Bison 6620 User manual

INSTRUCTION MANUAL

No 1201-01

PRECISION MACHINE VISES

TYPE 6620, 6621, 6622, 6623, 6624

Read your instructions !

„BISON” S.A.

POLAND

www.bison-chuck.com

2

TABLE OF CONTEST:

1. SCOPE OF MANUAL...........................................................................................3

2. PRECISION MACHINE VISES APPLICATIONS..................................................3

3. CONSTRUCTION OF PRECISION MACHINE VISES..........................................3

4. BASIC SPECIFICATIONS OF PRECISION MACHINE VISES.............................5

5. OPERATION........................................................................................................9

5.1.PREPARATION THE VISE TO OPERATION..................................................9

5.2.VISE POSITIONING ON MACHINE TOOL......................................................9

5.3.FASTENING VISES ON THE MACHINE-TOOL TABLE..................................9

5.4.CHANGING THE OPENING RANGE ............................................................11

5.5.CLAMPING THE WORKPIECES...................................................................12

5.6.USING THE SETS OF VISES........................................................................15

6. ACCESSORIES..................................................................................................16

6.1.STANDARD ACCESSORIES ........................................................................16

6.2.OPTIONAL ACCESSORIES..........................................................................17

7. MAINTENANCE .................................................................................................20

8. WORK SAFETY REGULATIONS.......................................................................20

9. FINAL REMARKS...............................................................................................20

3

1. SCOPE OF MANUAL

The manual covers characteristic, operating and maintenance of precision

machine vises of 6620, 6621, 6622, 6623 and 6624 type.

2. PRECISION MACHINE VISES APPLICATIONS

Precision machine vises are used for precision milling and grinding operations

on CNC and conventional machine tools. The design, accuracy and quality ensure

exact positioning the workpiece and obtaining large clamping forces. Vises may be

also set up into machining units directly on machine table for clamping large

workpieces or multi-machining.

3. CONSTRUCTION OF PRECISION MACHINE VISES

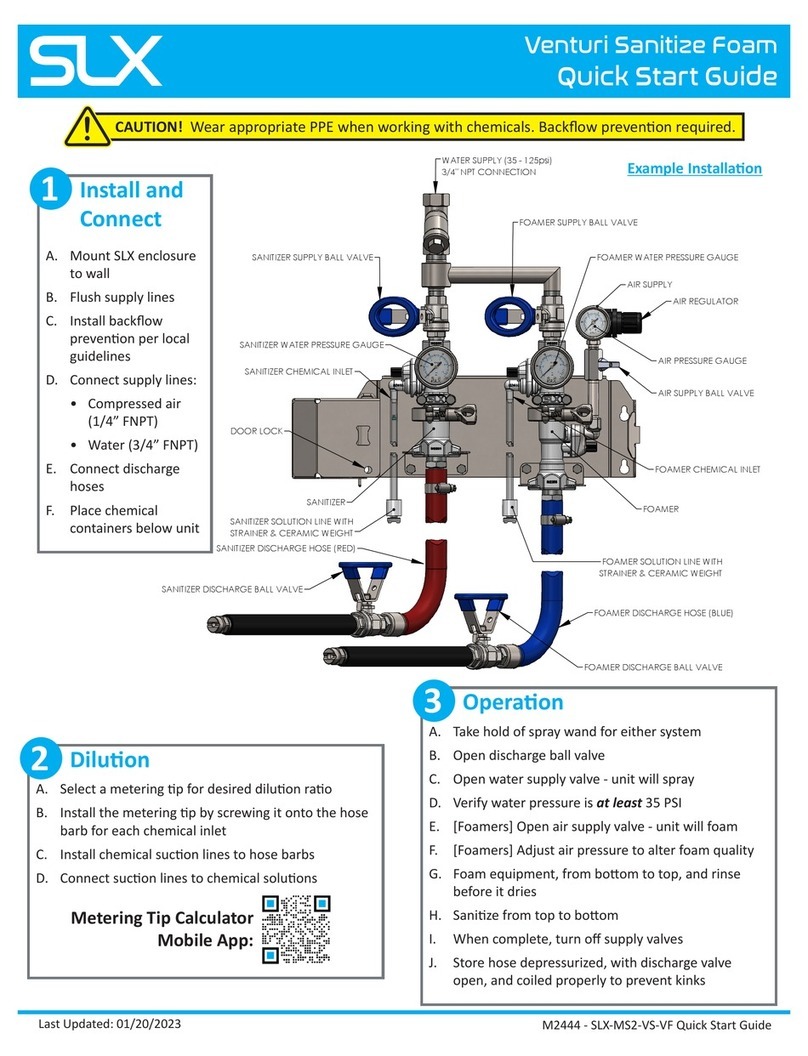

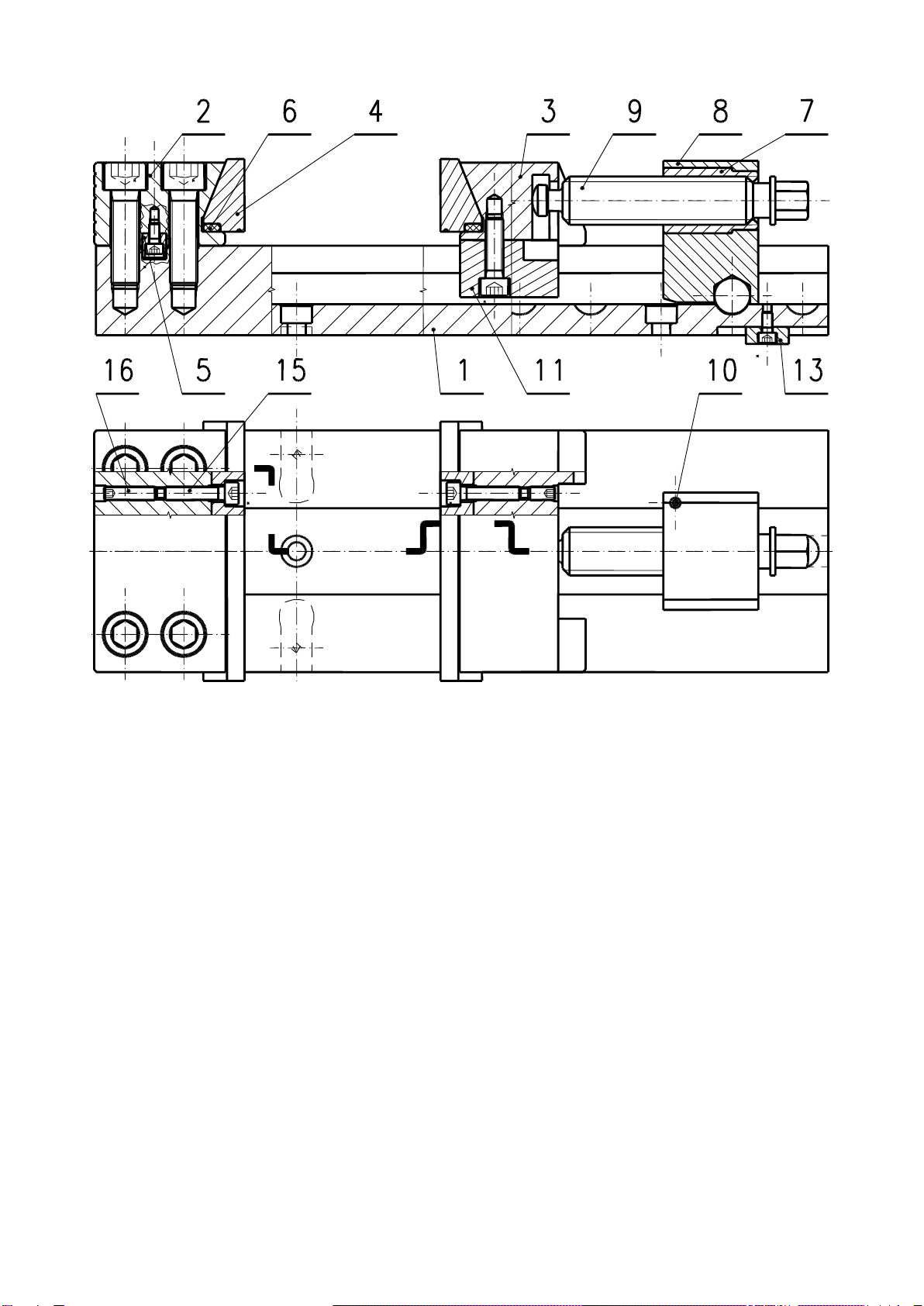

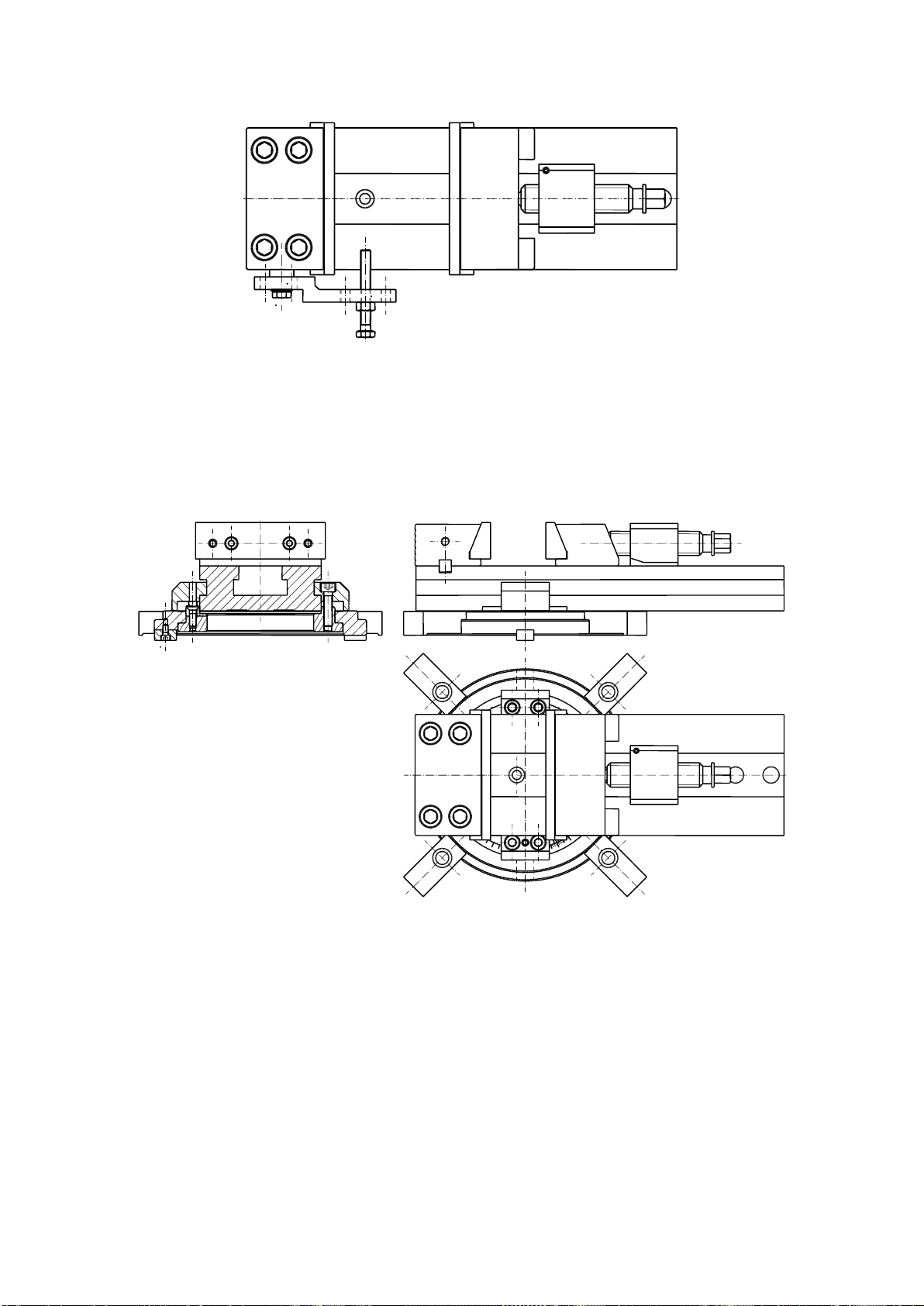

Construction of precision machine vises of 6620 is shown at Fig. 1 and 2.

Fig. 1. Construction of precision machine vises of 6620.

4

The cross-section of precision machine vise of 6620 type is shown at Fig. 2.

Fig. 2. Cross-section of precision machine vise of 6620 type

1. Base

2. Fixed jaw

3. Movable jaw

4. Clamping insert

5. Key

6. Thrust plate

7. Sleeve

8. Holder

9. Lead screw

10. Screw

11. Guide plate

12. Self-aligning guide plate

13. Fixture key

14. Clamping lug

15. Bolt

16. Screw

5

4. BASIC SPECIFICATIONS OF PRECISION MACHINE VISES

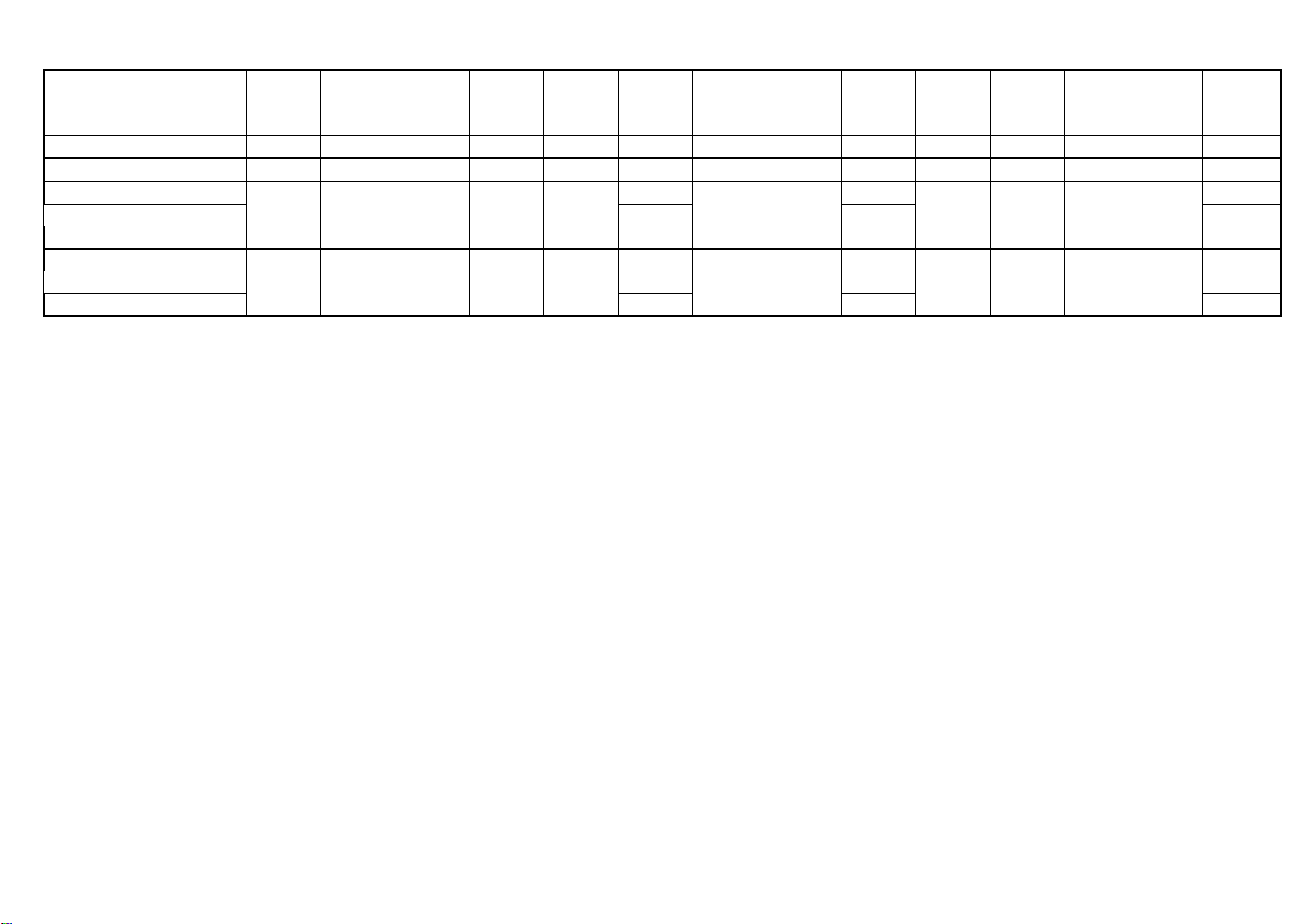

Basic specifications of precision machine vises - type 6620 and 6621 are shown

at Fig. 3 and Table 1.

Fig. 3. Basic dimensions of precision machine vises- type 6620 and 6621.

6

Table 1. Basic specifications of precision machine vises - type 6620 and 6621.

Type

S

A

B

C

H

L1

L2

L3

a

h

k

Max.clamping

force

Weight

-0,02

±0,02

M6

daN

kg

6620-100-320/165

100

85

35

13

65

320

61,8

18

165

30

12

2000

9,84

6620-125-335/165

125

105

42

15

82

335

68

24

165

40

12

3000

15,71

6620-150-425/210

425

210

31,95

6620-150-475/260

150

140

52

18

102

475

87,29

30,2

260

50

18

4100

35,18

6620-150-520/305

520

305

36,96

6620-200-535/260

535

260

58,95

6620-200-585/310

200

165

61

20

121

585

109,43

47,07

310

60

18

4500

61,66

6620-200-635/360

635

360

64,36

NOTE !

Dimension h in 6620 type vises is different then that in vises of 6566; 6567; 6568; 6569-M; 6571 and 6577

7

Basic specifications of precision machine vises - type 6622 and 6623 are shown

at Fig. 4 and Table 2.

Fig. 4. Basic dimensions of precision machine vises - type 6622 and 6623.

Table 2. Basic specifications of precision machine vises - type 6622 i 6623.

Type

S

A

B

-0,02

C

L

a

h

k

M6

Max.clamping

force

[daN]

Weight

[kg]

6622-100

100

85

35

13

140

48

30

12

2000

5,3

6622-125

125

105

42

15

160

60

40

12

3000

8,7

6622-150

150

140

52

18

210

86

50

18

4000

19,1

6622-200

200

165

61

20

240

78

60

18

4500

33,9

8

Basic specifications of precision machine vises - type 6624 are shown at Fig. 5

and Table 3.

Fig. 5. Basic dimensions of precision machine vises- type 6624.

Table 3. Basic specifications of precision machine vises - type 6624.

Type

S

A

B

-0,02

C

D

±0,04

L

L1

±0,02

h

k

M6

Max.

clamp

force

[daN]

Weight

[kg]

6624-100

100

85

35

13

80

155

10

30

12

2000

4,4

6624-125

125

105

42

15

84

160

10

40

12

3000

6,7

6624-150

150

140

52

18

110

210

12

50

18

4000

14,5

6624-200

200

165

61

20

127

240

15,5

60

18

4500

26,5

9

5. OPERATION

5.1. Preparation the vise to operation

After unpacking the vise please:

➢

Check if none of parts is missing,

➢

Remove the preservative from vise surfaces,

➢

The mating surfaces of clamping inserts (4), fixed jaw (2) and movable jaw (3)

should be covered with some grease,

➢

While transporting the vise to machine tool make sure that the holder is

protected against self-tilting by means of the screw (10),

➢

Screw (10) should not be screwed to the vise guides,

➢

Before attempting the operation check the gap width between clamping

inserts and jaws as stated in point 5.5.

5.2. Vise positioning on machine tool

Use the parallel and longitudinal keyways and fixture keys (13) to position the

vise on the machine-tool table.

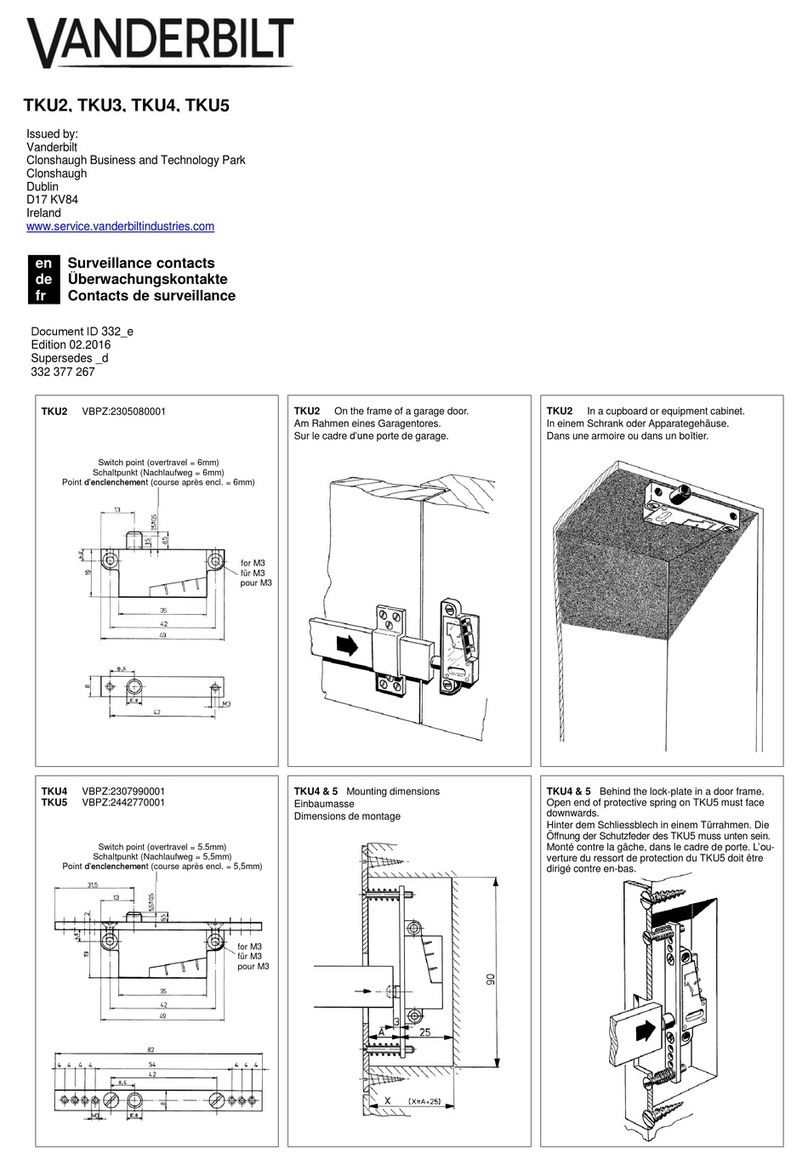

5.3. Fastening vises on the machine-tool table

Machine vises of 6620 type may be fastened on machine-tool table in

longitudinal and transverse way. The transverse fastening with clamping lugs,

delivered with vises, is able on tables with dimensions as shown in Fig.7 and Table

4. Location of clamping lugs is shown in Fig. 6.

Fig. 6. The way of fastening machine vises of 6620 type on machine-tool table.

10

Fig. 7 shows correct location of the vise on machine-tool table. Only unloaded

part of the vise base may project outside the table (the one beyond the holder).

Cases shown in Fig. 8 are forbidden.

Fig. 7. Correct location of vise on machine-tool table

Table 4. Machine-tool table dimensions

Type

Machine-tool table dimensions

a

t

M

100

12

50; 100

M10x35-10.9

125

12

32; 63

M10x35-10.9

150

18

50; 100

M16x45-10.9

200

18

63; 125

M16x45-10.9

11

Fig. 8. Forbidden location of vise on machine-tool table.

5.4. Changing the opening range

Before changing the opening range clean vise base (1), lead screw (9) and

holder (9). To change the opening range just tilt the holder (8) forward and move it

to engage the proper recess in the base (Fig. 9).

Fig. 9. Changing the opening range

The screw (10) located in holder (8) secures the holder from self-tilting and

accidental movement of whole assembly: holder-lead screw-movable jaw.

Holder (8) must be secured from self-tilting by screwing on the screw (10)

when:

➢

transporting or repositioning the vise on the machine-tool

➢

using the vise in vertical position

The screw (10) should not be screwed to the vise guides.

12

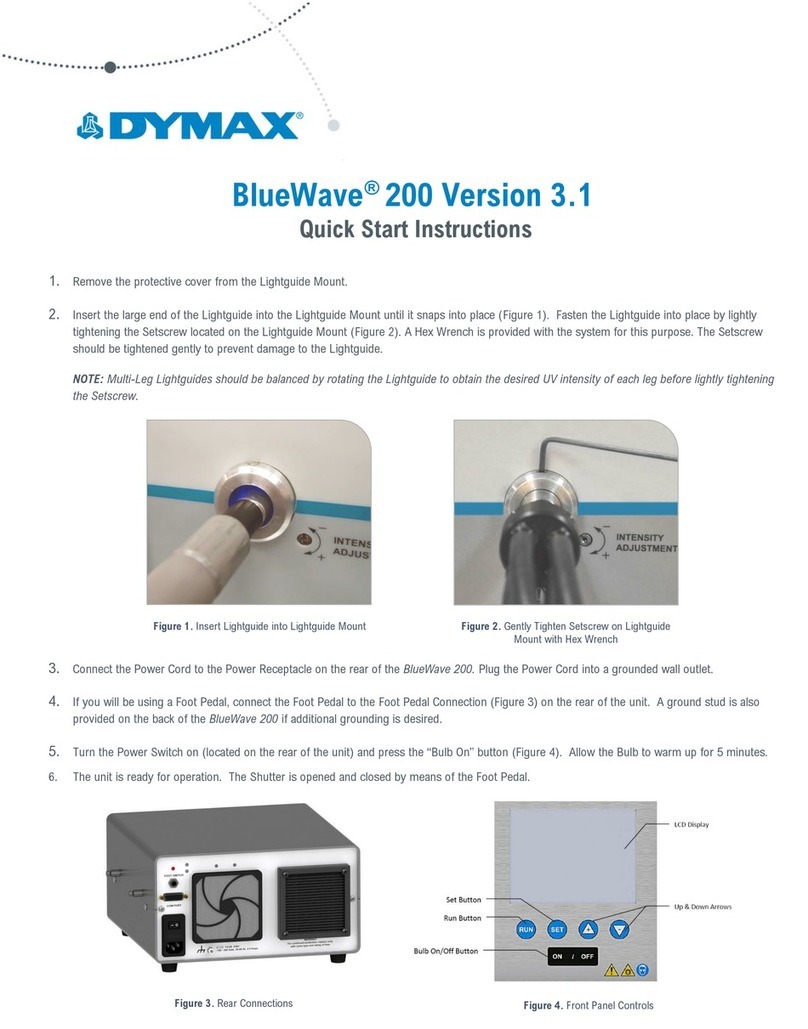

5.5. Clamping the workpieces

Clamping inserts are seated in vise jaws with play ensuring correct clamping

the workpieces. The value of play should be L = 0.2 mm with accuracy of positioning

0.01 mm. The difference between “L” dimensions in movable and fixed jaw should

not exceed 0.01 mm. Accuracy of positioning of clamping insert is shown in Fig. 10.

Fig. 10. Accuracy of positioning of clamping insert.

To obtain the required positioning of clamping insert do as follows:

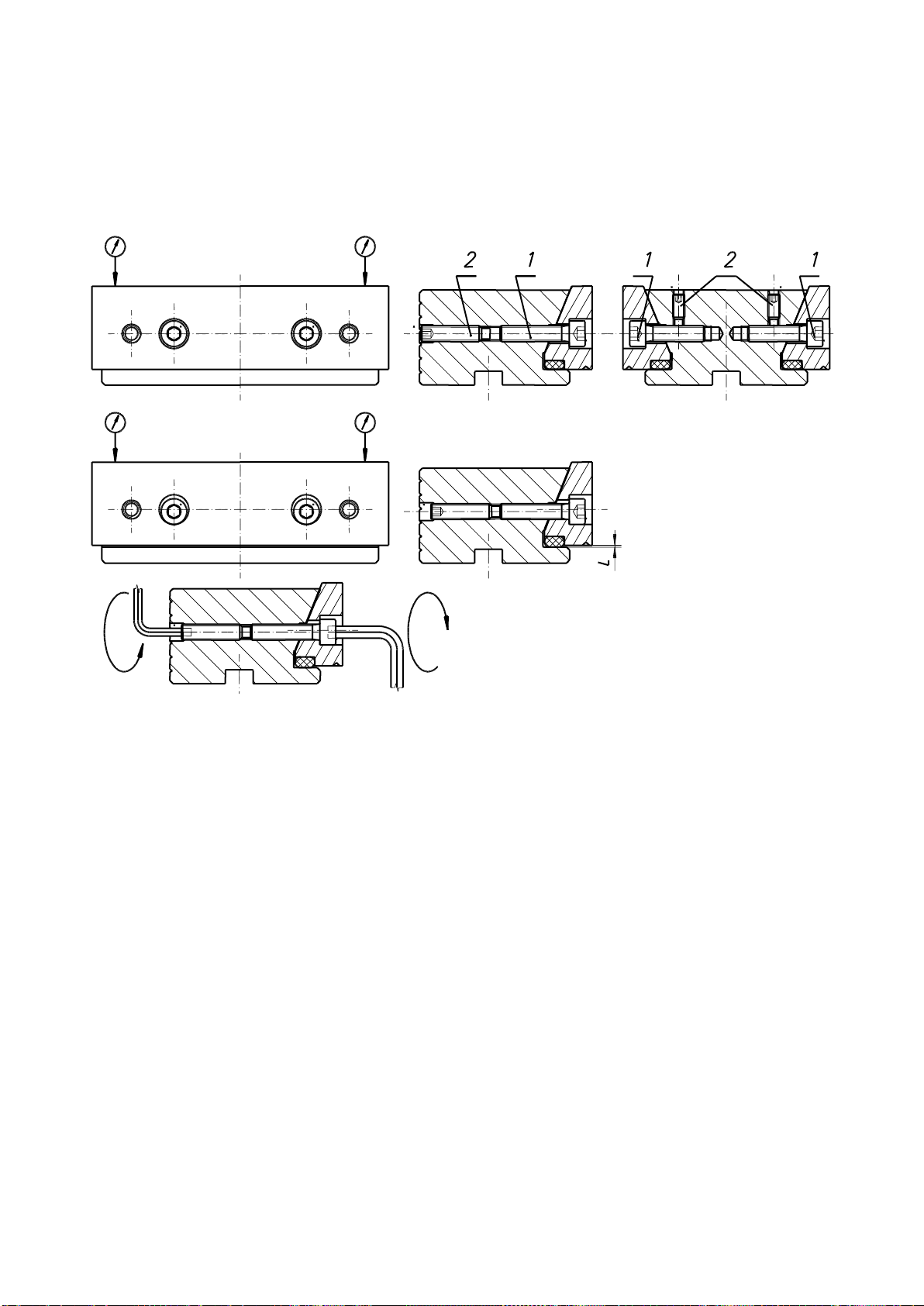

1. Loosen set screws (2).

2. Tighten the bolts (1) to make the clamping insert seat in jaw guide.

3. Check with dial gauge the parallelism of clamping insert toward the vise

base.

4. By loosing bolts (1) set required value of L = 0.2 (

0.01) mm.

5. Check with dial gauge the parallelism of clamping insert toward the vise

base, parallelism of clamping insert toward the vise base should be the same

as measured in point 3.

6. By tightening set screws (2) secure bolts (1).

Perform above steps for setting clamping inserts both in fixed jaw and movable jaw.

The proper clamping conditions is obtained when clamping inserts seat into jaw

guides. That assures the best clamping accuracy.

13

Each time after end of machining:

➢

clean thoroughly the base guides, clamping inserts, jaws and lead

screw,

➢

pay special attention to clean the gap between clamping inserts and

jaws (L dimension on Fig. 10).

If during the clamping, inserts do not seat on jaw guides:

➢

dismantle clamping inserts,

➢

clean insert surfaces mating the jaws and cover them with some grease

➢

by means of mounting bolts set the correct position of inserts to obtain

the required value of L.

Hammering the clamping inserts or the workpiece, base guides or the

wrench when clamping is forbidden.

Do not lengthen the wrench while clamping.

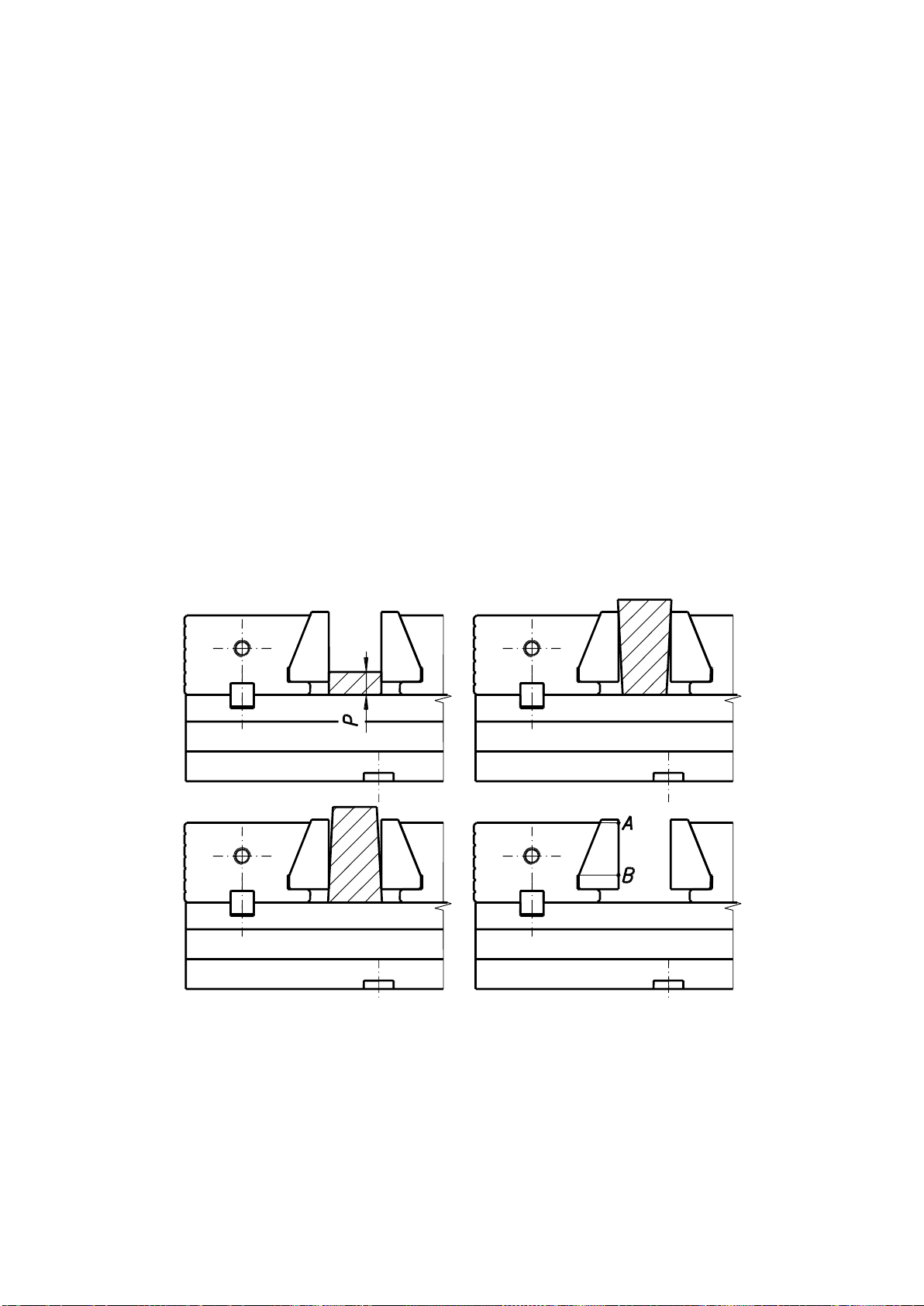

Inadmissible shape, thickness and way of clamping workpieces in vise jaws

presented in Fig. 9 are inadmissible. The workpieces should be clamped at the A-B

section of clamping insert (Fig. 11). The thickness of clamped workpieces (“P”

dimension as in Fig. 11) should not be less then 1/3 h (the “h” values as presented

in Fig. 3).

Fig. 11. Inadmissible shape of workpiece.

14

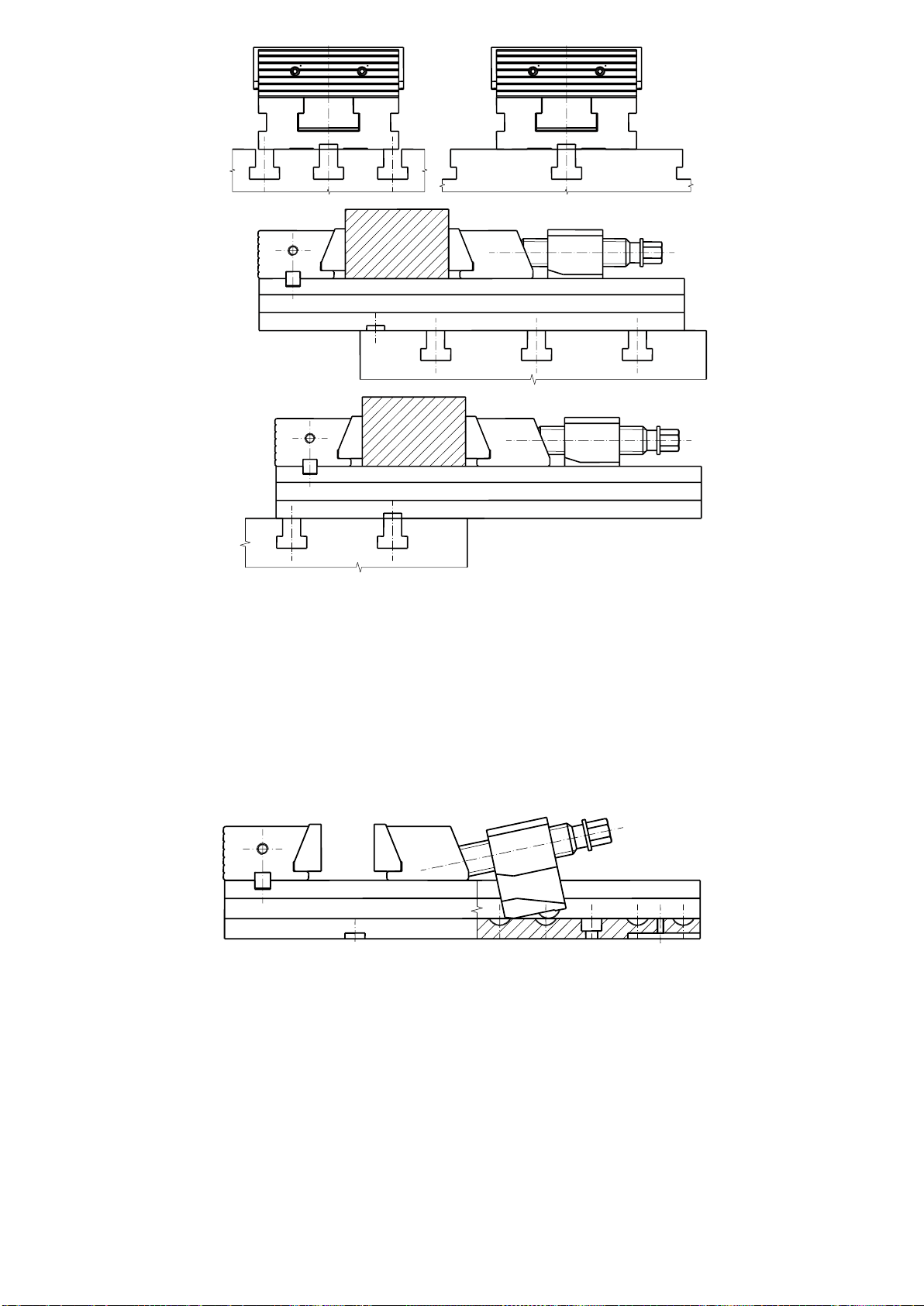

The ways of clamping the workpieces of irregular shapes are shown at Fig. 12,

13 and 14.

Fig.12. The way of clamping the workpiece of irregular shape.

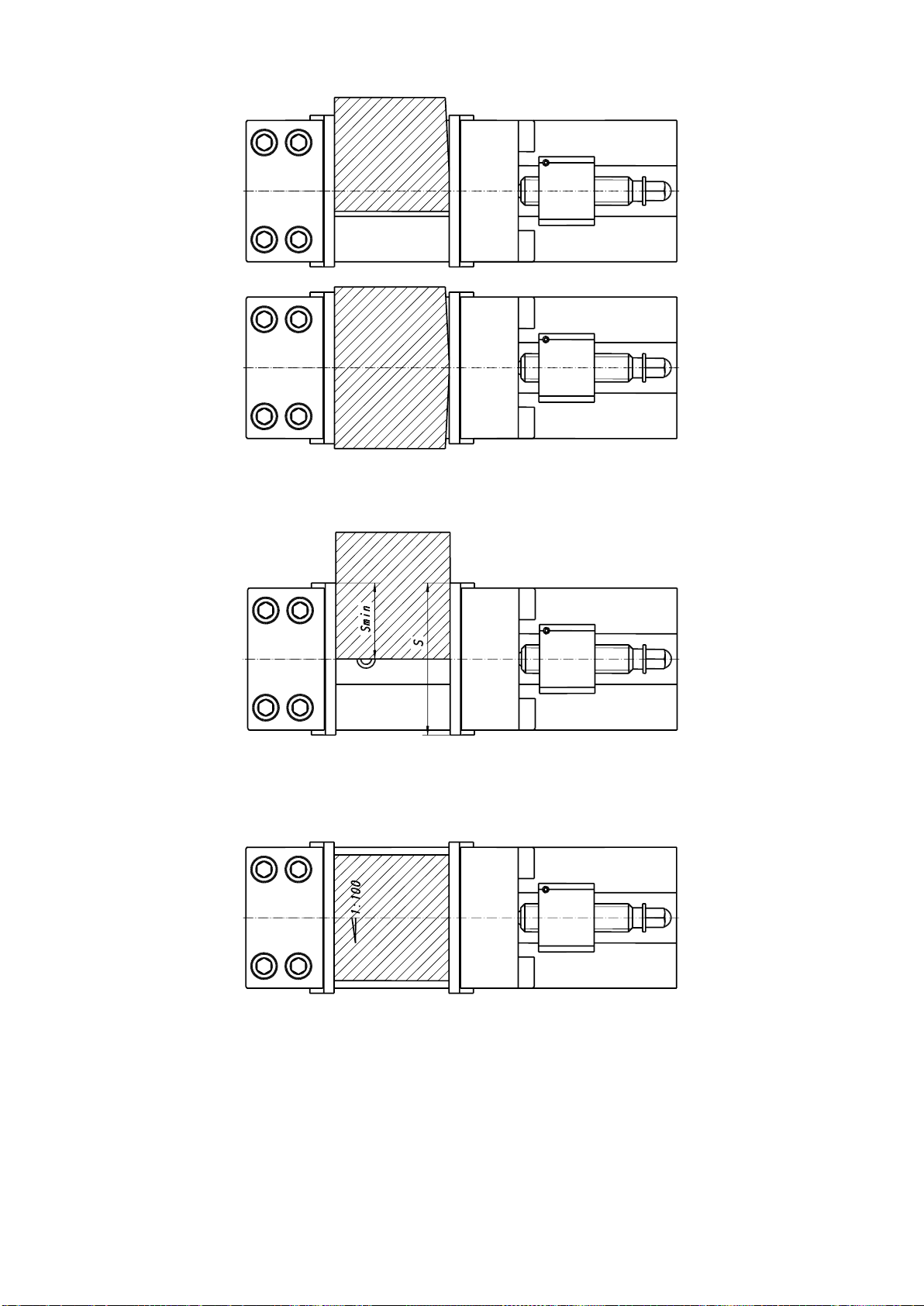

The right effectiveness of clamping is achieved when S

min

>1/2 S.

Fig. 13. The way of clamping the workpiece of irregular shape.

The clamping the workpiece with taper lower then 1:100 may be effective only

when it is clamped at entire length of jaws.

Fig. 14. The way of clamping the workpiece of irregular shape.

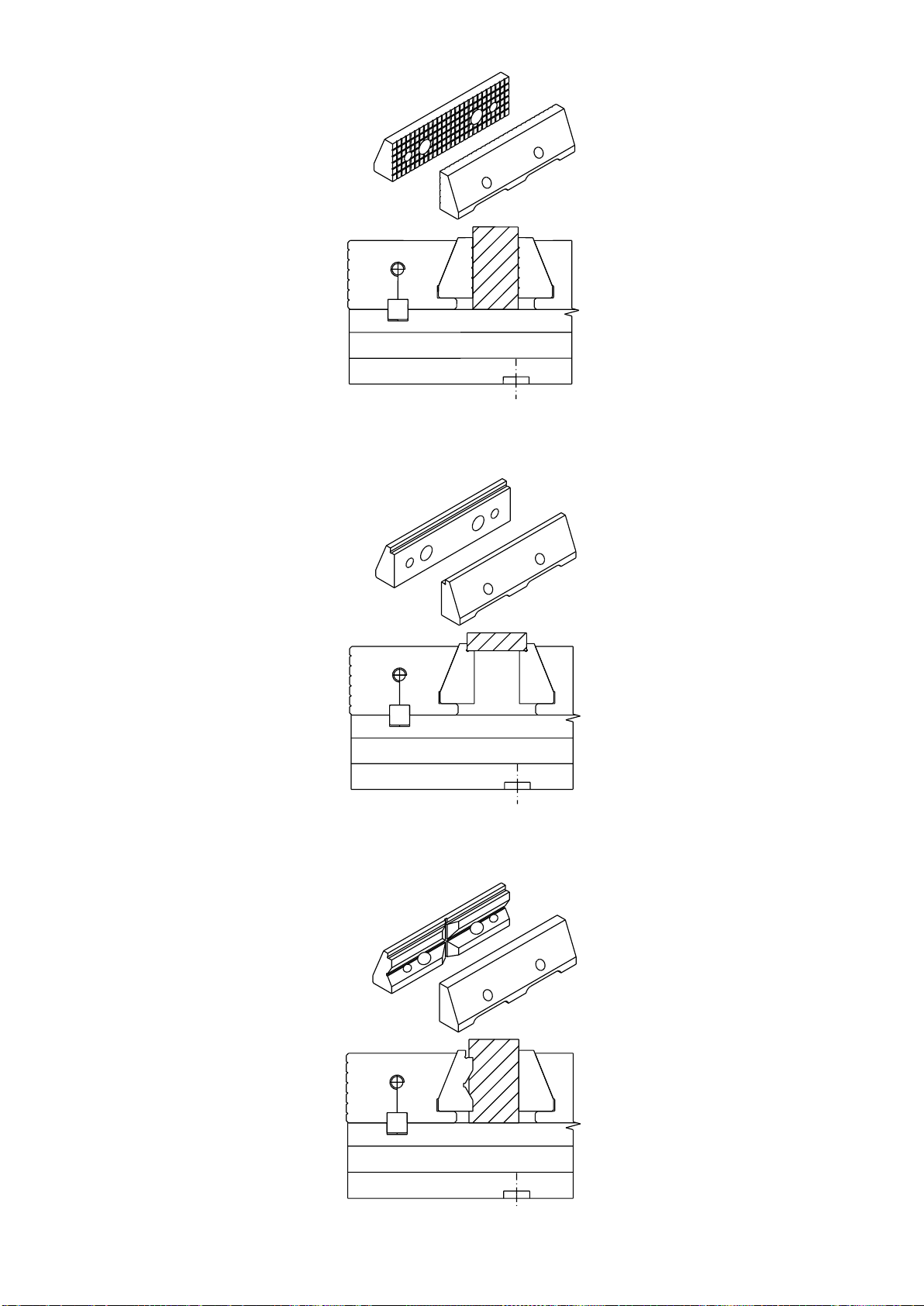

Jaw insert should be mounted on jaw guides when:

➢

Clamping the workpiece with jaw edges

➢

Clamping the workpiece with grooved surface of stationary jaw

➢

Clamping the workpiece with the prismatic or stepped jaw inserts

(Fig. 22, Fig. 23)

➢

Clamping the workpiece with the grooved jaw inserts (Fig. 21),

15

When clamping shafts with the prismatic jaw insert (Fig. 23) the other jaw insert

must have plain surface.

For clamping the workpieces with irregular shapes the swinging leading plate

can be used which allows the movable jaw to swivel by about ± 2°.

Fig. 15. Usage of self-aligning guide plate.

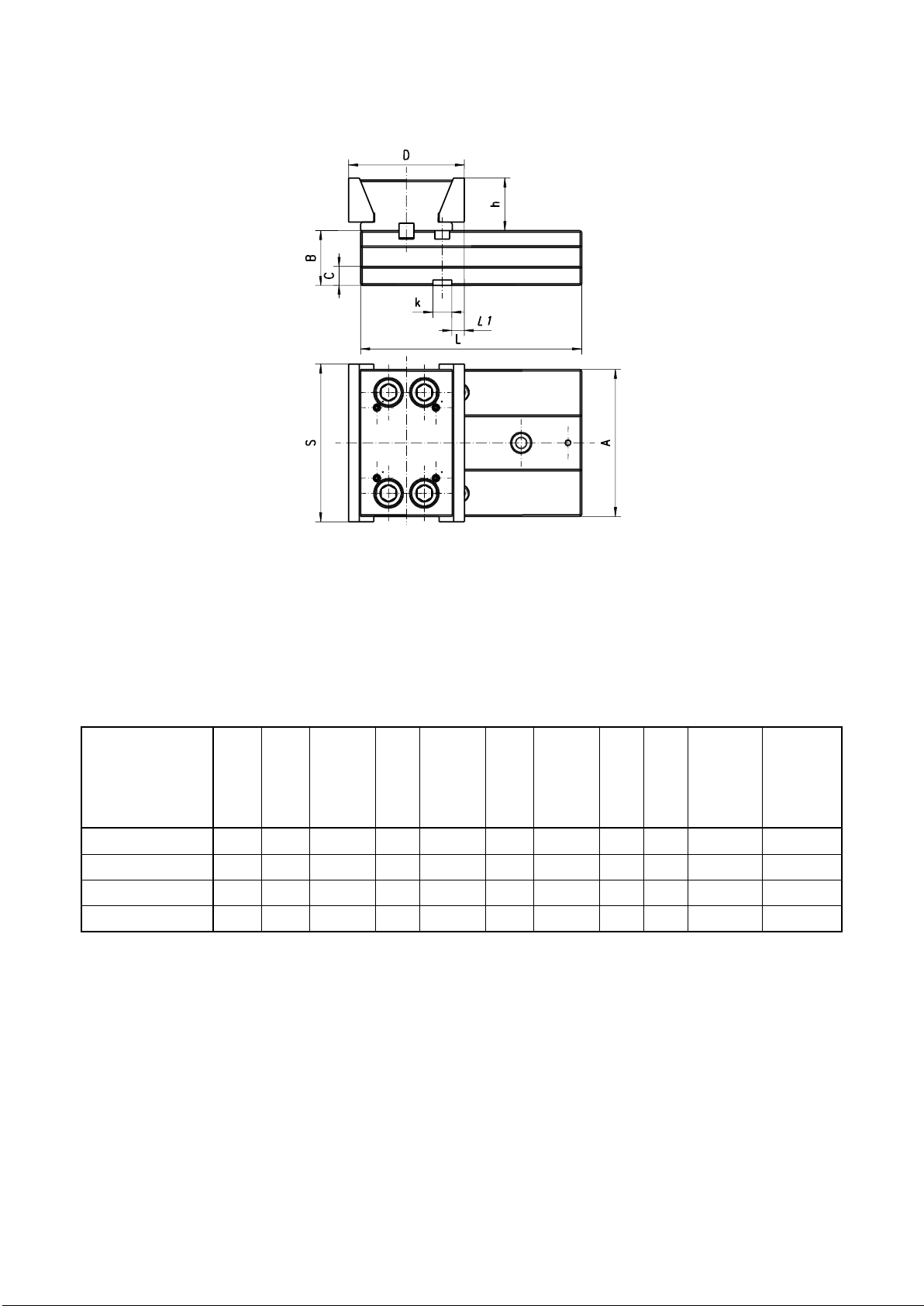

5.6. Using the sets of vises

Precision machine vises may be assembled in machining sets. It enables

machining large workpieces or multi-machining. Examples of clamping positions

with the use of vises of 6620; 6621; 6622; 6623; 6624; 6568; 6569M; 6571; 6577

type are shown in Fig. 17.

Fig. 16. Examples of clamping.

Type

L1

L2

L3

L4

100

0 –43

0 –40

7 –64

50 –107

125

0 –43

0 –50

8 –76

52 –120

150

0 –62

0 –75

12 –106

67 –166

200

0 –57

0 –65

13 –104

75 –166

16

Fig. 17. Examples of clamping positions.

6. ACCESSORIES

6.1. Standard accessories

Standard accessories for the precision vises include:

Item

Type

6620

6621

6622

6623

6624

Wrench

1

–

1

–

–

Clamping lug

6

6

4

4

4

Self-aligning guide plate

1

1

1

1

–

Wrench type 6596

–

1

–

1

–

Fixture key

2

2

2

2

2

Fixture key screws

2

2

2

2

2

17

6.2. Optional accessories

The optional accessories of precision vises include:

➢

Lead screw block - it may be replaced with hydraulic spindle block or may be

a spare part

Fig. 18. Lead screw block.

➢

Hydraulic spindle block - it may be replaced with lead screw block or may be

a spare part

Fig. 19. Hydraulic spindle block.

➢

clamping inserts plain

Fig. 20. Clamping insert - plain.

18

➢grooved jaw insert

Fig. 21. Grooved jaw insert.

➢stepped jaw insert

Fig. 22. Stepped jaw insert.

➢prismatic jaw insert with step

Fig. 23. Prismatic jaw insert with step.

19

➢

side stop of 6597 type - when fastened to the side of fixed jaw enables

positioning of workpieces parallel to inserts surfaces

Fig. 24. Side stop of 6597 type.

➢

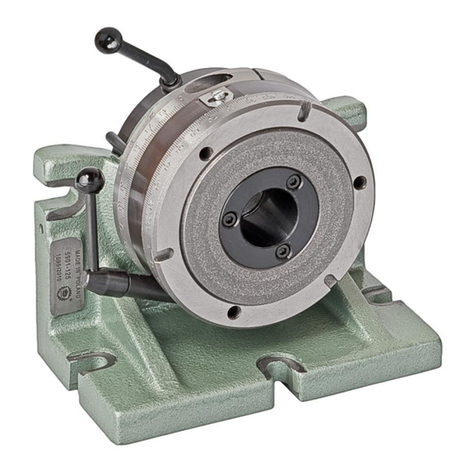

swivel base of 6586 type - enables rotating the vise around vertical axis at a

required angle. The base is graduated

90

in 1

increment.

Fig. 25. Swivel base of 6586 type.

20

7. MAINTENANCE

Each time after end of work:

➢

Clean thoroughly the vise.

➢

Dismantle the

clamping inserts.

➢

Clean inserts, jaws and thrust plates.

➢

Cover the surfaces of inserts mating with the jaws with some grease.

➢

By means of mounting bolts set the correct position of inserts to obtain the

required value of L dimension (point 5.5).

➢

Preserve the vise with the anti-corrosive.

8. WORK SAFETY REGULATIONS

➢

Operator must read this instruction before attempting to operation.

➢

In case of abnormal work of spacer or damages, stop the work and inform

supervision staff.

➢

Qualified personnel must perform repairs and overhauls.

➢

Except mentioned above regulations observe your local safety rules.

9. FINAL REMARKS

➢

Following the instructions given in this manual provides long lasting and

trouble-free vice operation.

➢

Failing to do this will void any manufacturer warranties and liability.

Manufacturer reserves the right to make the construction changes without notice

General Terms and Conditions of a Guarantee and Complaint of the

“BISON” S.A. Company Ltd. Products –are given in the

www.store.bison-chuck.com

This manual suits for next models

12

Table of contents

Other Bison Industrial Equipment manuals