Tel. +32-3-451 05 00 E-mail: Info@PowerClimber.be Fax +32-3-451 05 01

Website: www.PowerClimber.be

This document and all copies are the property of Power Climber BVBA. All dimensions and data are indicative only.

The user must ensure that the equipment complies with local rules and regulations.

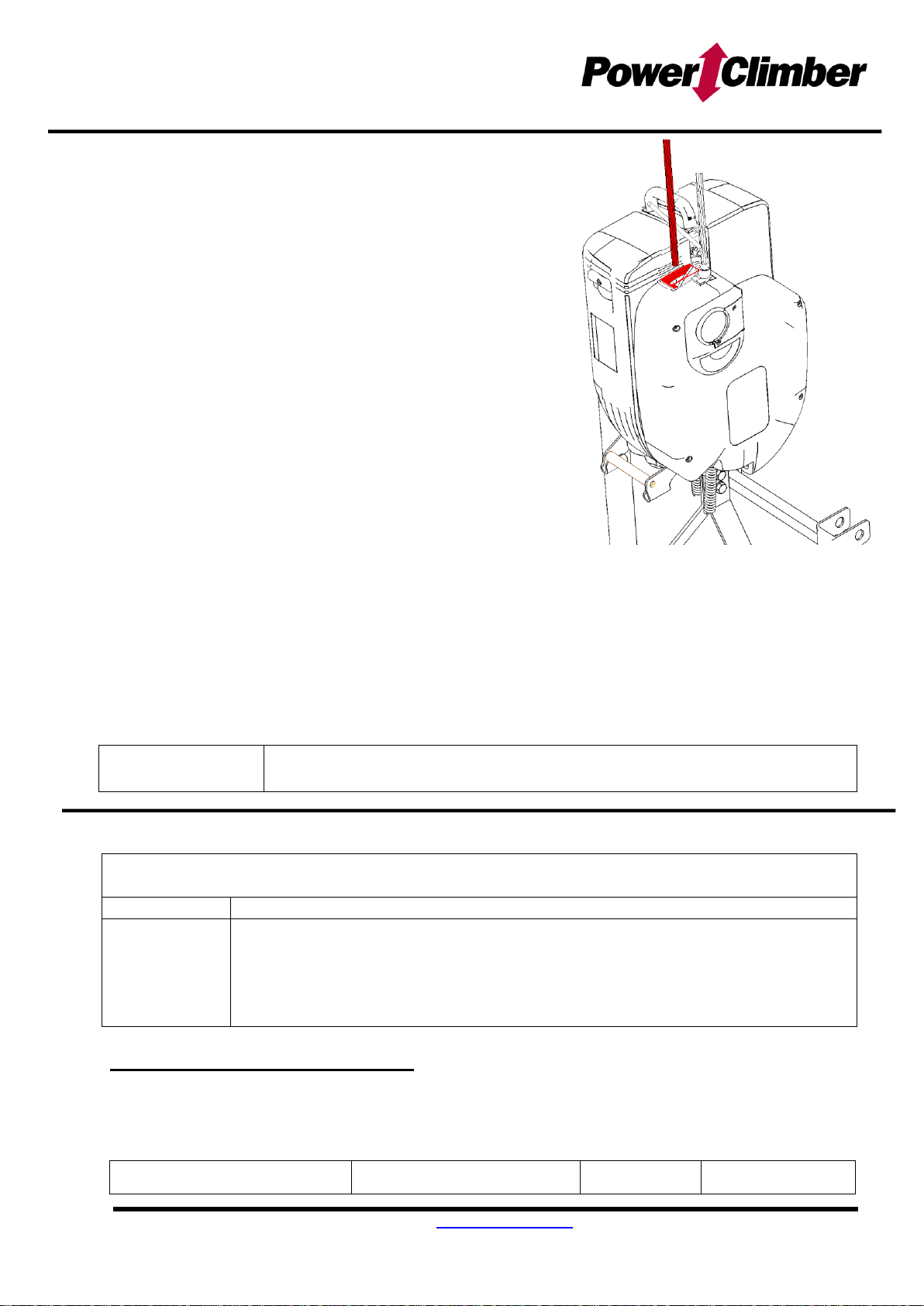

6. Automatic Levelling System

The central control box is fitted with an automatic levelling system that allows the

platform to maintain a stable horizontal position. An out of level condition can occur when

one of the hoists is working faster than the other, or if the load in the platform is not

evenly distributed.

When the platform is in motion, the automatic levelling system stops the hoist that is

going too fast and allows the other hoist to catch up. When both hoists are level again,

the levelling system is deactivated and both hoists will function simultaneously.

The automatic levelling system is activated when the platform is out of level by 3-6°.

The Automatic Levelling System can be tested by using the hoist selector switch to

create and out of level condition. Once the platform is out of level, check that the hoist

that is too high no longer works in the ’up’ direction and the hoist that is too low no longer

works in ‘down’ direction.

7. Overheating protection for hoist electric motor

The hoist motors are fitted with a thermal contact, which cuts power to the motors in case

of overheating.

When the overheating protection is activated, the ‘up’ movement is halted.

If a hoist motor has overheated, allow it to cool down to continue.

The overheating protectors of both hoists are connected in series. If one overheating

protector is triggered, then the ‘up’ movement of both hoists is halted.

8. Overspeed Safety device (OPTIONAL)

The overspeed safety device locks onto the suspension rope when the suspension rope

passes through the hoist (descent speed) at more than 15 m/min. The overspeed safety

device can also be triggered manually by pressing the manual release button.

To reset the overspeed safety device, first drive the hoist up a few centimetres and then

turn the reset knob clockwise in the direction of the arrow.

9. Use of Handwheel to reset safety device in case of power failure

If the slack rope safety device or overspeed safety device (optional) has been activated

and there is no power to the platform, it will be necessary to wind the hoist up a few

centimetres manually, to be able to reset the safety device.

1. Pull out main power plug to cut off power supply.

2. Remove plastic plug in the motor cover to expose shaft for the handwheel.

3. Remove the hand wheel from its storage position and insert shaft into hub.

4. Wind the hoist in the up-direction counter-clockwise ½ turn at the same time as you

pull up on the brake lever to open the brake.

5. Release brake lever and repeat.

TIP: Grab the hand wheel firmly while opening the brake to prevent it from turning and

going back down.

6. The overspeed safety device (optional) must be reset manually. The slack rope

safety device resets automatically.

7. Put plastic plug back on and return hand wheel to its storage position after use!

8. Plug in main power plug and resume.