Bison 2502 Series User manual

2502

INSTRUCTION MANUAL [Page 3]

The manual covers assembly, operation and

maintenance of power chucks with an integrated

pneumatic cylinder.

NOTE: Please read the instructions thoroughly

before attempting to operate on chuck!

BEDIENUNGSANWEISUNG [Seite 43]

Die vorliegende Bedienungsanleitung umfasst

Betrieb, Montage und Wartung der oben genannten

Kraftspannfutter mit integriertem Pneumatikzylinder.

ANMERKUNG: Vor der Arbeit lesen Sie bitte die

Bedienungsanleitung!

[Strona 23]

Instrukcja obejmuje montaż, eksploatację

i konserwację uchwytów mechanicznych

zintegrowanych z cylindrem pneumatycznym.

Инструкция включает в себя монтаж, эксплуатацию

и консервацию mеханическиx патронoв

интегрируемыx с пневматическим цилиндром.

!!

!!

MADE IN EU

1

Dear Customer,

On behalf of BISON-BIAL S.A. we would like to thank

you for choosing our product!

We believe that the use of our products will meet

your highest expectation.

Our staff will provide you with any technical

information and assistance as well as help you

choose the optimal products, spare parts, or

accessories from the wide range of BISON-BIAL S.A.

products all tailored for your specic needs.

The product you have purchased is covered with a

warranty, which is part of the service we provide to

our valued customers. Please take time to carefully

familiarize yourself with the included warranty

conditions.

Kind Regards,

BISON-BIAL S.A.

Sehr geehrter Kunde,

im Namen von BISON-BIAL S.A. bedanken wir uns

für den von Ihnen getätigten Kauf!

Wir hoffen, dass die Nutzung unserer Produkte Sie

zufrieden stellt und Ihnen viel Freude bringen wird.

Unsere Mitarbeiter stehen Ihnen jederzeit mit allen

technischen Informationen zu unseren Produkten

zur Verfügung und beraten Sie gerne hinsichtlich

der Auswahl von passenden Ersatzteilen und

geeignetem Zubehör.

Im Rahmen unserer Serviceleistungen gewähren

wir auf das von Ihnen erworbene Produkt eine

Garantie. Wir bitten Sie daher, die beigefügten

Garantiebedingungen aufmerksam zu lesen.

Mit freundlichen Grüßen,

BISON-BIAL S.A.

Szanowny Kliencie,

W imieniu BISON-BIAL S.A. pragniemy

podziękować za dokonane zakupy. Mamy nadzieję,

że użytkowanie naszych wyrobów przyniesie

Państwu zadowolenie i wiele satysfakcji.

Nasi pracownicy udzielą Państwu wszelkich

informacji technicznych i będą służyli pomocą

w doborze oprzyrządowania produkowanego przez

rmę BISON-BIAL S.A.

Zakupiony przez Państwa wyrób jest objęty

gwarancją, będącą jednym z elementów serwisu

świadczonego naszym drogim Klientom.

Z poważaniem,

BISON-BIAL S.A.

Уважаемые Клиенты,

От имени BISON-BIAL S.A. хотим поблагодарить

за покупку наших продуктов. Надеемся, что

пользование ними даст Вам удовольствие и много

удовлетворений.

Наши сотрудники дадут Вам всякие нужные

технические справки а также окажут помощь

при выборе оснастки, производимой фирмой

BISON-BIAL S.А.

Мы предоставляем гарантию на приобретенный

Вами продукт, которая является одной из частей

сервисного обслуживания наших дорогих

Клиентов.

С уважением,

BISON-BIAL S.A.

2

3

ENGLISH

1. APPLICATION

2. WORK SAFETY CONDITIONS

3. CHUCK STRUCTURE

4. TECHNICAL DATA

4.1. Hard top jaw clamping ranges

4.2. Gripping force loss

4.3. Chuck technical parameters

5. COMPRESSED AIR DISTRIBUTION SYSTEM

5.1. Clamping of the workpiece

5.2. Unclamping of the workpiece

6. INSTALLATION ON THE LATHE

6.1. Preparing the lathe

6.2. Preparing the chuck for mounting

6.3. Preparing the chuck for operating

7. DISMOUNTING AND MOUNTING

7.1. Dismounting the chuck

7.2. Mounting the chuck

8. MAINTENANCE

9. TROUBLESHOOTING

10. WARRANTY TERMS AND CONDITIONS

CONTENTS

4

4

5

6

6

7

12

16

16

16

17

17

17

18

18

18

19

19

20

20

PAGE

4

ENGLISH

2. Work safety conditions

1. application

The power chucks with an integrated pneumatic cylinder and a fixed pressure distributor (attached to the

headstock) are designed for accurate turning of very long components such as tubes with large diameters and

similar workpieces.

Chucks can work on the lathe machine with spindle, ensuring mounting of two chucks on its both ends. The

double spindle configuration increases clamping force and stability.

The clamping/ unclamping is performed at stopped spindle by intake/ exhaust operation into the cylinder

chambers with a compressed air.

■manufactured from high grade alloy steel, which

extends machine life while providing higher rigidity

and greater wear resistance,

■hardened and ground working surfaces ensure

longer life with maintained accuracy and

repeatability,

■rigid structure and large through-hole,

■master jaws secured against throw-off,

■master jaws and drawbar lubricated directly,

Chuck technical features:

■built-in a non-return valve maintains a constant

pressure ow in piston chambers in case of

supply pressure drop

■air pressure safety control distributor in the

clamping chambers,

■plain back mounting,

■internal and external clamping of the workpiece,

■unbalance class G 6,3.

1. Please read the instructions thoroughly before

attempting to operate on the chuck and strictly

adhere to this manual.

2. In case of fault, malfunction or damage of the

chuck, immediately stop working and contact

technical supervision.

3. Repair and overhaul of the vise must be

performed only by an appropriately qualied

person.

4. Any set-up works, maintenance and all other

application work must be carried out at

stopped spindle and disconnected pressure

distributor only.

5. The max. data as max. pressure, max. speed

and max. gripping force are engraved on the

chuck body. They must not be exceeded in

any case.

6. Always use original BISON top jaws only.

7. Check the sealness of both cylinder chambers

regularly.

8. The pressure distributor must be mounted on

the chuck body to eliminate throw-off risk.

Except as listed above, the operator should follow

the existing local Health & Safety Regulations.

By following the instructions covered in this manual,

a long life and trouble free operation of the vise will

be guaranteed.

NOTE: The spindle rotation can be turned

on only when there is no pressure in air

supply hoses!

!NOTE: The manufacturer assumes

no responsibility or liability for any

claims arising due to not following the

instructions covered in this manual.

!

NOTE: The manufacturer reserves the

right to make improvements or changes

to the product without describing herein.

!

5

ENGLISH

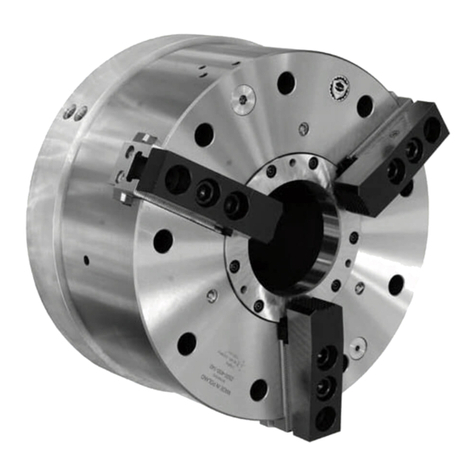

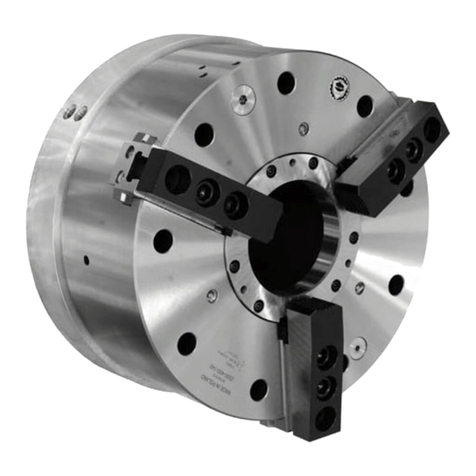

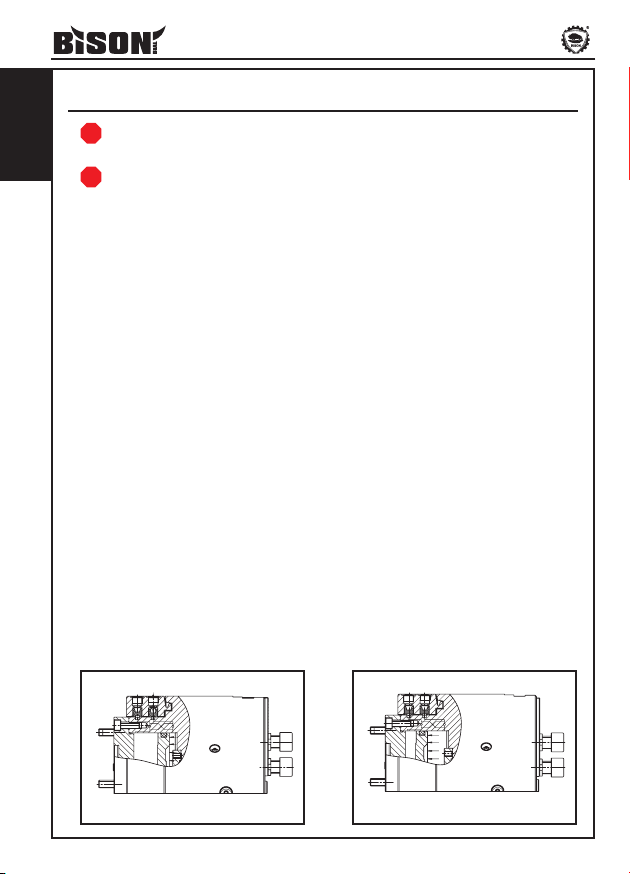

Chuck structure type 2502

The power chuck consists of a high alloy steel

body where the pneumatic cylinder connected with

a drawbar and three master jaws is mounted. The

jaws are adapted for mounting of hard top jaws.

Plain back mounting. The chuck is capable of both

internal and external clamping of the workpiece.

Power supply of the chuck through a fixed pressure

distributor placed on the adapter plate side.

The double-acting pneumatic cylinder use

the force of air pressure to move the drawbar

connected with jaws. The axial force of the

drawbar is transferred to jaws through the wedge

block system. The compressed air pressure is

transmitted through a safety control distrubutor

(mounted on the adapter plate side). A non-return

valve maintains a constant pressure flow in the

piston chamber in case of supply pressure drop.

3. cHUck strUctUre

Fig. 1

Fig. 2

Chuck component parts type 2502

NOTE: The manufacturer does not provide any pneumatic equipment, proximity switches that

work with chuck control devices as well as any parts working with the proximity switch devices.

!

Compressed air

Clamping force

Pulling force

12

78

9

5

12

13 611

3

4

1017 16 15

14

18

25

21

24 19

23

22

6

ENGLISH

4. tecHnical data

- Body -Non-return valve -O-ring (piston w/ drawbar)

- Drawbar -Control distributor -Baffle O-ring

- Master jaw -Plug (pressure control) -Adapter plate O-ring

- T-nut -Pressure distributor -O-ring (drawbar w/ cover)

- Cover -Cover screw -O-ring (baffle w/ drawbar)

- Adapter plate -Cylinder baffle screw -O-ring (adapter plate w/ cover)

- Cylinder piston -Piston screw -O-ring (piston w/ cylinder)

- Cylinder baffle -Adapter plate screw

- Valve cover -Hard top jaw screw

1

2

6

3

4

5

10

11

13

12

14

15

19

20

22

21

23

24

8

716

17

25

918

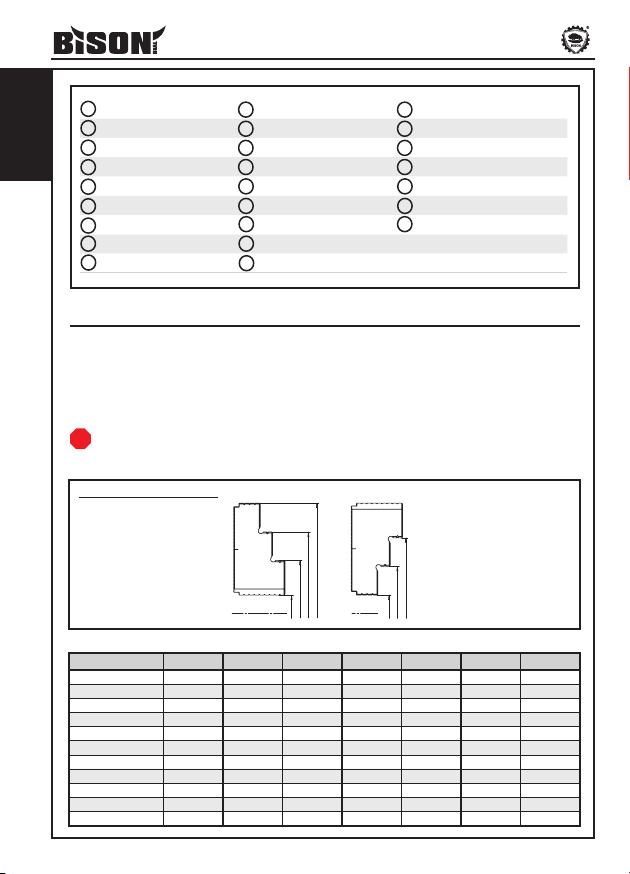

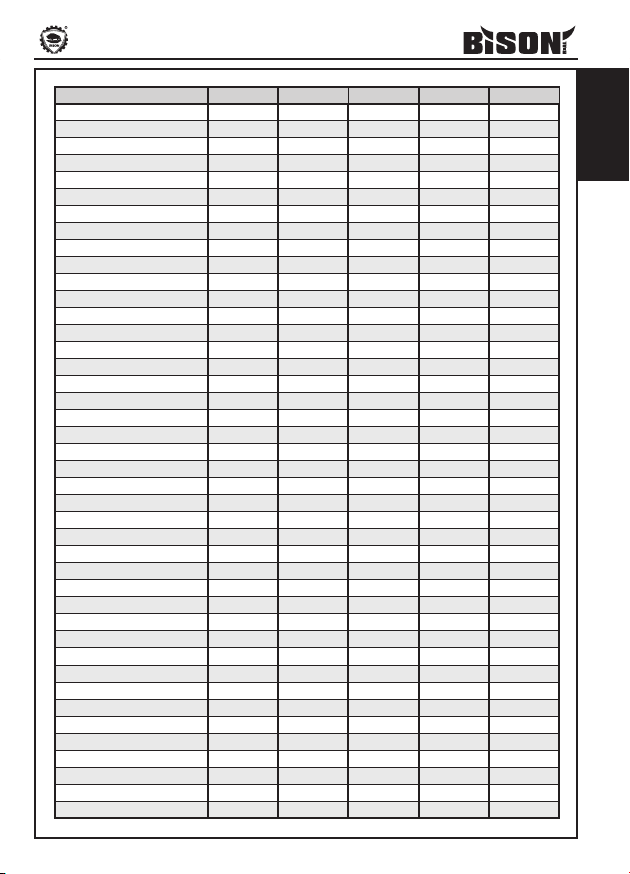

4.1 Hard top jaw clamping ranges

Fig. 13

Tab. 1

Hard top jaw clamping ranges

The jaw stroke of the master jaws and top jaws is different for different-sized chucks.

Please check whether the top jaws to clamp the workpieces are positioned correctly on the master jaws. 2/3 of the

total jaw stroke is used to clamp the workpiece, and 1/3 is for the remaining jaw stroke. Hard top jaws must only

be used in sets (marked with 1, 2, 3 part numbers).

NOTE: When mounting hard top jaws always use a torque wrench. Always tighten the mounting

bolts with correct torque adequate to a bolt size and its property class.

!

A1

J1

J2

J3

A2

A3

A4

Size A1 A2 A3 A4 J1 J2 J3

2502-160-38 7-74 67-130 115-180 163-180 18-67 66-115 114-160

2502-200-52 20-104 83-178 130-216 180-216 22-104 70-153 119-202

2502-250-65 24-124 104-207 168-266 232-266 25-122 88,5-188 152,5-252

2502-250-68 24-124 104-207 168-266 232-266 25-122 88,5-188 152,5-252

2502-315-105 64-184 142-262 206-326 270-326 64-184 128-252 192-316

2502-400-140 90-300 200-404 286-480 373-480 90-280 178-368 264-454

2502-500-230 176-402 286-510 370-596 460-600 176-402 264-490 350-576

2502-630-330 272-500 407-625 605-724 272-500 472-704

2502-800-365 326-674 434-780 600-862 326-674 494-842

2502-800-410 330-600 453-768 691-866 435-600 675-840

2502-1000-560 530-766 636-951 804-1026 530-845 698-1006

7

ENGLISH

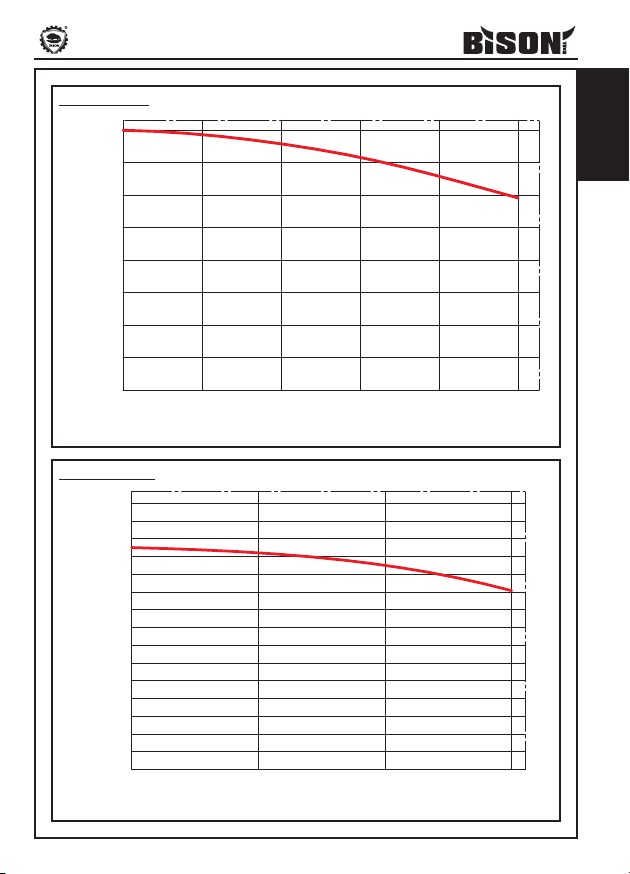

4.2 Gripping force loss

Type 2502-160-38

Type 2502-200-52

500 1000 1500 2000 2500 3000 3500 4000

5

10

15

20

25

30

35

40

0

Max. speed [rpm]

Gripping force [kN]

500 1000 1500 2000 2500 3000 3500 4000

10

20

30

40

50

60

70

0

Gripping force [kN]

Max. speed [rpm]

8

ENGLISH

Type 2502-250-65

Type 2502-315-38

0 500 350030002500200015001000

10

110

100

90

80

70

60

50

40

30

20

Gripping force [kN]

Max. speed [rpm]

10

110

100

90

80

70

60

50

40

30

20

5000 1000 1500 2000 2500 3000

Max. speed [rpm]

Gripping force [kN]

9

ENGLISH

Type 2502-400-140

Type 2502-500-230

0 250 500 750 1000 1250

20

40

60

80

100

120

140

160

180

Max. speed [rpm]

Gripping force [kN]

0 200 400 600 800 1000 1200 1400

20

40

60

80

100

120

140

160

180

200

220

240

Gripping force [kN]

Max. speed [rpm]

10

ENGLISH

Type 2502-630-330

Type 2502-800-365

0

20

40

60

80

100

120

140

160

180

200

220

200 400 600 800 1000

Max. speed [rpm]

Gripping force [kN]

0 150 300 450 600 750

50

100

150

200

250

300

350

400

450

Gripping force [kN]

Max. speed [rpm]

11

ENGLISH

Type 2502-800-410

Type 2502-1000-560

0 150 300 450 600 750

50

100

150

200

250

300

350

400

Max. speed [rpm]

Gripping force [kN]

0 150 300 450

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

Gripping force [kN]

Max. speed [rpm]

12

ENGLISH

A4

L15

L14

D8

A1

A3

A2

A

A

B

B

G1/4''

L7

L6

L5

L1

L13

L10

M2

L11

L12

L2

L18

L8

D5

D4

D2

D1

min L3

min L4

D6

1/16''x90

L16

M3

D10

D3

A-A

M1

L9

D7

M4

L17

D9

B-B

M1

L9

B-B

2502-250-65

Type 2502 Ø160-315

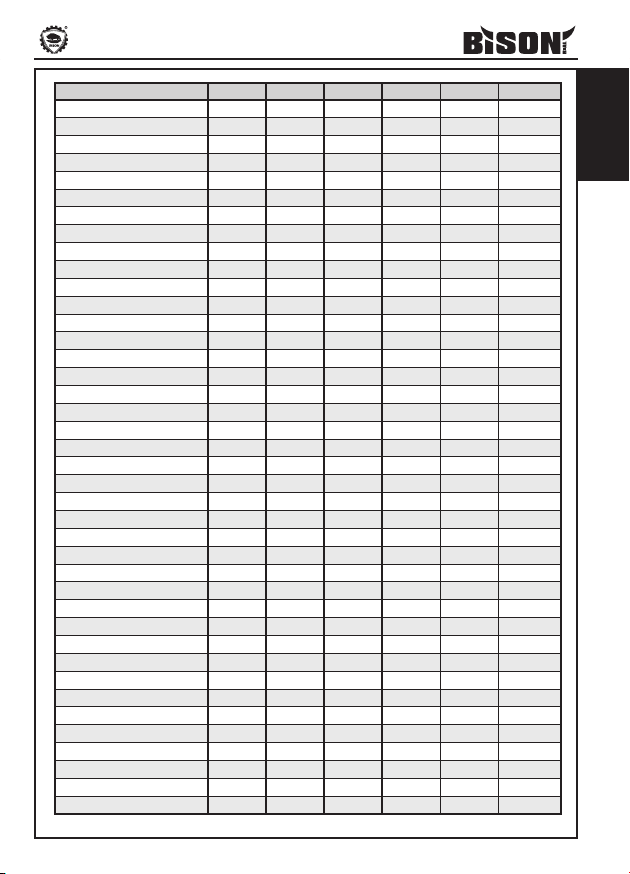

4.3 Chuck technical parameters

Safety control distributor

Safety control distributor

13

ENGLISH

Typ 2502-160-38 2502-200-52 2502-250-65 2502-250-68 2502-315-105

D1 255 300 372 372 372

D2 205 248 315 315 315

D3 184 230 296 296 296

D4 155 195 235 235 235

D5 Through-hole 38 52 65 68 105

D6 168 210 254 254 315

D7 180 223,8 296 290,5 290,5

D8 70 92 117 117 154

D9 242 285 358 358 358

D10 6 6 10 10 10

L1 140,5 154 174 174 183,5

L2 136,5 150 170 170 179

L3 30,2 37,5 48,1 48 66,6

L4 38,7 47 60,8 60 79

L5 27,5 28,5 35,5 28 33,5

L6 13 13,5 17 12,5 12,5

L7 33 25 25 33 33

L8 6,5 6,5 8 6,5 6,5

L9 40 40 16 40 40

L10 24 24,5 32 32 32

L11 45 49 58 58 58

L12 77 79 104 104 104

L13 2,6 2,6 3 3 0,6

L14 38 40 45 45 52

L15 17 17 21 21 21

L16 10 10 10 10 10

L17 12 12 12 12 12

L18 101,5 110 126 126 133

A1 30° 30° 30° 30° 30°

A2 60° 60° 60° 60° 60°

A3 60° 60° 60° 60° 60°

A4 60° 60° 60° 60° 60°

M1 6xM12 6xM12 6xM10 6xM12 6xM12

M2 M12 M12 M16 M16 M16

M3 M4 M4 M5 M5 M5

M4 6xM6 6xM6 6xM6 6xM6 6xM6

Total jaw stroke 3,5 5 5 5 6

Operating pressure [MPa] 0.2/0.8 0.2/0.8 0.2/0.8 0.2/0.8 0.2/0.8

Total clamping force [kN] 43 68 87 87 100

Max. speed [rpm] 4200 3800 3000 3000 3000

Weight (without top jaws) [kg] 31,3 48,8 84,8 85,6 93,4

Moment of inertia [kgm2] 0,18 0,41 1,3 1,2 1,44

14

ENGLISH

Type 2502 Ø400-1000

A1

L15

L14

A2

L10

D8

D9

A A

G3/8''

L7

L6

L5

L1

M2

L12

L11

L13

L2L9

M1

L8

L4

L3

D5

D4

D2

D1

D6

D7

3/32''x90

D10

L16

M4

L17

M3

D3

D9

A-A

L18

D1

D6

2502-1000-560

Safety control distributor

Safety control distributor

15

ENGLISH

Typ 2502-400-140 2502-500-230 2502-630-330 2502-800-365 2502-800-410 2502-1000-560

D1 467 570 685 850 850 925

D2 400 500 610 775 775 850

D3 374 474 580 745 745 815

D4 310 415 510 700 700 700

D5 Through-hole 140 230 330 365 410 560

D6 467 570 685 850 850 1000

D7 374 474 580 745 745 815

D8 200 306 385 420 465 625

D9 448 550 666 830 830 910

D10 12 12 12 12 12 12

L1 219 229,5 249 263,5 263,5 272

L2 216,5 224 243 258 258 266

L3 94,2 141,5 191,5 210 232,1 311,6

L4 114,6 155 205,1 223,6 245,6 328,2

L5 37 37 39,5 44,5 44,5 52,5

L6 17 17 19,5 19,5 19,5 19,5

L7 26 26 33 33 33 33

L8 8 8 8 8 8 10

L9 24 26 32 27 27 27

L10 43 43 46 55 55 43

L11 75 74 70 78 78 70

L12 141,5 141,5 166,7 181,5 181,5 137

L13 0,5 3,6 4,1 4,1 4,1 4,1

L14 60 60 70 70 70 70

L15 25,5 25,5 25,5 25,5 25,5 25,5

L16 20 20 20 20 20 20

L17 20 20 20 20 20 20

L18 - - - - - 105,5

A1 20° 15° 15° 15° 15° 15°

A2 40° 30° 30° 30° 30° 30°

M1 9xM12 12xM12 12xM16 12xM16 12xM16 12xM16

M2 M20 M20 M20 M20 M20 M20

M3 M6 M6 M6 M6 M6 M6

M4 6xM8 6xM8 6xM8 6xM8 6xM8 6xM8

Total jaw stroke 7 8,5 10 10 10 10

Operating pressure [MPa] 0.2/0.8 0.2/0.8 0.2/0.8 0.2/0.8 0.2/0.8 0.2/0.8

Total clamping force [kN] 180 220 200 412 400 250

Max. speed [rpm] 1300 1300 1000 750 750 450

Weight (without top jaws) [kg] 201 285 407,5 715,8 674,9 825

Moment of inertia [kgm2] 5,6 13 28,1 74,4 72,7 132

16

ENGLISH

5. air distribUtion system

Fig. 14

NOTE: The power chuck with an integrated pneumatic cylinder use the force of compressed air

pressure (clamping and unclamping of the workpiece), can be performed at stopped spindle only.

!

Fig. 15

NOTE: The air ow delivered must be clean, undamped and correctly lubricated.

!

The compressed air that flows into the ‘clamping’

chamber of the pressure distributor causes a

deformation of the profile seal, while sealing

the connection of a distributor and chuck body,

then the air flows through the non-return valve –

resulting in:

■Connection of the cylinder ‘unclamping’

chamber with the atmosphere,

■The air flows into the cylinder ‘clamping’

chamber while displacing the piston

position - connected permanently with the

pulling sleeve, which drive the master jaw

through the wedge block system,

■The above results in clamping of the

workpiece (see Fig. 14).

The compressed air supply cut-off in the

distributor chamber is causing (see Fig. 15):

■Profiled seal returns to its original position

(seal moves out from the surface of the

chuck body),

■The non-return valve cuts-off the connection

of the supplied cylinder chamber with the

pressure distributor,

■The non-return valve keeps the pressure in

the cylinder chamber.

The workpiece is clamped and ready for machining.

5.1 Clamping of the workpiece 5.2 Unclamping of the workpiece

The compressed air that flows into the

‘unclamping’ chamber of the pressure distributor

causes a deformation of the profile seal, while

sealing the connection of a distributor and chuck

body, then the air flows through the non-return

valve – resulting in:

■Connection of the cylinder ‘clamping’

chamber with the atmosphere,

■The air flows into the cylinder ‘unclamping’

chamber while displacing the piston

position - connected permanently with the

pulling sleeve, which drive the master jaw

through the wedge block system,

■The above results in unclamping of the

workpiece.

The compressed air supply cut-off in the

distributor chamber is causing:

■Profiled seal returns to its original position

(seal moves out from the surface of the

chuck body),

■The non-return valve cuts-off the connection

of the supplied cylinder chamber with the

pressure distributor,

■The non-return valve keeps the pressure in

the cylinder chamber.

The workpiece is unclamped.

17

ENGLISH

6. installation on tHe latHe

The lathe should be equipped with a special ring or

brackets, supporting the distributor in centric and

non-contact position with the chuck, as well as the

adapter plate (for chuck mount). The operator should

get these elements by himself or order.

Stiffly and permanently mount the ring or brackets

onto the lathe spindle or spindle bearing cover; the

adapter plate on the spindle end. The adapter plate

requires two I.D. holes of Ø14mm for the safety valve

pin output (the holes spacing according to drawings

provided in this manual).

After installation, the ring or brackets, and adapter

plate should meet the conditions indicated in Fig. 16.

..

Fig. 16

6.1 Preparing the lathe

6.2 Preparing the chuck for mounting

Chuck adapter plate and distributor bracket

The workstation should be equipped with the

compressed air connection, that contains a connecting

block and shut-off valve (block valve).

The control system and tooling operator should get

by himself or order.

For controlling, use the 2-way 3-position valve

located in a mid-position, connecting the chamber to

the atmosphere. (Fig. 17).

4 2

3 1

Fig. 17

Control valve scheme

NOTE: The manufacturer does not provide any pneumatic equipment, proximity switches that work

with chuck control devices as well as any parts working with proximity switch devices.

!

■open the package,

■check, if the delivered product is fully completed,

■dismount the distributor from the chuck,

■lift the chuck up via an eyebolt and remove from

the package,

■place the chuck down in a position preventing

chuck motion,

To mount the chuck on the lathe, please proceed as follows:

NOTE: Never place the chuck onto jaws!

!

■the protective lubricant needs to be removed

carefully. Pay attention while clearing out the chuck

seat as well as distributor seat,

,

■lift the chuck up via hoist and an eyebolt,

■place the distributor onto the chuck,

■center the spindle towards to chuck, so that

the safety valve pin catches the adapter

plate I.D. holes of Ø14mm,

■mount the chuck to the adapter plate,

■mount the pressure distributor,

■check, whether during the rotation the chuck

is not rubbing the pressure distributor, if it

does then needs to be centered,

■when dismounting from the lathe, please

proceed in the reverse order.

18

ENGLISH

7. dismoUnting and moUnting

6.3 Preparing the chuck for operating

■on the control arbors, mount the parts that work

with proximity switches,

■mount the proximity switches that work with chuck

control devices,

■while using the exible hoses, connect the

distributor together with a connecting block,

■the jaw mounting bolts must be tightened to the

specied torque,

To get the chuck ready for operating, please proceed as follows:

■perform several clamp/ unclamp test

operations,

■it is recommended to check the jaws

clamping force and adjust air pressure to

working conditions,

■while replacing the jaws, clean the teeth

surfaces thoroughly.

NOTE: After mounting the control tooling and device into the chuck of 2502 type, the machine

should meet the essential requirements complied in the Machinery Directive 98/37/ WE.

According to the Directive, the manufacturer is the party who has mounted the control tooling and

device and is obliged to issue the WE declaration of conformity.

!

NOTE: Any chuck operation work must be performed after previous pressure alignment with the

atmosphere in the chuck chambers.

!

■disconnect the air supply from the chuck,

■disconnect the chuck air supply hoses,

To align the pressure with the atmosphere in the chuck chambers, please proceed as follows:

■align the pressure with the atmosphere in the chuck

chambers,

■dismount the chuck from the lathe via hoist and

an eyebolt,

■dismount the top jaws,

■dismount the pressure distributor,

■place the chuck down in a position preventing

chuck motion,

7.1. Dismounting the chuck

NOTE: Never place the chuck onto jaws!

!

■dismount the control pressure distributor,

■unscrew the valve cover (9),

■dismount the non-return valve (10),

■place the chuck with jaws upside down on

a special pad, so the jaws can relocate easily,

■unscrew the adapter plate screws (17),

■dismount the adapter plate screws (6),

■unscrew the piston screws (16)

■dismount the cylinder piston (7),

■unscrew the cylinder bafe screws (15),

■dismount the cylinder bafe (8),

■dismount the drawbar (2),

■dismount the master jaws (3).

■unscrew the cover screws (14),

■dismount the cover (5),

■loosen the pressure control plug (12),

■loosen the valve cover (9).

To dismount the chuck, please proceed as follows:

NOTE: When using the special top jaws, the operator should check on (determine) the correct

jaw clamping force.

!

This manual suits for next models

11

Table of contents

Other Bison Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB Relion 670 series Applications manual

Reef Octopus

Reef Octopus Neck Cleaner-110 quick start guide

RF SOLUTIONS

RF SOLUTIONS MAINSLINK quick start guide

schmersal

schmersal SLC 425I operating instructions

Siemens

Siemens SIVACON 8PS BD01 installation instructions

Rittal

Rittal RiLine Compact Assembly instructions