Bird Electronic 8138 User manual

INSTRUCTION MANUAL

DUMMY LOAD

Coaxial Load Resistor

MODEL 8138

General Dynamics Drawing No. A16071

LITHO IN U.S.A.

BIRD ELECTRONIC CORP.

CLEVELAND, OHIO

TABLE OF CONTENTS

Paragraph Page

SECTION I. INTRODUCTION AND DESCRIPTION

1-1. Scope

1-3. Purpose ..

1-5. Leading Particulars

1-7. Description

1-

11. Theory of Operation

SECTION II. PREPARATION FOR USE

2-

1. General .

2-

3. Installation ..... .. . •.... ..

SECTION m. OPERATING INSTRUCTIONS

3-

1. General .

3-3. Transmitter Loading

3-

5. Loss Measurement and VSWR Measurement of Insertion ...

Components

SECTION IV. MAINTENANCE INSTRUCTIONS

4-

1. General .......... ....

4-3. Gleaning

4-

5. Checking VSWR

SECTION V, TROUBLESHOOTING

5-

1. Troubleshooting Chart •

SECTION VI. REPAIR INSTRUCTIONS

6-

1. General

6-3. Disassembly ..............

6-5. Cleaning and Inspection

6-

7. Reassembly

SECTION VII. REPLACEMENT PARTS LIST

7-

1. Parts List

1

1

1

1

2

3

3

4

4

4

4

4

4

5

6

6

6

7

8

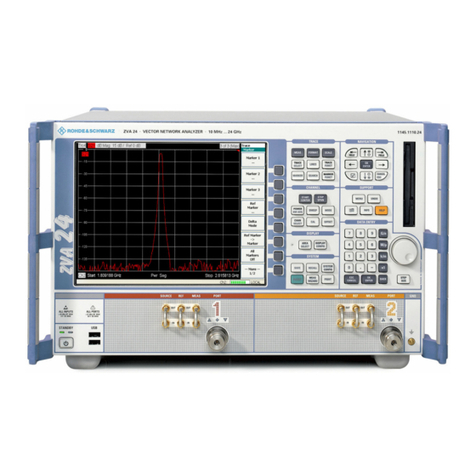

Figure 1-1. Model 8138 Dummy Load

1

SECTION I

INTRODUCTION AND DESCRIPTION

1-1. SCOPE

1-2. This technical manual provides adescrip-

tion, installation and maintenance instructions,

suggested uses, and other pertinent information

for the Model 8138 Dummy Load, manufactured

by Bird Electronic Corporation, Cleveland

(Solon), Ohio, for General Dynamics, their

drawing number A16071. (See figure 1-1.) This

manual is intended for use by the technicians

who are responsible for the operation and main-

tenance of this equipment.

1-3. PURPOSE

1-4. The Model 8138 dummy load is aresistor

designed to match 50- ohm coaxial lines. It is

used primarily for transmitter loading, conven-

iently dissipating transmitter power to replace

an antenna during transmitter tuning. In this

application it provides an almost purely re-

sistive load, independent of frequency. It is

also used for insertion loss measurement of

connectors, cables, filters, and similar compo-

nents. It is used as aerospace ground equipment

in support of the F-lllA/B.

1-5. LEADING PARTICULARS

1-6. Leading Particulars for the Model 8138

Dummy Load are given in Table I.

1-7. DESCRIPTION

1-8. The Model 8138 Dummy Load is ametallic

film on Pyrex glass cylindrical resistor which

is immersed in adielectric coolant. The re-

sistor and coolant are confined in aconical

internal housing which provides proper charac-

teristics for good coaxial line termination.

Table I. Leading Particulars

Wattage Rating (Continuous)

Characteristic impedance -•^g^^ss

Rated Frequency Range" !225 -400 megacycles/sec

VSWR (Voltage Standing Wave Ratio)

Line Con^e^orSd Female type

Optional Any common RF type

Amblert 0to *55'C (t-32 loblSl" F)

S-SKeraiing -»8«o *«-c <-» to f>

Non-Operating Sea Level to 50,000 ft

Relative Humidity Range *np;c;°r’

Operating (max.) -95 percent at 0o+55 C

Non-Operating (max.) 190 percent at -62 to +8 C

Coolant ^Transit Dielectric Oil

Volume 4/5 pt

Basic Overall Dimensions

Width 3-15/16 in.

Height (handle retracted) g'si/M in

^6lbs

Weight

1

Cooling fins are provided on the housing to help

dissipate resistor heat to the surrounding at-

mosphere. Asynthetic rubber bellows is mounted

on the back to compensate for changes in oil

volume caused by temperature changes of the

coolant. Avented metal cap protects the bel-

lows from damage.

CAUTION

Do not probe the vent hole of the dia-

phragm cap with asharp-pointed instru-

ment or the diaphragm may be damaged.

1-9. Ascrew-type coaxial cable connector is

provided at the front of the dummy load to

facilitate making line connections. The standard

model is equipped with aFemale ''N" type con-

nector. This mates with the Male type plug

of RG-8A/U and RG-9B/U type cables. If

another type of connector is required, sub-

stution can be made by removing the four No.

8-32 round-head machine screws that secure

the connector flange to the face of the load

resistor. Pull straight out on the connector to

remove it. Anew connector can be installed

by reversing the removal procedure. Alternate

quick-change connectors are available from Bird

Electronic Corporation.

1-10. The load rests on four rubber bumper

feet. These feet can be removed to provide

threaded holes for rigid mounting of the unit.

1-11. THEORY OF OPERATION

1-12. The dummy load consists of ametallic

film on Pyrex glass cylindrical resistor mounted

in an oil-filled housing. The resistor is ter-

minated with acoaxial connector which extends

from the housing. Within the housing the re-

sistor is mounted in aconical internal housing

which helps to provide the proper electrical

characteristics for coaxial line termination.

1-13. When aload is applied to the resistor,

the resistor converts the electrical input into

heat which must be dissipated to prevent the

parts from overheating. The heat generated in

the resistor is absorbed by the dielectric oil

which surrounds the resistor. The specific

gravity of the heated oil is less than that of

the cool oil, and the heated oil rises, causing

convection currents to flow within the housing.

The tapered end of the conical housing has

three slots top and bottom, and the wide end has

one round hole top and bottom to facilitate oil

circulation through the conical housing and

around the resistor. As the convection currents

flow through the outside housing, the hot oil

contacts the metallic housing, transferring the

heat to the housing to cool the oil. The external

housing has cooling fins which help dissipate

the heat to the atmosphere. This system operates

as long as the load continues to be dissipated

into the resistor.

1-14. When the oil heats, it expands and re-

quires agreater volume. This expansion is

compensated for by asynthetic rubber diaphragm

installed at the rear of the load, which accom-

modates the extra volume. The diaphragm is

protected by aspun metal cover. The cover at

the rear of the load and the resistor assembly

at the front of the load are retained by circular

V-clamps.

2

SECTION II

PREPARATION FOR USE

2-1. GENERAL

2-2. Model 8138 Dummy Load as received is

ready for operation. It has been factory filled

to the required coolant level with approximately

4/5 pint of GE Type IOC Transit Dielectric

Oil at room temperature. Upon receipt, check

for oil loss. Afew drops of oil loss will not

impair the efficiency of the equipment, but losses

greater than 10 percent may impair the opera-

tion, since cooling characteristics are important

to maintaining proper RF impedance and power

rating.

2-3. INSTALLATION

2-4. The following considerations should be

made when installing the Model 8138 Dummy

Load.

of free air space around and above the unit to

enable free air circulation necessary for cool-

ing. The dummy load will rest on its four

rubber feet.

c. If fixed mounting is desired, remove the

four rubber bumper feet to provide mounting

holes for mounting. Refer to figure 2-1 for

mounting dimensions.

CAUTION

Do not operate the dummy load with the

input connector pointing up. This will

prevent coolant from reaching the input

section of the dummy load and will

greatly disturb the RF impedance.

a. The unit has been designed to be operated

with the carrying handle positioned on the top.

If the dummy load is laid on either side, the

termination properties will not be impaired, but

the load power capacity will be reduced by a

considerable amount. This is due to the re-

stricted circulation of coolant when it is tipped.

b. Mount the dummy load on any convenient

flat surface. Make sure there is several inches

d. If the particular installation requires a

different type of coaxial connector, the connector

is easily replaced with adifferent type by re-

moving the four machine screws that secure the

connector to the dummy load and pulling straight

out to remove it. Install the correct connector

by reversing the removal procedure. Connect

the coaxial cable to the dummy load. Alternate

connectors are available from the manufacturer.

Figure 2-1. Mounting Dimensions

3

SECTION III

OPERATING INSTRUCTIONS

3-1. GENERAL

3-2. The dummy load has no switches, controls,

or indicators which the operator must mani-

pulate or watch. It must be used only in the

manner for which it was intended. Make sure

it is used only on 50- ohm RF lines within the

power limits for which it is rated. Some of the

most frequently used applications are given

below.

CAUTION

When the dummy load is operated at

close to its rated capacity for an ex-

tended period, the exterior housing will

become hot enough to cause burns. Take

care not to touch the metal under these

conditions.

3-3. TRANSMITTER LOADING

3-4. In this application, it is necessary only to

connect the load to the transmitter line. It

will provide astandardized load resistance with-

in its rating, dissipating the power in the form

of heat.

3-5, LOSS MEASUREMENT AND VSWR MEA-

SUREMENT OF INSERTION COMPONENTS

3-6. Loss measurements and VSWR measure-

ments of insertion components such as con-

nectors, filters, and cables can be made by

comparing measurements with and without the

component installed in aline terminated by the

dummy load. Highly accurate measurements of

this type can be made when aBird Model 43

Thruline Wattmeter is used in conjunction with

the dummy load.

SECTION IV

MAINTENANCE INSTRUCTIONS

4-1. GENERAL

4-2. Maintenance is normally restricted to

cleaning the exterior of the instrument and to

checking to assure that it is operating within

the required VSWR limits. Because of its

simple, rugged construction it requires little

care.

4-3. CLEANING

4-4. Wipe all dust and grime from the exterior

of the housing. Remove any greasy or gummy

deposits with acloth dampened with trichloro-

ethyline, Federal Specification 0-Y-236a. Clean

the connector contact and face with acotton

swab stick dampened with trichloroethylene.

4-5. CHECKING VSWR

4-6. To determine if the dummy load is oper-

ating satisfactorily, check the VSWR of the unit.

This can be done very simply by use of aBird

Thruline Model 43 Wattmeter. If the VSWR ex-

ceeds 1.1 when measured in the rated wattage

and frequency range, it will be necessary to

replace the resistor assembly. Refer to para-

graph 6-4.

4

SECTION V

TROUBLESHOOTING

5-1. TROUBLESHOOTING CHART

5-2. Table Hprovides alist of the most prob-

able troubles which might occur in the load.

For each trouble there is alist of probable

causes and remedies.

Table II. Troubleshooting Chart

TROUBLE PROBABLE CAUSE REMEDY

VSWR EXCEEDS 1.1 Poor connections. Clean connectors.

Tighten securely.

Defective resistive element. Replace resistive

element.

UNIT LEAKS OIL Defective O-ring. Disassemble and replace

O-ring.

Punctured diaphragm. Disassemble and replace

diaphragm.

UNIT OVERHEATS Excessive load. Remove excessive load.

Unit not in upright Set in upright position

position. with handle on top.

Insufficient coolant. Add dielectric oil to

required level.

Resistor assembly not Disassemble and position

properly oriented in resistor assembly so

housing. that coolant slots are

at top and bottom.

5

SECTION VI

REPAIR INSTRUCTIONS

6-1. GENERAL

6-2, Repair is normally limited to parts re-

placement. Do not disassemble unless trouble-

shooting indicates the necessity of parts re-

placement. To replace parts, disassemble and

reassemble only to the extent required as di-

rected below.

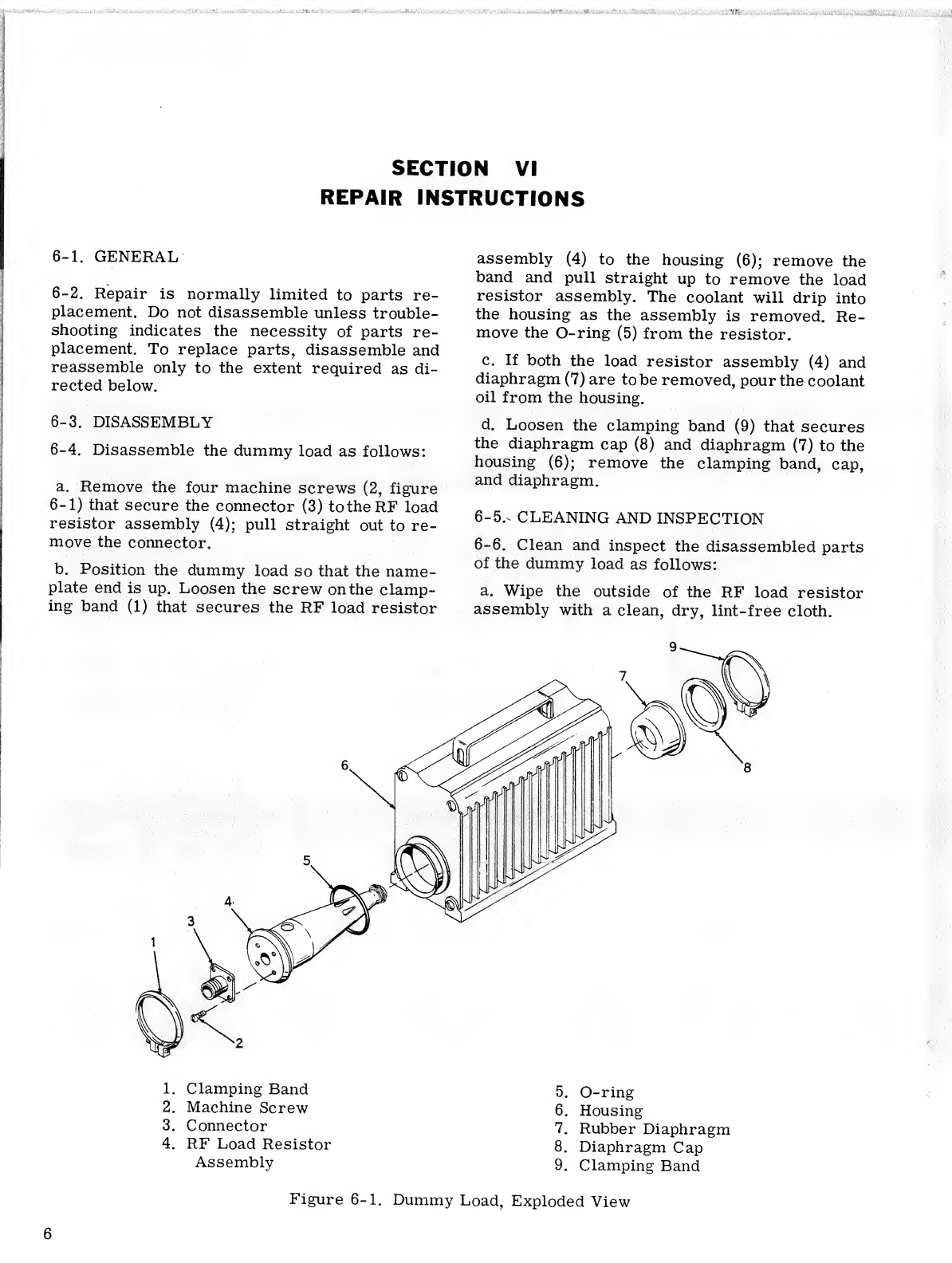

6-3. DISASSEMBLY

6-4. Disassemble the dummy load as follows:

a. Remove the four machine screws (2, figure

6-1) that secure the connector (3) to the RF load

resistor assembly (4); pull straight out to re-

move the connector.

b. Position the dummy load so that the name-

plate end is up. Loosen the screw on the clamp-

ing band (1) that secures the RF load resistor

assembly (4) to the housing (6); remove the

band and pull straight up to remove the load

resistor assembly. The coolant will drip into

the housing as the assembly is removed. Re-

move the O-ring (5) from the resistor.

c. If both the load resistor assembly (4) and

diaphragm (7) are to be removed, pour the coolant

oil from the housing.

d. Loosen the clamping band (9) that secures

the diaphragm cap (8) and diaphragm (7) to the

housing (6); remove the clamping band, cap,

and diaphragm.

6-5.^ CLEANING AND INSPECTION

6-6. Clean and inspect the disassembled parts

of the dummy load as follows:

a. Wipe the outside of the RF load resistor

assembly with aclean, dry, lint-free cloth.

1. Clamping Band

2. Machine Screw

3. Connector

4. RF Load Resistor

Assembly

5. O-ring

6. Housing

7. Rubber Diaphragm

8. Diaphragm Cap

9. Clamping Band

Figure 6-1. Dummy Load, Exploded View

6

b. Wipe the O-ring and diaphragm with acloth.

c. Clean all remaining metallic parts with

trichloroethylene, Federal Specification O-Y-

236a. Dry thoroughly, taking care to remove all

traces of solvent from the inside of the housing.

d. Inspect the O-ring and diaphragm for cracks,

scoring, deterioration, and other damage; re-

place damaged parts.

e. If predisassembly troubleshooting indicated

that the RF load resistor assembly was not

performing within required limits, replace it.

f. Inspect the housing for cracks, broken cool-

ing fins, damaged clamping band seats, and other

damage; replace adamaged housing.

g. Replace other parts that are cracked, dis-

torted, or otherwise damaged.

6-7. REASSEMBLY

6-8. Reassemble the dummy load as follows:

a. Position the rubber diaphragm (7, figure 6-1)

on the housing (6) so that the projecting end

enters the housing. Position the diaphragm cap

(8) on the housing and secure the parts with the

clamping band (9).

b. Position the housing so that the nameplate

end is up. Fill the housing to the required level

with GE Type IOC Transit Dielectric Oil (ap-

proximately 4/5 pint at room temperature).

c. Install the O-ring (5) on the RF load re-

sistor assembly (4). Position the load resistor

assembly so that it is fully seated in the hous-

ing. Make sure that the slotted holes on the

tapered end of the conical housing and the

round holes at the wide end of the conical

housing are positioned top and bottom.

CAUTION

Failure to orient the RF load resistor

assembly correctly in the housing will

result in obstructed coolant flow and

may affect the power rating and RF

impedance.

d. Secure the RF load resistor assembly (4) to

the housing with the clamping band (1). Tighten

the screw on the clamping band.

e. Position the connector (3) on the front of

the RF load resistor assembly (4); secure with

four machine screws (2),

f. After reassembly, check the dummy load for

coolant leaks. If coolant is leaking from around

the clamping bands, tighten the band screw and

check if the leaking stops. If it does not, re-

place the O-ring (5) or the diaphragm (7).

g. Check the VSWR of the dummy load by con-

necting it, along with aBird Model 43 Thruline

Wattmeter, to aproperly rated 50- ohm trans-

mission line. VSWR must not exceed 1.1.

SECTION VII

REPLACEMENT PARTS LIST

I

\

\

7-1. PARTS LIST

7-2. Alist of replaceable parts for the dummy

load is given below. Use the exploded view of

figure 6-1 for parts identification.

Index No.

Fig. 6-1 Bird

Part No. Nomenclature Qty

Reqd

1750254 BAND ASSEMBLY, Clamping 1

2COML SCREW, Machine, Rd hd, No. 8-32 x1/4 in., ..4

brs, sil pi

3424062 CONNECTOR, Female Ntype 1

4813002 RESISTOR ASSEMBLY, RF load 1

55229 O-RING 1

6NSS* HOUSING 1

724015 DIAPHRAGM 1

824050 CAP, Diaphragm 1

9750254 BAND ASSEMBLY, Clamping 1

N.I./ 5030 OIL, GE Type IOC Transit Dielectric 1pt

*Not Sold Separately

4-Not Illustrated

8

Table of contents

Other Bird Electronic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Rohde & Schwarz

Rohde & Schwarz ZVA8 operating manual

Compressed Air Alliance

Compressed Air Alliance FLP user manual

Boumatic

Boumatic TouchPoint OPERATION, SERVICE AND MAINTENANCE INSTRUCTIONS

OKOndt GROUP

OKOndt GROUP UTG-8 quick start guide

Test Equipment Depot

Test Equipment Depot SBS 2500 manual

Fluke

Fluke Datapaq Furnace Tracker user manual

Ametek Land

Ametek Land CYCLOPS L quick start guide

Triplett

Triplett CableRater instruction manual

Crowcon

Crowcon SprintPro 3 user manual

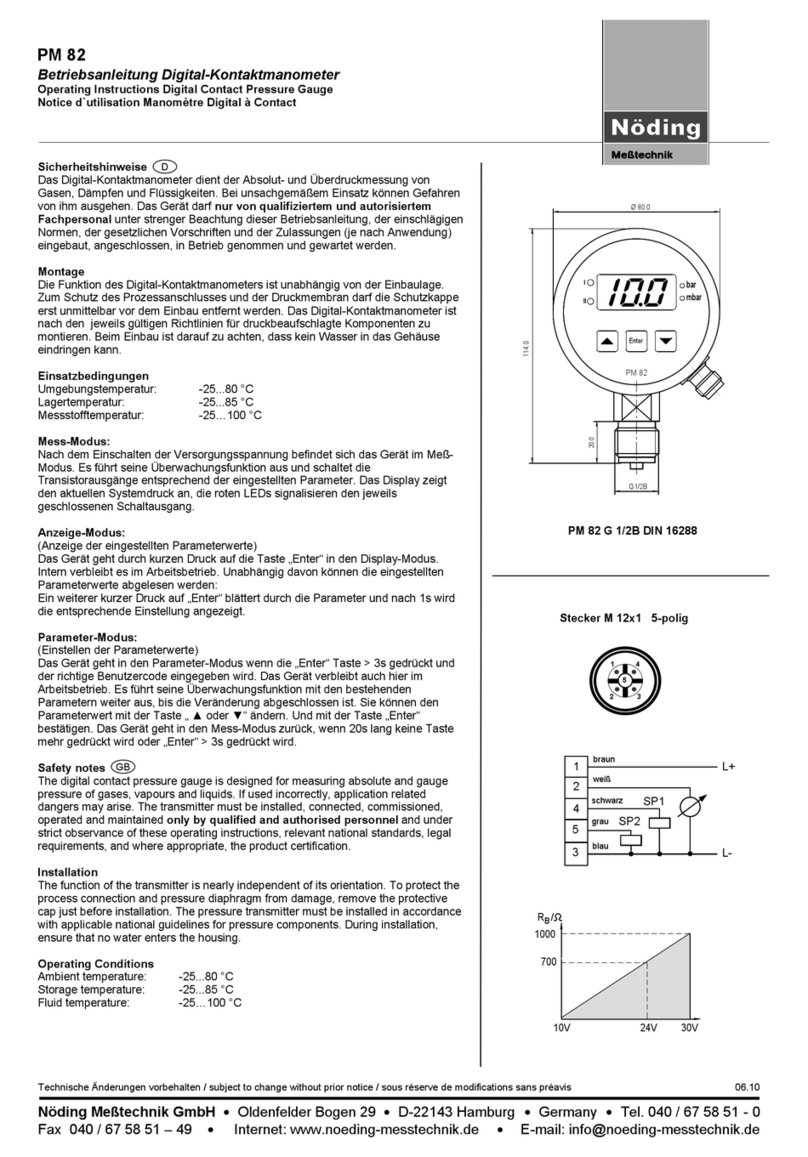

Noding

Noding PM 82 operating instructions

Makita

Makita SK106D manual

Dwyer Instruments

Dwyer Instruments DigiMag DM-1200 Series Specifications-installation and operating instructions