Blaze B100 User manual

Contemporary Styled Wood Heaters

OPERATING INSTRUCTIONS

Glen Dimplex Australia proudly supports the

activities of Landcare Australia through its

membership of the AHHA.

VERSION 1.0

BLAZE B100

1

TABLE OF CONTENTS

USER INSTRUCTIONS

1. Introduction .......................... 2

1.1. Air Controls...................... 2

1.2. Door Handle..................... 2

2. Using Appliance for the First Time ........ 3

3. Recommended Fuels .................. 3

4. Lighting the Fire ....................... 3

5. Running the Appliance................. 3

5.1. Maximum Heat Output ............ 3

5.2. Low Heat Output ................. 4

5.3. Reload with More Wood ........... 4

6. Burning Tips .......................... 4

6.1. Fuel Quality ..................... 4

6.2. Flue Draught..................... 4

7. Ash Removal ......................... 5

8. Flue/Chimney Fire ..................... 5

9. Cleaning Paintwork and Glass ........... 5

10. Cleaning the Flue ..................... 5

11. Troubleshooting Tips ................... 6

11.1. Glass in Door Blackening........... 6

11.2. Trouble Starting the Fire............ 6

11.3. Burning Too Quickly ............... 6

MAINTENANCE AND SERVICING

1. Replacement of Fire Bricks .............. 7

2. ReplacementofBafePlate ............ 7

3. Removing the Door.................... 8

4. Fitting New Door Glass ................. 8

5. Fitting a New Door Seal ................ 9

6. Door Handle Adjustment ............... 9

7. Warranty ............................ 10

8. Replacement Spare Parts List............ 12

2

User Instructions

1. INTRODUCTION

Before use of this appliance please read these

instructions fully.

WARNING: ANY MODIFICATION OF THE APPLIANCE

THAT HAS NOT BEEN APPROVED IN WRITING BY THE

TESTING AUTHORITY IS CONSIDERED AS BREACHING

AS/NZS 4013.

WARNING: DO NOT USE FLAMMABLE LIQUIDS OR

AEROSOLS TO START OR REKINDLE THE FIRE.

WARNING: DO NOT USE FLAMMABLE LIQUIDS OR

AEROSOLS IN THE VICINITY OF THIS APPLIANCE

WHEN IT IS OPERATING.

WARNING: DO NOT STORE FUEL WITHIN HEATER

INSTALLATION CLEARANCES.

WARNING: WHEN OPERATING THIS APPLIANCE AS

AN OPEN FIRE USE A FIRE SCREEN.

WARNING: OPEN AIR CONTROL BEFORE OPENING

DOOR.

WARNING: DO NOT BURN WOOD THAT IS PAINTED;

OR IS COATED WITH PLASTIC; OR HAS BEEN TREATED

WITH ANY CHEMICAL.

CAUTION: THIS APPLIANCE SHOULD NOT BE

OPERATED WITH CRACKED GLASS.

CAUTION: THIS APPLIANCE SHOULD BE MAINTAINED

AND OPERATED AT ALL TIMES IN ACCORDANCE

WITH THESE INSTRUCTIONS.

Theapplianceoruesystemshouldnotbe

modiedinanywaywithoutthewrittenapproval

of the manufacturer.

Extraction fans or rangehoods must not be placed

in the same room or space, as this can cause

appliance to emit smoke into the room.

3

1.1. AIR CONTROLS

The Blaze B100 wood heater features a single

air control system. It is designed to introduce

oxygenintothebaseofthere,controllingthe

rate of combustion of the wood as well as the

oxygenbeingdrawnintotheupperreboxwhere

combustion of the gases occurs.

The air control is operated by sliding the tab

handle located on the top left of the heater.

Sliding all the way to the left offers maximum burn

rate, while all the way to the right offers minimum

burn rate.

Secondaryairholesintherearoftherebox

provide additional oxygen for a more complete

combustion of the gases released from the

burning wood.

1.2. DOOR HANDLE

Warning: the door handle may get hot if

appliance has been left in High burn setting for an

extended period of time. A stainless steel handle

extension is supplied with the heater that can

be inserted in the end of the door handle when

opening and closing if too hot to handle.

2. USING APPLIANCE FOR THE FIRST

TIME

Therstfewtimestheapplianceislit,itwillgiveoff

some odorous fumes. This is caused by the paint

curing.

Do not touch the paint work while it is curing

otherwise it can leave a permanent mark on the

appliance.

Once the paint has cured it will not re-occur.

Keep the room well ventilated until these fumes

have cleared.

3. RECOMMENDED FUELS

Burn only seasoned hardwood timber with a

moisture content of less than 20%. Newly cut

wood should be allowed to dry/season for 12 to

18 months before use.

Wood should be stored in an environment

protected from the weather to minimise any

potential moisture content.

For best results, wood should not exceed 270mm

in length and 150mm in diameter. Any larger, and

the appliance will not operate at its optimum. It is

better to burn several smaller pieces of wood than

one large single piece.

Poor quality timber:

●Causeslowcombustionefciency

●Produces poor emissions (smoky)

●Results in additional buildup of creosote

(soot)intheuewhichwillthenrequire

regularcleaningandmayresultinauere.

Do not burn painted, impregnated/treated wood,

manufactured board products or pallet wood.

4

4. LIGHTING THE FIRE

1. Placerelightersorpaperanddrykindling

woodinthebaseoftherebox.

2. Lightthepaperorrelighters.

3. Open the air control located on the top left

corner of the appliance by sliding to the

left.

4. If necessary, leave the door slightly open as

thereestablishesandtheglasswarmsto

avoid the build-up of condensation.

5. Add larger pieces of wood. Too many logs

maysmotherthere.

6. Close the door.

Do not leave re unattended while door is open.

5. RUNNING THE APPLIANCE

5.1. MAXIMUM HEAT OUTPUT

Afterestablishingthereandloadingitwithlarger

pieces of wood, leave it running with the air slide

fully open (slid all the way to the left).

This setting will generate maximum heat output.

Running the appliance with the door open will not

produce maximum heating in the room, as it will

draw a lot of already warmed air out of the room.

Donotoverloadreboxwithfuel.

Note that this setting is not the most energy

efcientassomeheatislostuptheueinsteadof

being transferred into the room. However, once

thereisestablished,particulateemissionswillbe

very low in this setting.

5.2. LOW HEAT OUTPUT

The heat output of the appliance can be

reduced by closing the air slide, which will restrict

theoxygensuppliedtothereandslowdownthe

rate at which the wood burns.

Thissettingprovidesthebestenergyefciency

as the wood burns for longer. However, if not

operated correctly it may worsen emissions.

Priortoclosingtheairslide,ensurethatthereis

burning briskly. This may require opening the air

slide fully for 5-10mins before shutting down.

For the optimum between clean burning and

gettingthebestinefciency,fromthefullyclosed

position, open the air slide 4-5mm.

The air slide can be adjusted to any position

depending on desired heat output versus burn

time.

5.3. RELOAD WITH MORE WOOD

1. Open air slide before opening door.

2. Rake / break up any existing coals.

3. Load the wood with the length oriented

front to back.

4. Better results will be achieved by loading

several smaller pieces of wood rather than

one large piece.

5. Close door with air slide fully open, and

leave for a minimum of 10 minutes to allow

the fresh wood to catch.

6. After 10 or more minutes, the top air slide

can be adjusted to desired heat setting.

5

6. BURNING TIPS

6.1. FUEL QUALITY

Use wood with a moisture content of less than

20%. Logs should not feel moist or damp, or have

moss and fungal growths.

Symptoms related to wet wood:

●Difcultystartingandkeepingareburning

well.

●Smokeandonlysmallames.

●Dirtyglassand/orrebricks.

●Rapidcreosotebuild-upintheue/chimney.

●Low heat output.

●Short burn times, and blue/grey smoke from

theue/chimneyoutlet.

Run appliance at high heat output for a short

period each day to avoid large build-up of tars

andcreosotewithintheapplianceandue.

6.2. FLUE DRAUGHT

Theuehastwomainfunctions:

1. To safely remove smoke, gases and fumes

from the appliance.

2. Toprovideasufcientamountofdraught

(suction)intheappliancetoensurethere

keeps burning.

Draughtiscausedbytherisinghotairintheue

whentherehasbeenlit.

Theposition,heightandsizeoftheuecanaffect

theperformanceoftheuedraught.Referto

installationguidefordetailsonueinstallation.

Factorsaffectingtheuedraughtinclude:

●Insufcientueheight

●Trees or other buildings nearby causing

turbulence

●High and gusty winds

●Outside temperature and weather

conditions

●Blockedue

Foradviceonthecorrectionofpersistentue

problems consult your supplier/installer.

7. ASH REMOVAL

Depending on the type of wood burnt and

frequency, the ashes will need removing every 2

to 6 weeks.

Excess ashes should be removed when necessary,

placed in a non-combustible container with a

tightlyttinglidandmovedoutdoorsimmediately

to a location clear of combustible materials.

8. FLUE/CHIMNEY FIRE

Ifaue/chimneyreoccurs:

●Shutairslidecontrolfullytosmotherthere

●Donotusetheapplianceafterauere

until an accredited installer has assessed the

cause and any resultant damage.

9. CLEANING PAINTWORK AND GLASS

The appliance, when cool, can be cleaned with a

damp cloth.

Over the years, the black paint will fade and can

be touched up with Stove Bright metallic black

paint.

To clean the glass, we recommend using a

household window cleaner or general purpose

cleaner with a soft cloth. Do not use abrasive

cleaner or scourer pads.

6

10. CLEANING THE FLUE

Checkinsideofuepriortoeachseasonforany

build-up of creosote (wood tar). To do this:

1. Firstremovethebafe(referto“2.

ReplacementofBafePlate” under

Maintenance & Servicing section).

2. Using a small mirror and torch hold the mirror

onananglebelowtheuewiththetorch

shining at it and look for black creosote

build-up.Aneblackpowderylayeris

normal, but if built up layers of creosote can

beseen,thentheueneedscleaning.

3. Retthebafeifnocleaningisrequired.

Tocleantheue:

1. Auecleaningbrushcanbepurchased

from most wood heater retail outlets or

large hardware stores.

2. The objective is to pull the brush down

throughtheue.

3. Withthebaferemoved,tiearopetoone

end of the brush, and drop the rope from

the top (outside on top of the roof) down

theue.

4. Grabtheendoftheropeinsidetherebox

and pull the brush through.

5. Checktheinsideoftheuewiththemirror

and torch. Repeat if necessary.

6. Once clean, remove any excess creosote

fromthereboxandreplacethebafe.

Checkueintegritybycheckingthatthe900mm

uesectionshavenotseparatedatthejoins.

Alternatively,getauecleaningservicetodothe

job for you (it’s a dirty job).

11. TROUBLESHOOTING TIPS

11.1. GLASS IN DOOR BLACKENING

This can have several possible causes:

●Burning unseasoned wood — if the wood is

too wet, it will cause the glass to blacken.

●Appliance operated at low temperature —

after an overnight burn where the air slide

control has been fully closed, the glass may

haveblackened.Whenthereisre-stoked

and burning on the high heat setting, the

blackened glass should self-clean.

●Problemswiththeue—insufcientue

draught can cause the glass to blacken.

Iftheueistooshort,notproperly

insulated, or in a position that results in a

downdraught,thentherewillbeinsufcient

uedraught.Contacttheinstallershould

this happen.

11.2. TROUBLE STARTING THE FIRE

Ifallashhasbeenremovedfromtherebox,it

canupsetthesupplyofairtothebaseofthere.

Whencleaningouttherebox,retainingsomeash

canmakeiteasiertostarttherenexttime.

11.3. BURNING TOO QUICKLY

Ifyoundthattheheaterisburningthroughwood

too quickly, see below:

1. Latchneedsadjustment(referto“6.Door

HandleAdjustment”)

2. Doorsealneedsreplacing(referto”5.Fitting

aNewDoorSeal”)

3. Bafeneedsreplacing(referto“2.

ReplacementofBafePlate”)

7

Maintenance and Servicing

1. REPLACEMENT OF FIRE BRICKS

Thepurposeoftherebricksintheappliance

is to increase thermal mass and to guarantee

thelongevityofthesteelrebox.Overtimethe

rebricksmaybecomecrackedandcrumble

away. If so, they should be replaced.

Toreplacetherebricks:

1. Move any ash away from the bricks.

2. Remove the brick retainer and the bricks.

3. Replacewithnewbricks,andretthe

retainers which hold the bricks in place.

2. REPLACEMENT OF BAFFLE PLATE

The6mmthicksteelbafehelpstoretainthe

heatinthereboxbylengtheningthepathofthe

amessothattheydonotgostraightuptheue.

Overtime,thebafewillbegintosagalittledue

to the excessive heat. This will not affect the way

thereburns.

Eventuallythebafewillburnthrough(5+years)

and if so will need to be replaced.

Toremovethebafe:

1. Remove any excess ash and coals.

2. Remove the brick retainer and bricks from

therearandsidesoftherebox.

3. Liftthebafeupatthebackenough

to clear the rear support pegs and slide

forwardsothatthebafecanbelowered

at the back.

4. Loweringtherearofthebafewillallow

thefrontofthebafetoslidepastthefront

supportpegsonthesidesoftherebox.

5. Oncethebafehasclearedthefront

support pegs, angle it so that it can be

removedfromthereboxwithonesidein

the upper corner of the door opening and

the other in the opposite lower corner of the

rebox.

6. Repeat steps 1 to 6 in reverse to replace

withthenewbafe.

BAFFLE

8

3. REMOVING THE DOOR

To remove the door:

1. Open the door all the way.

2. Lift the door upwards until the door hinges

are freed from the body hinges.

3. If the door is not easy to lift upwards, swing

the door back and forth whilst applying

an upward force to overcome the static

friction.

4. FITTING NEW DOOR GLASS

This task may be easier with the door removed

fromtheheaterandlaidatonawork-bench.

To replace the door glass:

1. Two stainless steel strips hold the glass in

place. Remove the four M4 size Phillips head

screws from the stainless steel strips.

2. Gently lift the glass up and out, and check

ifthegreybreglassropebeneathneeds

replacing. If so replace this rope as well.

FIBREGLASS ROPE

3. Position the new glass on top of the grey

ropeandre-tthestainlesssteelstripsand

M4 screws.

4. Take extra care not to over-tighten the

screws, otherwise the glass will crack when

the heater gets hot and the door expands.

9

5. FITTING A NEW DOOR SEAL

This task may be easier with the door removed

fromtheheaterandlaidatonaworkbench.

1. Remove any old seal from the door.

2. Clean out the groove in the door that the

sealwasbeddedinusingaat-endscrew

driver or equivalent.

3. Run a thin bead of clear roof and gutter

silicone along the groove.

4. Starting at one end, press the new door seal

into the groove on the door.

5. Retthedoorifithasbeenremoved.

APPLY SILICONE

6. DOOR HANDLE ADJUSTMENT

Over time, the door seal can become

compressed resulting in a less than adequate

seal between the door and the front edge of the

rebox.Forexample,ifthewoodburnsunusually

fast even with the air slide shut, it may mean that

there is an air leak around the door.

In this situation, the door seal does not necessarily

need replacing - adjustment of the door handle

can tighten the seal.

1. Remove the nut from the door handle shaft

inside the door.

2. Remove the latch and remove washer.

3. Replace the latch and then place the

removed washer on the other side.

4. Retthenut.Donotovertightenotherwise

door handle will not turn easily.

If door seal is still not tight enough, replace door

seal.

10

7. WARRANTY

Warranty is provided in Australia by Glen Dimplex

AustraliaPtyLtd(referredas“GlenDimplex”).

Thiswarrantyisprovidedtotherstdomestic

purchaser of a Blaze Wood or Stove Fire (radiant

or convection). It applies for 10 years from the

date of purchase from or through an authorized

Blaze Fire Distributor in relation to each product.

Thedoorglass,doorseal,rebricks,brickretainer,

andbafecomponentsarecoveredfornormal

use only with a 1 (one) year warranty. Electric

fans and any remote/transmitter are warranted

against failure to operate for a period of 1 (one)

year from the original date of purchase. The

warranty does not apply to discolouration of the

surfaceortarnishingofchromettingsallofwhich

require regular service to maintain. Any breakage

or failure due to user error is not covered under

this warranty.

TYPE OF PART WARRANTY

(IN YEARS)

PARTS LABOUR

Wood Fire - Firebox 10 5

Door Glass & Seal 1 1

Fire Bricks & Retainer 1 1

BafeComponents 1 1

Fans & Electrical

Components 1 1

During the warranty period, Glen Dimplex will

repair or replace (at its option) any Blaze Wood

or Stove Fire which is found to be defective in

materials or workmanship. Repairs will be carried

out by an approved Blaze Heating Service Agent.

What is covered under this warranty?

●Repair or replacement of parts

●Labour costs relating to the Wood or Stove

Fire

Consumers may have additional rights under the

Australian Trade Practices Act 1974 including

the Australian Consumer Law or the Consumer

Guarantees Act 1993 New Zealand.

This warranty does not apply and will be void

where:

●The Wood or Stove Fire is not installed in

accordance with AS/NZS 2918:2018 or any

building code or consent;

●The Wood or Stove Fire is not installed by a

qualiedspecialistinstaller;

●Any electrical work has not been carried

out by a Registered Electrician;

●The Wood or Stove Fire has been moved

andreinstalled,orhasbeenmodiedin

a manner that is not consistent with the

Installation Guide or the Owner’s Manual;

●The Wood or Stove Fire has not been

installed or operated according to the

Installation Guide and the Owner’s Manual;

●The Wood or Stove Fire is acquired for

business use in any way.

What is not covered?

●Labour costs relating exclusively to

components not manufactured by Glen

Dimplex.

●Labour costs relating to removing or

replacing the Wood Fire or Stove

●Damage caused by incorrect use or the

burning of treated or painted wood,

driftwood or other fuels which are not

recommended.

11

●Travel costs for a distance greater than

50 km from the nearest approved Blaze

Heating Service Agent.

●Defects, malfunctions or failures caused

by incorrect installation, poor installation,

normal wear and tear, misuse, neglect,

accidental damage or failure to follow

operating instructions in the Owner’s

Manual (including fuel selection, product

operation and maintenance instructions),

repairsormodicationsbypersonsnot

authorised by Glen Dimplex, use of parts not

supplied by Glen Dimplex, or damage or

other events which have occurred since the

product left the control of Glen Dimplex.

●Removal or transportation of such product

or part (and any repaired or replacement

product or part) to and from the authorized

dealer’s or service agents place of business.

●Direct, indirect or consequential losses or

special damages of any kind (including

costs of collection and delivery) other

than repair or replacement of products or

components under this warranty, where

any goods are acquired or used for the

purposes of a business;

How to obtain warranty service?

●Warranty Claims must be made at place of

purchase.

●Reasonable proof of purchase date is

required to make a warranty claim. You

should keep your purchase receipt.

●Warranty repair will be completed

according to normal work practices of the

service agent.

●Make the faulty part(s) available to Glen

Dimplex for inspection so that the validity of

the claim can be established by them.

12

8. REPLACEMENT SPARE PARTS LIST

PART NO. PART DETAIL

N200-063 Fire Brick Set 7 @ 170 x 170 x 25mm

Upper Brick Retainers

(included in brick set) 4 X stainless brick retainer straight, 2 X corner

BBR1L Lower Brick Retainer (set) 1 X Left, 1 X Right

N200-034 BafePlate 570mm x 275mm x 6mm steel

N200-059 Door Seal 1520mm x 13mm round

N200-057 Glass Seal 1315mmx8mmx3mmatadhesivebacked

N200-052 Door Glass 468mm x 200mm x 5mm pyro ceramic

13

14

Glen Dimplex Australia Pty Ltd

8 Lakeview Drive,

Scoresby Victoria 3179

Australia

T: 1300 554 155

General&SalesEnquiries:[email protected]

TechnicalService:[email protected]

www.glendimplex.com.au

Table of contents

Other Blaze Heater manuals

Popular Heater manuals by other brands

heidenfeld

heidenfeld HF-GK100C manual

Neomitis

Neomitis TBLMC050C11 Installation and operating instructions

Sengoku

Sengoku MGN-110 owner's manual

Haverland

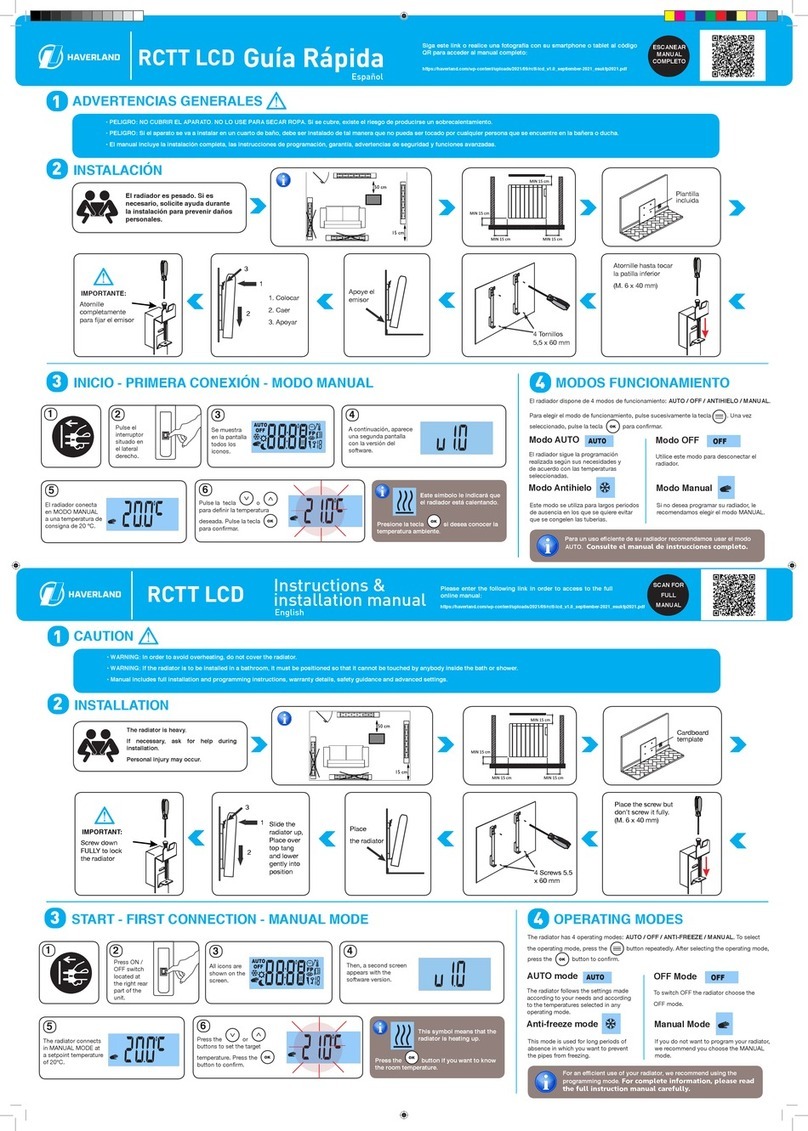

Haverland RCTT Instruction and installation manual

Prem-I-Air

Prem-I-Air EH1524 User and installation guide

Dimplex

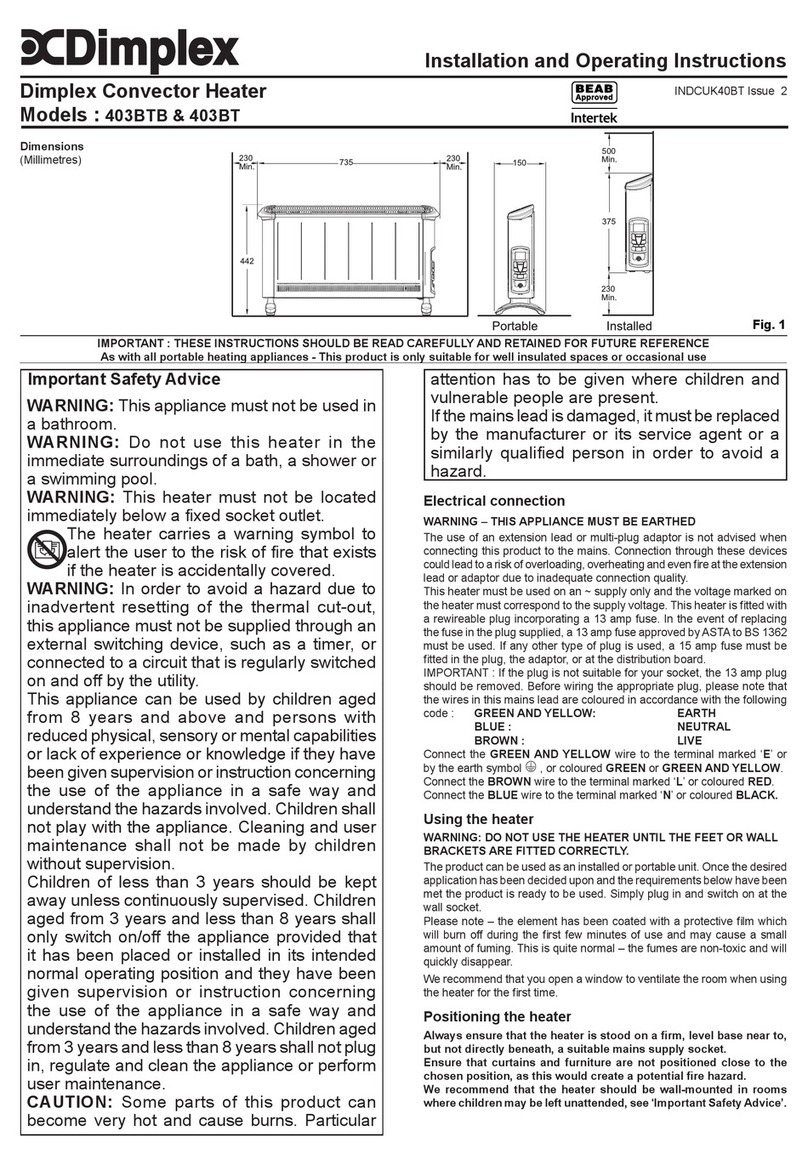

Dimplex 403BTB Installation and operating instructions