Dinel ULM -70 Series User manual

INSTRUCTION MANUAL

Read carefully the instructions published in this manual before the first use of the level meters. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

ULTRASONIC LEVEL METERS ULM–70

CONTENTS

Safety ...............................................................................................................................................3

Measuring principle..........................................................................................................................3

Range of application ........................................................................................................................3

Features of variants .........................................................................................................................3

Dimensional drawings ....................................................................................................................4

Installation instructions ....................................................................................................................5

Electrical connection ......................................................................................................................8

Set-up elements...............................................................................................................................9

Status signalization..........................................................................................................................9

Operation .......................................................................................................................................10

Basic settings.................................................................................................................................10

Advanced settings..........................................................................................................................13

Additional functions........................................................................................................................15

HART communication protocol......................................................................................................18

Order code .....................................................................................................................................18

Accessories....................................................................................................................................18

Safety, protection, compatibility and explosion proof....................................................................19

Use, manipulation and maintenance .............................................................................................19

Marking of labels............................................................................................................................20

Menu structure ...............................................................................................................................22

Technical specifications.................................................................................................................23

Area classification..........................................................................................................................24

Factory default ...............................................................................................................................24

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

SAFETY

All operations described in this instruction manual have to be carried out only by trained personnel

or an accredited person. Warranty and post warranty service must be exclusively carried out by

the manufacturer.

Improper use, installation or set-up of the level meter can result in crashes in the application (over-

filling of the tank or damage of system components).

The manufacturer is not responsible for improper use, losses of work caused by either direct or

indirect damage, and for expenses incurred during installation or use of the level meter.

MEASURING PRINCIPLE

The ULM® ultrasonic level meters are compact measurement devices including an electroacoustic

converter and an electronic module. Using the electroacoustic converter, the level meters transmit

the sequence of ultrasonic pulses that spread towards the surface level. The converter recuper-

ates reflected acoustic waves that are subsequently processed in the electronic module. The

intelligent evaluation block filters out interfering signals, compares the cleaned received signal

with the false reflection map (e.g. from mixers, ladders, reinforcement etc.) and selects a suitable

reflection (echo). Based on the period during which the individual pulses spread towards the

surface level and back and based on the measured temperature in the tank, the instant distance

to the surface level is calculated. According to the level height, the level meter output is set and

the measured value is displayed on the display.

RANGE OF APPLICATIONS

For continuous non-contact level measurement of liquids (water solutions, sewerage water, etc.),

mash and paste materials (sediments, sticks, resins etc.) in closed or open vessels, sumps,

reservoirs and open channels. In case the level of bulk-solid materials is measured, the meas-

urement range is reduced.

The level meters can continuously measure levels of bulk-solid materials with a low concentration

of dust particles. Consult the manufacturer on recommended use of the level meter for bulk-solid

materials.

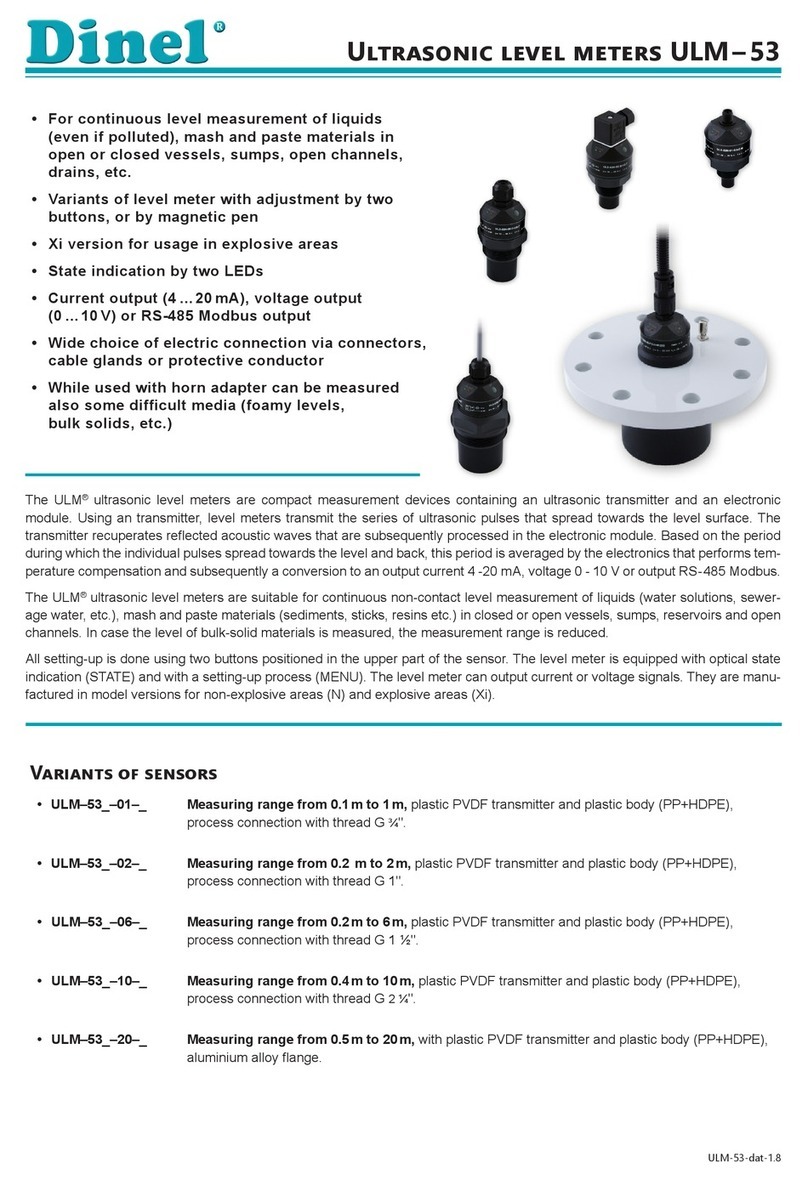

ULM–70_–02–I Measuring range from 0.15m to 2m, plastic PVDF transmitter, mechanical

connection with thread G 1".

ULM–70_–06–I Measuring range from 0.25m to 6m, plastic PVDF transmitter, mechanical

connection with thread G 1 ½".

ULM–70_–10–I Measuring range from 0.4m to 10m, plastic PVDF transmitter, mechanical

connection with HDPE polyethylene flange (version "N") or aluminium alloy

flange (version "Xi").

ULM–70_–20–I Measuring range from 0.5m to 20m, plastic PVDF transmitter, mechanical

connection with aluminium alloy flange.

FEATURES OF VARI ANTS

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

DIMENSIONAL DRAWINGS

ULM–70_–02–I ULM–70_–06–I

ULM–70N–10–I

ULM–70_–20–I

ULM–70Xi–10–I

Al alloy

Al alloy

HDPE

Pg11 cable gland

Ground terminal

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

Fig. 2: Level meter dead zone

m – Dead zone

INSTALLATION INSTRUCTIONS

Install the level meter in the• vertical position into the upper lid of the tank or reservoir using

a welding flange, a fastening nut or a flange so that the level meter axis can be perpendicular to

the surface level of the measured liquid (Fig. 1).

The min.• dimensional parameters to install the

level meter into a lid or a ceiling of a tank are given

in Fig. 3.

When installing in an• open channel (reservoir, drain

etc.), install the level meter onto a bracket as close as

possible to the expected max. level.

In connection with the measurement principle, no•

signals reflected in the area immediately under the

level meter can be evaluated (dead zone). The dead

zone (Fig. 2) determines the min. distance possible

between the level meter and the highest surface lev-

el. The min. distances to the medium are given in the

chapter "Technical specifications" (p. 24).

It is necessary to install the level meter so that the•

bin level cannot interfere with the dead zone when

filled up to the maximum. If the measured level in-

terferes with the dead zone, the level meter will not

work properly.

Fig. 1: Recommended installation

in the tank

Fig. 4: Possible installation of the installation neck

a – Neck height

b – Neck width

m – Dead zone

ULM–70–02;06 a <3 b

b>100 mm

ULM–70–10 a<1,5 b

b>100 mm

ULM–70–20 a<1,5 b

b>150 mm

Fig. 3: Installation distance from the tank wall

ULM–70–02;10 d >1/12 c

(min. 200 mm)

ULM–70–06 d>1/8 c

(min. 200 mm)

ULM–70–20 d>1/10 c

(min. 200 mm)

d – Distance from

the tank wall

c – Measurement

range of the level

meter

If the maximum surface level in the tank interferes with the dead zone, the level meter has•

to be mounted into a higher installation neck. In this way, the tank can be filled nearly up to

the maximum volume. The inner neck surface has to be even and smooth (without edges and

welded joints); the inner edge should be rounded where the ultrasonic wave leaves the pipe.

The neck diameter should be as large as possible but the neck height should be as low as

possible. Recommended dimensions of the input neck are given in Fig. 4.

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

During filling, mixing and other processes,• foam

can arise on the surface level of the measured

liquid. The thick foam considerably absorbs the

ultrasonic signal which might cause malfunction

of the level meter (Fig. 5). For such cases, it is

necessary to set up "SENSITIVITY" mode (p. 14)

to "high" or contact the manufacturer if need.

If the emitted acoustic signal of the level meter•

is affected by near objects (roughness on walls

of the tank, various partitions, mixers etc.), it is

necessary to map false reflections by activating

the mode "TEACHING" (see p. 14). In case of in-

stalled mixers, it is necessary to put the mixers

to position under the level meter (direct the mixer

blade to the ultrasonic signal beam).

Fig. 6: False echo from obstacles in

the tank

Fig. 8: Level meter installation outside the influence of filling

Fig. 5: Thick foam on the surface

Do not install the level meter in or above the• filling point (Fig. 8).

In case the level of bulk-solid materials is measured, the measurement range is reduced. We•

recommend to consult the use with the manufacturer.

Fig. 7: False echo from the mixer blade

!

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

Fig. 13: Intensely stirred surface

!

Fig. 10: Prevention to avoid

intrusion of humidity

Fig. 9: Solar radiation shielding cover

The level meter must not be installed in places•

with direct solar radiation and must be protected

against weather effects.

If the installation in places with direct solar ra-•

diation is inevitable, it is necessary to mount

a shielding cover above the level meter.

It is suitable to run the cable under a cable bush-•

ing (obliquely down in slack) according to Fig. 10

to prevent penetration of humidity. Then the

rain and condensing water can flow off freely.

The cable bushing and connector have to be• suf-

ficiently tightened to prevent penetration of hu-

midity.

To lower the minimum distance to the measured•

medium, a reflection board made from solid,

even and smooth material can be installed to the

level meter. Then the tank can be filled nearly up

to the maximum height. The solution is suitable

for open tanks and reservoirs.

Scattering or attenuation of the ultrasonic signal•

can result if the surface level has been moder-

ately stirred or rippled (by a mixer, coming liq-

uid etc.). It can result in reduction of the meas-

urement range or unreliable function of the level

meter (Fig. 12).

Rotating mixer blades can cause• that the sur-

face is stirred, which results in false reflections of

the ultrasonic signal from the surface level and

unreliable operation of the level meter (Fig. 13).

Fig. 12: Moderately stirred surface

Fig. 11: Reflection board

H + L = Dead zone

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

ELECTRICAL CONNECTION

The ultrasonic level meter is designed to be connected to supply unit or to controller through a cable

with the outer diameter of 6 ÷ 8mm (recommended cross-section of cores 0.5 ÷ 0.75 mm2) by means

of bolted clips placed under display module. Connect the plus pole (+U) to the terminal (+), the minus

pole to 0V to the terminal (-) and the shielding to

the terminal ( ) (only for shielded cables).

Procedure to connect the cable to the level

meter:

Unscrew the nut of the upper transparent lid.1.

Take the upper edge of the display module and2.

take it out carefully by mild swinging up.

If you cannot grasp the module, you can use3.

a small screwdriver. Insert it as far as the

seam and use from several sides to slightly

lift the module.

Release the cable bushing and thread the4.

stripped supply cable in.

Connectthecableintothe bolted clips according5.

to the diagram in Fig. 14.

Assemble the level meter and connect the6.

cable to the sequential unit.

Fig. 14: Connection diagram of the

level meter

Fig. 15: Internal view of terminal

block

Make the electric connection in voltage-free state!

The power supply can be a stabilized voltage supply unit of 18 ÷ 36V DC (version Xi - 30V DC) that

is included in evaluation or display unit.

Considering possible occurrence of electrostatic charge on non-conducting parts of the level me-

ter, it is necessary to ground all level meters intended for environments with risk of explosion

(ULM–70Xi–_ _–I). It will be done using a screw placed on the head of the level meter under the

cable bushing.

Display unit

connector

Termi nal

block

Metal clip

utton Symbol in the manual [OK]

– Set-up mode access

– Confirmation of selected item in the menu

– Move the cursor in the line

– Saving of set-up data

Button Symbol in the manual [ ↑↓]

– Move in the menu

– Change of values

Button Symbol in the manual [ESC]

– Cancelling of carried out changes

– Shift one level up

Teaching

mode activation Echo receiving Units

Display

of measured values

Set-up elements

Ultrasonic transmitter

Upper lid nut

Cable gland

Control buttons

OLED display Label

Fig. 16: Full view of ultrasonic level meter

STATUS SIGNALIZATION

display function

"NO ECHO" Lighting intermittently – the level meter is not able to receive echo

for a long time. Incorrect installation of the level meter

"DEAD ZONE" Lighting intermittently –the measured level is in the "dead zone" of

the level meter or the ultrasonic converter is dirty.

"NO PASSWORD"

It will appear in the item "MENU" –the level meter is protected

using a password against unauthorised setting. Enter the correct

password (see p. 17).

symbol "T" 1) Lighting permanently –"TEACHING" mode activation.

symbol "E" 1) Lighting intermittently –correct echo receiving (of the reflected

signal) from the measured surface level.

1) symbol appears in the lower left corner of the display

SET-UP ELEMENTS

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

"AUTO MIN" (Automatic setting of the 4mA limit)

After the mode is enabled, the actual measured level will be set as the min. level. The 4mA value

will be assigned to the level meter output. The setting is recommended only if the tank can be

flooded up to the required min. height.

BASIC SETTINGS

Before the first starting, you must carry out the basic configuration

of the level meter. The settings are accessible in the basic menu

under the item "BASIC ADJUSTMENT".

ACTUAL LEVEL: Actual distance in mm

DISP: Display of measured values on the display

U: Unit selection (mm, cm, m, l, m3,mA, %)

ACTUAL LEVEL: Actual distance in mm

DISP: Display of measured values on the display

U: Unit selection (mm, cm, m, l, m3,mA, %)

OPERATION

Set the level meter using 3 buttons placed on the display module (see Chapter Set-up elements).

After 5 min. of inactivity, the level meter automatically returns back to the measurement mode.

If the password is active, the level meter will be also locked. The values that have not been

confirmed using the button [OK]will not be saved! After the meter is locked, you cannot change

the setting! When you attempt to edit, the words "NO PASSWORD" will appear on the display.

How to unlock the level meter is given on page 17.

1. Fill up the tank up to the required level.

2. Press the button [OK]to access the basic menu. Use the same button to select the item "BASIC

ADJUSTMENT" and then "AUTO MIN".

3. Now the item "AUTO MIN" is displayed. The level meter assigns the 4mA value for the measured

value automatically.

4. Using the buttons [OK]and [

↑↓

], set the values to display on the display "DISP" and select the

units "U".

5. After the setting is completed, save the data using the button [OK]. By repeated pressing the

button [ESC], you leave the menu and the display of the level meter and return back to the

measurement mode.

"AUTO MAX" (Automatic setting of 20 mA limit)

After the mode is enabled, the actual measured level will be set as the max. level. The 20mA value

will be assigned to the level meter output. The setting is recommended only if the tank can be

flooded up to the required max. height.

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

1. Press the button [OK]to access the basic menu. Use the same button to select the item "BASIC

ADJUSTEMENT". Then use the button [

↑↓

]and [OK]to select the item "MANUAL MIN" or

"MANUAL MAX".

2. Now the item "MANUAL MIN" or "MANUAL MAX" is displayed (as selected). Using the buttons

[OK]and [

↑↓

], set the output current "OUTPUT" and distance for the defined current "LEVEL",

display of the value on the display "DISP" and unit selection "U".

3. After the setting is completed, save the data using the button [OK]. By repeated pressing the

button [ESC], you leave the menu and the display of the level meter and return back to the

measurement mode.

1. Fill up the tank up to the required level.

2. Press the button [OK]to access the basic menu. Use the same button to select the item "BASIC

ADJUSTMENT" and then use [

↑↓

]and [OK]to select the item “AUTO MAX”.

3. Now the item "AUTO MAX" is displayed. The level meter assigns the 20mA value for the measured

value automatically.

4. Using the buttons [OK]and [

↑↓

], set the values to display on the display "DISP" and select the

units "U".

5. After the setting is completed, save the data using the button [OK]. By repeated pressing the

button [ESC], you leave the menu and the display of the level meter and return back to the

measurement mode.

"MANUAL MIN and MANUAL MAX" (Manual setting of limits)

In these items, you can define min. or max. level, to which you can assign an optional output current in

the range of 4

÷

20mA. This is recommended to carry out if the final value of the min. and max. level is

known but it is not possible to flood the tank up to these limits.

For convenience, it is suitable to assign 4mA cur-

rent to the min. value and 20mA current to the

max. value.

OUTPUT: Setting of output current (4 ÷ 20mA)

LEVEL: Setting of distance of the level from the

front of the level meter in mm

DISP: Display of measured values on the display

U: Unit selection (mm, cm, m, l, m3,mA, %)

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

"DAMPING" (Speed of the measurement response)

Setting of the speed of the measurement response. The function can be used to suppress devia-

tions of the displayed values in case of quick or step changes of the level (e.g. stirred surface).

The response time of the subsequent measurement will be longer and the level meter will react to

quick changes with a defined delay.

The damping time can be set in the interval from

0 to 99 sec.

1. Press the button [OK]to access the basic menu. Use the same button to select the item "BASIC

ADJUSTEMENT". Then use the button [

↑↓

]and [OK]to select the item "DAMPING".

2. Now the item "DAMPING" is displayed. Using the buttons [OK]and [

↑↓

], set the damping time

(0-99 sec.).

3. After the setting is completed, save the data using the button [OK]. By repeated pressing the

button [ESC], you leave the menu and the display of the level meter and return back to the

measurement mode.

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

ADVANCED SETTINGS

In the supplemented configuration, you can set parameters of

sensitivity, mapping of false reflections, temperature difference

compensation, behaviour in case of fault conditions or HART

communication. Here, you can set the sensor into the initial state

or reset it as well.

The settings are accessible in the basic menu under the item "SERVICE".

"SENSITIVITY" (Level meter sensitivity)

The setting is defined in three steps of the level meter sensitivity.

"low" – Low sensitivity in case of surrounding interferences affecting the measurement.

"medium" – Medium sensitivity (suitable for most applications).

"high" –

High sensitivity for measured mediums partly absorbing the ultrasonic signal (bulk-solid mat., foams)

You can set the sensitivity in three degrees:

"low", "medium" and "high".

If there are no above obstacles in the tank, it is

not necessary to start this mode

"TEACHING" (Mapping of false reflections)

The mode serves for suppressing false reflections resulting from reflection of the ultrasonic

signal from roughnesses on walls of the tank, various partitions, mixers or other obstacles. The

sensor starting this mode detects false reflections and save them in the memory. Then these false

reflections will not affect the subsequent measurement (they are masked).

Before starting the mode, empty the tank under the level of the last obstacle in the tank.

1. Press the button

[OK]to access the basic menu. Press the button [ ↑↓] to select the item

"SERVICE" and press the button [OK]to confirm. In the next menu use the buttons [ ↑↓]

and [OK] to select the item "TEACHING".

2. Now the item "TEACHING" is displayed. Press the button

[OK]to set the value "LEVEL DISTANCE"

– the expected distance of the sensor front from the medium surface level. If you do not know the

level distance exactly, set a smaller value (in the tolerance field according to Fig. 17.).

3.

After the value of "LEVEL DISTANCE" is set, use the button [OK]to start the mode "TEACHING"

(mapping of false reflections). During the mapping process, the word "RUNNING" is displayed

on the display.

4. The mapping of false reflections is completed after the word "DONE" is displayed. Then you can

leave the menu by pressing the button [ESC].

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

Mapping of false reflections lasts 5...30 sec.

according to the level meter type.

"MEDIUM TEMPERATURE" (Temperature compensation)

If the temperature of the measured substance (liquid) in the tank is different from the temperature where

the level meter is installed (see the mode "DIAGNOSTICS", p. 17), it is necessary to compensate the

temperature because of accuracy of the measurement. After the medium temperature is set, the level

meter calculates an average value (from the medium temperature and the temperature where the level

meter is installed) and uses this average temperature for calculation of the level position.

Inactive compensation (initial state), the word

"NO" appears on the display.

In case of installed mixers, it is necessary

to position the mixers under the level me-

ter (direct the mixer blade to the ultrasonic

signal beam).

Note: If there are significant obstacles in

the upper half of the tank, multiple false

reflections can occur especially in closed

tanks. In such cases it is necessary to

reduce the level in the tank as much se

possible to correctly mask these possible

multiple false reflections. Fig. 17: The "Level distance" zone

1/2 tank

obstacles

Tolerance zone for "LEVEL

DISTANCE" value

NO ECHO: Current in case of echo loss (3.75mA)

DEAD ZONE: Dead zone current (22mA)

The values can be set in three steps - 3.75mA,

22mA and LAST (last measured data).

"FAILURE MODE" (Fault conditions)

It defines the output current of the level meter when the measured medium level is in the dead

zone ("DEAD ZONE") or outside the measurement range in case of echo loss ("NO ECHO").

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

After you press the button [OK], "RUNNING"

will be displayed for about 3 sec. After the initial

values are set, "DONE" will be appear on the

display.

"FACTORY DEFAULT" (Default factory setting)

To reset the initial values of the level meter set by the manufacturer, press the button [OK] (see

the Factory default table, p. 25)

"RESET" (Level meter restart)

Complete restart of the level meter. The same effect has also a short-time interruption of the supply

voltage. To enable the resetting, press the button

[OK].

During the restart process, "RUNNING" will be

displayed. Then the level meter will be automati-

cally turned off and on.

"HART" (HART address setting)

HART mode (point to point, multidrop) and multidrop mode address setting. Up to 15 units can be

connected to one two-wired cable in the multidrop mode.

In case of the address "00", the point to point

mode is enabled. The range from "01" to "15" is

reserved for addresses in the multidrop mode.

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

ADDITIONAL FUNCTIONS

Additional functions include modes to display temperature in the tank or to find out the actual

flowing current in the loop. Besides, to lock modifications using a password and information about

the level meter version. All of the functions are accessible from the main menu.

"DIAGNOSTICS" (Diagnostic information)

It contains information about the actual temperature inside the tank

(or about the compensated temperature) "TEMPERATURE" and

current flowing through the loop "CURRENT". If the temperature

compensation ("MEDIUM TEMPERATURE") is activated, the

corrected temperature is displayed.

The temperature is measured inside the tank where

the levelmeter is installed.

If the temperature of the measured medium is differ-

ent, we recommend you to carry out the tempera-

ture compensation "MEDIUM TEMPERATURE"

because of accuracy (see p. 15). Then the displayed

temperature is an average value from the tempera-

ture set in the "MEDIUM TEMPERATURE" and the

actualtemperature measured bythesensor.

"PASSWORD " (Lock the level meter)

You can set any digital combination to lock the level meter and prevent an unauthorised person

from setting.

1.

Use the buttons [OK]and [ ↑↓] in the menu "PASSWORD" to select the mode "ENTER" for

entering the password or the mode "CHANGE" for changing the password (when activated,

the words are displayed inversely). Press the button [OK]once again to confirm the selection.

You can change the password only when the level meter is unlocked. Otherwise, the words

"NO PASSWORD" will be displayed.

2

. Now you can edit the password. The actual edited item is displayed inversely. Press the button

[OK]to move to the next position (clockwise direction); the button [ ↑↓] serves to change the

values (0 ... 9).

3

. After the operation is completed, confirm the edited data by pressing the button [OK].

Display of status information to confirm data:

"YES" – correctly edited password

"NO" – incorrectly edited password

"OK"–the passw.saved (only in caseof"CHANGE")

The password is automatically hidden after it is

edited or changed ("00000" will appear).

To deactivate the password, edit the numerical

combination "00000" in the mode "CHANGE".

If the password is lost, contact the manufacturer.

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

"INFO" – (Type data)

Information about the type, serial number and production date of the level meter.

ST: Level meter type

SN: Serial number

SW: Firmware version

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

HART COMMUNICATION PROTOCOL

Universal communication interface for data communication of peripheral devices with the level

meter. Data transmission runs through the same line as the 4 ÷ 20mA current loop without impact

on analog communication.

Fig. 18: Typical PLC/mA configuration with HART

HART

modem

USB / RS232

HART

communicator

ULM–70

PC

≈250 R Voltage supply unit

ORDER CODE

ACCESSORIES

Standard – included in the price of the level meter Optional – for extra charge

• 1x Seal (only for ULM–70_–02–I, 06–I) • Stainless fixing nut UM–G1''

(for ULM–70_–02–I)

• Stainless fixing nut UM–G1½''

(for ULM–70_–06–I)

Performance:

Maximum range: 02 - 0.15 ... 2 m

06 -0.25 ... 6 m

10 -0.4 ... 10 m

20 -0.5 ... 20 m

Output type: I- Current

ULM – 70 ––

N- Normal - usable in non-explosive areas only

Xi - Ex. proof - suitable for explosive areas

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

SAFETY, PROTECTION, COMPATIBILITY AND EXPLOSION PROOF

The level meter ULM–70 is equipped with protection against reverse polarity and output current

overload.

Protection against dangerous contact is secured by low safety voltage that complies with

EN 33 2000-4-41.

Electromagnetic compatibility according to EN 55022/B, EN 61326/Z1 and EN 61000-4-2 to 6.

Explosion proof of ULM–70Xi type complies with the following standards: EN 60079-0 : 2007;

EN 60079-11 : 2007 ; EN 60079-26 : 2007 and examined by FTZÚ-AO 210 Ostrava - Radvanice

certificate No.: FTZÚ 09 ATEX 0277X.

USE, MANIPULATION AND MAINTENANCE

The level meter does not require any personnel for its operation. Follow-up displaying device is

used to inform the technological entity operating personnel on the measured substance level

height during the operation.

Maintenance of this equipment consists in verification of integrity of the level meter and of the

supply cable. Depending on the character of the substance measured, we recommend to verify at

least once per year the clarity of the ultrasound transducer emitting field and to clean it, respec-

tively. In case any visible defects are discovered, the manufacturer or reseller of this equipment

must be contacted immediately.

It is forbidden to perform any modifications or interventions into the ULM–70 level meter without

manufacturer's approval. Potential repairs must be carried out by the manufacturer or by a manu-

facturer authorized service organization only.

Installation, commissioning, operation and maintenance of the ULM–70 level meter has to be car-

ried out in accordance with this instruction manual; the provisions of regulations in force regarding

the installation of electrical equipment have to be adhered to.

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

Symbol of producer: logo Dinel• ®

Level meter type:•

ULM–70N–02–I, ULM–70N–06–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Supply voltage: U• i

=18÷36 V =

Output current range: I•

=4÷20 mA

Ambient temperature range: t• a= -30 ... +70°C

Protection class: IP67•

Compliance mark:•

Electro-waste take-back system mark:•

Level meters label data

ULM–70N–10–I and ULM–70N–20–I:

Symbol of producer: logo Dinel• ®

Level meter type:•

ULM–70N–10–I, ULM–70N–20–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Supply voltage: U• i

=18...36 V =

Output current range: I•

=4÷20 mA

Ambient temperature range: t• a= -30 ... +60°C

Protection class: IP67•

Compliance mark:•

Electro-waste take-back system mark:•

Level meters label data

ULM–70Xi–02–I and ULM–70Xi–06–I:

Symbol of producer: logo Dinel• ®

Level meter type:•

ULM–70Xi–02–I, ULM–70Xi–06–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Output current range: I•

=4÷20 mA

Limit operating parameters:• Ui

=30 V=, Ii= 132mA; Pi

=0,99W; Ci=370nF; Li= 0,9 mH

Ambient temperature range for the zone• 0: ta= -20 to +60°C

Ambient temperature range• : ta= -30 ... +70°C

Label of non-explosive device• : ; Performance: II 1/2G Ex ia IIB T5

Number of certificate of intrinsically safety• : FTZÚ 09 ATEX 0277X

Protection class: IP67•

Compliance mark•

: ,

No. of authorized person examining control of system quality:1026

Electro-waste take-back system mark:•

MARKING OF LABELS

Level meters label data

ULM–70N–02–I and ULM–70N–06–I:

www.jetec.com.tw

久德電子

TE L:+886-4-23729418 FAX:+886-4-23724011

(40349)台中市西區福人街11號

Other manuals for ULM -70 Series

1

This manual suits for next models

11

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

Dinel ULM-53L User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel PDU-40-W Series User manual

Dinel

Dinel GRLM-70 User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM-55N User manual

Dinel

Dinel ULM - 54 User manual

Dinel

Dinel CLM-70 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel CLM-36-10 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM-70 Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel DLM-35 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel MLM-35 User manual

Dinel

Dinel ULM -70 Series User manual