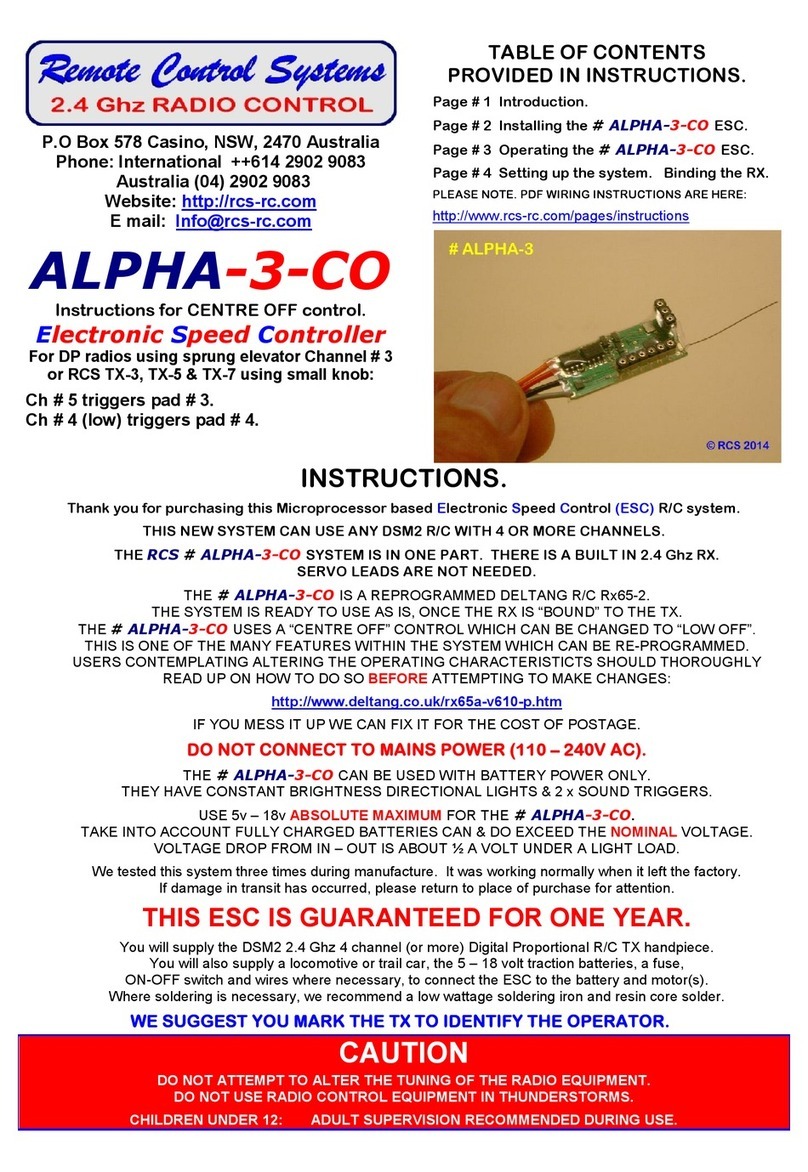

EVC300i

Generator Automatic Voltage Regulator

Operation Manual

Page 1 of 7 Updated on 02 Feb2015

Updated on 02 Feb2015

122 mm

93 mm

80 mm

108 mm

VOLT STAB UFRO DROOP

ENGGA

www.engga.com.cn

Sensing Input : V - V220 for 220Vac , 180 to 250Vac, 50/60 Hz

V - V380 for 400Vac , 350 to 480Vac, 50/60 Hz

Power Input : 180 to 250Vac, 50/60Hz, 1

Output : 90 Vdc,6A

EVC300i

Figure 1. Outline Drawing

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

Page 2 of 7

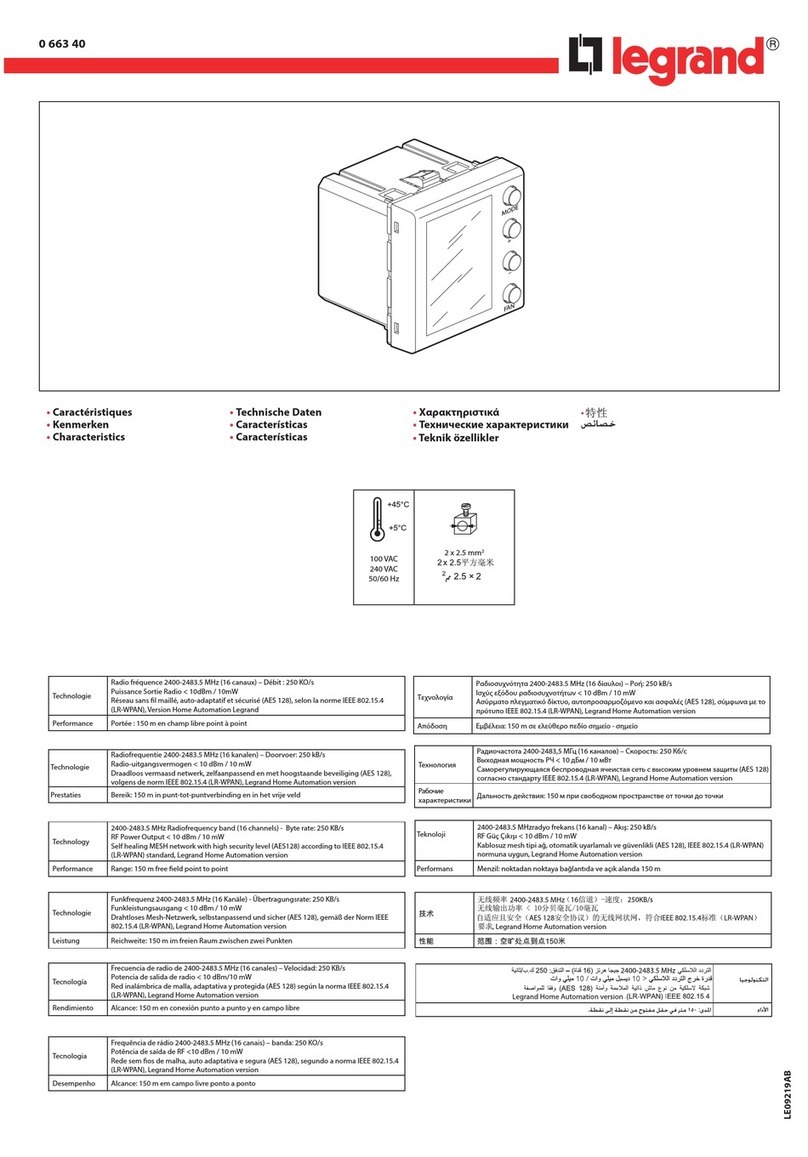

4. MECHANICAL SPECIFICATION

DRAWING

S 1 ON - Increase in

Response Time.

OFF - Response as per

STAB pot Set

:

SW : ON - 60 HZ

OFF - 50 HZ

2

122 mm

93 mm

108 mm

80 mm

S1S2 VR VR V380 N

V220 V F+ F-

2 1

A-

A+

2 X 4.4 mm

1

2

O/L

LED

O/L

POT

TRIM

UFRO LED

FUSE 6.3 Amps

38 mm

U

U

U

F+

V

V380

VR1

S1

S2

VR2

V220

NF-

H

Figure 2. The Drawing For Trimmer

ON

W

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

AVR can be mounted directly on the generator, switchgear or control panel that conforms to the

mounting specification.

All voltage readings are to be taken with an average-reading voltmeter. Meggers and high-potential test

equipment must not be used with AVR connected to generator. Use of such equipment could damage

the AVR.

5. WIRING

1. V - V - V : Sensing Input Voltage.

V

output voltage 220Vac

output voltage 400Vac

2. F+. F- : Excitation Output

3. Power Input:

For 400 Vac system

For 220 Vac system

4. S1 - S2:

220 380

Sensing Input is between & (220Vac) or

& (400VAC). For 2 Phase sensing one

phase is connected to terminal of AVR and

second phase is connected to or as

explained below:-

- For generator , connect

sensing phase to terminal .

- For generator , connect

sensing phase to terminal .

The sensing should be connected “Line to Line”

from generator output. Refer Figure 3 & 4.

.

Connect the brushless exciter field to terminals F+

and F-. Be sure to observe polarity.

AVR power input is between N

& V. N is connected to

Neutral of generator & V to V Phase of generator.

, N is connected to U Phase

& V to V Phase of generator. Refer to Figure

3 & 4.

Current compensation input.

Current Transformer(CT) secondary current = 1A,

0.8 PF.

V V

V

V

V V

V

V

220

380

220 380

220

380

External Voltage Adjustment.

If an external voltage adjust control is being used,

connect a 100 K / 1 watt potentiometer to

terminals and as shown in Figure 3 & 4.

If not in use then let VR1 & VR2 is left open.

: Analog Voltage Input.

Fully isolated analog voltage from PF controller or

any other type of Digital (PLC) controller can be

injected into AVR for variation of generator output

voltage. Analog voltage range is ± 5VDC maximum

and can be connected to A+ & A- terminals for

at least 10 % variation in terminal voltage.

When 60Hz operation, AVR response

time needs to be reduced. For that turn ON Switch1

so that extra fixed response time is now added with

STAB POT setting such that no over or under shoot

of voltage occurs during loading-unloading of

generator at 60Hz.

: When 50Hz operation, no need to

decrease response time as STAB POT setting is

proper for optimum stability of generator with

minimum over-under shoot of Voltage during

loading - unloading of generator.

For 60 Hz operation of UFRO

For 50 Hz operation of UFRO

5. VR1 - VR2:

VR1 VR2

6. A+ & A-

7. DIP SWITCH:

a) SW1 - ON:

SW1 - OFF

b) SW2 - ON:

SW2 - OFF:

6. ADJUSTMENT

All trimmer build in back of the AVR board, except

the and Trimmer. The trimmers include

as shown in

Figure 2. For Trimmer and Trimmer refer

to Figure 1

The generator output can be altered by

adjustment of the trimmer on the AVR board,

or by the external trimmer (100K ohm 1W) if fitted.

a) The terminals and must be left

unconnected if no hand trimmer is required.

O/L TRIM

DROOP, UFRO, STAB and VOLT

O/L TRIM

1. VOLT: Voltage Adjustment.

VOLT

Vset is factory set for 400 Vac , If Vset is

disturbed and set value is not known then

proceed as below :

VR1 VR2

.

Connect a voltmeter to generator output voltage

terminals.

d) Start the generator set and run on no load at

nominal frequency 50 - 53 Hz or 60 - 63 Hz.

e) If the red Led is illuminated, refer to the under

frequency roll off adjustment.

f) Carefully turn volt trimmer clockwise until rated

voltage is reached.

Stability Pot is factory set for optimum performance

& is advisable not to disturb. But if required then

with the generator in ON Condition, rotate STAB

POT clockwise direction till voltage start oscillating

fast.

b) Before starting the generator, please turn the

trimmer on the AVR board fully anti-

clockwise.

c)

VOLT

2. STAB: Stability Adjustment.

Page 3 of 7 Updated on 02 Feb2015

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

Page 4 of 7

value (which is set using O/L POT), internal timer

starts and if overloading condition continues for 20

seconds then after 20 seconds AVR cuts off field

voltage and generator voltage is shut off. O/L LED

continues to light indicating O/L Trip. Adjustable from

0.1Amp to 7Amp DC. When O/L POT is fully

anticlockwise is minimum setting and fully clockwise

is maximum. Internal delay timer is fixed and delay

time is 20 seconds ±1%

To operationally test any EVC300i, refer to Figure 5

and perform the following steps:

a. Connect the voltage regulator as shown in Figure

5 and apply 230 Vac 50 Hz.

b. Adjust the rear panel trimmer fully

clockwise (CW).

RESULT: Observe that the lamp lights up full.

c. Adjust the rear panel trimmer fully counter-

clockwise (CCW).

RESULT: Observe that the lamp is not lit.

d. Adjust the rear panel trimmer until the

lamp just goes out.

Regulator operation is satisfactory if the above

results are obtained. Stability, however must be

tested with the generator and regulator operating.

OPERATIONAL TEST

VOLT

VOLT

VOLT

From this position, rotate STAB POT anti-

clockwise direction till voltage is stable. Load the

generator and check for stable voltage and if not

then rotate more towards anticlockwise till voltage

is stable.

The EVC300i under frequency adjust is factory

preset to cause voltage drop in the generator

line voltage when the frequency is between 56.8

and 57.2 Hz for 60 Hz applications. For 50 Hz

applications, the frequency roll-off is factory preset

to between 46.8 and 47.2 Hz.

To reset the frequency roll-off, proceed as follows:

a. Adjust the prime mover RPM to the desired

frequency compensation (corner frequency roll-off)

point.

b. If UFRO LED is ON adjust the back panel

trimmer anticlock wise to just OFF the LED

If UFRO LED is OFF then adjust UFRO trimmer

clockwise to turn ON LED and then anticlockwise

to just turn it OFF.

c. Bring the prime mover up to rated speed. The

output voltage should return to set level.

Generator intended for parallel are fitted with a

quadrature droop CT which provides a power

factor dependent signal for the AVR. The CT

connected to and of AVR. CT with

secondary N:1A is required to provide minimum

10% droop at 0.8 PF. Percentage of droop

required can be adjusted using DROOP POT in

the range of 0 to 10%. Fully anticlockwise is 0%

and fully clockwise is maximum as per CT current

and load power factory. Factory set is 0% so that

mostly during solo operation there is no droop in

terminal voltage.

Trim Pot is used to decrease the effect of analog

input voltage on generator output voltage. When

set fully anticlockwise, there is no variation in

generator voltage on application of DC voltage on

A+ & A- Fully clockwise has maximum effect. Thus

using this POT we can get intermediate

percentage variation of the full scale - 10% at

± 5VDC.

.

Over load protection provides protection to

generator against overloading. It is based on field

current when field current increase above set

3. UFRO: Frequency Roll-Off Adjustment.

UFRO

4. DROOP: Droop Adjustment.

S1 S2

5. TRIM: Analog Voltage Input Adjustment.

6. O/L : Over Load Protection

Updated on 02 Feb2015

Figure 3. Connection Diagram for 400 Vac Operation

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

Page 5 of 7

S1 S2VRVR

V380

NV220

V

F+F- 21

Exciter

Field

+

-

Armature Stator Wire

100K/1W

+ 5 Vdc Analogue Input

CT

1A

1

2

W

N

V

U

-

IN :

A+A-

FUSE 6.3 Amps

O/L LED

O/L POT

TRIM

ON

SW : ON - 60 HZ

OFF -50 HZ

.2

SW1 ON - Increase in

Response Time.

OFF - Response as per

STAB pot Set

:

Note : All doted lines are optional connections.

Updated on 02 Feb2015

UFRO LED

Figure 4. Connection Diagram for 200 Vac Operation

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

Page 6 of 7

S1 S2VRVR

V380

NV220

V

F+F- 21

A+A-

Exciter

Field

+

-

Armature Stator Wire

+/- 5 Vdc Analogue Input

W

V

U

CT

1A

IN :

100K/1W

SW : ON - 60 HZ

OFF -50 HZ

.2

SW1 ON - Increase in

Response Time.

OFF - Response as per

STAB pot Set

:

FUSE 6.3 Amps

O/L LED

O/L POT

TRIM

ON

1

2

Note : All doted lines are optional connections.

Updated on 02 Feb2015

UFRO LED

UFRO LED

Figure 5. Operational Test

OPERATING MANUAL FOR AUTOMATIC VOLTAGE REGULATOR

MODEL NO : EVC300i

Page 7 of 7

S1 S2VRVR

V380

NV220

V

F+F- 21

220V100W

LAMP

230Vac/50Hz

A+A-

FUSE 6.3 Amps

O/L LED

O/L POT

TRIM

SW : ON - 60 HZ

OFF -50 HZ

.2

SW1 ON - Increase in

Response Time.

OFF - Response as per

STAB pot Set

:

ON

1

2

Updated on 02 Feb2015

Table of contents

Other ENGGA Controllers manuals