Note

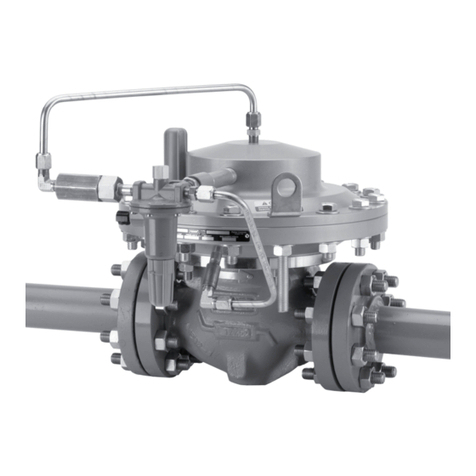

backpressure regulator be installed

case is unobstructed at all times. For

or downspouts and be sure it is above

CAUTION

®E-body, damage

if necessary.

Overpressure

Maximum inlet pressures depend upon body

materials and temperatures. Refer to the nameplate

for the maximum inlet pressure of the relief valve

or backpressure regulator. The relief valve or

backpressure regulator should be inspected for

damage after any overpressure condition.

valve or backpressure regulators are NOT ASME

safety relief valves.

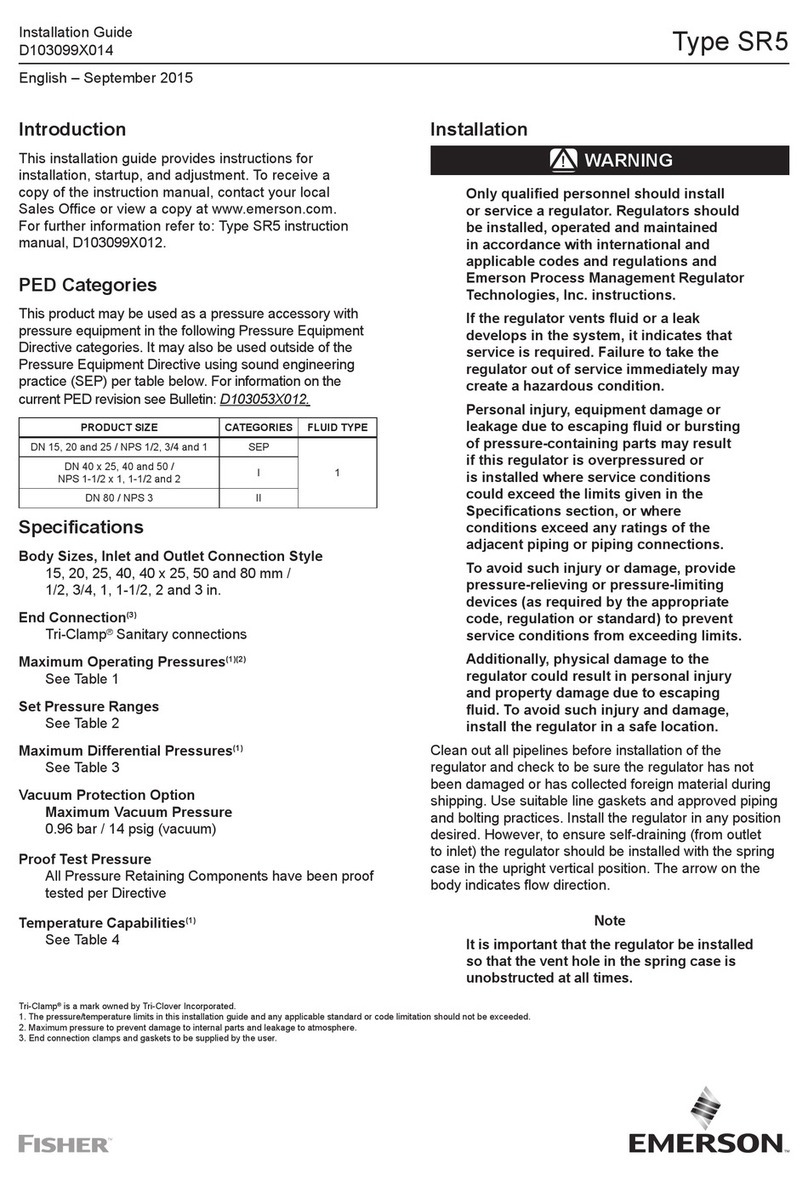

Table 1. Type LR128 Main Valve Body Sizes, End Connection Styles, Structural Design Ratings and

Maximum Operating Inlet Pressures(1)

MAIN VALVE

BODY SIZE MAIN VALVE

BODY MATERIAL END CONNECTION STYLE

STRUCTURAL

DESIGN RATING(3)

MAXIMUM OPERATING

RELIEF (INLET)

PRESSURE INCLUDING

BUILD-UP(3)

MAXIMUM

OPERATING OUTLET

PRESSURE

DN In. bar psig bar psig bar psig

25, 50,

80 and

100

1, 2,

3 and

4

WCC Steel

NPT or SWE (1 and 2 in. only) 103 1500 31.0 450 31.0 450

CL150 RF 20.0 290 20.0 290 20.0 290

CL300 RF 51.7 750

31.0 450 31.0 450CL600 RF 103 1500

PN 16/25/40 RF 40.0 580

CF8M

Stainless steel

NPT (1 and 2 in. only) 99.2 1440 31.0 450 31.0 450

CL150 RF 19.0 275 19.0 275 19.0 275

CL300 RF 49.6 720

31.0 450 31.0 450CL600 RF 99.2 1440

PN 16/25/40 RF 40.0 580

1. The pressure/temperature limits in this Installation Guide and any applicable standard or code limitation should not be exceeded.

2. Ratings and end connections for other than ASME standard can usually be provided. Contact your local Sales Ofce for assistance.

3. Maximum cold working pressure (CWP) per ASME B16.34 or product bulletin limit, whichever is lowest. Temperature may decrease these maximum pressures.

Table 2. Type MR98H Pilot Maximum Cold Working Pressure(1)(2)

BODY SIZE BODY AND SPRING CASE MATERIAL MAXIMUM INLET PRESSURE MAXIMUM OUTLET PRESSURE

1/2 NPT Steel or Stainless steel 31.0 bar / 450 psig 31.0 bar / 450 psig

1. The pressure/temperature limits in this Installation Guide and any applicable standard or code limitation should not be exceeded.

2. Temperature and/or the body end connection may decrease these maximum pressures.

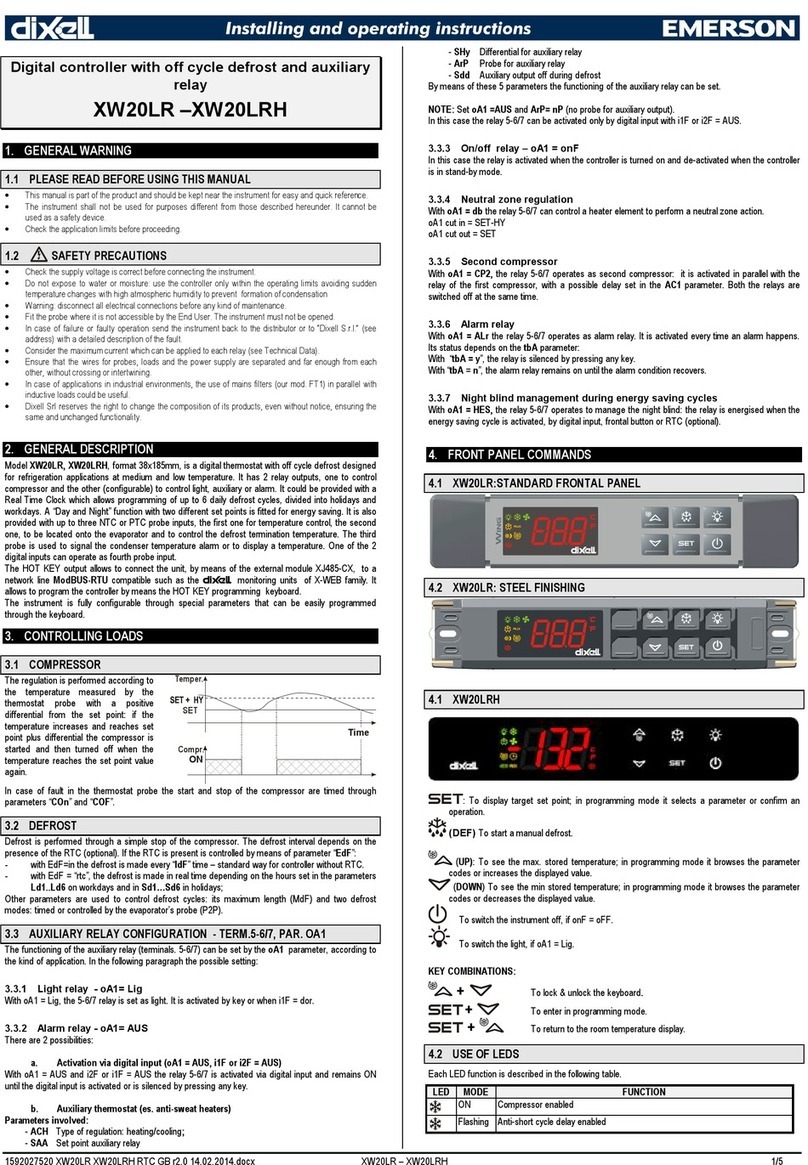

Startup

The relief valve or backpressure regulator is factory

set at approximately the midpoint of the spring range

or the pressure requested, so an initial adjustment

may be required to give the desired results. With

proper installation completed and relief valves properly

adjusted, slowly open the upstream and downstream

shutoff valves (if applicable).

To change the outlet pressure, remove closing

cap or loosen the locknut and turn the adjusting

screw clockwise to increase outlet pressure or

counterclockwise to decrease pressure. Monitor

the outlet pressure with a test gauge during the

adjustment. Replace closing cap or tighten the locknut

to maintain the desired setting.