Blast DEFIANT 2 User manual

O

PERA T O RS

M

ANUAL

Defiant 2 Manual ƒ 5/31/05 5:44 PM Page 1

C

C

o

o

n

n

t

t

e

e

n

n

t

t

s

s

T

Ta

ab

bl

le

eo

of

f

S

S

a

a

f

f

e

e

t

t

y

y

Table of Contents

Section Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Trigger Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Ammunition Aspects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gas Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Anti Chop Eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Board Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Selecting Firing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Competition Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Assembly & Disassemly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Trigger Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Regulator Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Body Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

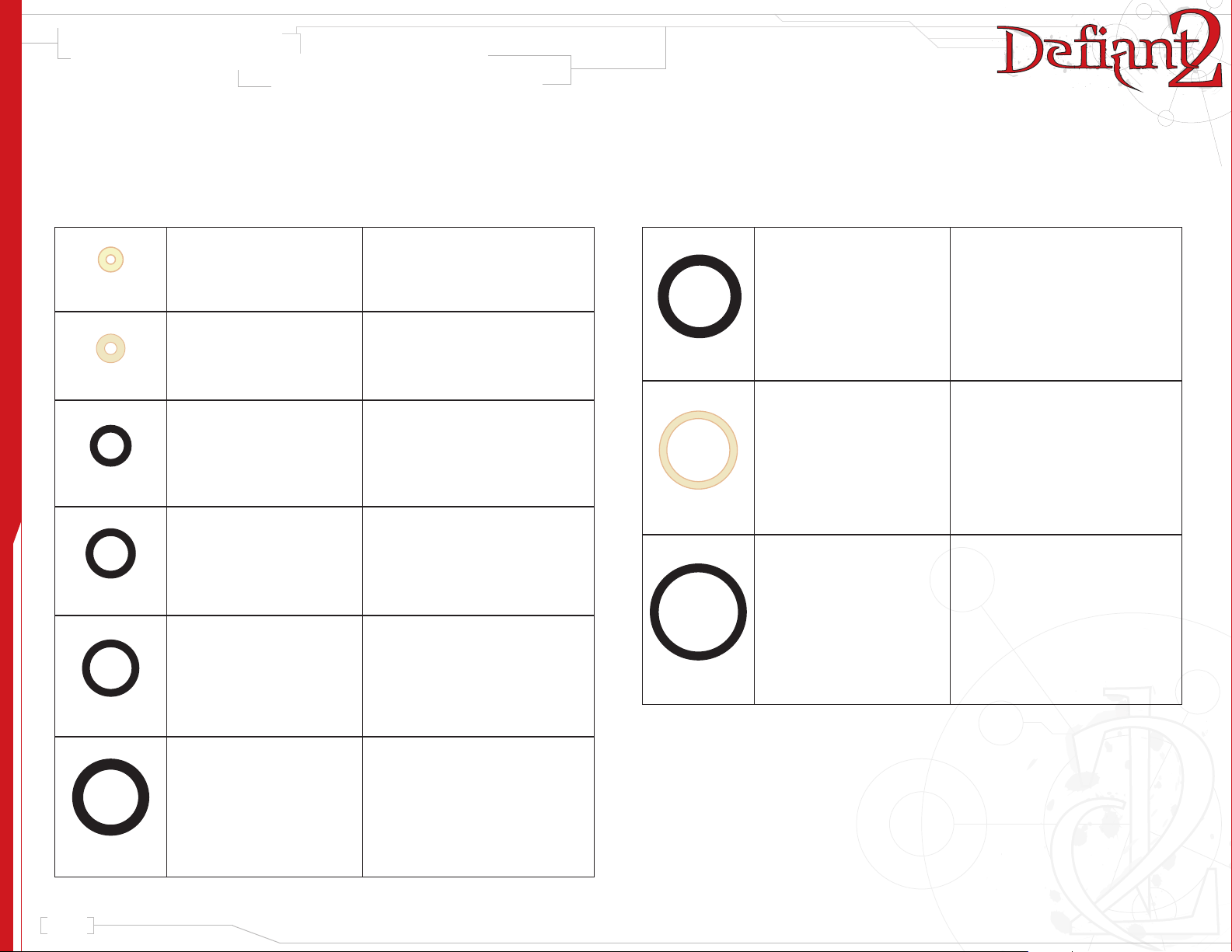

O-ring Specifications/Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Screw Specifications/Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

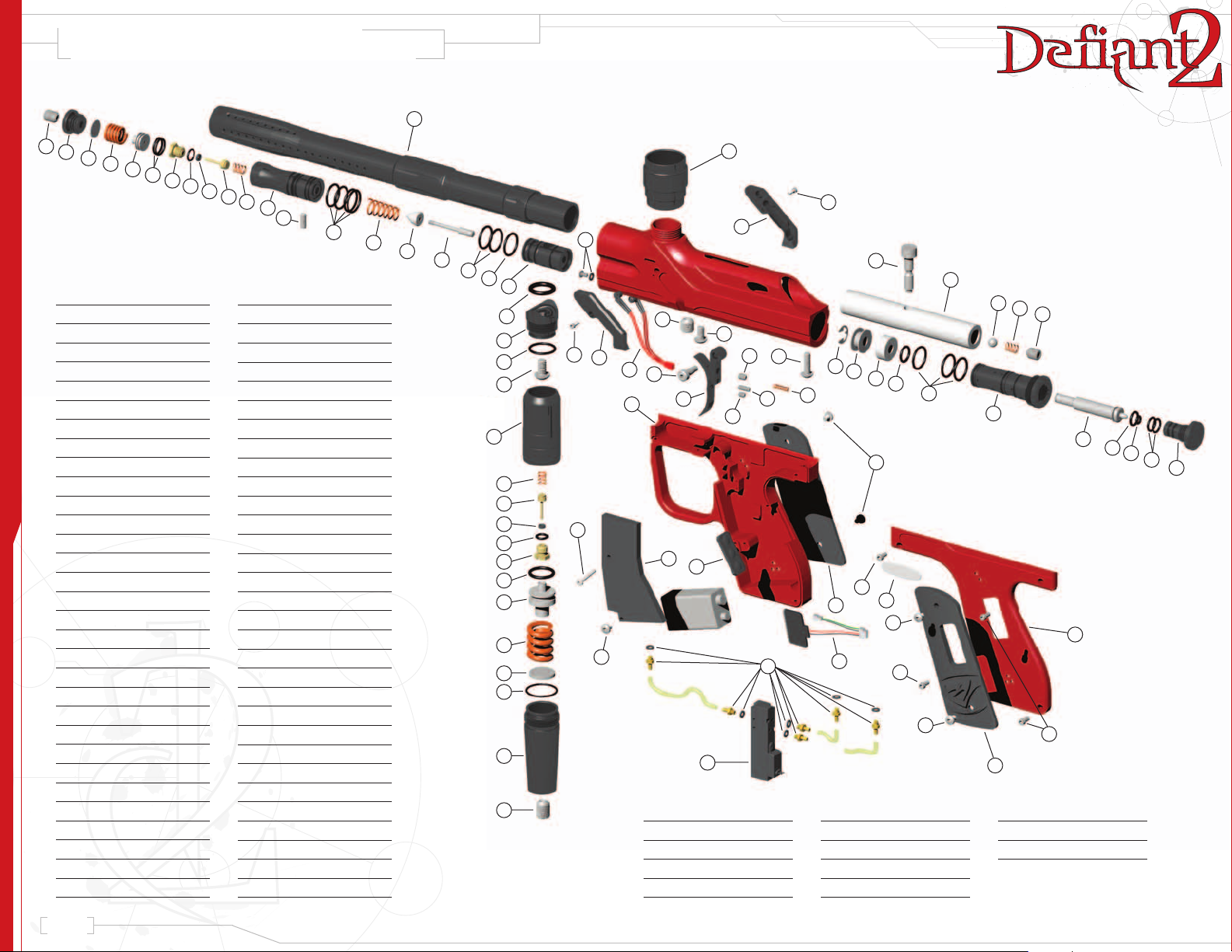

Complete Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1

Safety

2

defiant

Congratulations on your purchase of the DEFIANT 2 Paintball Marker. The DEFIANT 2

represents the latest in Paintball Marker technology at a very affordable price. Before

operating your DEFIANT 2, please read the entire manual thoroughly.

W

WA

AR

RN

NI

IN

NG

G

This Paintball Marker is not a toy. Misuse or mishandling can result in serious injury or death. Every

person within range of a loaded Paintball Marker must wear eye protection specifically designed for

Paintball. Recommended at least 18 years of age to purchase, 14 years old to use with adult

supervision or 10 years old to use on Paintball fields meeting ASTM standards F1777-97. Be sure

to read the entire instruction manual before operating your DEFIANT 2.

S

SA

AF

FE

ET

TY

Y

Please follow all local, state, and federal laws concerning the operation and use of Paintball Markers.

By purchasing this Paintball Marker “YOU” assume all liability. B.L.A.S.T. assumes no liability for injury

or death due to misuse or mishandling of this Marker.

C

CA

AU

UT

TI

IO

ON

N

Never point a Paintball Marker at anyone not wearing Paintball-Approved goggles. Even at the lowest

possible operating velocity, a Paintball will cause serious injury should it hit someone in the eye area.

Never under any circumstances look down the barrel of your Marker. Even if wearing Paintball

approved goggles, you should Never look down the barrel.

Before performing any maintenance on the Marker, ensure air source is disconnected and

Marker has been degassed. Always ensure Marker is OFF whenever Marker is not operational.

Always insert barrel plug in barrel when Marker is not operational. Remove barrel plug only

in designated operational areas.

Only play at commercial playing fields that have a chronograph, referees, and clearly marked

safe areas. Chronograph your Marker before each game to ensure Marker is operating at a safe

velocity. Safe velocity is considered to be 280 feet per second (fps).

LLooookkssccaannkkiillll

LLooookkssccaannkkiillll

2

Defiant 2 Manual ƒ 5/31/05 5:44 PM Page 3

LLooookkssccaannkkiillll

LLooookkssccaannkkiillll

W

W

A

A

R

R

N

N

I

I

N

N

G

G

I

I

N

N

T

T

R

R

O

O

Introduction

2

defiant

Always ensure Marker is not shooting at a dangerous velocity. Ensure all participants

are wearing the proper Paintball safety equipment. You will be held liable if someone

is injured by a Paintball fired from your Marker regardless of fault.

WARRANTY

B.L.A.S.T. warrantees the DEFIANT 2 against damages in Manufacturing Defects only.

Electrical components are warranted for a period of 90 days. Solenoids are not warranted.

When utilizing after market Drop-Forwards ensure attachment bolts DO NOT protrude

into internal grip assembly. When utilizing aftermarket grips ensure attachment bolts

DO NOT protrude into internal grip assembly. Failure to do so may damage the internals

and will result in void of warranty. Use of Teflon tape will void warranty. Aftermarket

anodizing will result in void of warranty.

For questions concerning your

DEFIANT 2

manual please call (925) 625-7929.

OPERATION

The

DEFIANT 2

Marker is a solenoid controlled open-bolt design. The bolt is locked onto

a slotted bolt receiver that is attached to a dual pressurized machined slider (RAM),

and is controlled by the solenoid (An electronic 4-way valve control). The newly designed,

encapsulated ram sleeve features two chambers (one toward the front and one toward

the rear). The back of the chamber is pressurized to move the bolt forward, and the front

is pressurized to move the bolt backward. This allows for very low cycling pressure, as well

as much less cocking recoil.

GENERAL DESCRIPTION

The

DEFIANT 2

is a low pressure operating, open bolt, electronic Marker, featuring microchip

managed solenoid control, anti-chop eyes (ACE), dedicated low and high pressure regulators,

and unique patented pending modular ram sleeve.

The field strippable pull pin bolt is connected to a slotted bolt receiver that is attached to

a dual pressurized sliding ram. This ram is held within the encapsulated ram sleeve located

in the lower tube of the body. The low pressure regulator supplies air through the lower tube

of the body, through the valve, through the front barb, to the front barb of the solenoid. Upon

activation, the solenoid redirects alternating pressure through the rear barbs, from the

chamber in front of the ram to the back chamber behind the ram. The forward shifting ram

will then strike the poppet, opening the main valve which releases high pressure regulated

air up through the transfer port and into the upper tube of the body. The pull pin connected

bolt pushes the paintball into the breech while simultaneously redirecting the charge of air

to propel the projectile (paintball) to its target.

Warning

The DEFIANT 2 is controlled via the MEMBRANE PAD located on the rear of the Trigger Frame, as

well as the Dip Switch Control Panel located on the front side of the Frenzy Board. All of the

functions of the DEFIANT 2 can be easily accessed and changed by using both the Membrane

Pad and Dip Switch Panel.

GETTING STARTED

To power up your DEFIANT 2, Press the ON/OFF button. To turn off your DEFIANT 2, press and hold the

ON/OFF button for approximately 1 second until the LED turns Red and release. Buttons 1 and 2 allow

the user to change the Eye Sensor’s operational mode. Once powered up, pressing Button 1 will

change the Eye Sensor to Dry Fire Mode (also known as Simulation Mode), while Button 2 sets the

Eye Sensor to Delay Mode. Every DEFIANT 2 is equipped with a 3-Color, Light Emitting Diode (LED),

located on the side grip panel (left of the membrane pad)which allows the user to verify the current

Eye Sensor Mode and/or Battery Status. A detailed description of each function can be found in the

Board Operation section.

NOTE: The Frenzy Board IS NOT Programmable via the trigger.

TRIGGER ADJUSTMENT

The trigger is fully adjustable using the three screws within the trigger. The upper screw controls

the return spring tension, the center screw adjusts micro-switch activation point and the lower

screw adjusts the trigger stop point.

B

BA

AR

RR

RE

EL

L

The DEFIANT 2 comes standard with a one piece, .689 Bore, 12-inch Assassin barrel.

Barrel threads for the DEFIANT 2 are Auto-cocker type.

SPECIFICATIONS

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DEFIANT 2

Caliber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electro-Pneumatic

Air Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Compressed Air/Nitrogen

Battery Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-Volt Battery

Cycle Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15bps Capped and/or Unlimited

Firing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Semi Auto and/or Ramping Modes

Effective Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150+ feet

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(With 12” Assassin Barrel) 2lbs., 1oz.

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(With 12” Assassin Barrel) 18.25 inches

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.875 inches

*Weight of Marker without 12” Assassin Barrel is 1lbs., 13oz.

43

*

Defiant 2 Manual ƒ 5/31/05 5:44 PM Page 5

I

I

N

N

T

T

R

R

O

O

O

O

P

P

E

E

R

R

A

A

T

T

I

I

O

O

N

N

Operation

Introduction continued

REGULATORS

Included with the DEFIANT 2 are 2 High-Flow Regulators. The Low Pressure Regulator (LPR)

uses a standard 1/8 inch hex key for adjustment, while the High Pressure Regulator (HPR)

uses a standard 3/16 inch hex key for adjustment. Turn the adjustment screw clockwise to

increase pressure and counter-clockwise to decrease pressure.

LOW PRESSURE REGULATOR

The low pressure regulator is mounted towards the front of the Marker under the barrel. It

controls the cycling pressure of the Marker. The ideal operating pressure should be between

85 – 95 PSI. NEVER EXCEED 100 PSI AS OVER-PRESSURIZING CAN DAMAGE SOLENOID. The

low pressure regulator is not used for velocity adjustments but for cycling pressures only.

HIGH PRESSURE REGULATOR

The high pressure regulator (also called the inline regulator) is the vertical regulator that screws

into the bottom of the ASA Receiver. All velocity adjustments are done with the High Pressure

Regulator. Typically, pressures vary from 200 PSI to 280 PSI depending on chronograph speed.

AMMUNITION ASPECTS

H O P P ER

The DEFIANT 2 requires a high feed rate of paintballs to make full use of its features.

To satisfy this need, the use of a motorized loader is recommended.

PAINT

Using top grade paint ensures the utmost in performance and accuracy.

GAS CONFIGURATIONS

Preset and Adjustable Tanks

A Compressed Air System also known as a Nitrogen Air System is the recommended propellant air

source for operating the DEFIANT 2. If you are using an Adjustable Tank the output pressure should

be set between 400 & 500 PSI, and Preset Tanks should be low pressure or 400 PSI output, however

a high pressure system is acceptable.

Co2

Co2 IS NOT the recommended propellant for the DEFIANT 2. You should only use a Compressed

Air System to operate your DEFIANT 2. When attaching air system hose fittings to your Marker,

DO NOT USE TEFLON TAPE. Use a thread sealant such as Loctite 545 instead.

GETTING STARTED

Maintenance for the DEFIANT 2 is very simple.

The Bolt should be lubricated sparingly with TRI-FLOW. Lubricating once a day or when dirty will

increase the life of the Ball Detents and also eliminate bolt drag.

The Ram or “Hammer” should be greased every 5000 shots with DOW 55. First degas your Marker.

Next, remove Bolt and Encapsulated Ram Sleeve Assembly, then remove the E-clip securing the

threaded Bolt Pin Receiver and Delrin Spacer and unscrew both. Next, unscrew the End Cap from

the Encapsulated Ram Sleeve and Ram will slide out of the rear of the Sleeve. Clean inside of Ram

Sleeve with a Q-tip and grease the internal O-ring located at the front end of the Ram Sleeve with

DOW 55, grease the Rear Ram O-ring and reassemble.

The Low Pressure Regulator Piston and the High-Pressure Regulator Piston O-rings should be greased

every 10,000 shots. Performing this simple maintenance will increase the life of the O-rings and keep

the Marker performing at the highest level possible.

NOTE: Always ensure Air Source is disconnected and Marker is fully degassed BEFORE performing

any/all maintenance, or when Marker is not operational.

65

2

defiant

Defiant 2 Manual ƒ 5/31/05 5:45 PM Page 7

2

defiant

W

W

a

a

r

r

n

n

i

i

n

n

g

g

BATTERY INFORMATION

The DEFIANT 2 uses a standard 9v battery. To change the battery, remove the Left Rubber Grip Panel,

then remove the 4 allen screws securing the two Trigger Frame halves. You’ll notice the battery

fits into the bottom of the grip frame. Disconnect the old battery and re-connect the new.

WARNING!

At this time it is good to verify screws are not protruding through the bottom of the grip and into the

interior components. Failure to do so may result in damage to the battery and/or Circuit Board.

ANTI- CHOP EYES (ACE)

The DEFIANT 2 incorporates a Break Beam, Anti-Chop Eye system, commonly referred to as

the ACE system. The ACE system consists of a set of sensors mounted near the bottom of

the breech to restrict firing until a ball is completely loaded into the breech. Always operate

the DEFIANT 2 with the eyes on. Failure to do so will more than likely result in broken paint

in the breech. The Transmitter Eye can be identified by the red and black wires and metal

casing. The Receiver Eye can be identified by it’s blue and black wires and black plastic casing.

Both Eyes run onto a single wiring harness. Always inspect ACE System wiring and harness

upon removal to ensure there is no damage present. If there is damage to either the wiring and/or

harness the Eyes should be replaced to ensure the ACE system does not fail during operation.

FACTORY SETTINGS

Standard factory FRENZY Board settings are as follows:

EYE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Forced

DEBOUNCE . . . . . . . . . . . . . . . . . . . . . . . . . . . 2ms

FIRING MODE . . . . . . . . . . . . . . . . . . . . .Semi-Auto

DWELL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8ms

A detailed description of each function is in the board operation section.

E

E

L

L

E

E

C

C

T

T

R

R

O

O

N

N

I

I

C

C

S

S

B

B

O

O

A

A

R

R

D

D

O

O

P

P

E

E

R

R

A

A

T

T

I

I

O

O

N

N

Board

Operation

Electronics

Normal Operation/FORCED Mode Eye Sensor Malfunction/DRY FIRE Mode Battery Low/Power OFF

123

Button Membrane

3

GETTING STARTED

Powering Up

1. To power up your DEFIANT 2, press the ON/OFF Button. A Green Flashing Light indicates Standard

Operation Mode. A more detailed description of Modes and their pertaining colors can be found below.

2. To turn off your DEFIANT 2, press and hold ON/OFF Button for approximately 1 second until the LED

turns Red, and Release. Your DEFIANT 2 is now OFF.

Light Emitting Diode (LED)

The DEFIANT 2 features a 3-Color LED that aluminates in either Green, Orange, or Red, and indicates the

operational Status of the Marker. Once the Marker is powered up the LED will flash Green and can be

seen through the Left Rubber Grip Panel. Upon Powering Up, the factory default Eye Sensor Mode is

FORCED/SEMI-AUTO and is indicated by the flashing Green LED. Pressing Button 1 will change the Eye

Sensor to DRY FIRE MODE, and is indicated by the flashing Orange LED. Pressing Button 2 will change the

Eye Sensor to DELAY MODE, however this function WILL NOT change the color of the LED. For example; If the

marker is set to FORCED and the LED is flashing Green, pressing Button 2 will change the Eye Sensor

to DELAY MODE and the LED will continue to flash Green. A Red flashing LED indicates LOW BATTERY.

NOTE: The LED will also flash Orange to indicate an Eye Sensor Malfunction.

SELECTING FIRING MODES

The DEFIANT 2 features 2 Firing Modes (Semi-Auto and Ramping)that are accessable via the Dip

Switch panel located on the front side of the Frenzy Board. See Figure “B” on the following page

1. GREEN LED Indicates Normal Operation for Both Modes (Semi-Auto and Ramping).

Upon Power-Up the Eye Sensor setting will always default to FORCED, regardless of Mode.

2. ORANGE LED Indicates EYE SENSOR MALFUNCTION and/or DRYFIRE Mode.

(DRY FIRE Mode Formerly known as SIMULATION Mode, Demonstrates how

the Marker should operate with an appropriate supply of paintballs and fully

charged air system.)

3. RED LED Indicates LOW BATTERY and/or Powering OFF.

Below are views of each LED Color as well as the corresponding description(s)for each.

87

Defiant 2 Manual ƒ 5/31/05 5:45 PM Page 9

2

defiant

B

B

O

O

A

A

R

R

D

D

O

O

P

P

E

E

R

R

A

A

T

T

I

I

O

O

N

N

I

I

N

N

T

T

R

R

O

O

Competition

Lock

Board Operation

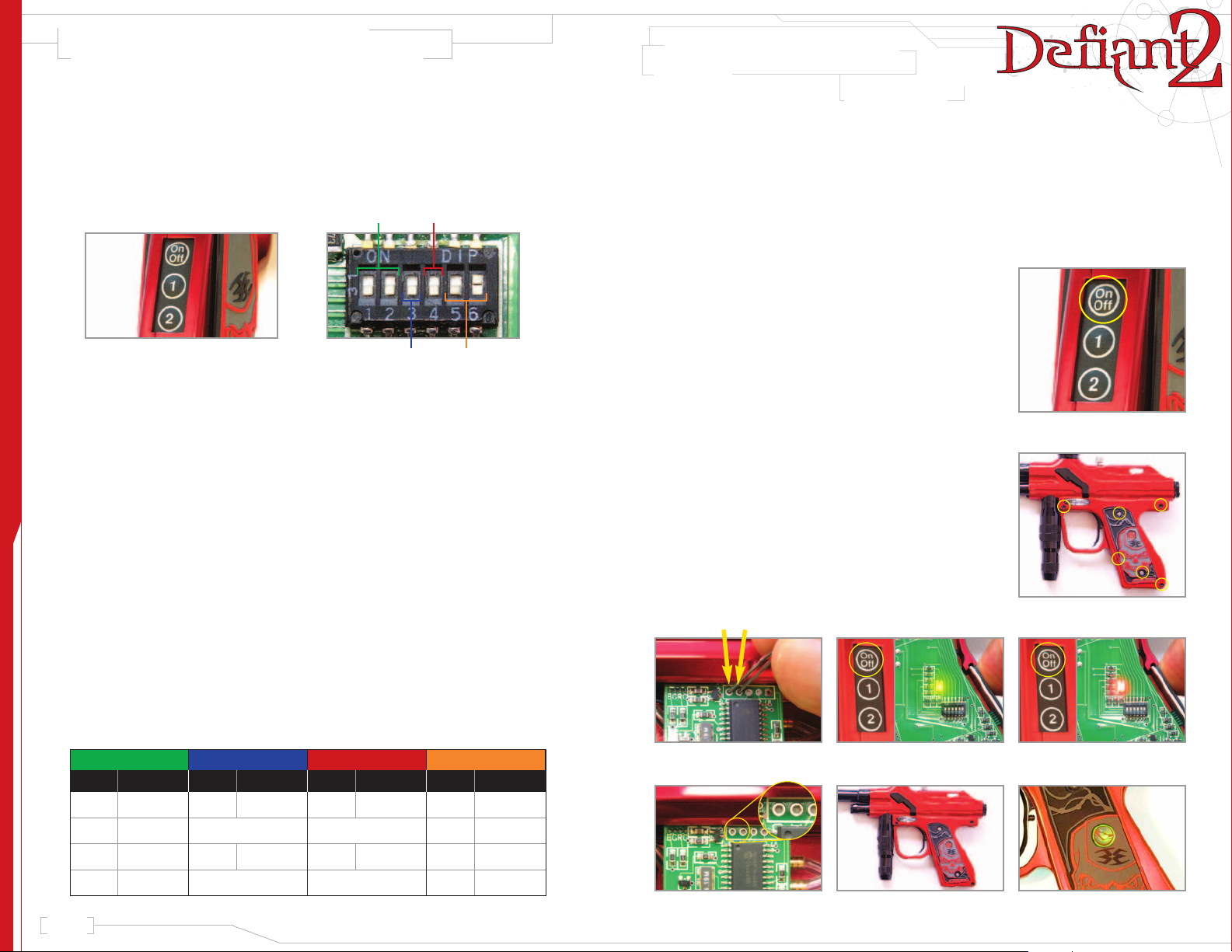

MODE SELECTION (Version 127.4T FRENZY only)

The LED FRENZY Board is driven via the Two-Button Membrane Pad on the rear of the Trigger Frame

(figure “A”) as well as the On-Board Dip Switch Panel (figure “B”) located on the front side of the Fenzy

Board and is accessed by removing the left trigger frame panel. Dip Switches 1 and 2 control DEBOUNCE,

Dip Switch 3 controls CAPPED MODE, Dip Switch 4 controls FIRING MODE, and Dip Switches 5 and 6 control

DWELL. Below are descriptions of the different modes and how they affect the Marker’s performance.

EYE - Upon Powering up, the DEFIANT 2’s ACE System will always default to FORCED MODE. Pressing

Button 1 will Deactivate the ACE System and the marker will resume operation utilizing the

currrently selected Firing Mode, in DRY FIRE MODE. Pressing Button 2 will change the current

ACE System Setting to DELAY MODE. Listed below are descriptions of each ACE System Setting.

FORCED - Marker fires only when ball is present at time of trigger pull.

DELAY - Marker fires when ball is present at time of trigger pull and if a ball IS NOT

present the Marker will wait 1 second before firing.

DRY FIRE - ACE System is Bypassed (OFF)and Marker fires at time of trigger pull.

DEBOUNCE - Determines (in milli seconds) how long after each trigger pull, the board will ignore

further trigger activity. (see figure “C” for details)

CAPPED MODE - Determines if marker operates at an unlimited rate of fire or under a 15bps Cap.

FIRING MODE - Determines which Firing Mode is selected. (see figure “C” for details)

DWELL - Determines how long the bolt remains in the forward position before repeating cycle.

Changing Dip Switch Settings is very simple. Sliding Switches UP sets them to the ON position,

while Sliding Switches DOWN sets them to the OFF position. A small paper clip works well for

toggling Dip Switches. The chart below illustrates how the Dip Switch Panel affects the settings.

Dindicates DOWN, while Uindicates UP.

COMPETITION LOCK - With Competition Lock ON, Dwell and Debounce settings are locked and

cannot be changed until Competition Lock is DISABLED. While in Competition Mode the Eye Sensor

setting can be changed as normal to Dry Fire Mode or Delay Mode. When Competition Lock is

active, the LED will aluminate Green as normal upon powering up. (Marker is not BPS capped

while using competition Lock)

ACTIVATING COMPETITION LOCK:

1. Turn Marker OFF.

2. Open up Trigger Frame to gain access to the Circuit Board.

3. Short out Cand DTerminals (holes)at the top of the board.

Paper clips work well for this. Bend the clip so that one

end is touching the Dand the other end is touching C.

4. Turn Marker ON.

5. Turn Marker OFF.

6. Disconnect the Dand Cshort and leave off

for at least 30 seconds.

7. Reassemble Trigger Frame.

8. Ready to use with COMPETITION LOCK.

To turn OFF Competition Lock follow the same procedure.

When Competition Lock is active the marker will only operate

in Semi-Auto Mode and Ramping Mode will be disabled.

For information and instructions regarding previous and/or

future versions of the FRENZY Board (Other than version 127.4T),

please refer to separate instructions sheet included in box.

Turn Marker OFF

Membrane Pad

1

Open Trigger Frame

2

Disconnect Short, Leave OFF Reassemble Trigger Frame COMPETITION LOCK

678

Short out C and D Terminals Turn ON Comp Lock ON

345

Turn OFF

Terminals

C D

continued

109

DEBOUNCE FIRING MODES

DWELL

CAP MODES

Dip Switch Panel

BA

DEBOUNCE

[1][2]RESULT

D D 2mS

D U 5mS

UD 15mS

DD 50mS

CAP MODE

[3]RESULT

UCAPPED

D UNCAPPED

FIRING MODE

[4]RESULT

URAMP MODE

D SEMI-AUTO

DWELL

[5][6]RESULT

D D 6mS

DU8mS

UD 10mS

DD 12mS

*

**

*

NOTE: (****)Indicates the Factory Default Setting

While in CAPPED Mode the Marker

will be limited to a 15bps limit.

While UNCAPPED the Marker will

operate at an unlimited Rate of fire.

RAMPING will comense after 4 rapid

trigger pulls in succession.

While in SEMI-AUTO MODE the Marker

will fire one shot per trigger pull.

figure C

Defiant 2 Manual ƒ 5/31/05 5:45 PM Page 11

2

defiant

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

&

&

D

D

I

I

S

S

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

Assembly&Disassembly

GETTING STARTED

WHEN DISASSEMBLING THE DEFIANT 2 ALWAYS ENSURE THE MARKER IS DEGASSED.

The DISASSEMBLY portion of this manual will be divided into three sections.

I. Trigger Frame Disassembly

II. Regulator Disassembly

III. Body Disassembly

NOTE: When ASSEMBLING the DEFIANT 2, perform the entire disassembly

process in reverse order.

I. TRIGGER FRAME DISASSEMBLY

1. Remove left side LED Grip.

2. Remove 4 allens to separate Trigger Frame Halves, exposing circuit board.

3. Disconnect Battery.

4. Remove 2 Board retaining screws. (1-1/16 Allen Head screw and 1-Phillips Head screw)

5. Flip Board over towards left side to expose wiring..

6. Lift up on black LCD ribbon locks located on each side of membrane ribbon harness and

remove complete membrane assembly from trigger frame.

7. Remove Battery and Solenoid Harness.

I. TRIGGER FRAME DISASSEMBLY (continued)

8. Remove Eye Sensor Wire Harness.

9. Remove Circuit Board.

10. Remove Shouldered Trigger Retaining Screw and lift out Trigger and Trigger Return Spring.

11. Loosen Front Frame Retaining Screw.

12. Remove Rear Frame Retaining Screw.

13. Lift Out Front Hose from Around Hose Guard. (A small allen wrench works well)

14. Slide Trigger Frame Back from Body.

15. Remove Trigger Frame.

16. Diconnect Solenoid from Body.

NOTE: Use care when removing airlines.

Always inspect hoses after removal to ensure no tears or damage occurred during removal.

Flip Board To Expose Wiring Lift Up LCD Ribbon Locks Remove Battery/Solenoid Harness

Separate Trigger Halves Disconnect Battery Remove Board Retaining Screws

WARNING!

Ensure Air Source is disconnected and Marker

is discharged before making any mechanical

adjustments to Marker internals or electronics.

Slide Frame Back From Body Remove Trigger Frame Remove Solenoid From Body

Loosen Front Frame Retaining Screw Remove Rear Frame Retaining Screw Lift Hose From Around Hose Guard

Remove TriggerRemove Board

Remove Eye Harness

234

7

56

Grip Removal

18

13

16

12

15

11

14

910

1211

Defiant 2 Manual ƒ 5/31/05 5:46 PM Page 13

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

&

&

D

D

I

I

S

S

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

Assembly&Disassembly

REGULATOR DISASSEMBLY (continued)

HIGH-PRESSURE REGULATOR (HPR)

1. Unscrew Allen Adjuster.

2. Unscrew Lower End of (HPR)

High-Pressure Regulator Housing.

3. Remove Regulator Spring Washer.

4. Remove Regulator Spring.

5. Remove Piston.

NOTE: At this time the Regulators are disassembled. Listed below are key elements to

remember during assembly.

1. Piston: Ensure cupped end of Piston is facing towards Pin Valve.

2. Pin Valve: Ensure Pin Valve is not bent and seats in cupped end of Piston.

Failure to do so will cause Regulators to function improperly.

3. Air Barb: Ensure fiber washer is on Air Barb base when installing.

This will ensure Air Barb does not leak.

4. Poppet Spring Attachment: Ensure small end of Spring sits firmly on Poppet.

5. ASA Receiver: Place small portion of Loctite on Retaining Allen when installing.

This will ensure ASA Receiver does not work itself loose during operation.

4. LPR Retaining Screw: Place small portion of Loctite on Retaining Allen when installing.

This will ensure LPR (Low-Pressure Regulator)does not work itself loose during operation.

6. Remove Pin Valve Retainer.

7. Remove Teflon Washer.

8. Remove Pin Valve.

9. Remove Spring from Upper Reg. Housing.

10. Upper End of (HPR)High-Pressure

10. Regulator Housing.

Torpedo/High-Pressure Regulator

LOW-PRESSURE REGULATOR (LPR)

1. Unscrew Allen Adjuster.

2. Unscrew LPR End Cap (Part 2)from

Low-Pressure Regulator Base (Part 10).

3. Remove Regulator Spring Washer.

4. Remove Regulator Spring.

5. Remove Piston.

Low-Pressure Regulator

3 54 86 7 9 101 2

743 85 6 9 101 2

II. REGULATOR DISASSEMBLY

1. Remove High-Pressure Regulator to gain

proper clearance to the LPR Retaining Screw.

2. Remove LPR Retaining Screw from Body.

3. Slide LPR Assembly from Body.

Remove Spring and Poppet Remove ASA Retaining Screw Transfer Hole Screw

4

Remove HPR

1

5

Remove LPR Retaining Screw

2

6

Slide LPR Assembly from Body

3

2

defiant

6. Remove Pin Valve Retainer.

7. Remove Teflon Washer.

8. Remove Pin Valve.

9. Remove Spring from Upper Reg. Housing.

10. Low-Pressure Regulator Housing/LPR Base.

4. Remove Spring and Poppet Assembly.

5. Remove ASA Receiver Retaining Screw.

6. NOTE: The Transfer Hole Screw will only need to

be removed if a leak is detected, or a great deal

of debris is present.

1413

Defiant 2 Manual ƒ 5/31/05 5:46 PM Page 15

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

&

&

D

D

I

I

S

S

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

Assembly&Disassembly

BODY DISASSEMBLY (continued)

9. Tilt front end of Encapsulated Ram Sleeve Up, and allow ram to slide out from rear.

NOTE: BEFORE reinserting the Ram, be sure to clean the inside of the ram sleeve

with a Q-tip and inspect the internal O-ring located toward the front of the Ram Sleeve.

Check for excessive wear and/or damage. If the O-ring needs to be replaced,

carefully remove it using a dental pick or the like, and replace. Be sure to lubricate

the internal O-ring with Dow 55 before reinserting Ram.

10. Turn Body over to expose bottom of marker body and remove Valve Retaining Screw.

11. Remove the Valve through front end of the Marker Body.

(Gently push the Valve from the rear with a barrel swab)

12. Remove Feedneck from Body.

NOTE: At this time the Body is disassembled. Listed on the following page are key points to remember during assembly.

III. BODY DISASSEMBLY

First: Ensure Barrel of Marker is removed.

a1. Remove both Eye Sensor Covers (one on each side) by removing Retaining Screw.

a2. Remove both Eye Sensors (one on each side) by carefully pulling sensor heads from mounting holes.

a3. Lift up on Bolt Retaining Pin and slide Bolt out of rear of Marker.

4a. Unscrew Encapsulated Ram Sleeve Assembly from Marker Body. (turn counter-clockwise)

4b. Remove Encapsulated Ram Sleeve Assembly by sliding it out from rear of Marker Body.

a5. Remove E-clip from front of Ram.

a6. Remove Slotted Bolt Pin Receiver. (turn counter-clockwise)

a7. Remove Delrin Bolt Pin Receiver Spacer. (turn counter-clockwise)

a8. Unscrew Ram Sleeve End Cap from Ram Sleeve.

Remove Eye Sensor Covers

1

Remove Eye Sensors

2

Remove E-clip from Front of Ram

5

Remove Slotted Bolt Pin Receiver

6

Remove End Cap from Ram Sleeve

8

Tilt Ram Sleeve Up and Remove Ram from Rear

9

Remove Valve through Front

Remove Valve Retaining Screw

10

11

Remove Feedneck from Body

12

Lift Bolt Pin and Remove Bolt Unscrew Ram Sleeve Remove Ram Sleeve Assembly

34a. 4b.

Remove Delrin Bolt Pin Receiver Spacer

7

2

defiant

1615

Defiant 2 Manual ƒ 5/31/05 5:47 PM Page 17

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

&

&

D

D

I

I

S

S

A

A

S

S

S

S

E

E

M

M

B

B

L

L

Y

Y

Assembly&Disassembly

ASSEMBLY TIPS

KEY ELEMENTS TO REMEMBER DURING ASSEMBLY.

O-Rings: LUBRICATE ALL O-RINGS UPON INSTALLATION.

Ram Sleeve O-rings: Always ensure all O-Rings are in good condition upon installation.

Air Barb: Ensure fiber washer is on Air Barb base prior to installation. This will ensure a proper seal.

LPR Retaining Allen: Use small amount of Loctite on LPR Retaining Allen when installing.

Failure to do so may result in LPR sliding off the Marker Body, causing extreme damage to

the Marker and/or possibly injuring the operator and others. A firm snug is all that is required

to maintain a secure fit.

Poppet installation: Before installation, inspect Poppet thoroughly. If Poppet shows signs of

excessive wear, it must be replaced in order to ensure a proper seal. Allow Poppet to slide into

the Valve when installing. Once seated, tap on Poppet end to mate Poppet with Valve. Ensure

small end of spring seats firmly on Poppet.

Valve Retaining Allen: Use small amount of Loctite on Valve Retaining Allen when installing.

Failure to do so may result in Valve sliding within the Marker Body, causing extreme damage

to the Marker and/or possibly injuring the operator.

Eye Sensor Harness: Ensure Harness is seated in grove provided before attaching Eye Covers.

Failure to do so may result in pinched wires and render the eyes inoperable.

Eye Covers: Ensure Ball Detents remain aligned and in Covers upon install. Do not over tighten

the cover screws. A firm snug is all that is required to maintain a secure fit.

Feedneck: Removal of the Feedneck may require the use of a Strap Wrench since it is firmly

attached during initial assembly. Simply wrap the Strap around the Feedneck and turn counter-

clockwise. To Reinstall simply screw the Feednack back onto the body and tighten firmly using

a Strap Wrench.

NOTE: Once Marker is completely disassembled, carefully inspect all Screws, O-Rings, Ball Detents,

Air Barbs, Hoses, Eye Sensors, Wiring, Electronics, Battery, Regulators, and Feedneck Threads,

etc., for signs of premature or excessive wear, stripping and/or damage.

If ANY parts show signs of premature or excessive wear, stripping and/or damage, and you need

to order them, please refer to the chart on the facing page for reference. A more detailed

description of parts and/or the corresponding PART NUMBER(S)can be found in the COMPLETE

PARTS CHECKLIST located on the inside back cover of the manual. Simply call B.L.A.S.T. at the

number provided and a Customer Service Representative will assist you.

*PLEASE HAVE PART NUMBER(S)READY WHEN CALLING.

GENERAL MAINTENANCE

WARNING: NEVER use lightweight gun oil on Marker. Oil will destroy internals of Air Valve and O-rings.

Keep foreign obstructions out of Marker internals and Lubricate all O-rings within the Marker with a

generous coat of Dow 55 Lubricant. The Ram requires Lubing every 5,000 rds. fired. Regulator

O-rings should be Lubed every 10,000 rds. fired. Failure to do so will reduce recovery time of

Regulators. Additionally, the Piston will wear a groove in the Regulator housing. Ensure the Pin

Valve lines up with the Cupped End on the Piston during reassembly. This will eliminate the

inadvertent bending of the pin.

Below is a list of the most common Consumable Components of the DEFIANT 2.

CONSUMABLE COMPONENTS

COMPONENT QUANTITY SIZE

Body Assembly

Ram Front O-ring (Inside Front of Sleeve)1012

Ram Rear O-ring 1011

Ram Rear Bumper O-ring (Teflon)1006

Pressurized Ram Sleeve O-ring 3015

Sleeve End Cap O-ring 2011

Regulator Assembly

HPR Housing O-ring 1016

HPR Piston O-ring 1113

HPR Pin Valve Base Washer 1010

HPR Pin Valve Washer (Teflon)1006

LPR Piston O-ring 2011

LPR Pin Valve Base 1010

LPR Pin Valve Washer (Teflon)1006

ASA Receiver Mounting O-ring 1113

Trigger Assembly

Airline 1 to front of body 5.0 in.

Airline 1 to middle of body 5.0 in.

Airline 1 to rear of body 2.5 in.

Circuit Board 1004

2

defiant

1817

Defiant 2 Manual ƒ 5/31/05 5:47 PM Page 19

T

TR

RO

OU

UB

BL

LE

ES

SH

HO

OO

OT

TI

IN

NG

G

T

T

R

R

O

O

U

U

B

B

L

L

E

E

S

S

H

H

O

O

O

O

T

T

I

I

N

N

G

G

Troubleshooting

NOTE: Refer to Assembly/Disassembly to perform repairs indicated below.

1. Replace Poppet

2. Replace Ram Sleeve O-rings

1. Open Trigger Frame and

reconnect Hose

2. Tighten or Replace Air Barb

1. Check LPR Pressure. It should

be between 85-95 PSI.

2. It is not recommended to

disassemble Solenoid.

Call B.L.A.S.T. for assistance

1. Check Dwell and Reset to Factory

Settings Via Dip Switch Panel

2. Turn in LPR Set Screw. Pressure

should be between 85-95 PSI.

3. Open Frame and check hoses

4. Push Reset Button on Solenoid

when Marker is pressurized. If

Marker does not fire call B.L.A.S.T.

6. Open Trigger Frame and check

Solenoid connection/Wiring

1. Lube Piston with DOW 55

2. Check Dwell and set to

Factory Settings

3. Replace 011 O-Ring

4. Check pressure and

reset to 85-95 PSI

5. Use appropriate size

paintball.

1. Poppet is not sealing

2. Ram Sleeve O-rings

are damaged

1. Air Hose has become

disconnected

2. Hose Barb has come loose

or is broken

1. Marker is over pressurized

2. Foreign material has lodged

inside Solenoid

1. Dwell is to low

2. LPR too low

3. Pinched Hose

4. Debris in Solenoid

5. Check the LED.

If LED is not Flashing at time of

Trigger Pull it is the Micro-Switch

6. If LED is Flashing it is

possible the Solenoid connector

is disconnected or damaged

1 .High Pressure Regulator

Piston is dry

2 .Dwell too low

3. Large Ram O-ring (011) is worn.

4. LPR Pressure too low

5. Paint does not fit Barrel

Marker leaks down Barrel

Marker leaks from inside

Trigger Frame

Marker leaks from Solenoid

Marker is pressurized and

will not fire

Inconsistent Velocity

1. Replace O-rings

2. Replace Regulator Seat

3. Tighten Brass Nut

4. Replace O-ring

1. Check Dwell and reset

to Factory Settings

2. Check output pressure of

High-Pressure Regulator

1. Check depth of Pin Valve

2. Raise LPR pressure

1. Check and make sure Eyes

are ON and/or operational

2. Replace Ball Detents

3. Size paint for Barrel

4. Use winter-fill paint in

winter or heat your paint

1. Check Eye Alignment

2. Clean Eyes

3. Open and inspect Eye Wires

and Harness

4. Replace Bad Eye(s)

1. Call B.L.A.S.T.

for assistance

1. LPR Base 0-rings are bad

2. Regulator Seat is bad

3. Brass Nut isn’t tight enough

4. 010 0-ring on Brass

Nut is worn or damaged

1. Low dwell

2. High-Pressure Regulator spiking

over pressurizing valve chamber

1. Preset tank pin valve is

depressed too far or not enough,

starving Marker of air

2. LPR pressure too low

1. Eyes are turned off

and/or damaged

2. Missing or worn ball detents

3. Paint too large for barrel

4. Using brittle paint in

cold weather

1. Eyes misaligned

2. Dirty Eyes

3. Pinched or cut wires

4. Bad Eye(s)

1. Faulty Micro-Switch

LPR spikes

Marker fires with low

first shot

Marker dies off with

rapid fire

Marker is Breaking paint

Eyes fail when in delay

Marker fires on pull

and release

2

defiant

2019

PROBLEM DIAGNOSIS REPAIR PROBLEM DIAGNOSIS REPAIR

Defiant 2 Manual ƒ 5/31/05 5:47 PM Page 21

T

T

E

E

C

C

H

H

N

N

I

I

C

C

A

A

L

L

.

.

.

.

.

.

S

S

P

P

E

E

C

C

S

S

Technical

Specifications

PARTS IDENTIFICATION

O-ring Sizer/Identifier

O-ring & Size Quantity Discription/Breakdown

Teflon Regulator Seat Washer2 Per Marker

006 (Polyurethane)

Ram Bumper O-ring1 Per Marker

006 (Teflon)

Brass Nut O-ring for

Low-Pressure Regulator &

High-Pressure Regulator (1 each)

2 Per Marker

1 - Ram REAR

2 - Ram Sleeve Cap

2 - LPR Piston

(Low-Pressure Regulator)

5 Per Marker

010

011

FRONT Ram O-ring

(Inside Front of Ram Sleeve)

1 Per Marker

012

FRONT Valve O-rings2 Per Marker

112

O-ring & Size Quantity Discription/Breakdown

4 - LPR Housing O-rings

3 - Encapsulated Ram Sleeve O-rings

1 - Valve Base O-ring

1 - ASA Thread Base O-ring

9 Per Marker

015

HPR Lower End O-ring1 Per Marker

118

1 - ASA Receiver Mounting O-Ring

1 - HPR Piston O-ring

(High-Pressure Regulator)

2 Per Marker

113

NOTE: The number below each O-ring on the left column indicates the size of the O-ring.

For instance if you need to purchase a Ram Bumper O-ring, you would ask for an O-ring size 006 Teflon.

2

defiant

2221

NOTE: O-rings are shown in actual size.

Defiant 2 Manual ƒ 5/31/05 5:47 PM Page 23

2

defiant

T

T

E

E

C

C

H

H

N

N

I

I

C

C

A

A

L

L

.

.

.

.

.

.

S

S

P

P

E

E

C

C

S

S

Technical

Specifications

Trigger Mounting Screw

(Secures Trigger to frame)

1 Per Marker

8/32 x 9/16

(Shouldered)

PARTS IDENTIFICATION (continued)

Screw Sizer/Identifier

Screw & Size Quantity Discription/Breakdown Screw & Size Quantity Discription/Breakdown

NOTE: Screws are shown in actual size. NOTE: The number under each Screw on the left column indicates the size of the Screw. For instance if you

need to purchase a LOWER Circuit Board Retaining Screw, you would ask for a 4/40 x 1/4 LOWER Circuit Board

retaining Screw Screw.

Rubber Grip Screws

4 Per Marker

6/32 x 3/16

4 - Trigger Frame Screws

1 - Transfer Hole Screw

6 Per Marker

4/40 x 1/4

Trigger Frame Mounting Screw Washer1 Per Marker

4/40 x 1/4

FRONT Trigger Frame Mounting Screw1 Per Marker

10/32 x 3/4

UPPER Circuit Board Retaining Screw1 Per Marker

0/80 x 3/8

LOWER Circuit Board Retaining Screw

1 Per Marker

4/40 x 1/4

UPPER Trigger Adjustment Screw

(Adjusts Return Spring Tension)

1 Per Marker

8/32 x 1/4

CENTER Trigger Adjustment Screw

(Adjusts Micro-Switch Activation Point)

1 Per Marker

6/32 x 1/2

LOWER Trigger Adjustment Screw

(Adjusts Trigger Travel Stop Point)

1 Per Marker

6/32 x 3/16

Retaining Set Screw for Bolt Pull Pin1 Per Marker

5/16 x 18 x 5/16

ASA Receiver Retaining Screw1 Per Marker

1/4 x 20 x 5/8

LPR Retaining Screw1 Per Marker

8/32 x 3/8

Valve Retaining Screw1 Per Marker

3/8 x 24 x 3/8

LPR Pressure Adjustment Screw

1 Per Marker

1/4 x 20 x 1/4

HPR Pressure Adjustment Screw

1 Per Marker

3/8 x 24 x 3/8

Eye Cover Screws2 Per Marker

2/56 x 3/8

(Stainless Steel)

(Stainless Steel)

REAR Trigger Frame Mounting Screw1 Per Marker

10/32 x 5/8

(Stainless Steel)

(Rear Screw Only)

(Stainless Steel)

(Stainless Steel)

(Stainless Steel)

(Stainless Steel)

(Stainless Steel)

(Stainless Steel)

(Stainless Steel)

2423

Defiant 2 Manual ƒ 5/31/05 5:47 PM Page 25

2

defiant

P

P

A

A

R

R

T

T

S

S

C

C

H

H

E

E

C

C

K

K

L

L

I

I

S

S

T

T

Parts Checklist

PARTS CHECKLIST

1. LPR Adjustment Screw

2. LPR Front End Cap

3. LPR Spring Washer

4. LPR Spring

5. LPR Piston

6. LPR Piston O-Rings (011)

7. LPR Brass Nut (2 per marker)

8. LPR Brass Nut O-ring (010)

9. Regulator Seat Washer (006)

10. Regulator Pin Valve (2 per marker)

11. Pin Valve Spring (2 per marker)

12. LPR Housing/Base

13. LPR Retaining Screw

14. LPR Housing O-rings (015)

15. Poppet Spring

16. Poppet Cup Seal

17. Poppet Shaft

18a. FRONT Air Valve O-Rings (112)

18b. REAR Air Valve O-Ring (015)

19. Air Valve

20. ASA Mounting O-ring (113)

21. ASA Receiver

22. ASA Thread Base O-ring (015)

23. ASA Retaining Screw

24. HPR Upper Housing

25. HPR Piston O-ring (113)

26. HPR Piston

27. HPR Spring

28. HPR Spring Washer

29. HPR Lower Housing O-ring (118)

30. HPR Lower Housing

31. HPR Adjustment Screw

32. Eye Cover Retaining Screws

33. Eye Covers

34. Eye Wire Harness

35. Valve Retaining Screw

36. Grip Mounting Screws

37a. LEFT Rubber Grip Panel

37b. RIGHT Rubber Grip Panel

38. Trigger Frame Assembly Screws

39. Bob Long Jewel Sticker

40. Left Side Trigger Frame

41. Upper Board Retaining Screw

42. Lower Board Retaining Screw

43. Frenzy Board

44. Membrane Pad & Ribbon

45. Battery & Solenoid Harness

46. Solenoid

47. Air Barbs & Washers (6 per marker)

48. Trigger Retaining Screw

49. Trigger

50. Return Spring Tension Screw

51. Microswitch Activation Screw

52. Trigger Travel Stop Screw

53. Trigger Return Spring

54. FRONT Frame Mounting Screw

55. REAR Frame Mounting Screw

56. Right Side Trigger Frame

57. Bolt Receiver Retaining E-clip

58. Slotted Bolt Receiver

59. Bolt Receiver Spacer (Delrin)

60. Front Ram Sleeve O-ring (012)

61. Ram Sleeve O-rings (015)

62. Encapsulated Ram Sleeve

Designed by Robert Rivera - 305.819.1009

123

57 58 59 60

62

63

67

66

65

64

61

456789101112

15 16 17

18a 18b 19

20

21

22

13

14

23

11

10

46

8

9

7

25

26

27

28

38

39

36

38

36

29

30

31

24

33

32

34

42

54

50

51

32

53

40

36

37b

45

55

72

33

74

69

71

75

68

70

73

35

48

56

44

41

43

38

37a

47

49

52

63. Ram/Hammer

64. Rear Ram O-ring (011)

65. Ram Bumper (006-teflon)

66. Ram Cap O-Rings (011)

67. Ram Sleeve Cap

68. Bolt Pin Tension Set Screw

69. Bolt Pin Tension Spring

70. Bolt Pin Retaining Bearing

71. Delrin Bolt

72. Bolt Pin

73. Feedneck

74. Transfer Hole Screw & Washer

75. 12” Assassin Barrel

To order parts for your DEFIANT 2, please call (925) 625-7929. Please have part numbers ready.

Defiant 2 Manual ƒ 5/31/05 5:47 PM Page 27

Table of contents