BLH NOBEL G5 User manual

G5 Weighing Instrument

Program version 1.3.X

Fieldbus Option Manual

PM and RM types

CONTENTS

1. Introduction ...................................1-1

General................................................1-1

Module installation ..............................1-1

Ordering information ...........................1-2

2. Modules ........................................2-1

Profibus-DP Module............................2-1

DeviceNet Module...............................2-3

ControlNet Module ..............................2-5

EtherNet/IP Module.............................2-6

3. Set-up ...........................................3-1

General................................................3-1

Fieldbus related parameters ...............3-1

4. Output Data...................................4-1

Commands..........................................4-2

5. Input Data......................................5-3

Number format....................................5-9

Examples.............................................5-9

6. Fieldbus interface..........................6-1

EtherNet/IP..........................................6-2

Profibus DP-V1 ...................................6-3

DeviceNet............................................6-3

ControlNet...........................................6-3

7. Maintenance..................................7-1

General................................................7-1

Technical Manual

PRECAUTIONS

READ this manual BEFORE operating or servicing this instrument. FOLLOW these

instructions carefully. SAVE this manual for future reference.

INTENDED USE

The G5 Instrument family are measuring and control devices intended for industrial

systems. Its basic function is to convert the signals from transducers to useful

information. Transducer excitation is included as well as parameter controlled signal

processing, indication of output levels, error supervision and operation of optional

external equipment. The instrument supports several types of communication

interfaces.

INSTRUMENT INSULATION AND GROUNDING

The cable connector for mains power supply should include protective grounding for

safety. The cable for 24VDC power supply (screw terminal connector) should include a

ground connected to terminal GND.

The input groups of the instrument are insulated from each other by functional

insulation. The mains connection of AC-powered instruments has reinforced insulation

according to IEC 61010. Terminals intended for connection of cable shields are

connected to the protective ground of the mains or GND terminal of 24VDC input but

must not be considered as protective grounding. Shield connection of load cell input is

not connected to mains protective ground or 24VDC GND terminal.

Change description

Revision 0: First release of this document.

!

WARNING

Only permit qualified personnel to install and service this instrument.

Exercise care when making checks, tests and adjustments that must be

made with power on. Failing to observe these precautions can result in

bodily harm.

DO NOT allow untrained personnel to operate, clean, inspect, maintain,

service, or tamper with this instrument.

G5 Weighing Instrument

1-1

1. Introduction

General

The G5 Instruments are high performance single-channel weight indicators (PM model,

panel mounted) or weight transmitters (RM model, DIN rail mounted) intended for

industrial systems. This manual describes the functionality of the optional Fieldbus

interface of the G5 Instrument. The instrument supports the following busses:

ProfibusDP, DeviceNet, ControlNet and EtherNet/IP. The optional fieldbus module is

mounted in the Fieldbus slot.

l fieldbus settings are done with setup parameters in the instrument. No settings are

done on the module itself.

Module installation

Make sure the instrument power supply is off or disconnected. Remove the plastic

cover from the fieldbus slot. Insert the adaptor very carefully and make absolutely

sure that the adaptor slides correctly into the guidesin the connector on the PCB.

Tighten the two fastening screws at the adaptor front and check that the two securing

hooks locks into the PCB.

Module type Connector Baud rate Address Bus Supply

Voltage

Profibus-DP

Profibus

9-pin, female

D-sub (DB9F)

9.6 kbps –

12 Mbps or

Auto set by

parameter

1 – 125,

set by parameter

DeviceNet

5 pin male

connector. 125, 250,

500 kbps or

Auto set by

parameter.

0 – 63,

set by parameter According to

DeviceNet (Node)

specification:

nominal 24 VDC,

range 11 – 25

VDC.

ControlNet

BNC. Fixed 5

Mbit/s. 1 – 99, set by

parameter

EtherNet/IP

Dual RJ45

(Only port 1

,P1) is

supported

Selectable Static

or DHCP. If static

choosen IP-

address, Net

Mask and Default

Gateway are set

by parameters.

Technical Manual

1-2

Ordering information

If an (optional) fieldbus module is needed it must be ordered together with the

instrument. Ordering numbers are shown below. If multiple instruments and/or fieldbus

modules are purchased in the same order it must be clearly specified which module

should be mounted in which instrument.

Optional ProfibusDP fieldbus module

P/N: 110559 (ordering number).

Optional DeviceNet fieldbus module

P/N: 110560 (ordering number).

Optional ControlNet fieldbus module

P/N: 110838 (ordering number).

Optional EtherNet/IP fieldbus module

P/N: 110859 (ordering number).

Example showing product information

and installed option(s).

G5 Weighing Instrument

2-1

2. Modules

Profibus-DP Module

Profibus module front view

(1) Operation mode LED.

(2) Status LED.

(3) Profibus connector.

Operation mode LED

State Indication

Off Not online / No power

Green On-line, data exchange

Flashing Green On-line, clear

Flashing Red (1 flash) Parameterization error

Flashing Red (2 flashes) Profibus configuration error

Status LED

State Indication

Off No power or not initialised

Green Initialised

Flashing Green Initialised, diagnostic event(s) present

Red Exception error

OP ST

PROFIBUS DP-V1

(1) (2)

(3)

Technical Manual

2-2

Profibus connector (DB9F)

Pin Signal Description

1 - -

2 - -

3 B line Positive RxD/TxD, RS485 level

4 RTS Request to send

5 GND Bus Ground (isolated)

6 + 5V Bus Output +5V termination power (isolated)

7 - -

8 A line Negative RxD/TxD, RS485 level

9 - -

Housing Cable shield Functional ground internally connected to the

module protective ground via cable shield

filters according to the Profibus standard.

For connection of the adaptor to the Profibus master, use a Profibus standard cable

and connector according to the diagram below.

8. A-Line

3. B-Line

Shield

For reliable fieldbus function, line termination must be arranged in both ends of the

transmission line. For a G5 instrument, at the end of the cable, a connector with line

termination should be used. For all other G5 Instruments, connection without line

termination should be used.

For configuration of the adaptor, a GSD file (VISH0F83.GSD) is available and should

be installed in the master.

Select the 8 words output module + 2 x 16 words input modules + one 8 words input

module. This will give 16 bytes of output data and 80 bytes of input data. The PLC set-

up should match this exactly including the order of the input modules.

G5 Weighing Instrument

2-3

DeviceNet Module

DeviceNet module front view

(1) Network Status LED.

(2) Module Status LED.

(3) DeviceNet connector.

Network Status LED

State Indication

Off Not online / No power

Green On-line, one or more connections are established

Flashing Green (1 Hz) On-line, no connections established

Red Critical link failure

Flashing Red (1 Hz) One or more connections time out

Alternating Red/Green Self-test

Status LED

State Indication

Off No power

Green Operating in normal condition

Flashing Green (1 Hz) Missing or incomplete configuration

Red Unrecoverable fault(s)

Flashing Red (1 Hz) Recoverable fault(s)

Alternating Red/Green Self-test

NS MS

DeviceNet

(1) (2)

(3)

(Pin 1)

Technical Manual

2-4

DeviceNet connector

Pin Signal Description

1 V- Negative bus supply voltage

2 CAN L CAN low bus line

3 Shield Cable shield, functional ground.

4 CAN H CAN high bus line

5 V+ Positive bus supply voltage

For connection of the adaptor to the DeviceNet master, use a standard cable for

DeviceNet or similar shielded cable with twisted pairs and a connector according to the

diagram below. The bus supply voltage shall be 11 – 25 VDC.

2. CAN L

4. CAN H

1. V-

5. V+

3. Shield

For reliable fieldbus function, line termination must be arranged in both ends of the

transmission line. For a G5 Instrument placed at the end of the line, terminate line by

placing a 121-ohm resistor between CAN L (pin 2) and CAN H (pin 4).

For configuration of the adaptor an EDS file is supplied with the instrument that should

be installed in the master. Note that the EDS file is a generic type supplied by the

module manufacturer. The file doesn’t contain any reference to the G5 Instrument or to

BLH Nobel.

G5 Weighing Instrument

2-5

ControlNet Module

ControlNet module front view

(1) Network Status LED A.

(2) Module Status LED.

(3) Network Status LED B.

(4) ControlNet connector A.

(5) ControlNet connector B.

Network Status LED A/B

LED State Indication

LED A and B Off Not online / No power

Flashing Red (1 Hz) Incorrect node configuration, duplicate MAC ID

etc.

Alternating Red/Green Self-test of bus controller

Red Fatal event or faulty unit

LED A or B Off Channel is disabled

Alternating Red/Green Invalid link configuration

Flashing Green (1 Hz) Temporary errors (node will self-correct) or

node is not configured to go online

Green Normal operation

Flashing Red (1 Hz) Media fault or no other nodes on the network

Status LED

State Indication

Off No power

Green Operating in normal condition, controlled by a Scanner in

run state

Flashing Green (1 Hz) The module has not been configuration or Scanner in idle

state

Red Unrecoverable fault(s), EXCEPTION, fatal event

Flashing Red (1 Hz) Recoverable fault(s), MAC ID has been changed after

initialization etc.

ControlNet connectors

These connectors provide ControlNet connectivity. If redundancy is wanted both

connectors should be used. Otherwise either connector can be used.

A B

ControlNet

B

(1) (2) (3)

(4) (5)

Technical Manual

2-6

EtherNet/IP Module

ControlNet module front view

(1) Network Status LED.

(2) Module Status LED.

(3) Link/Activity Port 1.

(4) Link/Activity Port 2.

Network Status LED

LED State Indication

Off No power or no IP address

Green Online, one or more connections established (CIP class 1 or 3)

Green, flashing Online, no connections established

Red Duplicate IP address, fatal error

Red, flashing One or more connections timed out (CIP class 1 or 3)

Module Status LED

State Indication

Off No power

Green Controlled by a Scanner in run state

Flashing Green (1 Hz) Not configured or Scanner in idle state

Red Major fault (EXCEPTION state, fatal error etc.)

Flashing Red (1 Hz) Recoverable fault(s)

Link/Activity LED 3/4

State Indication

Off No link, no activity

Green Link (100 Mbit/s) established

Green, flickering Activity (100 Mbit/s)

Yellow Link (10 Mbit/s) established

Yellow, flickering Activity (10 Mbit/s)

NS MS

EtherNet/IP

(1) (2)

(3) (4)

P1 P2

G5 Weighing Instrument

3-1

3. Set-up

General

All operating functions in the G5 Instrument are controlled by parameters. The

parameter values are permanently stored in the instrument and will not be lost when

the unit is switched off. At delivery the parameters are factory-set to default values,

giving the instrument an initial standard function.

The actual setting of the parameter values can be read and edited during normal

measuring operation in sub menu ‘Parameter Set-up’. Editing of parameter values can

be performed using the color display and keys on the front panel of the instrument or

by using a Web Browser on a PC connected on the same network as the instrument.

After editing hardware parameters the instrument will be restarted.

In the instrument there are two levels of security locks provided to protect from

unauthorized access to instrument functions and editing of parameters and values. The

locks are opened by four-digit codes.

Fieldbus related parameters

On the following pages a survey of fieldbus related parameters is presented. The

parameters are divided in groups following the menu they belong to. For choice

parameters the available choices are given. For numerical parameters, a value range is

given.

At the end of the table, the default value is given in < >.

To the right there is a short parameter explanation and, in italic, the results for

the different alternatives.

Range/Alternatives Explanation and

<default value> result of alternatives.

Menu Hardware Configuration

Fieldbus Module

None

Profibus

DeviceNet

ControlNet

EtherNet/IP

< None >

Available Fieldbus choices.

When this set-up is changed the instrument will be restarted.

The user must confirm that the instrument is restarted. If the set-

up does not match the installed module the instrument will start

up in error state. After the mismatch is corrected and the

instrument is restarted the instrument will be operational again.

Menu Fieldbus

Note: The Fieldbus menu is not shown if parameter Fieldbus (in

Hardware Configuration menu) is set to None.

Profibus, Address

Range 1 - 125

< 126 > Profibus address setting.

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to Profibus.

Fieldbus Manual

3-2

Range/Alternatives Explanation and

<default value> result of alternatives.

DeviceNet, Address

Range 0 - 63

< 63 > DeviceNet address setting

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to DeviceNet.

ControlNet, Address

Range 1 - 99

< 99 > ControlNet address setting

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to ControlNet.

DeviceNet, Baudrate

125 kbps

250 kbps

500 kbps

Auto

< Auto >

The baud rate for a DeviceNet type of module. Must be selected

to suite the master.

125 kbps: Fixed baudrate 125 kbits/s.

250 kbps: Fixed baudrate 250 kbits/s.

500 kbps: Fixed baudrate 500 kbits/s.

Auto: Auto setting 125 – 500 kbits/s.

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to DeviceNet.

IP Address

< 192.168.99.151 > The ip address of the EtherNet/IP interface.

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to EtherNet/IP. Restart the

instrument when the ip-address has been changed.

Net Mask

< 255.255.255.0 > The net mask of the EtherNet/IP interface.

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to EtherNet/IP. Restart the

instrument when the net-mask has been changed.

Default Gateway

< 192.168.99.1 > Default gateway of the EtherNet/IP interface.

Note: This parameter is only shown if parameter Fieldbus (in

Hardware Configuration menu) is set to EtherNet/IP. Restart the

instrument when the default gateway has been changed.

Data Format

Floating Point

Integer

< Floating Point >

Sets what data format should be used. The data format choice

applies to weight and some other values. Status, error code and

other similar data which is inherently integer data is always

given as integers (no decimals)

Floating Point:IEEE 32 bit floating point format.

Integer: 32 bit integer format.

Note: This parameter is not shown if parameter Fieldbus (in

Hardware Configuration menu) is set to None.

G5 Weighing Instrument

4-1

4. Output Data

Output data mapping is shown in the table below. Output data is 8 bytes as described

in table below. Data direction is from network (PLC) to G5 Instrument.

Byte

Size

Description

0 – 1

2

Command

2 – 3

2

Parameter ID

4 – 7

4

Data to write

Command

Bytes 0 - 1: The command byte is used when writing data to the instrument and to

issue various scale related commands such as taring, zeroing etc.

Note that a new command is detected when the content of the command register is

changed. If the same command shall be issued again, the command byte must first be

set to 0 and this should be verified by reading command acknowledge. Then the

desired command may be issued.

The response to a given command is the ‘Command acknowledge’ and the

‘Command error’ bytes in the input data of the connection.

Parameter ID

Bytes 2 - 3: The selected Level (1 - 4) or Setpoint (1 - 4) to set. The data in byte 2 and

3 are ignored for any other commands than 221 and 222.

Data to write

Bytes 4 to 7: The value of the Preset tare, Level, Setpoint, Digital outputs or Analog

Output to set. Note that the format of the value should be floating point or integer

depending on the Data Format parameter. The data in bytes 4 to 7 are ignored for any

other commands than 200, 201, 220 – 222. No of decimals in an integer value is

according to the weight and flow rate set-up. Analog output (command 200) is always 3

decimals.

Example: A value with 3 decimals e.g. 7.234 should be written as 7234 to the

bytes 4 – 7.

Byte order

The byte order in multi byte values (more than one byte) is depending on the type of

fieldbus used.

Profibus DP: MSB first (Most Significant Byte first).

DeviceNet: MSB first.

ControlNet: MSB first.

EtherNet/IP: LSB first (Least Significant Byte first).

Fieldbus Manual

4-2

Commands

Cmd #

Command Name

Description

0 No action When the same command is repeated the no action

should be sent between the commands to make it

possible for the instrument to detect new commands.

1 Start operation When the instrument is in ‘Wait for start state’, this

command can be used to start up the instrument.

2 Enter Remote operation This command disables the keys on the instrument.

This means that an external computer is controlling the

instrument or the instrument is controlled using digital

inputs.

3 Exit Remote operation This command enables the keys and leaves the remote

operation.

10 Auto tare Perform a tare operation

11 Set scale to zero Zero the gross weight

12 Select gross mode Switch to gross mode (display)

13 Select net mode Switch to net mode (display)

14 Weight display Switch from flow to weight display

15 Flow rate display Switch from weight to flow display

16 Print command Initiate a print output

100 Activate setpoint 1 Activate the setpoint

101 Deactivate setpoint 1 Deactivate the setpoint

102 Activate setpoint 2

103 Deactivate setpoint 2

104 Activate setpoint 3

105 Deactivate setpoint 3

106 Activate setpoint 4

107 Deactivate setpoint 4

132 Activate setpoints 1 - 4 Activates all 4 setpoints

133 Deactivate setpoints 1 - 4 Deactivates all 4 setpoints

200 Set Analog output Remote control of analog output. Set actual current or

voltage output value.

201 Set digital outputs Remote control of digital outputs. Set or reset the 4

outputs.

220 Set Preset Tare value Set Preset Tare to desired value.

221 Set Level value Set selected Level to desired value.

222 Set Setpoint value Set selected Setpoint to desired value.

223 Clear Acc. Weight Set accumulated weight to zero.

252 Clear Program reset bit Clear the Program reset bit in the Instrument Status

register. Set at power up.

G5 Weighing Instrument

5-3

5. Input Data

Byte

Size

Description

Note

0 1 Instrument error 8

1 1 Instrument Status 8

2 1 Instrument State 8

3 1 Command acknowledge 8

4 1 Command error 8

5 1 Level status 8

6 1 Setpoint status 8

7 1 Input and Output status 8

8 – 9 2 Error code 8

10 – 11 2 Scale status 8

12 – 15 4 Gross weight 1, 2

16 – 19 4 Net weight 1, 2

20 – 23 4 Flow rate 1, 3

24 – 27 4 Input signal 1, 4

28 – 31 4 Level 1 1, 2, 3

32 – 35 4 Level 2 1, 2, 3

36 – 39 4 Level 3 1, 2, 3

40 – 43 4 Level 4 1, 2, 3

44 – 47 4 Setpoint 1 1, 2, 3

48 – 51 4 Setpoint 2 1, 2, 3

52 – 55 4 Setpoint 3 1, 2, 3

56 – 59 4 Setpoint 4 1, 2, 3

60 – 63 4 Preset tare 1, 2

64 – 67 4 Acc. weight Low 1, 5

68 – 71 4 Acc. weight High 1, 5

72 – 75 4 Analog Output 1, 6

76 – 79 4 Aux. analog input 1, 7

80 – 81 2 Clock, year 8

82 1 Clock, month 8

83 1 Clock, day 8

84 1 Clock, hour 8

85 1 Clock, minute 8

86 1 Clock, second 8

87 1 Not used 8

88 1 No of decimals in weight values 8

89 1 No of decimals in flow rate 8

90 - 105 16 Spare 9

Fieldbus Manual

5-4

Note 1: This value is in integer format if parameter Data Format is set to Integer or in float

format if parameter Data Format is set to Floating Point.

Note 2: The number of decimals used in these values depends on the resolution setting for the

scale. Actual number of decimals is shown in byte 88.

Note 3: The number of decimals used in flow rate depends on the resolution setting for the flow

rate. Actual number of decimals is shown in byte 89.

Note 4: The input signal always has 5 decimals. Unit is mV/V.

Note 5: Low part has 3 decimals.

Note 6: Analog output value always with 3 decimals.

Note 7: Analog input value always with 3 decimals.

Note 8: The value is in integer format, i.e. it does not have any decimals.

Note 9: These bytes are not used in the standard version of the G5 software. The content is

always 0.

Input data mapping is shown in the table on previous page. Input data is 106 bytes as

described in the table. Data direction is from G5 Instrument to network (PLC).

Instrument error

This register holds the overall error code for the instrument.

Normally this register should contain ‘00’ which means no error.

Instrument status

This register holds the overall status for the instrument

Bits set to 1 in this register have the following meaning:

Bit no Function Comment

0 Remote operation ‘1’ = On ‘0’ = Off

1 Program reset The bit is set each time the program starts, and it

indicates that volatile data is lost.

The bit is reset as Instrument status is read, over serial

communication (Modbus RTU) or over Ethernet (Modbus

TCP), for the first time after reset/power-up. Note that the

reply contains the set bit if it was set.

Reading Instrument Status via Fieldbus interface will not

reset this bit. To reset this bit with fieldbus interface a

specific reset command must be used.

Care must be taken if more than one interface is used to

communicate with the instrument and the Program reset

bit is to be used.

2-15 Not used

G5 Weighing Instrument

5-5

Instrument state

This register contains the state of the G5 instrument.

Code Description

00 ‘Starting up’ state.

The instrument is starting up after a reset or power on.

01 ‘Wait for start’ state.

The instrument is waiting for a start command to go in process.

02 ‘Warming up state’

The parameter ‘Warm up time’ is set to a value other than zero, and

the instrument is waiting for the warming up time to pass.

03 ‘Normal’ state.

There are no parameter errors in the system.

Note: Weight errors still indicate normal state.

04 ‘Error’ state.

An error has been detected during startup of the instrument.

05 ‘Fatal error’ state.

An error has been detected during startup of the instrument.

It’s not possible to enter any other state from here.

06 ‘Power fail’ state.

A power fail has been detected and the instrument will respond to

communication for a short moment until the power supply reserves are empty

(this is normally just a few ms). Weight values should be regarded as invalid.

Command acknowledge

This byte returns the value of the command if it could be executed. If there was an

error executing the command the value 240 (hex F0) will be returned in this byte. This

byte should be used to verify that a command has been executed.

Note that a new command is detected when the content of the command register is

changed. If the same command shall be issued again, the command byte must first be

set to 0 and this should be verified by reading command acknowledge. Then the

desired command may be issued.

Command error

This byte holds the error code when a command has been sent to the instrument.

Normally this register should contain ‘00’ which means no error. Error codes 0 to 255

are valid in this register.

Level status 1 - 4

Bits in this byte have the following meaning:

Bit no Function Comment

0 Above level 1 The weight is above Level 1.

1 Above level 2 The weight is above Level 2.

2 Above level 3 The weight is above Level 3.

3 Above level 4 The weight is above Level 4.

Fieldbus Manual

5-6

Setpoint status 1-4

Bits in this byte have the following meaning:

Bit no Function Comment

0 Setpoint 1 activated See description for setpoint function.

1 Setpoint 1 cycle done -“-

2 Setpoint 2 activated -“-

3 Setpoint 2 cycle done -“-

4 Setpoint 3 activated -“-

5 Setpoint 3 cycle done -“-

6 Setpoint 4 activated -“-

7 Setpoint 4 cycle done -“-

Status of digital inputs and outputs

Bits in this byte have the following meaning:

Bit no Function

0 Digital input 1 activated.

1 Digital input 2 activated.

2 Digital input 3 activated.

3 Digital input 4 activated.

4 Digital output 1 activated.

5 Digital output 2 activated.

6 Digital output 3 activated.

7 Digital output 4 activated.

Scale Error code

This register holds the error code for the scale. Normally this register should contain ‘000’

which means no error. Error codes 000 to 255 are valid in this register.

This manual suits for next models

2

Table of contents

Other BLH NOBEL Accessories manuals

Popular Accessories manuals by other brands

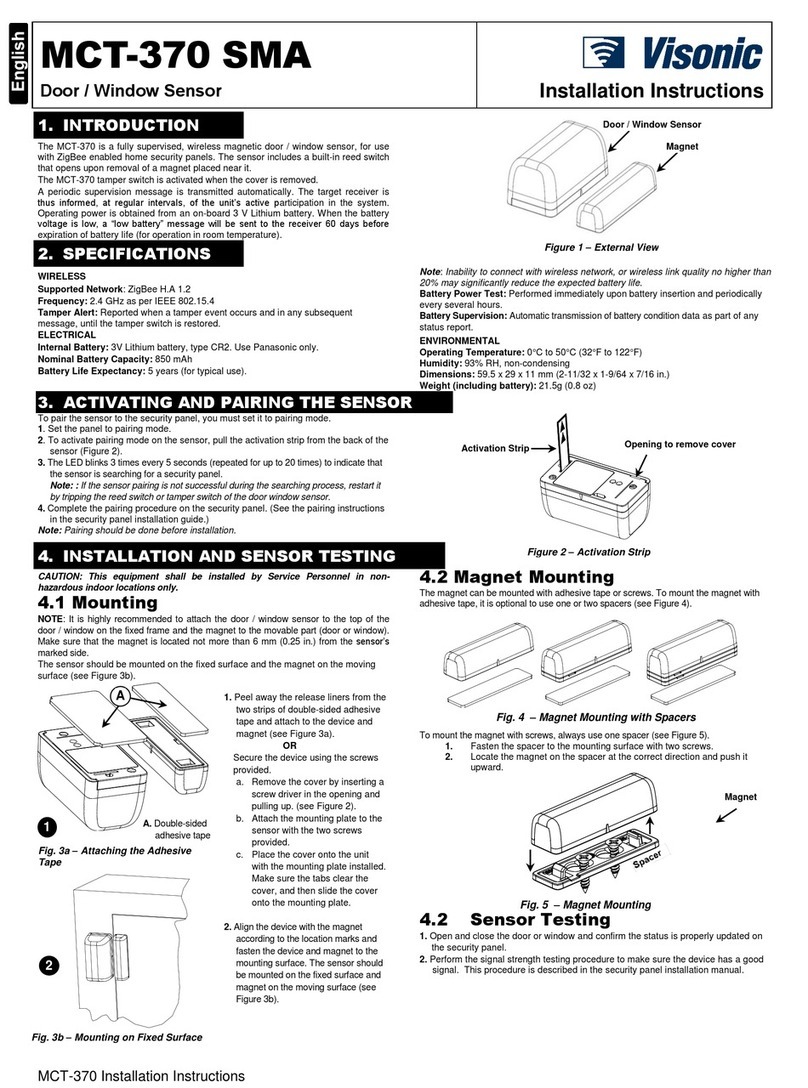

Visonic

Visonic MCT-370 SMA user manual

Heitronic

Heitronic 45017 Installation and operating instructions

Powerfix Profi

Powerfix Profi 270249 Operation and safety notes

Balluff

Balluff BES M12MG2-GNX20B-S04G-EXC user guide

HELPINSTILL

HELPINSTILL 280 quick start guide

Burkert

Burkert SE30 Ex Namur instruction manual

Dorner

Dorner SmartFlex 2200 Series Installation, maintenance & parts manual

IPVideo Corporation

IPVideo Corporation Halo Administrator's manual

AVCOM

AVCOM Galaxy Installation & operation manual

Sentronik

Sentronik SE9000A instruction manual

BERGER

BERGER K22 user manual

Philips

Philips SB7G17B Specifications