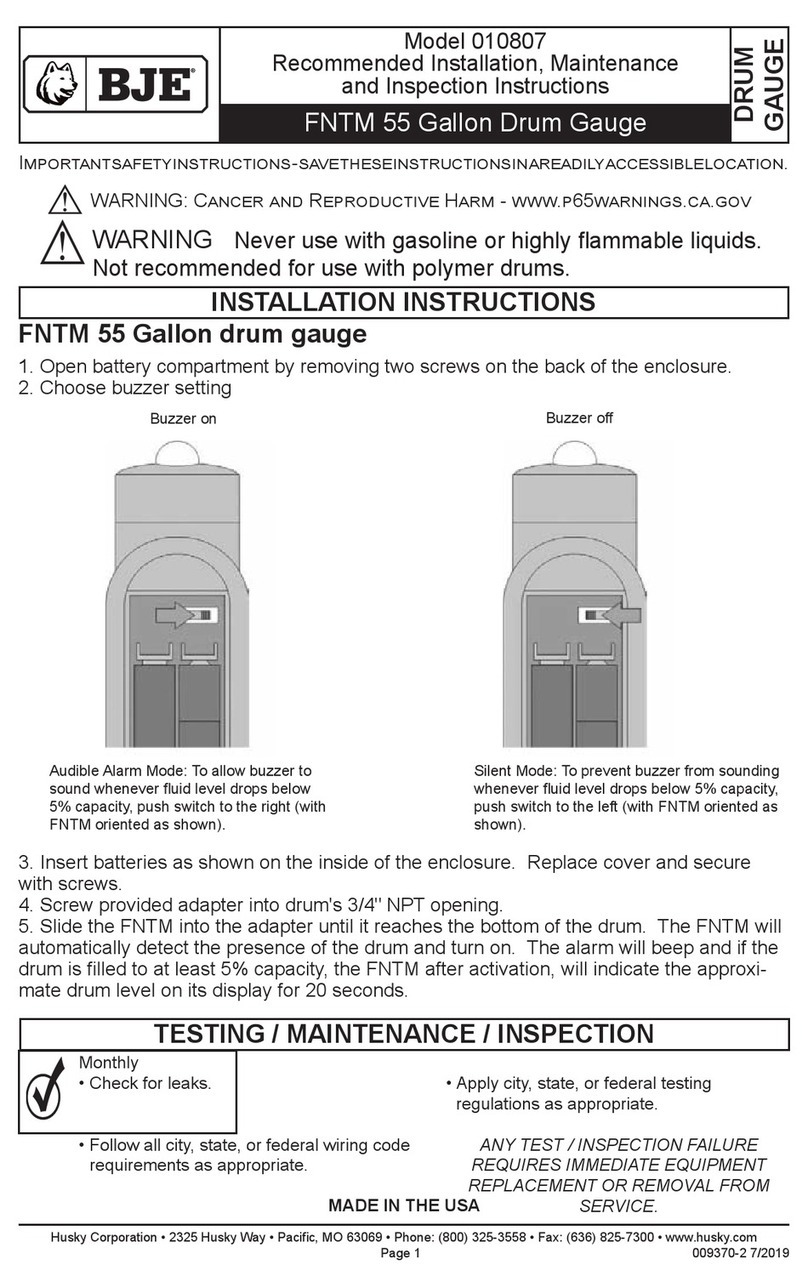

BJE 007685 Installation instructions

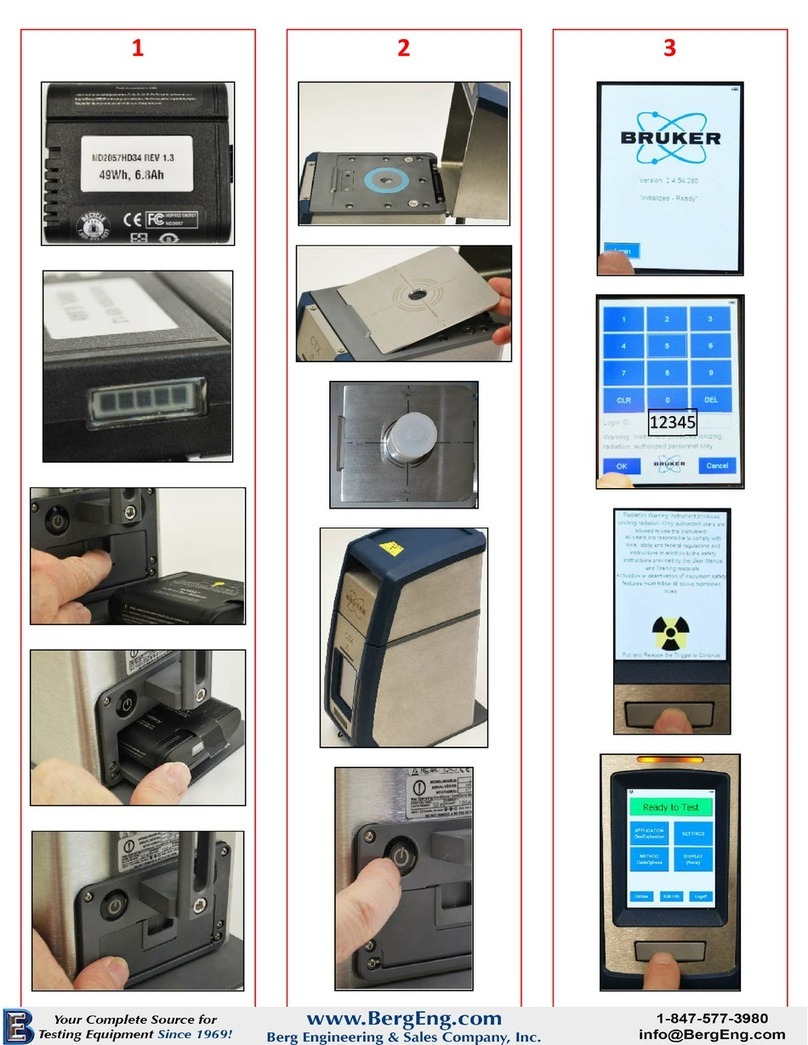

1. Locate the most visible location to install control panel.

2. Securely (not permanently) mount control panel to wall.

3. Assemble gauge (do not install to tank).

4. Loosen thumbscrews on sensor.

5. Slide sensor to desired depth (high or low).

6. Connect an ohmmeter to sensor leads.

8. Once proper setting is achieved, lock sensor in place using thumbscrews - tighten

9. Remove glass jar and linkage assembly from bung adaptor - do not disturb sensor

setting.

10. Use appropriate sealant on the male threads of bung adaptor.

past hand tight, but do not overtighten.

12. Install linkage assembly into bung adaptor. Float arm must travel freely and not contact

overtighten.

14. Solder (or wire nut) sensor leads then tape the connections.

15. Seal hole with silicone or appropriate sealant.

16. Connect wire to printed circuit board terminals marked "FLOAT".

17. Install 9-volt battery.

DO NOT OVERTIGHTEN. DO NOT USE SIGHT GLASS AS A WRENCH.

TESTING / MAINTENANCE / INSPECTION

Jarhead

WARNING

Page 1 009313-6 7/2019

INSTALLATION INSTRUCTIONS

Daily

"ON" position.

• Remove sensor from tank and

system goes into alarm mode.

connected to control panel and

sensor(s).

Biannually

• Replace 9-volt battery.

Replace 9-volt battery if tank alarm

occurs.

• Follow all city, state, or federal wiring

• Apply city, state, or federal testing

regulations as appropriate.

ANY TEST / INSPECTION FAILURE

REQUIRES IMMEDIATE EQUIPMENT

REPLACEMENT OR REMOVAL FROM

SERVICE.

MADE IN THE USA

Jarhead Tank Gauge

and Inspection Instructions

007685

007686

008646

008664

008677

009969

CAUTION: MONITOR IS DISABLED WHEN TOGGLE SWITCH IS

TURNED OFF!

ALWAYS ADHERE TO INSTALLATION / USAGE INSTRUCTIONS AND WARNINGS.

Improper use may result in injury, damage, or hazardous spill.

Husky Corporation will, at its option, repair, replace, or credit the purchase price of any BJE®product deemed to be defective

in material and/or workmanship for a period of one (1) year.

Buyer must return the products to Husky®, transportation charges prepaid. The warranty excludes damages due to

malfunction, failure to follow manufacturer's installation, operation or maintenance instructions and guidelines, unauthorized

The warranty provisions contained herein apply only to original purchasers who use the equipment for commercial or

Husky assumes no liability for labor charges or other costs incurred by Buyer incidental to the service, adjustment, repair,

incurred by the purchaser during the time necessary to repair the equipment. Husky assumes no liability for any incidental,

consequential, or other damages under any warranty, express or implied, and all such liability is hereby expressly excluded.

Husky reserves the right to change or improve the design of any Husky Oil Filter Crushers, Tank Monitors, Tank Gauges,

WARRANTY

• Use of equipment is at individuals’ own

risk.

and federal regulations regarding

use and installation of monitoring

equipment.

manufacturer’s installation and

maintenance instructions.

during maintenance activities.

damaged equipment immediately.

to appropriate authorities.

equipment during maintenance and

inspection activities.

extinguishing equipment within 5 ft /

1.5 m of tanks.

®tape or appropriate

thread sealant.

• The tank contents are the sole

responsibility of the tank owner.

• Never allow waste product to touch eyes

or skin.

• Never install monitors outdoors without

proper protection from the elements.

• Never use on below ground storage

tanks.

• Never exceed the maximum milliamps

and maintenance instructions.

• Never solely rely on this product; there is

no substitute for human supervision.

• Never to be used as a component of any

automatically controlled pump

transfer system.

GENERAL WARNINGS / INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS:

Applications Single or double walled above ground

tanks.

Fluids Test and warranty for oil, waste oil, diesel

fuel, antifreeze, water and other uids with

a low ash point

Pipe ½" x 6" (12.7 mm x 152.4 mm) NPT PVC

Sensor Buna

Shipping 5 - 8 lbs / 2.2 - 3.6 kg (depends on

Weight length of Jarhead)

Thread 2" / 50.8 mm NPT

Case Quantity 2 - 5 (depends upon length of Jarhead)

WIRING CONNECTIONS

GENERAL TECHNICAL DATA

Audible alarm won't shut o... 1. Replace control panel.

System won't go into alarm mode... 1. Verify all wires are connected properly.

2. Replace the 9-volt battery.

Audible alarm won't sound... 1. Conrm toggle switch is in "ON" position.

Bulk Product Sensor activates alarm prematurely... 1. Conrm oat is in the correct position.

2. Conrm pipe is not over 10 ft (3 m) long.

TROUBLESHOOTING GUIDE

Husky Corporation • 2325 Husky Way • Pacic, MO 63069 • Phone: (800) 325-3558 • Fax: (636) 825-7300 • www.husky.com

Page 3 009313-6 7/2019

Model 007675, 007676 Leak Guards

007680,007681OverllGuards

1. Remove eyelet connector from end of chain and save.

2. Determine tank depth in inches.

3. Stand oat on end on a at work surface alongside a

measuring tape and pull chain taut to desired measurement.

4. Subtract 2" (50.8 mm) from determined measurement and

mark chain.

5. Cut chain on mark then feed chain through bottom center hole

in shaft and back out either side hole of shaft.

6. Secure chain with eyelet by crimping eyelet closed.

7. Loosen thumbscrews on sensor.

8. Slide sensor, positioning arrow just inside top of clear window.

9. Connect an ohmmeter to sensor leads.

10. Using chain, pull orange indicator to bottom of gauge and

conrm circuit is open.

11. Slowly release chain tension allowing spring to raise orange

indicator to its full extension

12. Conrm circuit is now closed.

13. Tighten thumbscrews rmly, approximately 1 to 2 turns past

hand tight - do not overtighten.

14. Apply appropriate sealant to the male threads of bung adaptor.

15. Slowly lower weighted oat into tank and tighten gauge,

approximately 1 to 2 turns past hand tight, onto tank bung.

16. Conrm orange indicator is at proper level - if tank is empty

it should not be visible. (If visible, remove sight glass and

depress orange indicator. Reinstall sight glass. If orange

indicator is still visible, recheck measurements in steps 2 - 4

and shorten chain as required).

17. Solder (or wire nut) sensor leads then tape connections.

18. Seal hole with silicone or appropriate sealant.

19. Connect wire to printed circuit board terminals marked

"FLOAT".

SENTRY REMOTE LEAK / OVERFILL GUARDS

12-VOLT TRANSFORMER

Model 007595

1. Select a non-switched 24-hour hot 115v outlet, preferably

dedicated solely for use with the monitor.

2. Temporarily remove the 9-volt battery.

3. Connect transformer to printed circuit board terminals marked

"OPTIONAL XFORMER". Observation of polarity is not

necessary.

4. Reinstall 9-volt battery.

5. Secure transformer to outlet using outlet plate screw.

6. Test control panel to conrm audible siren sounds.

NOTE: Connection of the transformer should always be the last

connection to the control panel.

Use 18-gauge / 2 conductor wire up to

150 ft (45.7 m)

or

14 gauge / 2 conductor wire up to 350 ft

(106.6 m) to connect all components.

This manual suits for next models

5

Table of contents

Other BJE Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Levelflex FMP50 operating instructions

Wohler

Wohler BC 600 operating manual

Flomotion Systems

Flomotion Systems LT260 Operation and maintenance manual

Riken Keiki

Riken Keiki GX-8000 operating manual

DIDIESSE

DIDIESSE Baby Frog operating instructions

MRC

MRC DI-900 Operation manual