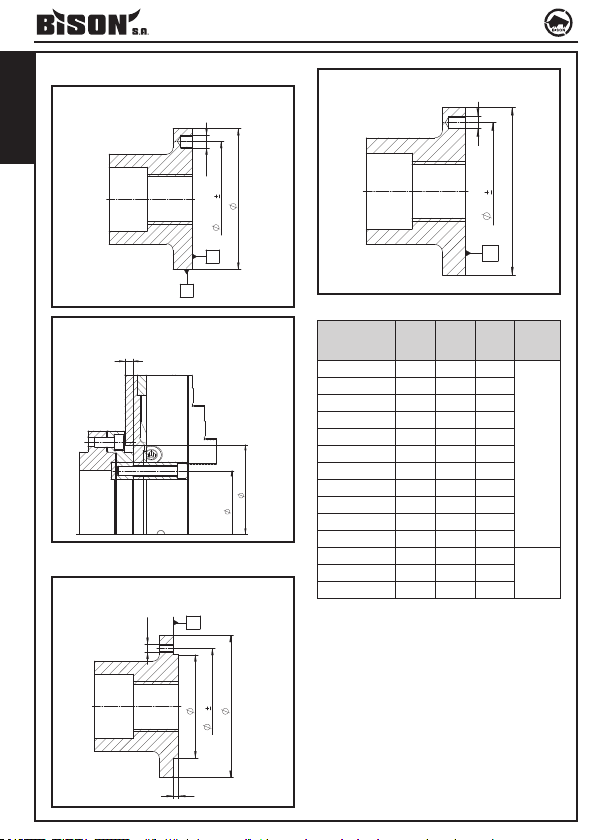

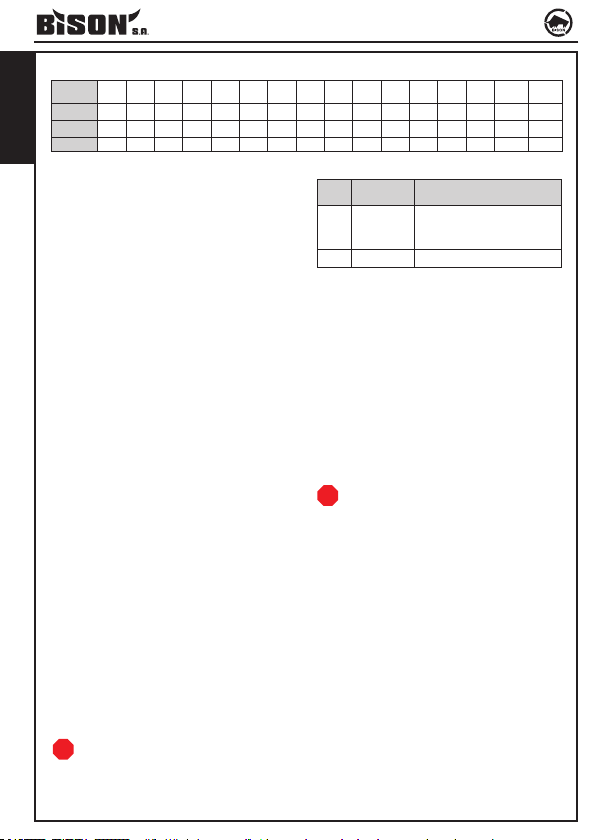

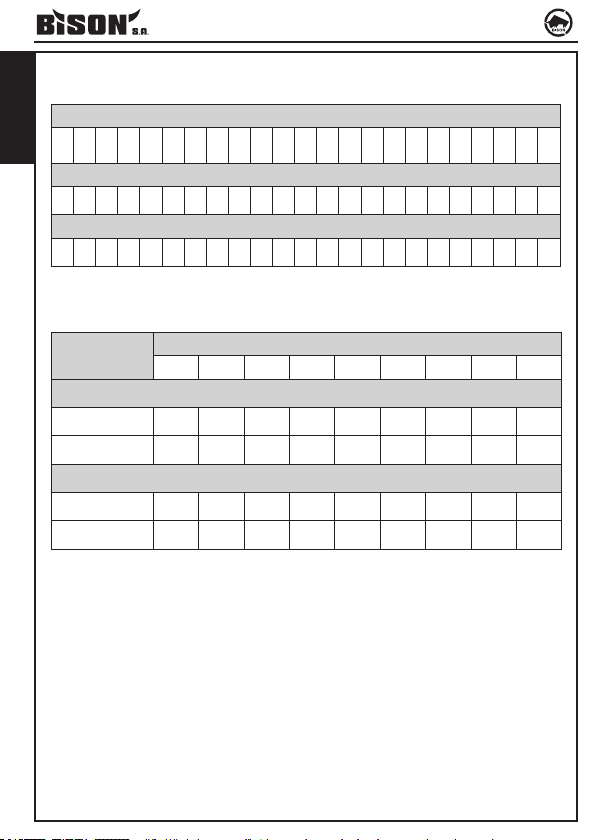

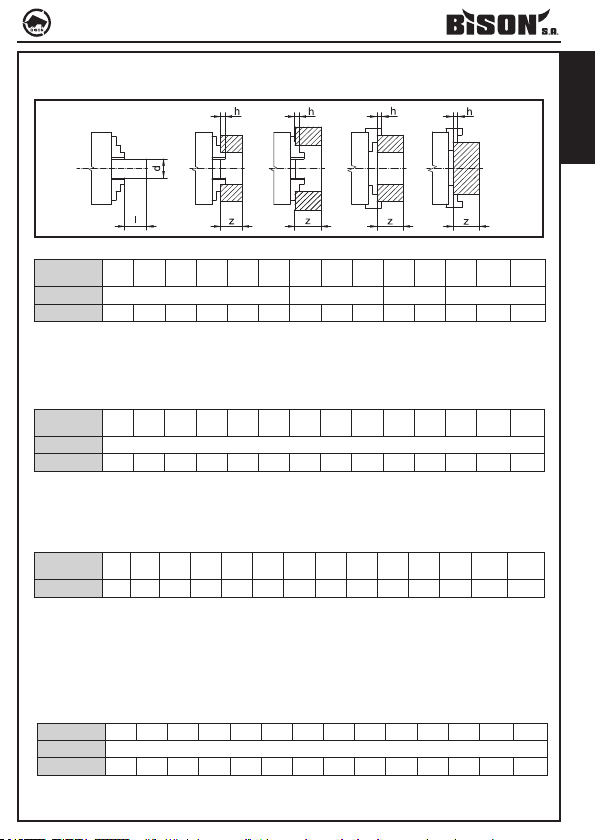

Bison 32 Series User manual

This manual suits for next models

60

Table of contents

Languages:

Other Bison Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

CAVIDYNE

CAVIDYNE Caviblaster 2040-ROV-M2 Operation & maintenance manual

NeoDen

NeoDen 7 user manual

MICRO-EPSILON

MICRO-EPSILON scanCONTROL 25 Series operating instructions

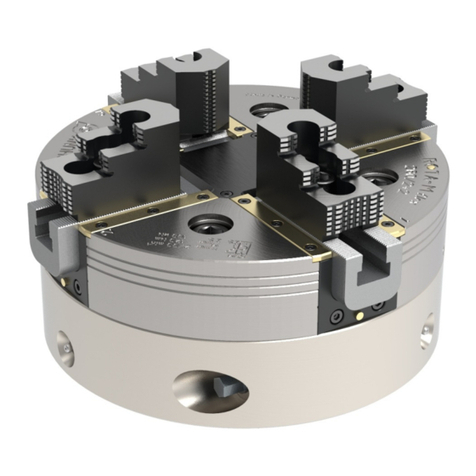

SCHUNK

SCHUNK ROTA-M flex 2+2 Series Assembly and operating manual

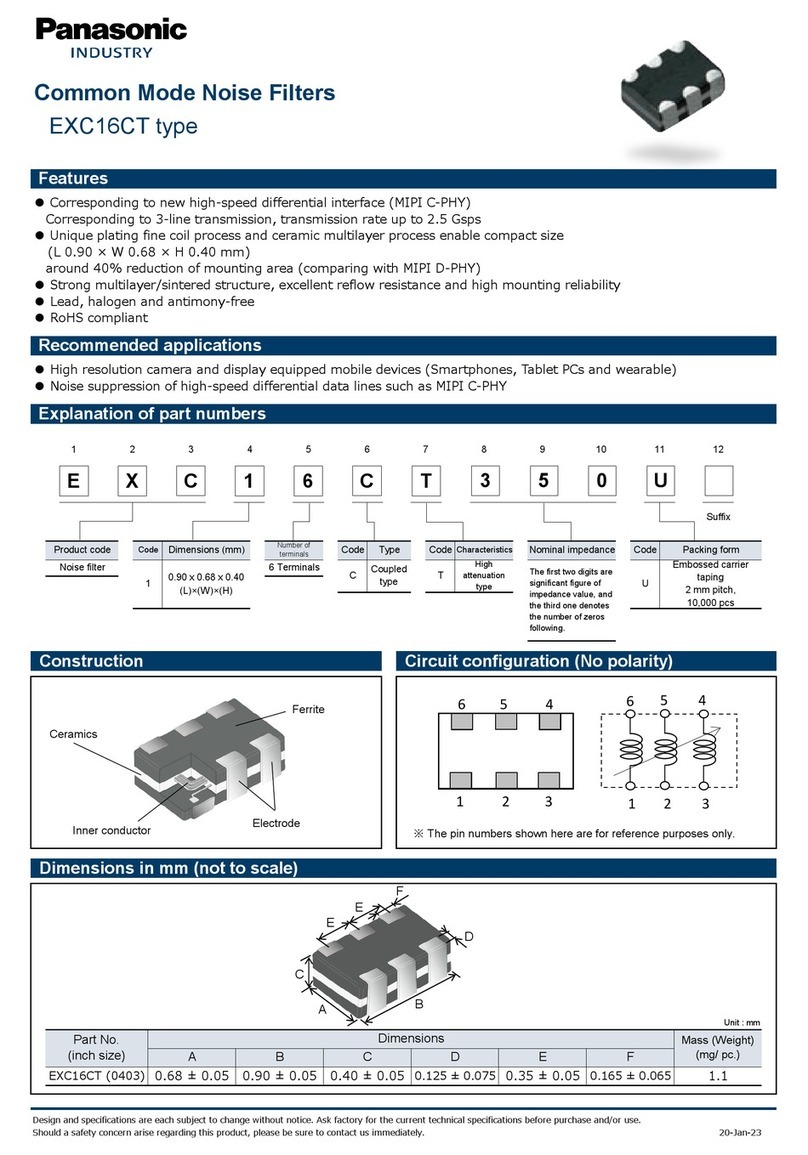

Panasonic

Panasonic EXC16CT quick start guide

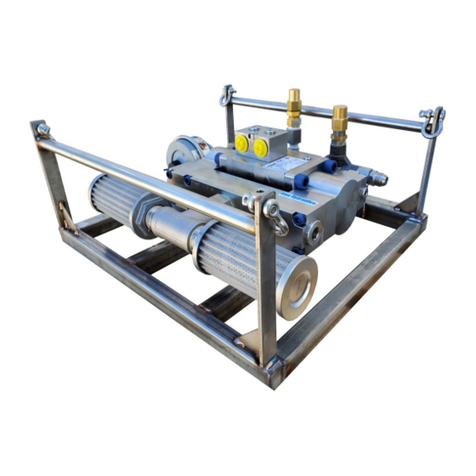

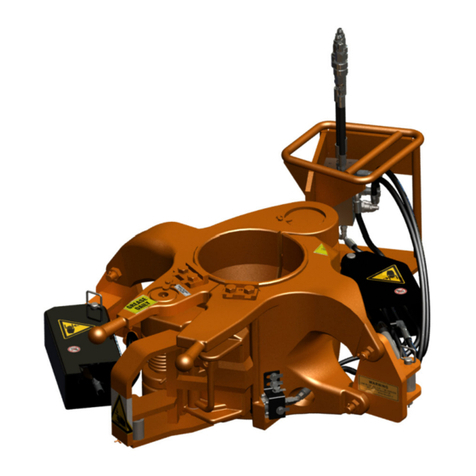

Blohm + Voss Oil Tools

Blohm + Voss Oil Tools VES-HCL 350 Original instructions

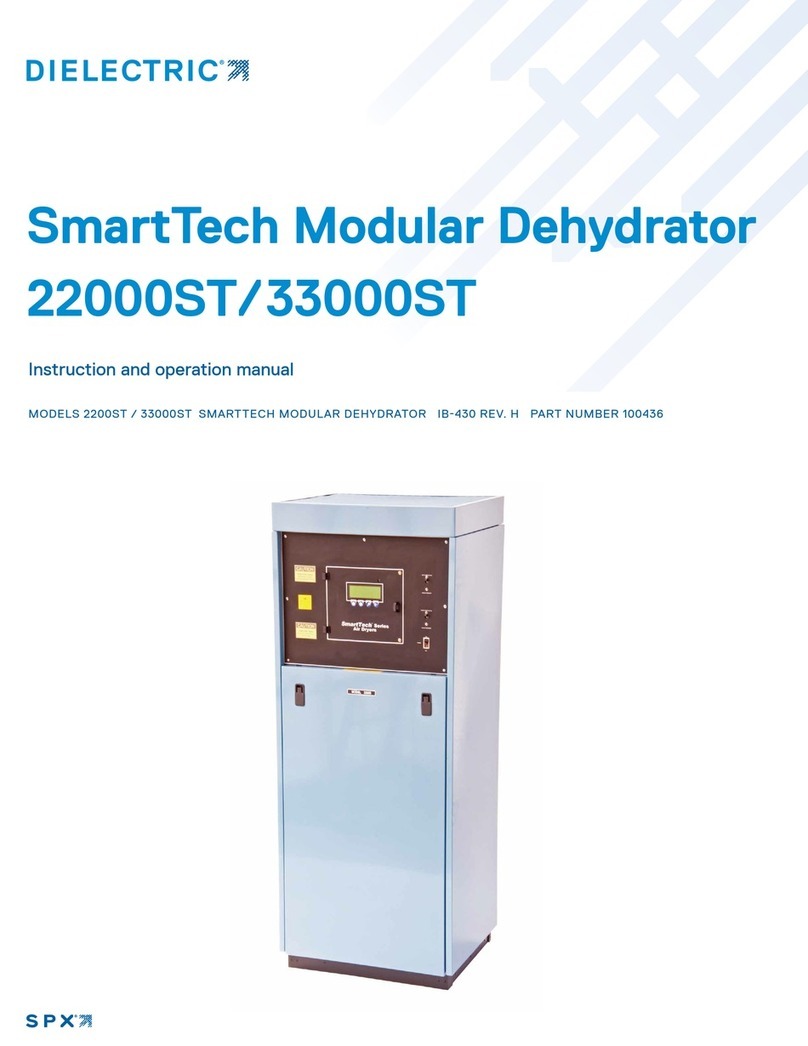

Dielectric

Dielectric 2200ST SmartTech Modular Dehydrator Instruction and operation manual

Kval

Kval EFX Operation manual

GIGAIPC

GIGAIPC QBiX-Pro-AMDA1606H-A1 quick start guide

INOXPA

INOXPA CPG Series Installation, service & maintenance instruction

PERGO

PERGO SCHWAMMFIX POWER SPONGE 620P User & Safety Instructions

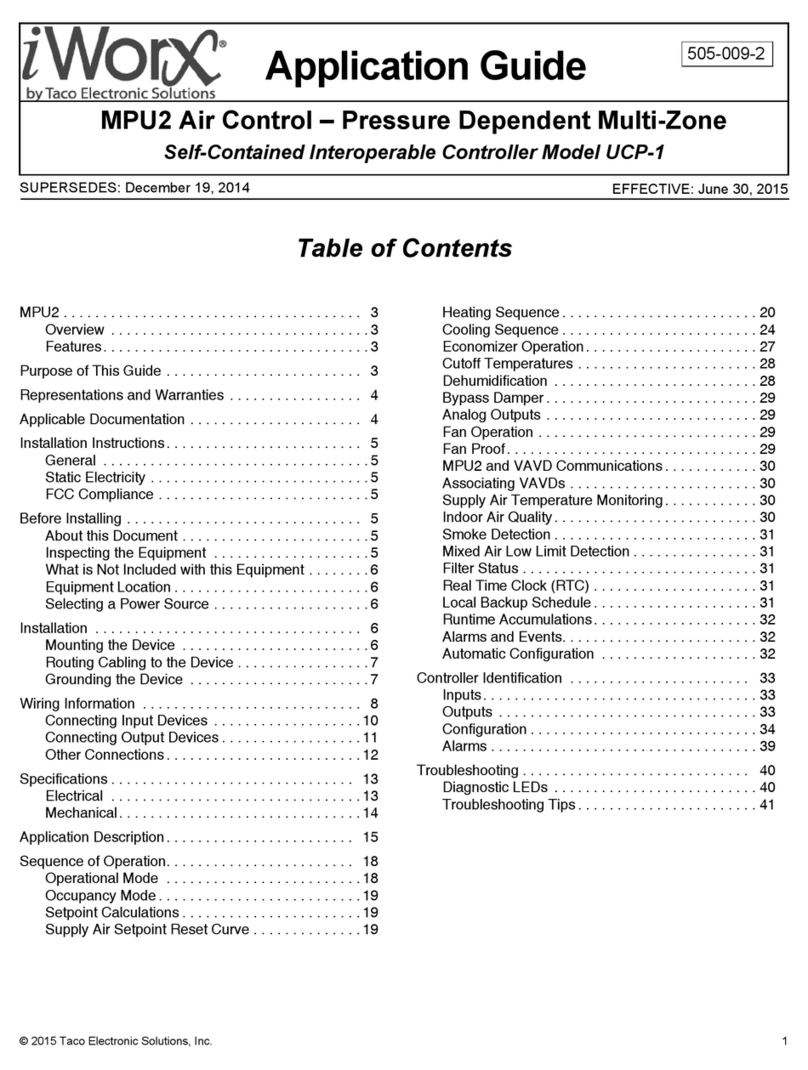

Taco Electronic Solutions

Taco Electronic Solutions iWorx MPU2 Application guide