Black Ridge WFX-1503A User manual

1 2

Model: WFX-1503A

Stroke: 3600 RPM

Recommended Operating Pressure: 90 PSI (6.2 BAR)

Minimum Air Flow Required: 120-170 LPM (4.2-6CFM)

Air Inlet: 1/4”

Cluttered areas invite injuries. Avoid any ignition

sources, such as smoking, open flames and electrical hazards.

Do not use machines or power

tools in damp or wet locations. Do not expose to rain. Keep work area

illuminated.

Children should be kept out of the work area. Do

not let children handle machines, tools or extension cords.

When not in use, tools must be stored in a dry

location to inhibit rust. Always lock up tools and keep out of reach of children.

Do not attempt to force a small tool or

attachment to do the work of a large industrial tool. There are certain

applications for which this tool was designed. It will do the job better and

more safely at the rate for which it was intended.

WARRANTY

This product is guaranteed against defects for a period of 12 months from date of

purchase. This warranty is provided by Super Cheap Auto Pty Ltd ACN 085 395

124 (Supercheap Auto) of 751 Gympie Rd Lawnton QLD 4501 Ph (07) 3482 7500.

Supercheap Auto will offer a repair, replacement product or store credit if the product

is assessed as being defective during the warranty period.

To claim under this warranty, take this product to the Front Service Desk of your nearest

Supercheap Auto store. For store locations, visit www.supercheapauto.com.au (AUS)

or www.supercheapauto.co.nz (NZ). You will need your receipt or proof of purchase.

Additional information may be requested of you to process your claim. Should you not

be able to provide proof of purchase with a receipt or a bank statement, identification

showing your name, address and signature may be required to process your claim.

This product may need to be sent to the manufacturer to assess the defect before

determining any claim. Faults or defects caused by product modification, misuse and

abuse, normal wear and tear or failure to follow user instructions are not covered under

this warranty.

Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law. You are entitled to a replacement or refund for a major failure and

for compensation for any other reasonably foreseeable loss or damage. You are also

entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

Any expenses incurred relating to the return of this product to store will normally have

to be paid by you. For more information contact your nearest Supercheap Auto store.

The benefits to the consumer given by this warranty are in addition to other rights and

remedies of the Australian Consumer Law in relation to the goods and services to

which this warranty relates.

3 43 4

1. Unscrew and remove the cutter’s sleeve (#1).

2. Unscrew and remove the nut (#2).

3. Unscrew and remove the screw cap (#3).

4. Pull the cutter out of the pushing rod (#5).

5. Replace the cutter, making sure the tip of the cutting edge fits snugly into the

pushing rod.

6. Reverse the steps above to re-assemble the air nibbler.

ALWAYS DISCONNECT THE AIR NIBBLER FROM THE AIR

SUPPLY WHEN CLEANING, REPLACING OR SERVICING.

(for best results you should incorporate

an air regulator with filter).

• Make sure the material to be cut does not exceed the capacity for this air

nibbler: maximum of 1.5mm for steel and 1.8mm for aluminium.

• Make sure the tool is connected to the air supply and the air pressure is at

90 PSI (6.2 BAR).

• On the material, make the line or shape to be cut.

• Grip the air nibbler firmly and depress the trigger to begin cutting.

• Apply light pressure to move the air nibbler through the material. If the air

nibbler stalls while cutting, release pressure on the trigger to turn off the tool.

• Then back the tool out an inch and restart the cutting process.

• The air nibbler is designed for cutting straight lines or gradual curves,

not 90 degree corners.

• When finished cutting, release pressure on the trigger to turn off the tool, then

disconnect the air nibbler from its compressed air supply source.

• Always work at the recommended air pressure. Tool life will be reduced if you

always work at pressure exceeding 90 PSI (6.2 BAR).

Do not wear loose clothing or jewellery as they can be

caught in moving parts. Protective, electrically non-conductive clothes and

non-skid footwear are recommended when working. Wear restrictive hair

covering to contain long hair.

Always wear impact safety glasses underneath a

full face shield during use. Also wear heavy duty work gloves.

Keep proper footing and balance at all times. Do

not reach over or across running machines.

Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing

accessories. The handles must be kept clean, dry and free from oil and

grease at all times.

Check that the keys and

adjusting wrenches are removed from the tool or machine work surface

before starting work.

Watch what you are doing, use common sense. Do not

operate any tools when you are tired.

Before using any tool, any part that

appears damaged should be carefully checked to determine that it will

operate properly and perform its intended function. Any part that is damaged

should be replaced.

When servicing, use only

identical replacement parts.

Read warning labels on prescriptions to determine if your

judgment or reflexes will be impaired while taking drugs. If there is any

doubt, do not operate the tool.

• Inspect the tool carefully to make sure no parts are broken or damaged.

Never operate the tool until the damaged or missing parts are replaced.

• Disconnect the air hose before changing or adjusting any accessories.

• Ensure the tool is in the “off” position before connecting the tool to the air

hose.

Before each use, inspect the condition of the cutter. If dull or

damaged, the cutter should be replaced. To replace, follow these steps:

3 45 6

• If the length of the air hose you are using is within 3m, then it is recommended

that a hose with an inner diameter of 8mm is used.

• If the length of the air hose you are using is within 7m but longer than 3m,

then it is recommended that a hose with an inner diameter of 10mm or 12mm

is used.

Keep the hose away from heat, oil and sharp objects. A damaged

air hose should be replaced before use.

If necessary, wipe with a damp cloth. You may use a mild detergent or

non-flammable solvent.

• Before connecting the hose for operation, apply 4 or 5 drops of air tool oil into

the air inlet and add a little lubricant on the nibble head. Do not use thick oils

such as engine oil as this may lead to reduced performance or malfunction.

• Oiling is necessary every 1-2 hours of continuous operation.

• After connecting the nibbler to the air supply, cover the exhaust hole with a

cloth and operate the tool for about 2 minutes in order to release excess oil.

direct the exhaust hole at yourself or others when operating.

• After use, remove the air hose and pour 4 or 5 drops of air tool oil into the air

inlet and add a little lubricant at the nibble head, then connect the hose again

and run the tool for a few seconds. This will ensure oil is present in the tool

whist in storage and prolong the tool life.

• Avoid storing the tool in a location subject to high humidity, which may result

in rust deposits inside the tool.

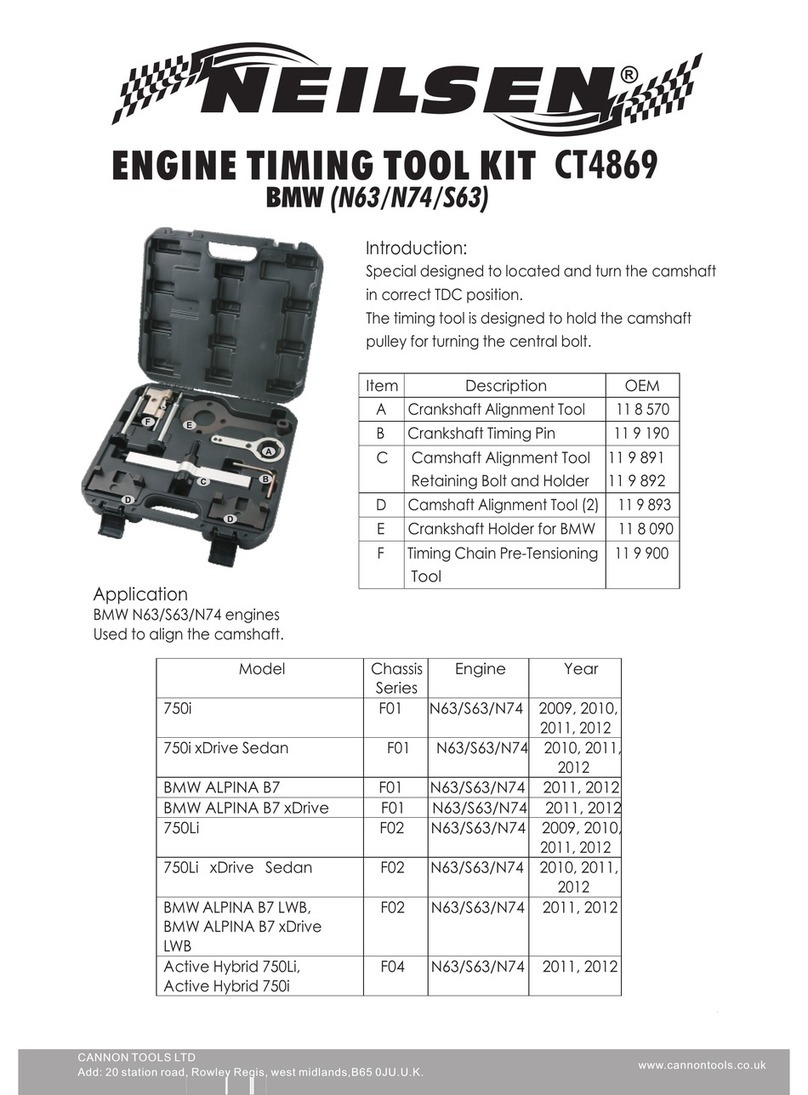

1 Hexagon Nut 1 13 Planet Gear 3

2 Screw 1 14 Gear Ring 1

3 Connecting Rod 1 15 Washer 1

4 Shaft Bushing 1 16 Straight Pin 2

5 O-Ring 1 17 Rivet 1

6 Screw 1 18 Air Inlet Connector 1

7 Swing Block 1 19 O-Ring 1

8 Washer 1 20 Pin 1

9 Snap Ring 1 21 Spring 1

10 Hexagon Nut 1 22 O-Ring 1

11 Idler Wheel Seat 1 23 Nut 1

12 Pin 3

3 47 8

Tool doesn’t run at a

normal speed or at a

variable speed.

Air supply is not

sufficient.

Check the air hose to see

whether it is blocked or

twisted causing a loss of

air supply.

Speed controller breaks

down.

Check the air compressor

to

gain the correct air

pressure required.

Tool fails to operate

under normal air

pressure.

Rotor blades/switch

breaks down.

Replace with new rotor

blades.

Dust gets into the motor. Disassemble the tool and

clean the inner structure

under proper instructions.

Automatically starts

when connected to

compressed air.

Throttle lever or starting

trigger malfunction.

Check and fix the throttle

lever or starting trigger for

accurate operation.

Stroke frequency

reduces.

Air leakage at the inlet

or somewhere else.

Check the air leakage and

fix it under proper

instruction.

Bearing damaged. Replace new bearings.

Correspondent o-ring is

worn or out of position.

Replace damaged o-ring

and put it back in its

correct position.

Housing becomes

excessively hot.

Lack of lubrication. Oil/lubricate the tool

consistently until it gains

the right speed.

Table of contents

Other Black Ridge Power Tools manuals