Black Diamond Equipment HELIO 350 Quick start guide

M13844_A 05/2020

WARNING! DANGER!

This binding is equipped with systems generating weak magnetic fields that could interfere with the

proper functioning of life-saving medical devices such as implanted pacemakers or defibrillators

but also magnetic cards, watches or compasses.

Keep the binding at a distance of at least 10cm from any device whose proper operation

could be affected by the magnetic field generated by the systems contained in the binding.

Translated with www.DeepL.com/Translator (free version)

INSTALLATION, USE and MAINTENANCE GUIDEBOOK

HELIO 350

TOE PATTERN ON JIG: P3-P3-H1-H1

HEEL PATTERN: H-H-H-H

MAX SKI WIDTH UNDERFOOT: 120 MM

t

WARNING!

SEAL OF LIABILITY AND REMOVAL OF THE SAME

A “Seal of Liability” has been securely and carefully applied to each binding produced by

the manufacturer during the packaging operations.

The removal of this seal MUST BE EXCLUSIVELY PERFORMED by the original user itself.

The removal of the “Seal of Liability” represents the proof of the full, direct, careful and conscious

acknowledgment of the entire content of this “INSTALLATION, USE and MAINTENANCE GUIDEBOOK”

included within the product packaging. In particular, it represents the full acknowledgment of the

whole parts and paragraphs highlighted by the words “ WARNING!” or “ WARNING! DANGER!”

regarding the risks raising within the use of the product itself for the User and/or third parties and the

producer “PRODUCT LIABILITY LIMITATIONS” clauses.

In the event that the “Seal of Liability” is not present on the purchased binding, please DO NOT USE the

product and immediately contact the manufacturer.

The “Original User” assumes the absolute responsibility of delivering this “INSTALLATION, USE and

MAINTENANCE GUIDEBOOK” to any secondary users of this product (even if temporary) and to verify

that they have received the correct training on how to use the product as well as having fully and

unequivocally understood the whole parts of this manual.

2

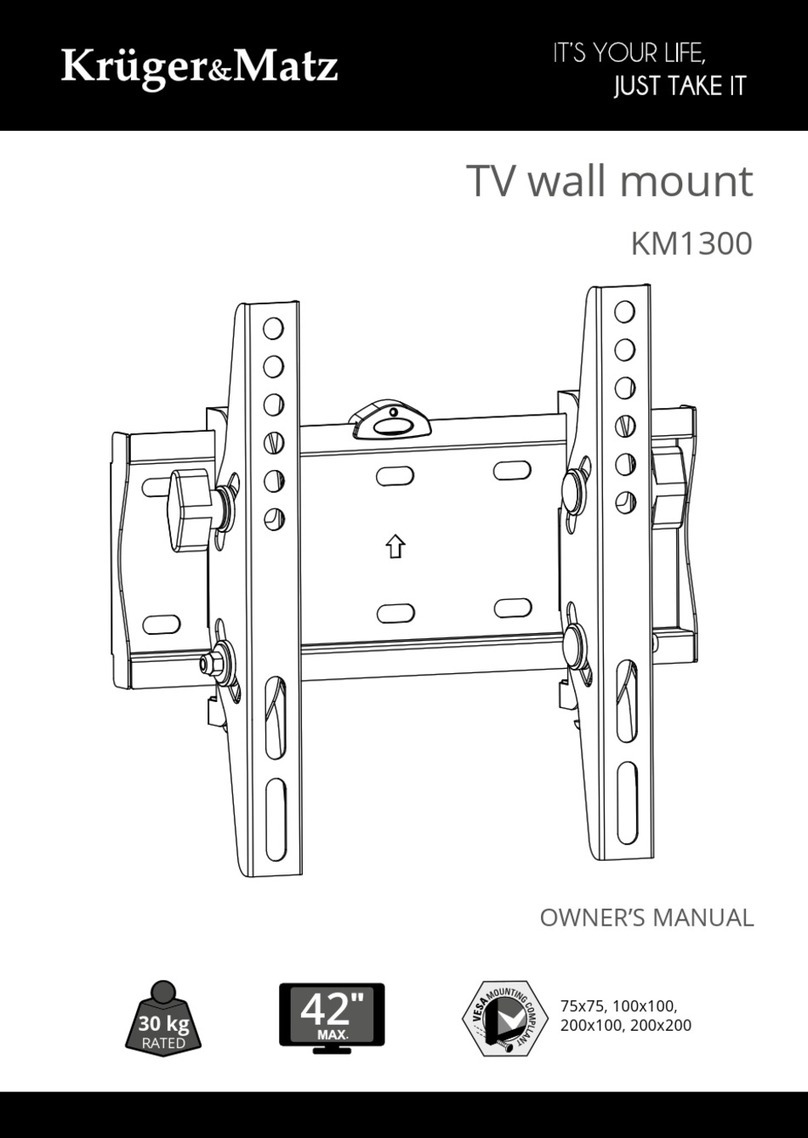

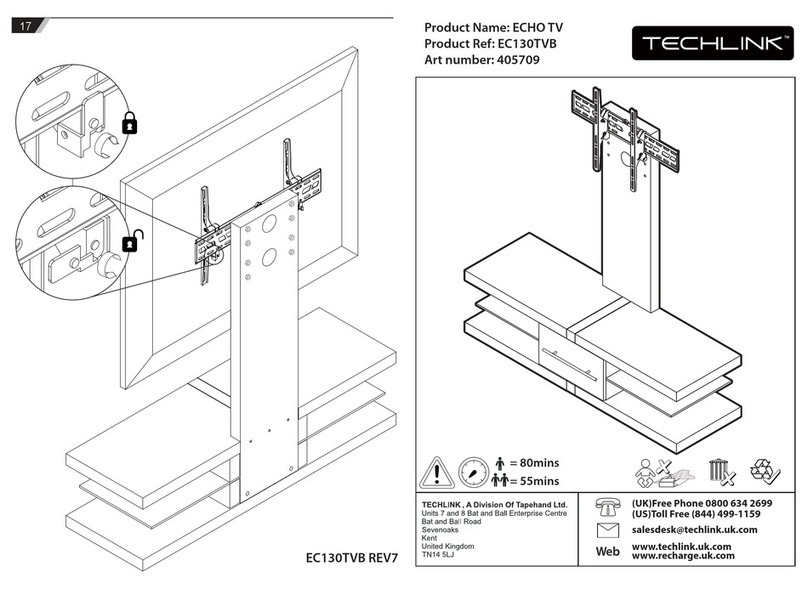

1| DEFINITION OF THE BINDING’S MAIN PARTS

WHAT WILL YOU FIND INTO THE PRODUCT BOX?

NR. 2 TOES, NR. 2 HEELS, NR.1 “SEAL OF LIABILITY” applied to the product, NR. 8 TOE SCREWS 15 mm, NR. 8 HEEL SCREWS 11mm,

NR.1 “WARNING STICKER”, NR. 1 “INSTALLATION, USE and MAINTENANCE GUIDEBOOK”, NR. 2 ski brake’s spacers, NR. 1 4 MM

SPACER

WARNING!

The images included within this manual are purely illustrative. The images may show accessories not included in the product

package, such as adjustment plates. Black Diamond reserves the right to make any changes to the technical or graphic design of

the product at any time.

3

WARNING! DANGER!

Before proceeding with any use, please make sure that you have fully understood what is written and

explained in this "INSTALLATION, USE and MAINTENANCE GUIDEBOOK ".

In case of any doubts and/or uncertainties, please contact the manufacturer for additions or

clarifications regarding any content of the manual.

WARNING! DANGER!

This binding model

DOES NOT COMPLY WITH ANY DIN/ISO SAFETY STANDARD NOR ANY SAFETY CERTIFICATION.

In particular, this binding does not comply with DIN/ISO 11088 and/or DIN/ISO 13992 safety standards.

Therefore, the release systems offered by the binding could fail in releasing the boot when necessary

and/or expected with a consequent danger for the User’s safety.

2| GENERAL WARNINGS AND RECOMMENDATIONS

• Please, be aware that ski-mountaineering, like many other high mountain activities, is a DANGEROUS

SPORT, that may cause injuries to the ski mountaineer itself and/or third-party.

WARNING! DANGER!

• This binding is conceived, developed and produced for FreeTouring activities. The high performances

and the extreme lightness required to this product can influence and/or reduce the safety features of

the product itself, including the quality or repeatability of the boot release in the event of a fall.

• This binding can only be used in combination with Alpine Touring boots, provided with standard “tech”

inserts and general geometries that comply with market standards.

• This binding heel part offers adjustable release systems with values in between 5 to 12. Calibrating the

most suitable release value for the User’s characteristics may reduce the risk of injuries to the inferior

limbs under the femur.

• The user, by removing the "SEAL OF LIABILITY" from the binding, consciously assumes all the

responsibility raising from the use of this product, and therefore releases Black Diamond from any

damage caused to himself and/or third parties during the use of the product.

4

• In the practice of ski mountaineering, dangerous and/or unpredictable situations may occur; never

overestimate your capabilities, never ski if sick of wounded or under the effect of alcohol, medicines or

drugs.

• The Helio bindings are realized for, and tested in combination with, boots provided with standard “TECH

INSERTS” in perfect state and original dimensions; the use of boots with NON-STANDARD and/or worn

“TECH INSERTS” could modify the functional performance of the bindings and create a great danger for the

User. Before any use check the general condition of the gear: In case of doubts about the state of your

gear, reach an authorized Dealer for a deeper check or to start up a FACTORY SERVICE PROCESS.

• Installation, adjustment and calibration operations on these bindings must be exclusively performed by a

“SPECIALIZED TECHNICIAN”: any operation performed by a “NON-SPECIALIZED TECHNICIAN” is strongly

un-recommended and could lead to greater risks for the User’s safety.

• During transport (ex: car roof, backpack, bike) the bindings could be attacked by dirt or salt that may

damage the bindings or modify the regular functioning of the same: always protect the bindings with

adequate instruments by these external agents during transport.

• After hooking the boot, always check that the toe pins are correctly matching with their seats on the TECH

INSERTS by rotating the boot a few times on the toe piece, as shown at chapter 4.

• Before skiing, please remember to place the toe front lever in downhill position, checking that the “SKI”

logo marked on the front lever is fully visible. Skiing with the front lever in uphill position eliminated the

lateral release function of the binding with greater risks for the User’s safety. A toe release with the front

lever locked in uphill mode would lead to heavy structural damages on the product, with consequent

greater danger for the user (please check paragraph 4.3).

• Before each use check that the binding or the accessories do not have defective, worn or damaged parts,

that the release system is perfectly working and that the bindings have not been contaminated by debris or

ice/snow.

• Never use bindings with damaged parts: if there is any defective or broken part, or any doubt is raising in

your mind in regards to the state of your bindings, immediately stop the use of the product and promptly

bring your gear to an authorized dealer for a deeper check and/or to start up a FACTORY SERVICE

PROCESS.

• Frequently check (each 30 days of use or immediately after each extraordinary event, such as bad falls)

that: 1) the binding is correctly fixed to the ski 2) that the screws are correctly tightened 3) the ski internal

structure is not damaged 4) the ski is flat in the binding mounting area in order to get a perfect matching

with the binding base plates. If one or more of these conditions are not confirmed, or cannot be confirmed

by the User, please immediately stop the use of your ski-set and promptly bring it to SPECIALIZED

TECHNICIAN for a deeper check and avoid structural damages to the binding and greater risks for the users,

or to a dealer to start up a FACTORY SERVICE PROCESS.

• The use of a ski brake or a leash is strongly recommended, in order to limit the risk of losing the skis

and/or create damages to the gear or third parties.

• In case of deep fresh snow or hard snow, the efficiency of any SKI BRAKE is very limited: in these snow

conditions the use of a leash is strongly recommended.

• Any MODIFICATION to components and NON-PROPER USE of any Helio binding may invalidate the

product warranty and raise the risk of injuries for the user and/or third-party.

• The use of non-original Helio accessories may cause damages to the bindings with greater risks for the

user.

• Safely keep these user’s guide and check it in case of any doubt.

5

3| INSTALLATION, ADJUSMENT AND CALIBRATION

1

3.1| INSTALLATION

WARNING! DANGER!

These bindings and the connected accessories can be exclusively installed, adjusted or calibrated by a

“SPECIALIZED TECHNICIAN”

A “SPECIALIZED TECHNICIAN” is any technician operating in the ski/ski touring business field provided with

the following minimum requirements:

1) Is in possession of the original Helio “AUTOMATIC DRILLING JIG” addressed to the installation of the

product and has perfectly understood the entirety of the respective guidebooks.

2) Is in possession of the experience, know-how and skills raising from years of practice in the field of

“TECH” bindings installations, adjustment and calibration.

3) Is in possession of the whole instruments and tools needed to perform a perfect installations,

adjustment and calibration of an Helio ski touring “TECH” binding, including the specific testing

machinery needed to check the real and correct release performance of the binding.

The “SPECIALIZED TECHNICIAN” shall:

1) Perfectly install, adjust and calibrate the product and its

accessories.

2) Deliver the product to the “Original User” including the

“SEAL OF LIABILITY”, still complete and correctly applied

to the product.

3) Check that the “WARNING STICKER” is properly applied to

one of the two skis in front of the toe piece area.

4) Deliver this “INSTALLATION, USE and MAINTENANCE GUIDEBOOK” to the “Original User”.

The installation, adjustment and calibration of a Helio binding is strictly forbidden to any technician that

does not meet the whole 3 above mentioned minimum requirements, because of the greater risks raising

from a wrong installation, adjustment and calibration.

WARNING! DANGER!

TOE PIECE SCREWS MAX TORQUE: 7 N/m

HEEL PIECE SCREWS MAX TORQUE: 5 N/m

• A wrong setting distance in between boot and binding may create an early and sudden fail of the binding, creating irreparable

damages to the ski/binding/boot system and/or eliminate/modify the release function in case of fall with consequential

damages to the athlete and third parties.

• Always check that the penetrating lenght of the screws fits the depth of the drilled holes, and anyway with the height of the ski

in the mounting area; otherwise, use proper screws or contact ATK® at info@atkrace.com .

• The binding must be installed only ON NEW SKIS, which present an absolutely flat mounting area and a structural reinforce for

the screws tightening and anchoring.

• Each boot has its own substantial geometry: always use the boot used for installation, setup and check of the correct

functionality of the binding in combination to the binding itself.

6

3.2| ADJUSTMENT

3.2.1| ADJUSTMENT: HOW TO ADJUST THE HEEL PART POSITION

1. Hook the boot to the toe part.

2. Translate the heel part on the plate

by adjusting the back screw to obtain

a position of the heel pins that allows

the boot to step in.

3. Step into the heel part with the boot

and insert the 4 mm gauge in

between boot and heel.

4. Micro-adjust the heel position and

eliminate any free room in between

gauge, heel and boot.

WARNING! DANGER!

The binding model “C-R12” is provided with the

“E.R.S.” system (ELASTIC RESPONSE SYSTEM),

developed to support an aggressive and heavy

charge skiing style with an elastic response to

compressions and jumps, improving the ski

control, precision and flex performance. (8mm)

“E.R.S.” does not eliminate the need of a gap of

4 mm in between boot and heel: to respect the

imposed distance is a compulsory point in order

to miss undesired malfunctions and /or

damages to the material, with consequent

dangers for the user or third parties.

• The adjustment operation must be done manually by using a good quality PH2 screwdriver.

• The adjustment range provided by the plate is 25 mm (0,+14mm,-11mm); the adjustment range is marked

by a scale and included within two “STOP” logos.

• During the adjustment operations it is ABSOLUTELY FORBIDDEN to overtake the two side lines marked

with the “STOP” logo.

• Using the heel with an over range adjustment could lead to malfunctions and/or structural damages to

the binding with possible greater dangers for the User.

• A wrong installation distance between boot and binding (smaller than 4 mm or bigger than 5 mm) can

cause an early as sudden structural failure of the binding with irreparable damages to the binding/ski/boot

system and/or prevent or modify the release performance in the event of a fall with consequent greater

risks for the athlete or third parties.

•

7

5. Completely release the boot and step in again to doublecheck with the 4mm gauge that the boot-heel

distance is correct: the gauge must enter the space without forcing and there must not be any left room in

between boot, gauge and heel. (Pictures 1, 2, 3)

3.2.2| ADJUSTMENT: BOOT-BINDING COMPATIBILITY CHECK

PICTURE 1

PICTURE 3

PICTURE 2

WARNING! DANGER!

• Bellowed touring boots or NTN standard boots with TECH inserts are NOT COMPATIBLE WITH ANY

HELIO TOURING BINDING.

• In walk mode, the contact point in between the boot and the front locking lever must not exceed the

vertical line marked at PICTURE 4 and 5.

PICTURE 4 shows a boot which is COMPATIBLE with the binding: the boot tip gets in touch with the

front lever in a point behind the vertical line marked on the picture.

PICTURE 5 shows a boot which is NOT COMPATIBLE with the binding: the boot tip gets in touch with

the front lever in a point over (even if slightly) the vertical line marked on the picture.

The use of a NON-COMPATIBLE boot-binding combination is strictly FORBIDDEN, due to the high

risk of an undesired and/or accidental activation of the front locking lever of the binding that may be

moved from UPHILL WALKING MODE to DOWNHILL SKIING MODE during the uphill walking phase

with a great danger for the User’s safety.

PICTURE 4

PICTURE 5

8

WARNING! DANGER!

This binding model

DOES NOT COMPLY WITH ANY DIN/ISO SAFETY STANDARD NOR ANY SAFETY CERTIFICATION.

In particular, this binding does comply with DIN/ISO 11088 and/or DIN/ISO 13992 safety standards.

• The release values set on the binding must be considered as INDICATIVE: the real release value may

sensibly differ from the shown one, variate during the entire life of the product and/or variate

according to the use and/or wear and tear conditions.

• These bindings offer a VERTICAL RELEASE SYSTEM (My) and a LATERAL RELEASE SYSTEM (Mz), both

driven by the heel part and fully independent.

• These bindings offer a release value adjustment range in between 5 and 12. Calibrating the most

suitable release value for the User’s characteristics may reduce the risk of injuries to the inferior

limbs under the femur.

• Calibrating an underestimated release value could lead to undesired pre-releases of the binding or

auto-rotations of the heel during the ascent phase and increase the risk of injuries for the User.

• The vertical release takes place thanks to the radial divarication of the two hooking pins under the

effect of a sufficient vertical extraction load. This release is driven by an independent elastic system.

• The lateral release takes place thanks to the rotation of the heel head under the effect of a sufficient

lateral load. This release is driven by an independent elastic system.

• These bindings do not provide any different release than vertical (My) and lateral (Mz) ones.

• While skiing, the front locking lever of the binding must be set in “DOWNHILL MODE”. Skiing with

the front lever set in “UPHILL MODE”, the lateral release system is completely disabled, with a

greater risk for the user. (check out paragraph 4.3)

3.3| RELEASE SYSTEMS

WARNING! DANGER!

• Hook the boot at the binding and

set it for the uphill walking mode.

Rotate the boot on the toe up to

the front end of the rotation-

range and verify that the boot is

performing at least a 90° free

rotation.

If the free rotation range is smaller

than 90°, the boot tip and/or the

front part of the binding could be

damaged by a regular use of the

set.

9

WARNING! DANGER!

The adjustment of the release systems can be performed exclusively by a

“SPECIALIZED TECHNICIAN”

• The adjustment of the release systems must be performed accordingly with the physical and performance

characteristics of the User.

• A proper calibration of the release systems may reduce the risk of injury to the inferior limbs under the

femur.

• The release value must be included in between the maximum and minimum release value offered by the

adjustment scale; the adjustment screw shall never overpass the “STOP” logo laser engraved on the side

of the minimum and maximum release values available on the adjustment scale.

• The release systems calibration must be verified with specific binding’s release testing machinery.

• Before proceeding with the release test on the testing machine, remember to lubricate or humidify the

brake in the contact area between the brake pad and boot sole in order to avoid frictions that might

invalidate the release test.

• WARNING! Each boot has its own substantial geometry and the installation, adjustment and calibration of

the binding must be performed with the boot that will be used in combination with the binding itself. In

case of boot replacement (with a different one in model or size), a “SPECIALIZED TECHNICIAN” must

check the adjustment and calibration of the binding according to the new boot. If it is not possible to set

or adjust the binding for the new boot, a completely new installation, adjustment and calibration is

required.

3.3.1| RELEASE SYSTEMS SETTING

3.3.1.1| VERTICAL RELEASE SYSTEM CALIBRATION (My)

The vertical release system

adjustment can be performed

through the screw on the top of the

heel head (PH2 good quality insert)

(PICTURE ON THE SIDE).

The yellow pointer top border shows

the vertical release value set on the

binding. (PICTURE ON THE SIDE: E.G.

value “8”).

Turn clock-wise the adjustment screw to increase the release value.

Turn counter clock-wise the adjustment screw to decrease the release value.

10

WARNING! DANGER!

• It is highly recommended to strictly follow the operations described and illustrated in this chapter: a

wrong comprehension or execution of these procedures may create a greater risk for the user and/or

third parties, such as damages to the gear itself.

• Before proceeding with any operation or use, verify that the boots and the bindings are

COMPLETELY FREE from ice, dirt, debris or any other foreign body that may lead to a failure in the

regular functions of the bindings.

• Before proceeding with any operation, check the functional state and the wear condition of the

binding and its components: in case of doubts regarding the perfect functionality of one or more of

the binding’s components, immediately stop using the product and reach a dealer for a deeper check

on the product and/or to start up a factory service process.

• Some functions of the binding can be handled with a ski pole. The use of a ski pole may create

scratches and/or an early wear of the product surfaces.

• The binding includes some powerful elastic systems. An involuntary, wrong or uncareful activation of

these system is dangerous for the User’s or third party’s safety. Always handle these bindings with

the proper care.

• Keep these bindings out of reach of children.

3.3.1.2| LATERAL RELEASE SYSTEM CALIBRATION (Mz)

The lateral release system

adjustment can be performed

through the back screw shown by the

PICTURE ON THE SIDE (use a good

quality PH2 or PZ3 insert). The set

release value is shown through the

upper window (PICTURE ON THE

SIDE, e.g. value “5”).

Turn clock-wise the adjustment

screw to increase the release

value.

Turn counter clock-wise the

adjustment screw to decrease the

release value.

4| PRACTICAL USE INSTRUCTIONS

11

WARNING! DANGER!

• Before proceeding with your activities, always check the proper lubrication of the brake’s arms recall

walls in order to avoid malfunctions (see at chapter 5).

• Any operation on the brakes must be performed MANUALLY!

4.1| HOW TO USE THE REAR SKI BRAKES

4.1.1 WALK/UP-HILL MODE

1) From ski mode (PICT.6), manually press on the side button, moving it to the end of its sliding range (PICT.7).

2) Keeping the side button in the reached position, manually push the brake pedal all the way down towards

the ski (PICT.8).

3) From the reached position, release the side button and then the brake pedal that will be stabilized in walk

mode by the side button (PICT.9).

PICTURE 6

PICTURE 7

PICTURE 8

PICTURE 9

12

WARNING! DANGER!

• In this modality, the toe part is locked on the boot. This means that in case of fall, avalanche or any

other unluckily situation that can be faced by the user, the release of the boot will be nearly

impossible. This condition represents a GREAT DANGER for the user that could be dragged into an

avalanche by the ski and/or suffer serious injuries in case of fall or accident.

• When the binding is set in up-hill mode, the separation between boot and binding can only occur in

case of heavy material deformations due to an event, external load or particular stress: if this

happens, immediately stop using the product and reach a dealer for a deeper check on the product

and/or to start up a factory service process.

• During the ascent, an accidental impact or any other particular event, may move the front locking

lever of the binding from the uphill walking mode to the downhill skiing mode. This represents a

great danger for the user’s safety that may experience an undesired boot release, with consequent

risk of falling or slipping in dangerous conditions: frequently check the correct setting and

stabilization of the front lever of the binding, especially in case of accidental impact.

4.1.2 SKI MODE

In order to set the brake in ski mode starting from

the walk mode, operate as follows (PICT.10):

1) Push the brake pedal all the way down to the ski.

2) Push the side button up to the end of its sliding

range.

3) Release the brake pedal.

4) Release the side button.

5) Proceed with the desired activities.

4.2| UP-HILL/WALKING MODE

PICTURE 10

13

• Set the ski brake in walk mode as shown at paragraph 4.1.1

• Position the heel part in one of the configurations shown at “PICTURE 11”, rotating manually the heel

head and stabilizing the heel flaps into its seats.

PICTURE 11

14

• Check that the toe part is

in the position shown at

PICTURE 12, ready to

receive the boot, free

from ice, snow or other

debris. If toe is not in the

proper position, manually

press on the front locking

lever in order to reach

the stabilized position

shown at PICTURE 12.

• Move the boot tip towards the toe part, matching the front TECH insert seats with the toe hooking pins

(PICTURE 13). From this position, vertically push on the toe part to step in. (PICTURE 14/15). Rotate a

few times the boot in order to check the proper boot-binding coupling, as shown at PICTURE 15.

PICTURE 13

PICTURE 12

PICTURE 14

PICTURE 15

15

• Slightly pull the front locking lever towards the boot tip up to the uphill stabilized position in order to

lock the binding on the boot and allow the ascent, as shown at PICTURE 16.

• WARNING! Before approaching the up-hill, always check that the front locking lever is stabilized in the

locked position, as shown at PICTURE 17 and that the “SKI” logo marked on the front lever is NOT visible

(PICT. 17.1.)

PICTURE 16

PICTURE 17.1

PICTURE 17

16

WARNING! DANGER!

• The correct setting of the binding for the DOWNHILL MODE is explained at paragraph 5.2 of this

manual. This use modality may allow the release of the binding in case of ruinous falls: NEVER SKI

with the binding set for the UP-HILL WALKING MODE in order to avoid the deactivation or exclusion

of the release systems of the binding!

• It is absolute responsibility of the user to decide which behaviour/use modality represents a

MINOR RISK for its own safety and that one of third parties, according to the faced conditions.

• While skiing, an accidental impact or any other particular event, may move the front locking lever of

the binding from the downhill skiing mode to the uphill walking mode. This can happen suddenly and

without any voluntary action of the user: frequently check the position of the front locking lever,

especially in case of accidental impact.

4.3| DOWN-HILL MODE

• Move the heel on the stabilized position

shown at PICTURE 18 by rotating the

heel head with the hands. Then rotate

the heel flap towards the ski tail up to

the back end of the rotation range.

• Check that the toe part is in the position

shown at PICTURE 19, ready to receive the

boot, free from ice, snow or other debris. If

toe is not in the proper position, manually

press on the front locking lever in order to

reach the stabilized position shown at

PICTURE 19.

PICTURE 18

PICTURE 19

17

• Move the boot tip towards the toe part, matching the front TECH insert seats with the toe hooking pins

(PICTURE 20). From this position, vertically push on the toe part to step in. (PICTURE 21/22). Rotate a

few times the boot in order to check the proper boot-binding coupling, as shown at PICTURE 22.

• Check that the front locking lever is in downhill skiing mode, as shown at PICTURE 23, and that the “SKI”

logo marked on the front lever is completely visible, as shown at PICTURE 23.1; if not like that, slightly

push on the front locking lever in order to obtain the proper position, as shown at PICTURE 23.

PICTURE 20

PICTURE 21

PICTURE 22

PICTURE 23

PICTURE 23.1

18

WARNING! DANGER!

Before skiing downhill, it is very important to check that the perfect coupling in between boot and

binding has occurred. It is common and good behaviour to check the proper toe pin insertion into the

boot insert by locking the toe front locking lever and then immediately move it back into the downhill

mode.

In case that the locking operation has been difficult or impossible, it is strictly forbidden to proceed with

the downhill section and it is recommended to act as follows:

- Check that the boot tech insert is fully free from ice and dirt, otherwise clear it carefully.

- Check that no ice has built up underneath the toe piece locking mechanism, otherwise

carefully clear it out using a knife or a thin section tool.

After these operations, please repeat the above-mentioned test to check the perfect coupling in

between the toe piece and boot insert.

Before starting with your downhill section, always doublecheck that your toe piece has been set back

into downhill mode.

• Press on the heel part of the binding in order to step in and to obtain the complete hooking of the boot,

as shown at PICTURE 24.

PICTURE 24

19

WARNING! DANGER!

• While releasing the binding, firmly hold the ski that is going to be release from the boot in order to

avoid an uncontrolled ski loss that would represent a great danger for the skier and/or third parties

which may be hit by the ski.

• At the end of your ascent, carefully release the boot from the binding and immediately turn the ski

brake in braking mode (downhill mode) in order to reduce the risk of an uncontrolled ski loss.

4.4| HOW TO GET OUT FROM THE BINDING

• By the up-hill position, press on the

front locking lever as show at

PICTURE 25, moving it to the

downhill skiing position and proceed

as follows.

• By the downhill skiing position, press

again the front locking lever as

shown at PICTURE 26, in order to

fully open the toe part and release

the boot.

• Lift and rotate the foot tip moving

the boot forward in order to get out

from the heel part of the binding, as

shown at PICTURE 27.

PICTURE 27

PICTURE 26

PICTURE 25

20

WARNING! DANGER!

• The crampons should be fit into or removed from the binding when the boot is not ENGAGED into

the binding. (e.g. with the skis in your hands or skis laying on the snow).

• Crampons must be used only with proper snow conditions; improper snow conditions could lead to

heavy damages to the material and create a greater danger for the user or third parties.

• Do not force the crampon when not properly placed into its seat.

• Original Helio CRAMPONS fit best with your BINDINGS. Other crampons might work too, please

check with your “SPECIALIZED TECHNICIAN”.

4.5| HOW TO USE THE HELIO SKI CRAMPONS

• Place the crampon at 90° and slip it into the proper seat of the CRAMPONS SLOT, as shown at PICTURE 28.

• Once having correctly placed the crampon in its seat, release the crampon in order to obtain the position

shown at PICTURE 29.

• Manually test the lateral stabilization of the crampon and the free rotation of the same on its pivot, as

shown at PICTURE 29.

• When removing the crampon, place it back at 90° and slide it out (either right or left). A slight rotation

while sliding the crampon out (a few degrees back and forth) would make the sliding operations easier.

PICTURE 28

PICTURE 29

This manual suits for next models

1

Table of contents

Languages: