13

ENGLISH

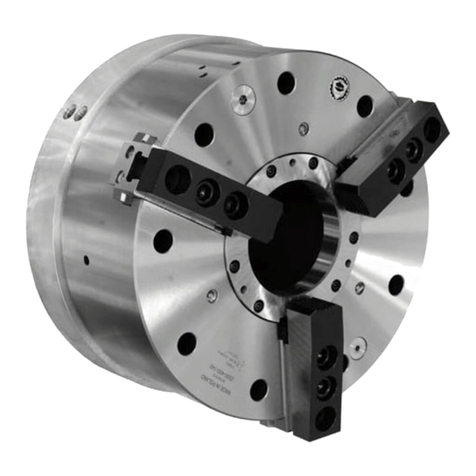

The situations below indicate how to proceed, when the chuck is not working properly or malfunctioning.

7. Before submitting the product to BISON-BIAL S.A.

the Buyer is obliged to clean, preserve, and secure

the product against damage and destruction that

may occur during transport. This also applies to

cases when the product is submitted to BISON-

BIAL S.A. through third parties.

8. The notied complaint will be processed under the

condition of returning the product in its original

packaging with its complete equipment and all the

documents (Manual and Quality Certicate).

9. The notied complaint will be processed within

30 days from the date of submitting the product to

BISON-BIAL S.A. However, should there be a need

to conduct necessary tests or expert’s studies,

or should it be impossible to correct the notied

defects for reasons beyond the control of BISON-

BIAL S.A. other than the ones indicated above, the

aforementioned period shall be extended by the

time necessary to correct the defects.

10. If the Buyer’s complaint, as referred to in §9 of

the General Warranty Conditions, is classied as

reasonable, BISON-BIAL S.A. shall correct the

defect within 21 days from the date on which the

complaint was recognized as reasonable, subject

to the provisions of §11 of the General Warranty

Conditions. The time of correcting the defect may

be prolonged should it be impossible to correct the

recognised defect for reasons beyond the control

of BISON-BIAL S.A.

11. The Buyer is entitled to have the product replaced

with a new one if:

1) There have been ve in-warranty repairs done

during the Warranty Period of BISON-BIAL

S.A.;

2) It is impossible to correct the defect;

3) BISON-BIAL S.A. does not correct the defect

within the time limit specied in §10 of the

General Warranty Conditions, subject to the

provisions of §13 of the General Warranty

Conditions.

12. BISON-BIAL S.A. shall replace the product with

a new one or provide the Buyer with a refund

within a period agreed on with the Buyer; but not

longer than 90 days from the date on which one

of the conditions specied in §11 of this General

Warranty Conditions occurred.

13. Rights arising from the Warranty may be lost

should the following conditions occur:

1) Improper use of the products, use of the

products not in compliance with their purpose,

instalment and exploitation as well as a

maintenance not compliant with the principles

included in the Manual;

2) The product has been repaired at an

unauthorised service point;

3) The Buyer has had arbitrary changes made

to the construction of the product or had the

product modied;

4) The product has been used with non-original

spare parts or equipment other than the

original one;

5) Use of consumables – lubricants or oils

– other than the ones recommended in the

manual to BISON-BIAL S.A. products.

14. Should the notied complaint on a defect appear

groundless, BISON-BIAL S.A. has the right to

charge the Buyer with the costs of return and

delivery of the product, as well as with the costs

of the control tests.

15. BISON-BIAL S.A. shall not be held responsible

for the consequences of the use of its products in

ways incompatible with their purpose, the use of

its products after modications and contrary to the

provisions included in the Manual.

16. The court competent to solve any disputes arising

in relation to the sale of the products is the court of

competent venue for BISON-BIAL S.A.

17. The fact that the Buyer has exercised his warranty

rights does not result in the transfer of the

ownership of the product to BISON-BIAL S.A.

18. The warranty on the product sold does not exclude,

limit or suspend any rights of the Buyer that result

from the nonconformity of goods with the contract

as referred to in the Act of 27th July 2002 on

special conditions of consumer selling and on

amending the Civil Code [Journal of Laws] No.

141, item 1176 as amended).

19. The provisions of this Rules and Regulations

regulating the rights or obligations of the Customer

in a manner contrary to or inconsistent with the

rights of consumers arising from the generally

applicable laws or adversely affecting consumers’

interest do not apply to consumers. This applies

in particular to §16 of the General Warranty

Conditions.