BLH NOBEL G4-HE User manual

G4 Multi Channel

Weighing Instrument

Program version 1.12.0.0

Technical Manual

PM/DT/HE types

1. Introduction

General .............................................1-1

Functions ..........................................1-2

Maintenance .....................................1-4

Safety information ............................1-4

Technical data ..................................1-5

Ordering information ......................1-12

2. Installation

Mechanical installation .....................2-1

Electrical installation .........................2-2

CPU unit............................................2-3

DC SUPPLY .....................................2-5

AC SUPPLY .....................................2-6

WF IN, WF IN2 and HS WF2 ...........2-7

AOUT1 and AOUT4 .......................2-10

DIO8 ...............................................2-11

Profibus-DP Fieldbus Adaptor.........2-12

DeviceNet Fieldbus Adaptor ..........2-14

Front panel .....................................2-16

3. Set-up

General .............................................3-1

Graphical touch display ....................3-3

Menu structure .................................3-6

Parameters .......................................3-9

Program options .............................3-46

4. Calibration

General .............................................4-1

Common parameters .......................4-2

Data sheet calibration ......................4-4

Table calibration ...............................4-5

Deadweight calibration .....................4-5

5. Operation

General .............................................5-1

Power supply ....................................5-1

Power-up sequence .........................5-1

Display alt. by normal operation .......5-2

Security locks ...................................5-4

Taring ...............................................5-5

Gross/Net operation .........................5-6

Zero setting ......................................5-6

Zero-track./Auto. zero setting ...........5-7

Motion ...............................................5-7

Weight printing .................................5-8

Batch report printing ........................5-9

Main menu .......................................5-9

Level supervision ...........................5-11

Setpoint function ............................5-12

Use of inputs and outputs ..............5-13

Filter function .................................5-13

Flow rate ........................................5-15

6. Communication

General ............................................6-1

Serial interface..................................6-1

Modbus RTU Slave ..........................6-1

Modbus TCP Slave ..........................6-2

External I/O.......................................6-3

EtherNet/IP .......................................6-4

Ftp Server.........................................6-4

Modbus protocol ..............................6-4

Fieldbus interface ...........................6-32

Fieldbus Data Definitions................6-33

Weight printing................................6-46

7. Remote Access

General ............................................7-1

Browser requirements.......................7-1

Using the Remote Access ...............7-2

Security.............................................7-2

Remote Access Login and Logout....7-3

Remote / Local Access.....................7-5

Remote Set-up..................................7-6

Remote Access Maintenance.........7-10

Instrument Restart ..........................7-18

8. Maintenance

General ............................................8-1

Diagnostics .......................................8-1

File handling ....................................8-5

Create Backup .................................8-5

Restore Backup ...............................8-6

Set Default........................................8-6

Program Upgrade .............................8-6

Instrument Restart ............................8-7

9. Troubleshooting

General.............................................9-1

Error codes ......................................9-1

Appendix

Declaration of Conformity.............App.1

Contents

Technical Manual

PRECAUTIONS

READ this manual BEFORE operating or servicing this instrument. FOLLOW these

instructions carefully. SAVE this manual for future reference.

USE IN HAZARDOUS LOCATIONS

See FM and cFM approvals.

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, II and III, DIVISION 2,

GROUPS A, B, C, D, E, F and G HAZARDOUS LOCATIONS or NON-HAZARDOUS

LOCATIONS.

WARNING- EXPLOSION HAZARD.

NONINCENDIVE FIELD WIRING CONNECTIONS TO CLASS I, II, III, DIV 2,

GROUPS A, B, C, D, E, F, G WHEN INSTALLED PER DWG 401706.

DO NOT REMOVE OR REPLACE CONNECTORS OR DISCONNECT EQUIPMENT

WHEN A FLAMMABLE OR COMBUSTIBLE ATMOSPHERE IS PRESENT.

TYPE 4X, INDOOR USE ONLY.

USB CONNECTION NOT ALLOWED TO BE USED IN HAZARDOUS LOCATIONS.

ATTENTION-DANGER D'EXPLOSION.

RACCORDEMENT POURATMOSPHERE NON EXPLOSIVE POUR CLASS I, II, III,

DIV 2, GROUP A, B, C, D, E, F, G INSTALLE SUIVANT PLAN 401706.

NE PAS DECONNECTER OU REMPLACER LES CONNECTEURS OU

DEBRANCHER L'EQUIPEMENT EN PRESENCE D'ATMOSPHERE INFLAMMABLE

OU EXPLOSIVE.

UTILISATION INTERIEURE UNIQUEMENT.

CONNEXION USB NON AUTORISEE EN ZONE DANGEREUSE.

INTENDED USE

The G4 Instrument family are multi-channel measuring and control devices intended for

industrial systems. Its basic function is to convert the signals from transducers to useful

information. Transducer excitation is included as well as parameter controlled signal

processing, indication of output levels, error supervision and operation of optional

external equipment.

The instrument supports several types of communication interfaces. The instruments

are modular and can be equipped with different types of I/O units. There are transducer

interface modules, digital and analog input/output modules.

!

WARNING

Only permit qualified personnel to install and service this instrument.

Exercise care when making checks, tests and adjustments that must be

made with power on. Failing to observe these precautions can result in

bodily harm.

DO NOT allow untrained personnel to operate, clean, inspect, maintain,

service, or tamper with this instrument.

G4 Multi Channel Weighing Instrument

1-1

1. Introduction

General

The G4 Instrument is a high performance multi-channel weight indicator intended for

industrial systems.

Its basic function is to convert the signals from strain gauge transducers to useful

weight information. Transducer excitation is included as well as parameter controlled

signal processing, indication of output levels, error supervision and operation of

optional external equipment. The instrument can be equipped with up to 8

synchronized weighing channels.

The instrument is modular and can be equipped with different types of I/O units to

match the demands in the specific applications. There are strain gauge transducer

interface modules, a digital input/output module, and analog output modules.

Internal solid-state outputs in the instrument can be used for output functions from level

supervision, setpoints, etc. or ‘In process’ indication, reporting the operating status of

the G4 Instrument.

The CPU unit in the instrument has several communication interfaces. It has two serial

communication ports, an Ethernet port, an USB port and a fieldbus slot.

Several G4 Instruments can be controlled from a master computer or PLC.

Serial communication interfaces are RS-485 and RS-232 for communication with a

computer/PLC (using Modbus RTU protocol) or for transmitting print out data to a

connected printer. The Ethernet interface is using Modbus TCP or (optional)

EtherNet/IP and the optional fieldbus interface uses Profibus or DeviceNet.

It is possible to access the instrument, set-up and maintenance functions, remotely

over the Ethernet connection using a Web Browser on a connected PC.

In the Weighing program there are three program options available, Flow Rate program

option, Scale Batching program option and EtherNet/IP Program option. By entering its

option code a program option is enabled. The option code can be purchased from your

supplier.

It is possible to load new software into the instrument using the USB port.

All functions in the G4 Instrument are controlled by set-up parameters. Setting of

parameter values can be performed with keys and/or graphical touch display on

the front panel.

24 V DC or 110/230 V AC powers the G4 Instrument. All input and output signals

are galvanically isolated from the power supply by operational insulation.

CPU

unit

I/O

unit

1

I/O

unit

2

I/O

unit

3

I/O

unit

4

I/O

unit

5

I/O

unit

6

Power

supply

unit

Backplane

Graphic color

display with

touch interface

Enclosure & mounting accessories

Operator panel

Key

pad

unit

Block structure of a G4 Instrument

Technical Manual

1-2

Functions

Measurement with strain gauge transducers.

Both excitation voltage and output signal are measured at the transducer to avoid

influence from voltage drop in the connection cable. Excitation to the transducer, from

the G4 Instrument is provided over separate wires.

A shielded 6-wire cable must be used to connect a distant transducer to the instrument.

A/D conversion.

The analog signals from the transducer are converted to digital form and filtered

to give an internal transducer signal with high resolution.

Calculation.

The transducer excitation and signal values are combined to form an internal

transducer signal, representing the load on the transducer. Influenced by calibration

data, this signal is converted to a digital measurement value, the weight value, which

can be presented at the local display window and at external equipment.

Error supervision.

As long as the error supervision detects no error, the signal ‘In process’ is present

but if an error is detected, ‘In process’ will be off and a specific error message will be

displayed. ‘In process’ can be set to control any digital output. Note that there are

weighing channel specific and instrument specific error detection.

Levels.

32 level comparators in the instrument can be set to switch at defined signal levels with

any selected hystereses added, meaning that the switch level can be different for

increasing and decreasing signal. Output signals from these comparators are available

on the serial communication. The level comparator outputs can also be set to control

digital outputs from the instrument.

Communication.

The G4 Instrument utilizes the serial interface, Ethernet and a fieldbus interface for

communication with control computer. The serial interface consists of a RS-232

(COM1) connection and a RS-485/RS-422 (COM2) connection. COM2 can be used

with 2- or 4-wire connection.

Weight values, level status, error status etc. can be collected and commands given

through the communication interfaces. Modbus RTU protocol is used for the serial

interfaces, Modbus TCP and EtherNet/IP for the Ethernet connection. For the optional

fieldbus interface Profibus or DeviceNet can be used.

The serial interfaces can also be used to connect a printer for printing of weight and/or

flow rate values etc. If the Scale Batching Program Option is enabled it is possible to

print batching reports.

G4 Multi Channel Weighing Instrument

1-3

Instrument modes.

In normal operation mode the G4 Instrument is presenting the measurement values on

the front panel graphical display. One or more weighing channels can be shown

simultaneously. The user can configure the display via set-up parameters.

During parameter set-up the instrument will continue normal operation. However if

hardware set-up parameters have been changed the instrument will be restarted.

The operator will always be notified before the instrument is restarted.

Parameter setting.

In the instrument all operating functions are controlled by set-up parameters with

numerical values, string values, or pre-selected values from a list of alternatives.

Parameter set-up is performed by the keys at the front panel of the instrument and/or

by using the buttons displayed on the touch display.

Presentation.

The instrument can present measured or calculated values, status of levels, parameter

settings etc. at the front panel. An extensive system of menus gives the possibility to

present various information about the instrument.

Measured or calculated values, status of levels and so on, can be transferred to

external equipment via the different communication interfaces (some are optional).

Scale Batching program option.

There is a batching function within the instrument, which is enabled with an option

code, which can be bought from the instrument supplier. The batching option gives the

possibility to perform individual batching with each scale. See the separate ‘Scale

Batching Program Option’ ‘Technical Manual Supplement’ available for the batching

option.

Flow Rate program option.

With the Flow Rate program option enabled the instrument can calculate the flow rate

based on the weight. The flow rate is calculated and set-up individually for each scale.

Flow rate can be shown on the display, sent to (optional) analog outputs and read

through any of the available communication alternatives in the instrument. An option

code is required to enable this program option. See the description of the flow rate

calculation in this manual.

Remote Access.

It is possible to access the instrument through the Ethernet connection. Using a Web

Browser on the connected PC most set-up and maintenance functions are available on

the PC. This possibility will simplify commissioning and service. It will make it possible

to access instruments from outside the local network (internet) providing the network

allow this.

Technical Manual

1-4

Maintenance

The G4 instrument needs no maintenance, performed by the end-user. Any service

or repair work must be performed by qualified personnel.

Contact your supplier.

Cleaning

Before cleaning the G4, break the power connection to the instrument.

Use a soft cloth to clean the exterior of the instrument. For cleaning

the instrument front panel, a soft, damp, cloth may be used.

Safety information

Utilization.

Before connecting power to the instrument, check that all fixation screws

at the modules are tightened so that the instruments functional grounding

by the housing is maintained.

The instrument may only be utilized for the measurement and control functions,

described in this Technical Manual. It is especially important to adhere to the load limits

of the input/output connectors. We accept no responsibility for any damage arising from

improper operation.

Any changes to the instrument, which causes any function changes, may only be

carried out by the manufacturer, or after discussion with and permission by the

manufacturer.

Meaning of symbols, used in this manual

Direct current.

Alternating current.

!

Caution, risk of danger. Documentation needs to be consulted.

G4 Multi Channel Weighing Instrument

1-5

Technical data

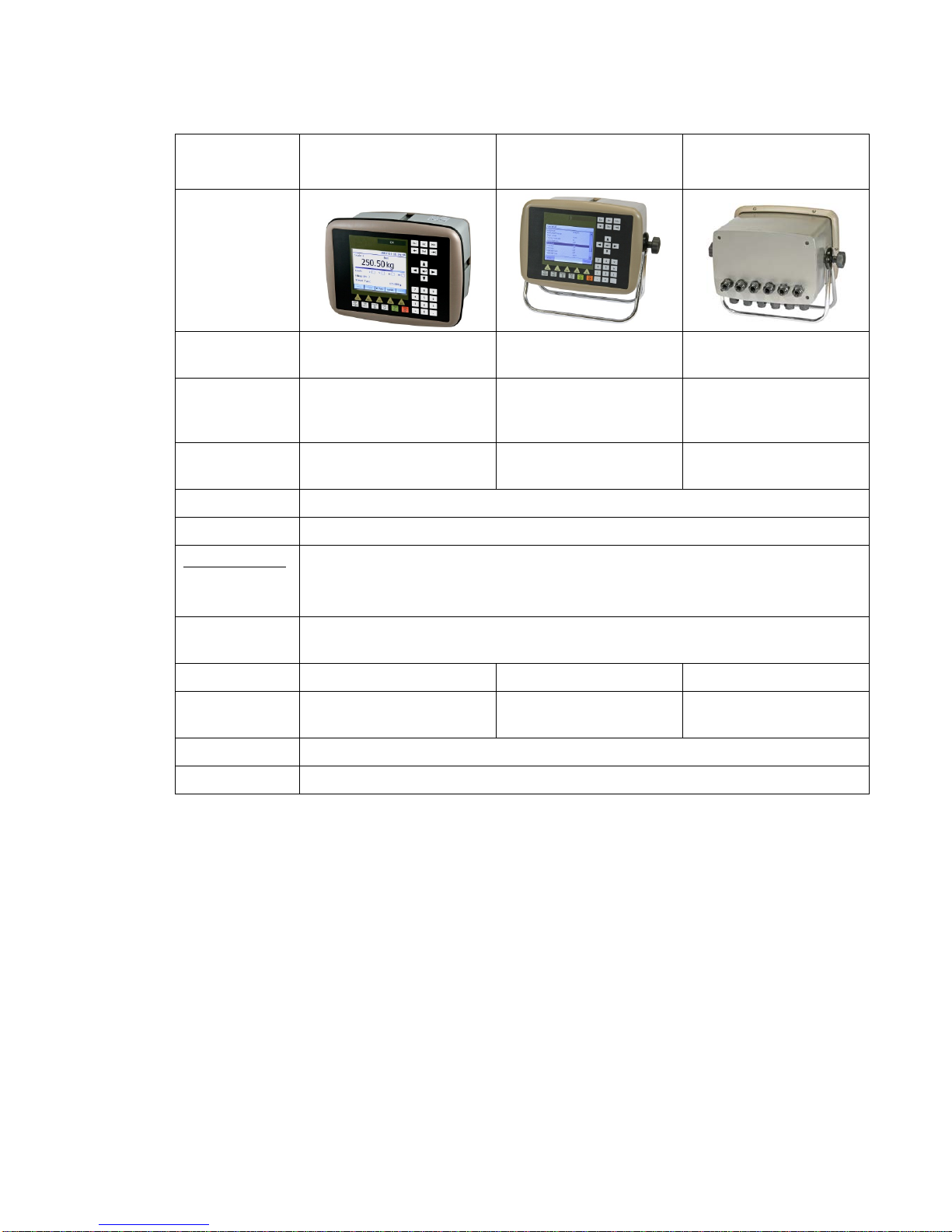

Enclosure

types PM - Panel mount DT – Desktop HE – Harsh

Environment

Enclosure

design Aluminum housing,

plastic panel Aluminum housing,

plastic panel Stainless steel housing,

plastic panel

Dimensions See figure

Panel thickness:

2 – 25 mm

See figure See figure

Strain relief — 6 pcs. for cable dia.

4.3 to 11.4 mm 6 pcs. for cable dia.

4.3 to 11.4 mm

Display Color TFT LCD screen with backlighting, 5.7” 320x240 pixels

Keyboard Touch screen and 34 membrane keys

Environmental

Temperature

range

Rated performance: -10 to +50 °C

Storage: -25 to +85 °C

Relative

humidity Max. 85% up to 40°C, decreasing linear to 50% at 50°C

Rated pollution Pollution degree 2 Pollution degree 3 Pollution degree 3

Protection IP65 (panel), indoor use IP65, indoor use.

Rated for wet locations IP65, indoor use.

Rated for wet locations

Altitude Up to 2000 m

EMC, RF CE (Industrial), OIML

Technical Manual

1-6

PM -Panel mount enclosure outlines and panel cutout.

DT -Desktop enclosure outlines

HE - Harsh environment enclosure outlines

G4 Multi Channel Weighing Instrument

1-7

CPU

Module type CPU module

RTC backup battery Manufacturer Type

Lithium battery Panasonic-BSG CR2032

CR2032 3V GP Batteries CR2032

Varta CR2032 (V)

COM1 (RS232) and

COM2 (RS485) For process data and control or printout data to a connected

printer. Isolated by operational insulation

Protocol Modbus RTU

Baud rate Up to 115 kbaud

Fieldbus For process data and control (optional)

Types Profibus or DeviceNet

USB Version 1

Keyboard USB keyboard for PC

USB Memory USB type for PC

For backup and restore of set-up parameters

For change to a new program version

Ethernet 10/100BASE-T. For process data, control, file transfer and

remote access.

Protocols Modbus TCP, EtherNet/IP, ftp, http.

RJ45 Indications Green LED: Transmitting. Yellow LED: Receiving.

DC SUPPLY

Module type Power supply module

Input 24 V ±15% including fluctuations, 40W

Impulse withstand (overvoltage)

category I of IEC 60364-4-443

Output 24 V output 0.1 A

The same voltage as input voltage

Technical Manual

1-8

AC SUPPLY

Module type Power supply module

Input voltage 110-240 V~ +10% -15% including fluctuations, 50/60 Hz,

40W

Impulse withstand (overvoltage)

category II of IEC 60364-4-443

Output voltage 24 V output 0.1 A

WF IN / WF IN2

Module type Weight/Force input module

Max. # of transducers 8 (350 ohm) per channel

Maximum 48 transducers per instrument

Excitation voltage: 5 VDC

A/D conversion: 3.9 kHz, 16 000000 units (24 bits)

Input range +/- 7 mV/V

Update rate: 2.3 −300 readings per second

No. of channels: WF IN has 1 Weight/Force channel

WF IN2 has 2 Weight/Force channels

Sensitivity: 0.1 µV

Zero drift: <10 nV/V/K

Span drift: <2 ppm/K

Digital I/O 4 inputs, 24 V ±15%, 5 mA from external power supply,

isolated by operational insulation

and with common return

2 outputs, 24 V ±15%, max 100 mA from external

power supply, isolated by operational insulation

and with common return

G4 Multi Channel Weighing Instrument

1-9

HS WF2

Module type High Speed Weight/Force input module

Max. # of transducers 4 (350 ohm) per channel

Excitation voltage: 10 VDC

A/D conversion: 20 kHz, 16 000000 units (24 bits)

Input range +/- 4.5 mV/V

Update rate: 12.5 −800 readings per second

No. of channels: HS WF2 has 2 Weight/Force channels,

separately isolated by operational insulation

Sensitivity: 0.1 µV

Zero drift: <10 nV/V/K

Span drift: <2 ppm/K

Digital I/O 4 inputs, 24 V ±15%, 5 mA from external power supply,

isolated by operational insulation

and with common return

2 outputs, 24 V ±15%, max 100 mA from external power

supply, isolated by operational insulation

and with common return

DIO8

Module type Digital input/output module

Separate I/O module 2 units can be used

Digital I/O 8 inputs, 24 V ±15%, 5 mA from external power supply,

isolated by operational insulation

and with common return

8 outputs, 24 V ±15%, max 100 mA from external power

supply, isolated by operational insulation

and with common return

Technical Manual

1-10

AOUT1 / AOUT4

Module type Analog output module

Number of channels 1 or 4 channels,

separately isolated by operational insulation

Resolution 65000 units, 16 bits

Voltage output 0 – 10 V, -10 – 10 V, > 1 kohm load

Current output 4 – 20 mA, 0 – 20 mA, -12 – 20 mA, -20 – 20 mA,

< 500 ohm load

Update rate Scale update rate, adjustable smoothing filter

Profibus-DP

Module type Profibus-DP fieldbus adaptor

Connector Profibus 9-pin, female D-sub (DB9F)

Baudrate Auto setting 9.6 kbps – 12 Mbps

Address 1 – 125, set by parameter

Fieldbus data 16 bytes from fieldbus to instrument.

32 – 244 bytes from instrument to fieldbus (may be limited

by the master).

See chapter ‘Communication’ section

‘Fieldbus communication interface’ for details on fieldbus

data mapping.

Mounting The fieldbus adaptor is mounted through the front of

the CPU module with LED’s and connector accessible

through the CPU front panel.

Remove the plastic cover from the fieldbus slot in the CPU

module front panel. Insert the adaptor very carefully and

make absolutely sure that the adaptor slides correctly into

the guides in the connector on the CPU PCB. Tighten

the two fastening screws at the adaptor front and check

that the two securing hooks locks into the CPU PCB.

Settings All fieldbus settings are done with setup parameters in

the instrument. No settings are done on the module itself.

G4 Multi Channel Weighing Instrument

1-11

DeviceNet

Module type DeviceNet fieldbus adaptor

Connector 5 pin male connector.

Baudrate 125, 250, 500 kbps or Auto. Set by parameter.

Address 0 – 63, set by parameter

Fieldbus data 16 bytes from fieldbus to instrument.

32 – 244 bytes from instrument to fieldbus (may be limited

by the master).

See chapter ‘Communication’ section

‘Fieldbus communication interface’ for details on fieldbus

data mapping.

Mounting The fieldbus adaptor is mounted through the front of

the CPU module with LED’s and connector accessible

through the CPU front panel.

Remove the plastic cover from the fieldbus slot in the CPU

module front panel. Insert the adaptor very carefully and

make absolutely sure that the adaptor slides correctly into

the guides in the connector on the CPU PCB. Tighten

the two fastening screws at the adaptor front and check

that the two securing hooks locks into the CPU PCB.

Settings All fieldbus settings are done with setup parameters in

the instrument. No settings are done on the module itself.

Bus Supply Voltage According to the DeviceNet (Node) Specification:

nominal 24 VDC, range 11 – 25 VDC.

Technical Manual

1-12

Ordering information

For Panel mount (PM), Desktop (DT) and Harsh environment

(HE) instruments

G4-PM-FB-S1-S2-S3-S4-S5-S6-P-SW

Instrument type

PM Enclosure type PM

DT

HE

Panel mount

Desktop

Harsh environment

FB Fieldbus interface 0

P

D

None

Profibus

DeviceNet

Si Slot 1 to 6 type 0

2

3

4

6

7

8

Blank

HS WF2 High speed weight/force input module, 2 ch

WF IN Weight/force input module, 1 channel

WF IN2 Weight/force input module, 2 channels

AOUT1 Analog Output module, 1 channel

AOUT4 Analog Output module, 4 channels

DIO8 Digital Input and Output module

P Power supply D

A DC power supply

AC power supply

SW Software (note 1)

W

F

S

(No code specified) Standard Weighing Program

Standard Weighing Program

Standard Force Program

Special Program (note 2)

Example: G4-PM-0-4-8-0-0-0-0-D-W

•G4 instrument (G4)

•Panel mount (PM)

•No fieldbus (0)

•Slot 1 = WF IN2 (4)

•Slot 2 = DIO8 (8)

•Slot 3 = Blank (0)

•Slot 4 = Blank (0)

•Slot 5 = Blank (0)

•Slot 6 = Blank (0)

•Power =DC supply (D)

•Software = Weighing program (W)

Note 1: The Software (SW) code specifies the program function that should be installed

in the instrument. If no code is specified the standard Weighing program will be

supplied.

Note 2: If a special program option is desired, the designation of the special program

must be specified when ordering.

G4 Multi Channel Weighing Instrument

1-13

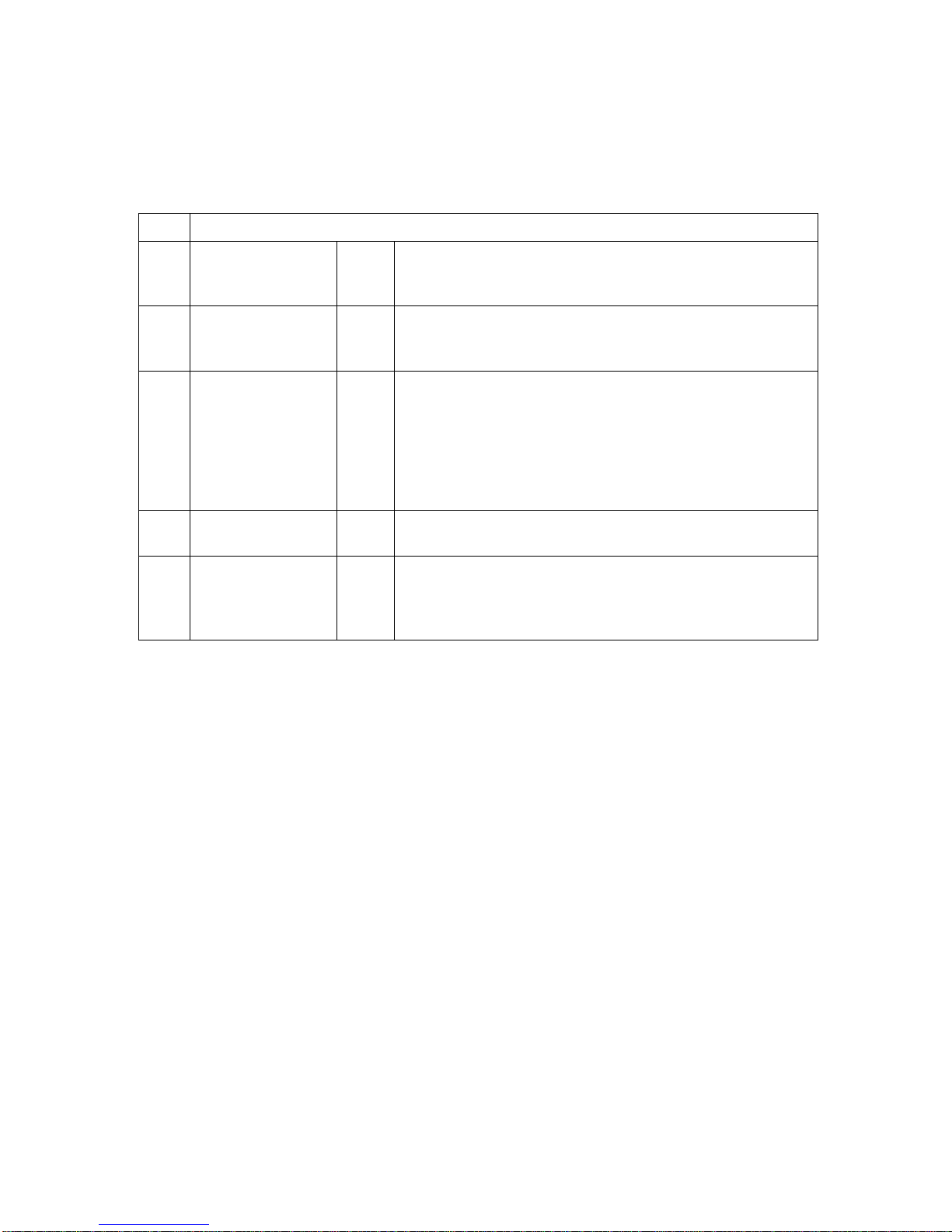

Separate modules

Spec.no

Module type Module name

110 544

CPU CPU unit

110 546

HS WF2 High speed dual Weight/Force input module

110 547

WF IN Single Weight/Force input module

110 548

WF IN2 Dual Weight/Force input module

110 549

AOUT1 Single channel analog output module

110 550

AOUT4 Four channel analog output module

110 551

DIO8 Digital input/output module

110 552

BLANK Blank panel

110 553

DC SUPPLY DC supply unit

110 630

AC SUPPLY AC supply unit

110 559

PROFIBUS-DP Profibus DP fieldbus adaptor

110 560

DEVICENET DeviceNet fieldbus adaptor

Module selection rules

Every system needs 1 Power supply module and 1 CPU module (can be equipped with

one fieldbus adaptor).

Limitations on number of I/O modules that can be used in one instrument:

•Maximum 6 modules.

•Maximum 4 WF IN / WF IN2 or 2 HS WF2 modules.

•HS WF2 and WF IN(2) cannot be mixed in the same system.

•Maximum 1 AOUT1 or 1 AOUT4 module.

•Maximum 2 DIO8 modules.

Technical Manual

1-14

G4 Multi Channel Weighing Instrument

2-1

2. Installation

Mechanical installation

See chapter ‘Introduction – Technical data’ for references to PM, DT and HE

mechanical measures: outer extents, body extents and panel cutout (PM).

PM type instrument:

Make sure the panel thickness meets the specification and that there is room enough

behind the panel for the instrument and the connected cables (minimum 200 mm).

Cut a panel opening according to the specification on page 1-5.

Insert the instrument through the opening. Hold it in place while attaching brackets

and wing-headed bolts to the four nuts, sliding in grooves of the housing.

Tighten the bolts and make sure the integrated gasket of the instrument is

compressed against the mounting panel, giving a sealed attachment.

DT and HE type instrument:

Arrange enough space for cables and strain reliefs behind or below the instrument.

DT instrument housings have 6 plugged openings facing downwards, intended for

the cable strain reliefs. As an alternative, knock-out openings in the back panel can be

knocked open for strain reliefs facing backwards.

HE instrument housings have 12 plugged openings for the cable strain reliefs, facing

downwards and backwards.

Enclosed with each instrument is a set of 6 strain reliefs. For each cable one strain

relief should be mounted with a sealing washer on the exterior and a locknut inside

the housing.

Mounting legs are fitted to the instrument housings by knob-headed bolts and threaded

holes or nuts. Use the enclosed fixing brackets to attach the legs to the table or a wall.

295

278

150 108

Dia. 4.4

Dia. 4.4

DT and HE instruments.

Fixing bracket, recommended distances to surrounding surfaces.

Technical Manual

2-2

Electrical installation

The field wiring of the instrument shall be suitable to the environment

(e.g. chemically) in the end-user application.

Mains cables shall be separated and routed away from SELV or

SELV-E field wiring.

For DT and HE instruments UL Listed and KAM cord type flexible cables shall be used.

The cable diameters must be selected in accordance with the strain relief specification.

See Technical Data.

Field wiring installation shall comply with any national regulations, hereunder National

Electrical Code (NEC) for US and/or Canadian Electrical Code for Canada.

•A switch or circuit-breaker shall be included in the building installation.

•The switch shall be in close proximity to the equipment and

within easy reach of the operator

•The switch shall be marked as the disconnecting device for the equipment.

•The equipment switch or circuit-breaker employed as disconnecting device shall

comply with relevant requirements of IEC 60947-1 and IEC 60947-3.

The power supply for the instruments can be

an external DC source and an internal DC SUPPLY unit

or external AC mains and an internal AC SUPPLY unit.

For electrical installation with an internal DC SUPPLY unit, see page 2-5.

For electrical installation with an internal AC SUPPLY unit, see page 2-6.

WARNING

Make sure that that the power to the instrument is turned off before:

-any modules are removed from or inserted in the instrument.

-any connections are connected to or disconnected from the instrument.

All modules should be regarded as ESD sensitive. Make sure that an ESD safe

environment is maintained when inserting modules, removing modules and when

handling modules separately from the instrument. Modules must be kept in

metallised ESD bag when not mounted in the instrument.

!

This manual suits for next models

2

Table of contents

Other BLH NOBEL Accessories manuals