OPERATION

Hoisting:

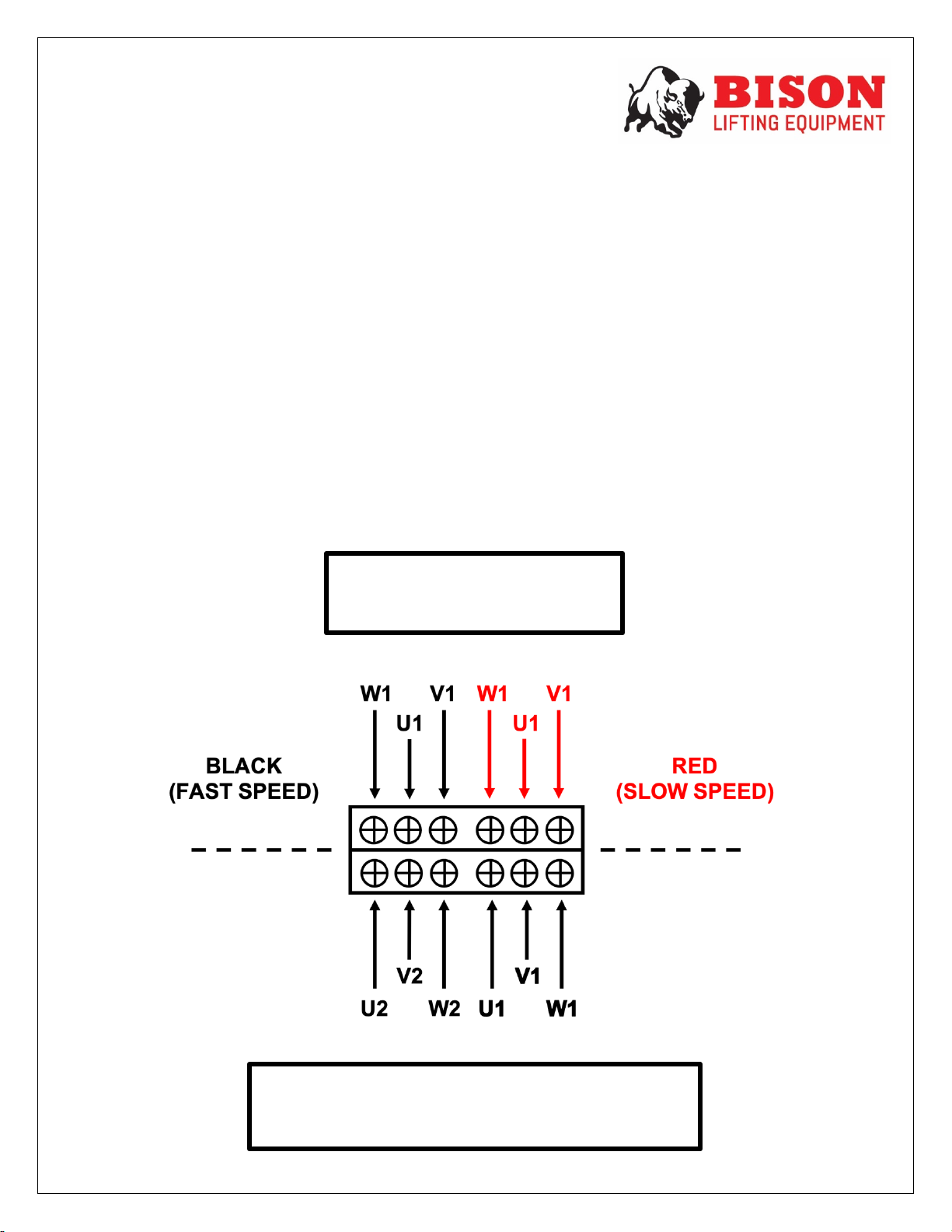

Dual speed models are controlled by pushing the pendent buttons down in 2 stages of

depression. Single depression engages a slow speed. Full depression engages the fast

speed.

Install the hoist to a support structure. It is the user/ owner’s responsibility to ensure the

chosen support structure has the sufficient strength to support the hoist and the rated

working load.

Do not attempt to lengthen the load chain in any way. Do not attempt to repair the

hooks.

General:

1. The friction-clutch is designed to allow the first reduction gear to slip on an

excessive overload. An overload is indicated when the hoist will not raise the

load. Also, some clutching noise may be heard if the hoist is loaded beyond rated

capacity. Should this occur, immediately release the raising control to stop

operation of the hoist. At this point, the load should be reduced to the rated hoist

capacity. When the excessive load is removed, normal hoist operation is

automatically restored. [CAUTION: the friction clutch is susceptible to

overheating and wear when slipped for extended periods. Under no circumstance

should the friction clutch be allowed to slip for more than a few seconds.]

2. Before picking up a load, check to see that the hoist is directly overhead. Avoid

off-center loading of any kind.

3. Take up as lack load chain carefully and start hoisting load gently to avoid shock

and jerking of the load chain. If there is any evidence of overloading, immediately

lower the load and remove the excess load.

4. Do not allow the load to swing or twist while hoisting.

5. Do not allow the load to be against the hook latch or the tip of the hook.

6. Make sure the pendant cord is straight and is not tangled in the chain. Be careful

not to snag the cord on any sharp edges or objects.

7. When handling material that is being immersed in water, baths or any liquid, use

a chain sling to prevent the hook block from having to be submerged- this will

stop any liquid from penetrating the bearing.

Precautions

• During overhead lifting operations, personnel should NOT stand beneath the

suspended load.

• Prevent the load chain from dragging over sharp edges or corners.

• Be cautious of having fingers caught in the mechanisms.

• Do NOT attempt to lift people.

• Do NOT use the load chain to basket or choke a load.

• Do NOT drag or drop the hoist.

• Do NOT put the bottom hook through the loop of the chain. (only applicable on 2-

fall models)