Bircher Swissdoor InTra6 3 User manual

Mode

Data

Translation of the original instructions

Safety an warning notices

InTra6 3, InTra6 3.LVAC

«Data» button

➔The electrical connection may only be set up by an electrician. ➔ The arrangement of the components depends on the structural conditions and

the gate design. ➔ Switch off the operating voltage before working on the system. ➔ The switching device monitors pressure-sensitive protective

devices from Bircher Reglomat A (proper use). ➔ Use of components not supplied by Bircher-Reglomat (including safety edges) will render the

guarantee and liability null and void. ➔Connect all operating and switching voltages to the same fuse. ➔Connect the operating voltage to the

same circuit as the industrial door controller. ➔Disconnect device from mains in the event of a fault. ➔Protection max. 10 A

Switching device with inductive transmission system used in combination with safety

edges to avoid dangers at crushing and shearing points in sliding gate systems.

Operation Display

3

Control buttons

on device:

«Mode» button

Please keep for future reference!

Diagnostic menu

5

Press the «Mode»and «Data»buttons simultaneously for 2 s ➔status LED flashes orange. Press «Mode»buttons briefly to change to the next mode.

Press the «Mode»button for 2 s to exit diagnostic menu.

Mode «C» current configuration Mode «h» current fall-delay time

Displays current configuration of

safety edge inputs, see configura-

tion table.

Configuration ➔ chapter 6

Displays current fall-delay time,

see fall-delay time table.

Configuration ➔ chapter 6

Mode «S» Both outputs

12

CLOSE Output

OPEN Output

Mode

Data

Dots

= Symbol for display flashes

System components

1

1

579

3

4

4322

76

9

5

1

Hole

grey

Hole

red

Mobile safety edge CLOSE

(primary closing edge)

INTR-MOB62, converter for

mobile safety edge

Mobile safety edge OPEN INTR-FIX60, coil

Stationary safety edge CLOSE InTra6 3, switching device

Stationary safety edge OPEN Steel cable (see chapter 9.3)

INTR-MOB61, converter for

safety edge

Open

Open

Close

Close

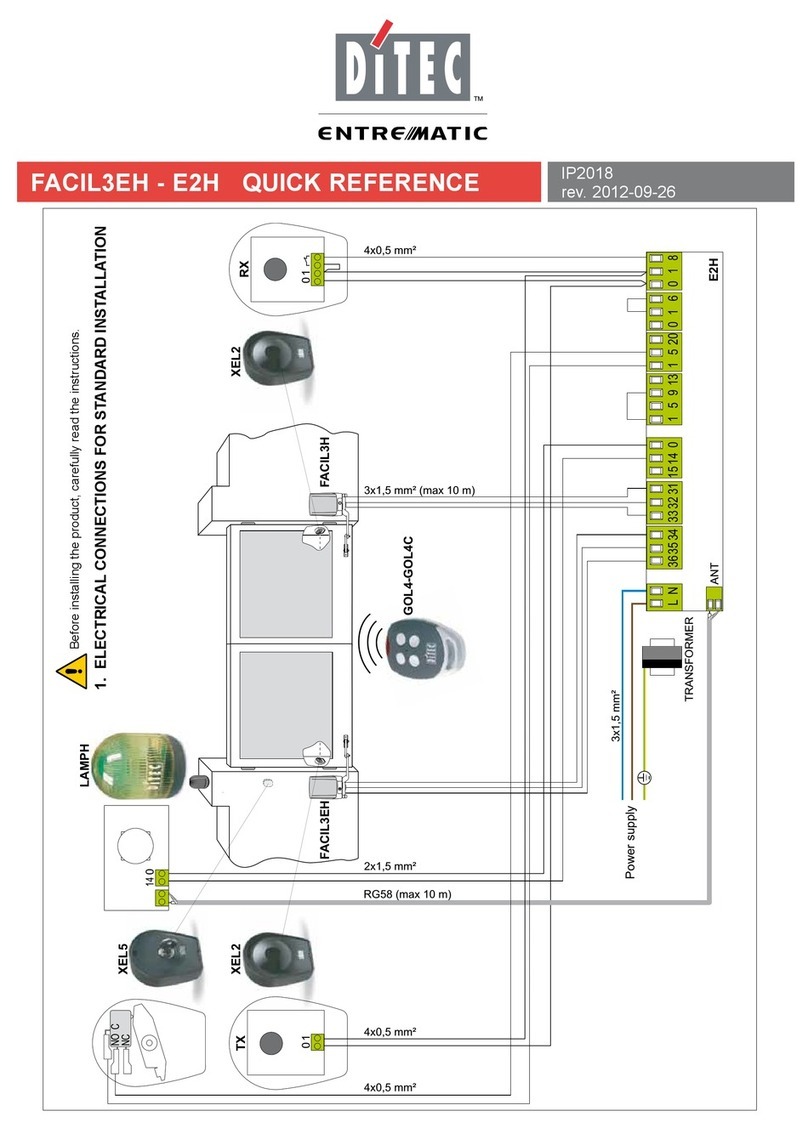

Electrical connection an terminal iagram

2

V rsion Op rating

voltag

Stationary saf ty

dg CLOSE

Stationary saf ty dg

OPEN

Coil

conn ction

Output

CLOSE*

Output

OPEN*

InTra6 3

InTra6 3.LVAC

+/~

–/~

A1

A2

1

2

3

4

TX

BN

WH

GN

YE RX

14

11

21

24

When everything is connected correctly:

Display after switching on:

Status LED lights up green

1

2

1

2

4

Dots

flash

Displays shown when safety edge is actuated: Status LED lights up orange

actuated: actuated: actuated: actuated:

Stan ar operation

Mode «r» Resistance Mode «S» Output CLOSE Mode «S» Output OPEN

Error display mode

The 5 most recent errors

can be interrogated.

The resistances of the

safety edges are displayed

Press the «Data»key briefly in

each case, and the errors are dis-

played one after the other. End

appears when the «Data»button

is pressed for the 5th time. The

malfunctions are displayed in

chronological order (new ➔ old)

Example:

8 = Resistance between

7 and 9 kohm.

1 = safety edge

To access the next safety edge:

Press the «Data»button

To access the configuration mode:

Press the «Mode» button

* The outputs are monitored ➔need to be connected, otherwise an error code is displayed (E007)!

– CLOSE output is deactivated

– No current flow ➔ OK

– Current flow ➔error

– Press the «Data» button

– No current flow ➔Error

(consumer missing)

– CLOSE output is activated

– Current flow ➔ OK

1

1

1

1

– OPEN output is deactivated

– No current flow ➔ OK

– Current flow ➔error

– Press the «Data» button

– No current flow ➔Error

(consumer missing)

– OPEN output is activated

– Current flow ➔ OK

2

2

2

2

– Both outputs deactivated

– No current flow ➔OK

– At least 1 output with current flow ➔Error

– Press the «Data» button

– At least 1 output without current flow

➔Consumer missing

– Both outputs are activated

– Current flow ➔OK

12

12

12

12

ENGLISH

255838W

08/13

Configuration fall- elay time

6.3

Display Fall-delay time

001 none

002 100 ms

003*200 ms

004 500 ms

005 1000 ms

Most important technical ata

8

Press the «Mode» button briefly.

Use the «Data» button to set the required fall-d lay tim (according to Table 2).

Then briefly press the «Mode» button and End appears.

➔ The system is configured.

➔ Press «Data» button to restart.

Configuration mo e (for configuration before starting up, via diagnostic menu, after mode «h»)

6

Please read chapters 6.1 to 6.3 in full before attempting configuration.

Configuration of saf ty dg inputs

6.2

Tabl 2

Display E001 E002 E003 E004 E005 E006 E007 E101/ E102

Error Safety edge (SE)

malfunction

SE mal-

function

SE mal-

function

SE mal-

function

Cable circuit

malfunction

Mounting ≠config.

mode Outputs not OK Undervoltage/

overvoltage

R m dy Check

safety edge

Check

SE

Check

SE

Check

SE

Check cable

circuit < 3 ohm

Check

configuration

Check connection

for outputs Check supply

12

Error isplays

7

If an error is detected then the outputs are deactivated and symbols & and an error code are displayed. The status LED lights up red.

Should other fault messages appear, please contact your supplier.

Configuration m nu can be xit d at any time by pressing the

«Mode» button (2 s).

«End» is displayed ➔Press «Data» button and release

➔Restart undertaken with new configuration.

Error messages may occur when restarting

after configuration if the inputs do not match

the configuration.

Activating configuration m nu

6.1

Status LED flashes orange,

press «Data» button

Press the «Mode» and «Data» buttons

simultaneously for 2 s.

Configuration menu is activated.

Use the «Data» button to set the configuration

you want for the safety edge inputs

(according to Table 1).

The current setting for the safety edge

inputs is displayed. Display

Mobile

safety

edge

CLOSE

Mobile

safety

edge

OPEN

Stationary

safety

edge

CLOSE

Stationary

safety

edge

OPEN

not configured

001* X X X

002 X X X X

003 X X

004 X X

005 X

006 X X X

007 X X X

008 X X

009 X X

010 X

011 X

UNC

*) Factory setting

Tabl 1

*) Factory setting

Operating voltage

InTra6 3 24 V AC/DC ± 15%,

InTra6 3.LVAC 100-240 V AC

50/60 Hz

Power consumption max. 3 VA

Safety edges 8,2 kOhm

Outputs Semiconductor relay, 24 V DC, max. 50 mA

Dimensions

(W x H x D)

Switching device 22,5x94x88 mm

Coil : 50x25x22 mm

Converter : 40x25x22 mm

Electrical installation

9.1

Mechanical mounting

9.2

Mounting

9

1. Check that electrical components are all present by referring to component list 9.3.

2. Mount switching device in designated position.

3. Mounting of mechanical parts (see chapters 9.2 and 9.3).

4. Connect electrical lines as shown in terminal diagram in chapter 2.

1. Check that mechanical components are all present by referring to component list 9.3

2. Mount the two mounting brackets and the coil .

3. Pull in the steel cable (see chapter 9.4 and 9.5). Mount converter INTR-MOB or .

4. Tension the steel cable cable and fix it via the retaining screw . Th st l cabl must b abl to mov unimp d d

through th INTR-FIX60 coil along th full l ngth of th gat .

5. Connect steel cable as described in chapter 9.5. Make sure the connection with the gate offers low resistance

(clean the contact points and remove any paint).

6. Establish the electrical connection as shown in the terminal diagram in chapter 2.

List of electrical components

9.3

Arrangement on a gate (example)

9.4

INTR-ASK60 components

Mounting bracket 2 For fastening the cable to the gate

Banjo bolt, smooth, 8x60 with steel

cable fixing screw (M4x10) 1Part of cable tensioning device

Banjo bolt 1 Part of cable tensioning device

Cable lug 2.5 mm2 2 For connecting steel cable to gate

Compression spring 1 Part of cable tensioning device

Hexagon bolt M6x12

including washer 6For fastening bracket / cable to gate

Hexagon nut M6 2 Part of cable tensioning device (on banjo bolt)

Plastic sleeve 2 For insulation between banjo bolt / hollow pin and mounting bracket

U-shaped washer for M8 2 Part of cable tensioning device (on banjo bolt)

Screw M4 x 10 2 For fixing the cable in the banjo bolt / hollow pin

Components Image Qty No. Function

INTR-MOB61 (grey) 1 Converter, mobile sensor unit, transmits sensor status of primary closing edge

INTR-MOB62 (red) evt. 1 Converter, mobile sensor unit, transmits sensor status of mobile secondary closing edge

INTRA6 3 switching device 1 Evaluation and switching device

INTR-FIX 1Coil, transmits energy and information

Steel cable 1 Steel cable, forms the low-resistance cable circuit together with the gate structure

(< 3 ohm!)

Manufacturer:

Bircher Reglomat AG

Wiesengasse 20

CH-8222 Beringen

Switzerlan

www.bircher-reglomat.com

Authorise representative:

Bircher Reglomat GmbH

Robert-Bosch-Strasse 3

D-71088 Holzgerlingen

Germany

www.bircher-reglomat.com

Contact ata

11

Manufacturer: Bircher Reglomat A , Wiesengasse 20, CH-8222 Beringen

Employee responsible for documentation: Bircher Reglomat mbH, Dr. Marc Loschonsky, Robert-Bosch-Strasse 3, DE-71088 Holzgerlingen

Product: Inductive signal transmission system, switching device

Models: InTra6 2, InTra6 3

Notified Body: Suva, Bereich Technik, SCESp 008, Kenn-Nr. 1246

Txpe-examination certificate: E 6934, E 6935

Fulfills the essential requirements in acc. with: 2006/42/E , 1999/5/E

Following standards were applied: EN ISO 13849-1:2008+AC:2009

Signee: CTO Dr. Marc Loschonsky, COO Daniel Nef

EC Declaration of conformity, ate of pro uction

10

Mounting substructure

9.6

Mounting steel cable9.5

EC Declaration of conformity

10.1

Date of pro uction

10.2

See shield ➔ week/year, e.g. 12/10 = week 12, 2010

Seller

Swissdoor ApS

Stenhuggervej 2

DK-5471 Søndersø

Tel.: +45 86 28 00 00

www.swissdoor.dk

This manual suits for next models

1

Popular Gate Opener manuals by other brands

SOMFY

SOMFY Dexxo Pro 800 Installation instruction

Matikgate

Matikgate HULK50 User& installer's manual

Nice

Nice 4024 Instructions and warnings for installation and use

Nice

Nice XFAB2124 Instructions and warnings for installation and use

Mighty Mule

Mighty Mule FM502 installation manual

Nortek Security & Control

Nortek Security & Control Mighty Mule HD272 installation manual