Blichmann BrewCommander Installation instructions

BrewCommander™ © Blichmann Engineering, LLC 2019

V. 1 - Firmware Ver1.0:1.1 1

BrewCommander™ Electric

Assembly, Operation, & Maintenance

Congratulations on your purchase, and thank you for selecting the BrewCommander™

Brewhouse Control from Blichmann Engineering™. We are condent that it will provide

you years of service and many gallons of outstanding beer. This manual will familiarize

you with the use and assembly procedures for the product.

Sections labeled “Warning” can lead to serious injury or death if not followed. Please thoroughly read these sections

and understand them completely before use. If you do not understand them or have any questions, contact your

retailer or Blichmann Engineering (www.BlichmannEngineering.com) before use.

Sections labeled “Caution” can lead to equipment damage or unsatisfactory performance of the equipment. Please

read these sections thoroughly. If you have any questions, contact your retailer or Blichmann Engineering

(www.BlichmannEngineering.com) before use.

Sections labeled “Important” should specically be followed to ensure satisfactory results with the product.

WARNING:

CAUTION:

IMPORTANT:

IMPORTANT INFORMATION

PLEASE READ AND THOROUGHLY UNDERSTAND THIS MANUAL PRIOR TO USE

FOR IMPORTANT SAFETY INFORMATION!

What’s In the Box?

120V / 240V Controller

aBrewCommander-120V

aBrewCommander-240V

Temperature Sensor Probe Temperature Sensor

Bulkhead Assembly

BE-001500-00

Power Cord

120V - BE-000365-01

240V - BE-000364-01

See Page 3 for

entire list of

Part #’s located

under Temperature

Sensor Assembly.

BrewCommander™ © Blichmann Engineering, LLC 2019 2

The BrewCommander™ Brewhouse Controller is an accurate and intuitive complete brewhouse control for automatically ramping and maintaining the

temperature of your boil kettle, mash tun, or hot liquor tank. With digital power control, automated mash profile ramping, boil addition timers, pump

control, delayed starting, and easy to use advanced control settings, the BrewCommander™ is clearly in a league of its own. It’s a perfect plug-and-play

match for controlling the power output of your BoilCoil™ electric immersion heater or RIMS Rocket™ electric recirculation heater, or any single phase heater

up to 30A at 240V (20A at 120V). Need to control a tank with more than one heater? The patent pending modular design offers the ability to add up to 4

relay modules to simultaneously control up to 5 elements!

The Electric BrewCommander™ Brewhouse Controller is, by design, modular. A single control module can be used for controlling one vessel, or multiple

temperature control modules can be combined for simultaneous control of multi-kettle systems.The controllers can operate as standalone units or can be

installed on the feature-richTOWER of POWER™ stand, which provides all of the fittings, plumbing, and valves and flow meters necessary in a convenient

package. Also available is the TOWER of POWER LTE™, offering a more compact design with basic features.

CAUTION: Always keep the controller away from heat and moisture. When necessary, clean with a damp cloth.

The BrewCommander™ Brewhouse Controller is available in either 120VAC or 208/240VAC. All units must be connected to the appropriate sized GFCI

circuit. Refer to the chart to determine the appropriate breaker required for your circuit. If you are uncertain about the power requirements or your service

location, contact a licensed and qualified electrician familiar with National Electrical Code standards and requirements.

OVERVIEW

POWER REQUIREMENTS

Blichmann BoilCoil™ Electric Heaters 3rd Party Electric Heaters

Unit Maximum Heater Power

(Watts)

GFCI Breaker

Size (Minimum)

Maximum Heater Power

(Watts)

GFCI Breaker Size

(Minimum)

120VAC 2250 20A 2400 25A

240VAC 5750 30A 7200 35A

WARNING: The Electric BrewCommander™ Brewhouse Controller is only to be used in conjunction with a Ground Fault Circuit Interrupter (GFCI)

protected power source. If you are uncertain about the status of your power source contact a licensed and qualified electrician familiar with National

Electric Code standards before proceeding. Operating the Electric BrewCommander™ Brewhouse Controller in any fashion other than described in this

manual can result in personal property damage, injury, electrocution, or death.

BrewCommander™ © Blichmann Engineering, LLC 2019 3

SENSOR INSTALLATION

TEMPERATURE SENSOR ASSEMBLY

For installation of temperature sensor in Hot Liquor Tanks and boil kettles , a ½”inch hole is required. Temperature sensors can be installed in the existing

BrewMometer™ hole in Blichmann Engineering BoilerMaker™ kettles. Install temperature sensor and bulkhead as shown in Figure 1.

For RIMS mash tuns, install the temperature sensor directly in the wort recirculation path immediately after the heat source (see Figure 1). Brewers using

the RIMS Rocket™ should reference the RIMS Rocket™ Owner’s Manual for detail instructions on installing the temperature sensor.

IMPORTANT: Installing the temperature sensor directly in the mash tun will result in instability and severe overshooting of mash temperature. Always

install the temperature sensor in the wort recirculation path as close to the heat source as possible as shown in Figure 2.

TIP: Use the optional temperature sensor fitting, part number BE-000268-00, for inline sensor installation as shown in Figure 3.

CAUTION:

•Do not pull sensor by cord, pull by stainless sheath only.

•Do not remove sensor when kettle is full of liquid without optional thermowell.

OPTIONAL THERMOWELL:

The optional Thermowell (BE-001500-00) is available to purchase to allow sensor removal in full kettles.

Number Part Number Description

1 BE-000882-01 Sanitary Nut

2 BE-000882-01 Sanitary Nut Inner Seal

3 BE-000882-01 Sanitary Nut Outer Seal

4 BE-000013-00 Bulkhead O-ring -113

5 BE-001474-00 Weldless Captive Bulkhead

6 BE-001476-00 Captive Nut O-ring -010

7 BE-001475-00 Captive Nut

8 BE-001500-00 Temperature Sensor Probe

Pump RIMS-Rocket™

Heater

Temperature

Sensor Sensor

Cable

Direction

of Flow

BrewCommander™

Optional Fitting

(BE-000268-00)

Figure 3

5

4

3

2

1

PAV

4/11/2019

SCALE:

SIZE

DWG. NO.

A

SHEET 1 OF 1

1:1

MFG APPR.

NAME

CHECKED

DRAWN

ENG APPR.

DATE

Weldless Captive Bulkhead Assy

FINISH

MATERIAL

DIMENSIONS ARE IN INCHES.

INTERPRET

GEOMETRIC TOLERANCING PER ASME Y14.5M-1994

TOLERANCES UNLESS OTHERWISE SPECIFIED:

ANGULAR:

1 deg

BEND:

0.020

ONE DECIMAL PLACE:

0.1

TWO PLACE DECIMAL:

0.02

THREE PLACE DECIMAL:

0.005

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

BLICHMANN ENGINEERING, LLC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

BLICHMANN ENGINEERING, LLC IS

STRICTLY PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

A

B

C

B

A

C

5

4

3

2

1

Figure 2

OPTIONAL 1/2”NPT ADAPTER:

The optional 1/2”NPT Adapter (TOP-007-01) converts

from 1/2 - 20 straight thread to 1/2”male NPT thread.

OPTIONAL 1.5”TRI-CLAMP ADAPTER:

The optional 1.5”Tri-Clamp Adapter (BE-001139-00)

allows the sensor to be installed on a 1.5”Tri-Clamp

fitting.

Figure 1

1 2 3

Kettle Wall

with ½”Hole

4 5 6 7 8

To Temperature

Probe Port

Inside Kettle Outside Kettle

COMPLETE TEMPERATURE SENSOR ASSEMBLY

BrewCommander™ © Blichmann Engineering, LLC 2019 4

CONNECTING POWER

First, ensure that the power switch on the front of the unit is in the off position before connecting power to the controller.

The 240V model of the Electric BrewCommander™ Brewhouse Controller is equipped with L6-30 connections. Blichmann Engineering™ offers six

optional power cord adapters to adapt common 240V outlets to an L6-30R connection as shown in Figure 4.

The 120V model of the Electric BrewCommander™ Brewhouse Controller is equipped with L5-20 connections on the controller, and a power cord

adapter with a 5-20P plug for the wall receptacle.

WARNING: Inspect all cables, wires, and connectors for wear and/or damage before every use. Do not use if cables, wires, and/or connections

are damaged, loose, or worn. Replace damaged and worn parts with genuine Blichmann Engineering™ parts available online at BlichmannEngineering.com.

Adaptors available for purchase from Blichmann Engineering™ for receptacles as shown below

5-20R

Figure 4

BrewCommander™ © Blichmann Engineering, LLC 2019 5

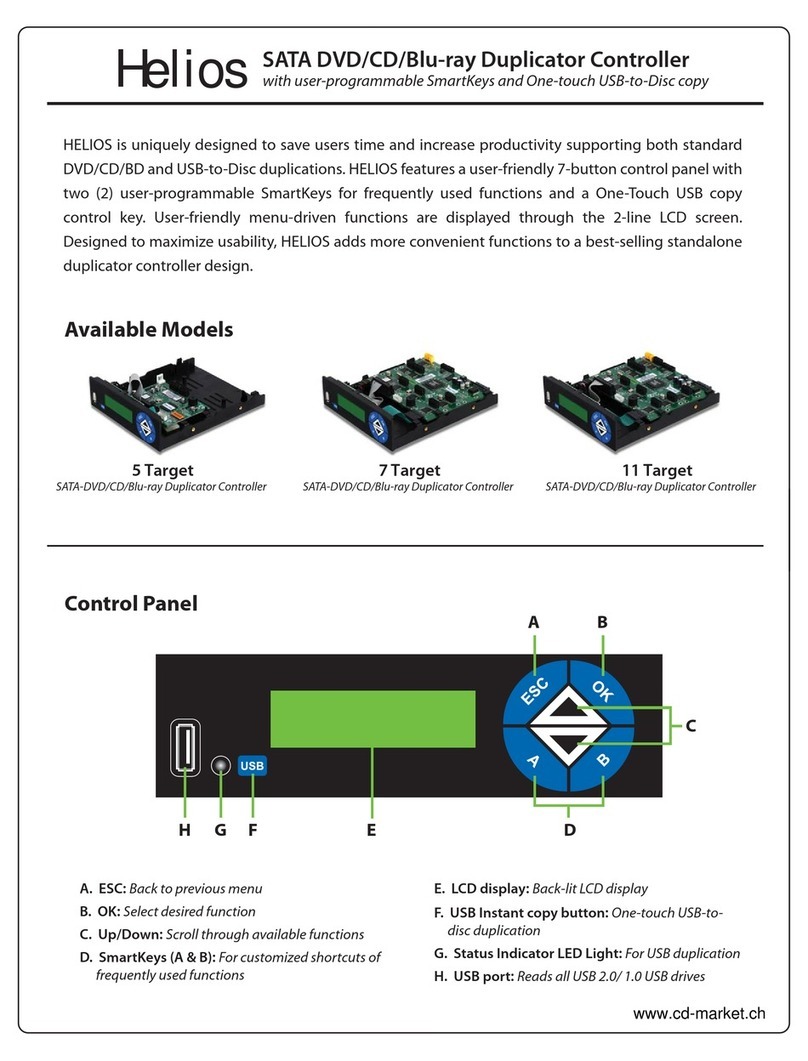

FEATURE CALLOUT

NOTE: For wiring out the bottom of the controller and for wall mounting, please visit our website at blichmannengineering.com to view the

instructional video.

POWER BUTTON

ON / OFF

PUMP RECEPTACLE

RELAY MODULE

WIRING PORT TEMPERATURE

SENSOR PORT

WIRED FROM

BOTTOM

BOTTOM OF

CONTROLLER

BOTTOM OF

RELAY MODULE

Female 240V

L6-30R

Male 240V

L6-30P

MALE 120V

NEMA 5-15

BrewCommander™ © Blichmann Engineering, LLC 2019 6

A universal mounting kit (PN: aPS-PowerCont-Mount) is available for purchase that includes a din rail and set of screws and nuts for mounting any of

our controllers and relay modules to a wall. To mount the Brew Commander™, the only parts from the kit that will be used are the DIN rail and the

small 8/32 set screws. Hardware for fastening the DIN rail to the wall is not included.

Steps:

1) Rewire your controller out the bottom by following the instructions given in the rewiring video on our Blichmann Engineering™YouTube

channel.

2)Trim the included DIN rail to be 1/8”shorter than with width of the controller.

3) Mount the DIN rail to the desired location on the wall.

4) Slide the controller onto the DIN rail using the channel on the back of the controller.

5) Install 2 of the 8/32 set screws into the top of the controller being careful not to over tighten. Stop tightening the screws once the controller can

no longer slide along the DIN rail.

WALL MOUNTING THE CONTROLLER

Hardware Required

from Mounting Kit:

4 Set Screws

DIN Rail

Set Screw

Location

Controller &

Relay Module

Shown with

DIN Rail

BrewCommander™ © Blichmann Engineering, LLC 2019 7

CONTROLLER SCREEN OPERATION

OFF/AUTO/ON - Cycle through power options.

ACTUAL TEMPERATURE - Displays the sensor temperature value.

NOTE: If the temperature is beyond the“out of range”value (programmable in basic settings) the text color will change. Blue is below (too cold), black is

in the desired range, and red is above the range (too hot).

SET TEMP - This is the desired temperature. Pressing this value will display a numerical keypad. Enter the desired value and press ENTER to accept.

POWER - This reduces the heating output of your heating element to the set percentage. Pressing this value will display a numerical keypad. Enter the

desired value and press ENTER to accept.

TIMER - This value displays the remaining time of the active timer. This value can’t be changed from the home screen.

OFF/AUTO/ON - Press button to cycle through the options below.

OFF - Power to the heaters is disabled.

AUTO - The heating element will automatically energize as needed to maintain the desired SET temperature at the selected power.

ON - The heating element will turn on and continually run at the selected power percentage. This setting overrides the automatic control. The SET value

will change to BOIL.

PUMP - Turns the auxiliary 120V receptacle located on the back of the unit on and off. Green illuminated button indicates that the power is in the ON

mode.

MENU - Pressing this button will open the main menu screen.

PUMP - ON/OFF.

HOME SCREEN

MENU SCREEN

MENU - Main Menu.

SET - Change the set temperature.

TIMER - Displays active timer.

ACTUAL TEMPERATURE

POWER - Change the % power.

MASH - Mash Prole.

BOIL - Boil Prole.

TIMER - Set a timer.

HOME - Return to the HOME

Screen.

SETTINGS

= Interactive= Active Button = Inactive Button

SCREEN CONVENTIONS

Firmware Version: Ver 1.0:1.1

Firmware 1.0:1.1

TIP: A screen operation tutorial video is available at

blichmannengineering.com.

BrewCommander™ © Blichmann Engineering, LLC 2019 8

PROFILE - Switch between 9 custom profiles that can be stored for future use. Values are saved upon entry.

SELECT - Press SELECT to cycle through TEMP and TIME.

KEYPAD - When a temperature or time is selected and flashing, press the keypad to change that value and press enter.

PLAY / PAUSE - Start / pause the selected profile. This button will become a pause button when a profile is active.

RESET - When a profile is active, press the RESET button to end the profile. To reset an active timer, press pause and then press reset.

HOME - To the Home Screen.

PROFILE - Switch between 9 custom profiles that can be stored for future use. Values are saved upon entry.

SELECT - Press SELECT to cycle through TEMP and TIME.

KEYPAD - When a temperature or time is selected and flashing, press the keypad to change that value and press enter.

PLAY / PAUSE - Start / pause the selected profile. This button will become a pause button when a profile is active.

RESET - When a profile is active, press the RESET button to end the profile. To reset an active timer, press pause and then press reset.

HOME - To the Home Screen.

MASH PROFILE

BOIL PROFILE

SELECT - Highlight a value.

PROFILE - Switch between 9 custom Mash Proles.

KEYPAD - Enter a value.

HOME - To the Home Screen.

RESET - Cancel the active prole.

PLAY / PAUSE - Start / pause the selected prole.

2

BOIL LENGTH

2SELECT - Highlight a value.

TIMER

PROFILE - Switch between 9 custom Mash Proles.

KEYPAD - Enter a value.

HOME - To the Home Screen.

RESET - Cancel the active prole.

PLAY / PAUSE - Start / pause the selected prole.

BrewCommander™ © Blichmann Engineering, LLC 2019 9

To navigate through the basic settings, press the SELECT button to scroll between them.

Use the up/down buttons to change the value. Pressing SELECT again will accept the new value.

START DELAY – The Start Delay is used to automatically heat mash strike water at a

future time. Enter the desired delay in hours. Press the HOME button. DELAY will show

in OFF/AUTO/ON button. The TIMER display will show remaining time. Be sure to set the

desired temperature and % power. If it is desired to have the pump turn on at the end of the

delay timer, first ensure that the pump is properly primed and the appropriate valves needed

for recirculation are open.Then, set the pump button to on (green). NOTE: As a safety feature,

the controller will automatically turn off the heater after 6 hours if the SET point has not been changed.

SET PT ALARM – This audible alarm will alert the user that the set point is close to being reached.

Values from 0-9˚can be selected. Choose OFF to disable this alarm. Default value is 5˚.

OUT OF RANGE – This setting will alert the user that the actual temperature is outside

of the desired SET temperature range. Values from 0-9˚can be selected. Choose OFF to disable

this alarm. Default value is 2˚. The text color of the temperature displayed on the home screen will change

based on this setting. Blue is below (too cold), black is in the range, red is above the range (too hot).

AUDIBLE ALARMS – Used to enable or disable ALL audible alarms. Color indicators will still function. Value is ON/OFF.

UNITS – Changes all temperature Units between C and F.

CALIBRATE - The sensor supplied with this product is extremely precise and accurate and does not require calibration. However, calibrate can be used for

sensor to sensor variation, if the user so desires to fine tune this reading, or simply match to another sensor. For example, if CALIBRATE is set to +0.7, the

sensor values will be increased by 0.7˚.

In the BASIC SETTINGS screen press the ADV button to navigate to the advanced settings screen.

The advanced settings are intended to enrich the user experience for the ultimate in performance.The

default values will provide excellent control for most applications.

MASH HEAT RATE - This setting is used to compensate for the heating delay time between mash steps

when using the Mash Timer. Since each system will vary in how fast it can heat, the user will need to

experiment with their system to measure the approximate heating rate in degrees per minute. The

controller will add extra time to the rest to allow the mash to heat to the rest temperature before

activating the rest timer. During the ramp time the TIMER will alternate between RAMP and remaining

time. Default setting is 2˚per minute.

Measuring the Ramp Rate

To measure the approximate ramp rate of your system measure the time it takes to go through a typical ramp. Divide the change in degrees by

the ramp time in minutes. For example, if ramping from 145 F to 155F takes 5 minutes, the ramp rate is (155-145)/5=2 deg/min. Enter this value

in MASH HEAT RATE.

RIMS OFFSET - This offset is used for Recirculation Infusion Mash System (RIMS), Heat Exchanger Recirculation Mash System (HERMS), or the Blichmann

Engineering™BrewEasy™Kettle RIMS system. In these systems the temperature at the sensor will read an average of a few degrees higher than the

actual temperature in the mash due to heat losses. The RIMS offset increases the temperature of the mash to match the Actual Temperature displayed on

the BrewCommander™ .

Measuring the RIMS Offset

Ensure the RIMS OFFSET is set to 0.0. Next, calibrate your mash thermometer to match the BrewCommander™ sensor so that you can accurately

measure the temperature difference between the mash and the recirculation temperature. Calibration at your typical mash temperature is most

accurate. During a mash, allow the mash thermometer to reach a steady state temperature. This may take 30-45 minutes. Subtract the mash

thermometer temperature from the BrewCommander™ temperature. Enter this value into the RIMS OFFSET. From this point forward, the

brewer can enter the desired mash SET temperature without having to compensate for temperature losses.

BASIC SETTINGS

ADVANCED SETTINGS

BrewCommander™ © Blichmann Engineering, LLC 2019 10

RIMS PROTECT - If a RIMS heater is on, but no wort is flowing, the wort will continue to heat and may scorch. The RIMS PROTECT feature is used to prevent

this situation by automatically turning the RIMS heater off when the pump is turned off. If the user desires, the pump and heater can be manually turned

back on. When set to OFF, this implies the user is not using the controller in a RIMS system and the auto heater disable feature will not be enabled. This

feature is not needed for HERMS systems. The default setting is OFF.

IGNITION DELAY - (intended for gas systems only) This value should always be set to 0.

CONTROL BAND -This value adjusts the range near the set point that the controller begins to cycle the power on and off. The default value is 6˚(+/- 3˚

from the set point) and should not need to be adjusted. Increasing this value reduces overshoot when ramping to the set point, but also increases the time

to reach the setpoint. Decreasing this value decreases the time to reach the setpoint, but also increases overshoot.

CYCLE TIME - This value determines how frequently the power is cycled on and off when the temperature is within the control band. The default value is

5 seconds.

SS OFFSET (Steady State Offset) - Steady State is when the temperature of the kettle is no longer rising or falling but has leveled out to a steady

temperature. The steady state offset corrects a difference between the Actual Temperature and Set Temperature on the BrewCommander™. This setting

adds a small increase in power to fine tune the system. This is particularly helpful when brewing in cold environments.

FACTORY RESET - This feature will reset all the settings from any altered state back to the original factory settings programmed into the controller. It will

give the user the option to select ELECTRIC defaults or GAS defaults. Please note that all mash and boil profiles will be erased during this reset.

WITHOUT SS OFFSET

The kettle’s thermometer has stabilized at 151˚F and will not get any hotter. The BrewCommander™ is set at 152˚F

After a 1˚F Steady State Offset was applied, the temperature of the kettle will now stabilize at the desired temperature.

For the BrewCommander™ electric modular brewing system to function properly in a recirculation system (RIMS / HERMS), your brewing system must meet

some basic requirements. If your system is unable to meet these requirements please contact your RETAILER for guidance. We cannot guarantee the

performance of the product if these basic minimums are not met.

For RIMS brewers, your mashing system must be capable of continuously recirculating wort with a pump for the duration of the mash without sticking.

The flow rates in the chart below are minimum values.

RIMS / HERMS SYSTEM REQUIREMENTS

Finished Batch Size Gal (L) Minimum Flow GPM (LPM)

5 (19) 0.5 (2.8)

10 (38) 0.75 (3.8)

15 (57) 1.25 (4.75)

20 (76) 1.5 (5.7)

32 (121) 2.25 (8.5)

IMPORTANT: Grain bed flow rates are highly dependent on

crush quality and mash tun geometry. Move to a coarser

crush if you are not able to achieve the above flow rates. It is

also recommended that you allow a 10 min dough-in prior to

turning on the pump. This allows air to purge from the grain

bed and for the grain to fully absorb the water.

WITH SS OFFSET

BrewCommander™ © Blichmann Engineering, LLC 2019 11

Finished Batch Size Gal (L) Minimum Flow GPM (LPM)

5 (19) 0.5 (2.8)

10 (38) 0.75 (3.8)

15 (57) 1.25 (4.75)

20 (76) 1.5 (5.7)

32 (121) 2.25 (8.5)

Recommended setting changes from the default settings.

BASIC SETTINGS

SET PT ALARM: 6°F

OUT OF RANGE: 8°F

ADVANCED SETTINGS

*RIMS OFFSET: 2.0°F

CYCLE TIME: 3 Sec

CONTROL BAND: 10°F

RIMS PROTECT: ON

IMPORTANT: It is recommended that before changing the above settings to read the descriptions in the basic and and advanced setting sections to fully

understand how these settings function.

General Operation

When using a RIMS Heater, such as the Blichmann Engineering RIMS Rocket™, the temperature readings taken in the RIMS Heater will be higher than vessel

temperature. This difference varies depending on the power supplied to the RIMS Heater and the rate of flow of the wort or hot liquor through it. When the

vessel is at a steady temperature this temperature difference is typically from 1˚to 4˚F due to normal heat losses in the system.When using the RIMS

Offset feature, the temperature displayed on the controller will always be the measured value from the temperature sensor minus the programmed RIMS

Offset value in the advanced settings.

Heating Strike Water

It is common to heat the strike water in the mash tun using the RIMS heater. However the rims offset for heating a mash is higher than that of heating strike

water. To compensate, use a set point 1-2 degrees below the desired strike water temperature. This can be fine tuned with experience using your system.

Mashing

The brew commander can compensate for losses in the system by using the RIMS OFFSET feature. The set point should be programmed to the desired mash

temperature. The above recommended Basic and Advanced settings are a good starting point, and can be adjusted with experience. Refer to the advanced

settings section for details.

TIP: If step mashing, decreasing your control band will help speed up the heating between steps, but larger temperature fluctuations will be experienced

in the RIMS Heater.

RIMS SETUP AND OPERATION TIPS

RIMS OFFSET: 0.0˚F RIMS OFFSET: 2.0˚ F

Mash Tun

Actual Temp:

148˚F

RIMS Heater

Actual Average Temp:

150˚F

Mash Tun

Actual Temp:

150˚F

RIMS Heater

Actual Average Temp:

152˚F

BrewCommander™ © Blichmann Engineering, LLC 2019 12

ADVANCED SETTINGS

MASH HEAT RATE: 1Deg

RIMS OFFSET: see Mashing section below

General Operation

It is important to be aware that when using a HERMS Coil during a mash the temperature readings taken in the HERMS kettle (typically the HLT) will be

higher than the actual temperature in the mash. This difference varies depending on rate of flow, whirlpooling in the HERMS vessel, and temperature

losses unique to the system. When using the RIMS Offset feature, the temperature displayed on the controller will always be the measured value from the

temperature sensor minus the programmed RIMS Offset value in the advanced settings.

Heating the Strike Water

A unique feature of HERMS systems is that there are many different ways to achieve the heating of strike water. These different methods have unique pros

and cons and varying equipment needs. Experimentation and practice with your particular system is the only way to truly fine tune strike water

temperature for your mash.

Method 1 is to recirculate the mash strike water through the HERMS coil while heating the HLT.

Method 2 is to heat the HLT (where the HERMS coil is located) to the desired temperature, while heating the strike water in your boil kettle with a second

controller. This method is faster due to using two heat sources.

Mashing

While mashing, the brewer must maintain a slightly higher temperature in the HLT than the desired mash temperature due to heat losses and inefficiency

of the heat exchanger. Whirlpooling in the hot liquor tank significantly increases the heat exchanger efficiency thereby reducing ramping times. For more

information about our Kettle Whirlpool Kit, visit https://www.blichmannengineering.com/whirlpool-kit.html.

The RIMS offset can be programmed to compensate for losses in the system. If whirlpooling in the HLT during the mash, the RIMS OFFSET should be

programmed to 3˚F. If not, this should be set to 5˚F. The SET point should be programmed to the desired mash temperature. With experience these

settings can be fine tuned.

For step mashing with a HERMS system, a mash heat rate of 1°F or lower is recommended over the default 2°F. This allows more ramping time between

steps to allow the slower heating rate of the HERMS system to reach the next mash step.

HERMS SETUP AND OPERATION TIPS

RIMS OFFSET: 0.0˚ F RIMS OFFSET: 3.0˚ F

HLT w/ HERMS

Actual Temp:

150˚F

Mash Tun

Actual Temp:

147˚F

HLT w/ HERMS

Actual Temp:

153˚F

Mash Tun

Actual Temp:

150˚F

BrewCommander™ © Blichmann Engineering, LLC 2019 13

CONNECTING THE RELAY MODULE

To wire the relay module to the BrewCommander™ first remove the plug on either the left or right of the controller as shown in Figure 1.

Remove the screws in the front (Figure 2) of the controller as well as the top (Figure 3) and back (Figure 4).

Slowly and carefully remove the bottom housing being sure the housing does not catch on any wires (Figure 5).

Locate the input terminals in the BrewCommander™ controller. Add the blue/white jumper to terminal 4(as shown in Figure 6 & 7). Add the

solid blue jumper to terminal 3 (as shown in Figure 6 & 7).

Run the jumper out the side of the bottom housing (as shown in Figure 8). Reattach the bottom housing to the controller with all the screws

previously removed.

The Relay Module is used to control multiple heating elements. The Relay Module will come with a jumper cable to wire between the relay module

and the BrewCommander™ controller.

BEFORE DISASSEMBLING THE BREWCOMMANDER™ READ EACH STEP THOROUGHLY.

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Figure 1

Blue/White Wire

White Wire

Jumper Cable

Black Wire

Blue Wire

Figure 2 Figure 3 Figure 4

Figure 5 Figure 6

Figure 7 Figure 8 Figure 9

BrewCommander™ © Blichmann Engineering, LLC 2019 14

Step 6:

Step 7:

Step 8:

Step 9:

Step 10:

Secure the other end of the jumper to the Relay Module by connecting the blue/white jumper to Terminal 4 and the solid blue jumper to Terminal 3

(as shown in Figure 10).

Run the end of the jumpers through the hole in the side of the bottom housing (as shown in Figure 11).

Connect the two jumper ends together (as shown in Figure 12).

Attach the DIN rail (Figure 13) to the back of both the BrewCommander™ and the Relay Module (as shown in Figure 14). Push the excess jumper

cable into both controller and slide them together to ensure jumper wires are inside the enclosure not jammed between them.

Secure the set screws on the DIN rail to hold both controllers in place (as shown in Figure 15).

Figure 10 Figure 11

Figure 12 Figure 13

Figure 14 Figure 15

NOTE: The BrewCommander™ can be wired out the bottom. For wiring the bottom of the controller, please visit our website at

blichmannengineering.com to view our video.

BrewCommander™ © Blichmann Engineering, LLC 2019 15

Blichmann Engineering ProductWarranty

A. Limited Warranty

1. Blichmann Engineering warrants to the original purchaser that this product will be free from manufacturing defects in material and workmanship for a period of one (1) year from the date of purchase by the customer. Proof of

purchase is required. Blichmann Engineering’s obligation to repair or replace defective materials or workmanship is the sole obligation of Blichmann Engineering under this limited warranty.

2. This product is for home use only.The limited warranty covers only those defects that arise as a result of normal use of the product and does not cover any other problems, including, but not limited to, those that arise as a

result of:

a. Improper maintenance or modification;

b. Damage due to incorrect voltage or improper wiring by customer;

c. Operation outside of the product’s specifications;

d. Carelessness or neglect to operate the product in accordance with instructions provided with the product;

e. Damaging the tamper label on the product;

f. Damage by over-tightening the fasteners;

g. Failure to follow cleaning and / or maintenance procedures; or

h. Exceeding published operational temperatures.

3. Blichmann Engineering reserves the right to request delivery of the defective component for inspection before processing the warranty claim. If Blichmann Engineering receives, during the applicable warranty period, notice

of a defect in any component that is covered by the warranty, Blichmann Engineering shall either repair or replace the defective component with a new or rebuilt component at Blichmann Engineering’s option.

4. Blichmann Engineering must be notified within seven (7) days of the delivery date of any shipping damage. Customer is responsible for shipping damage outside of this time period. Approval for return must be provided by

Blichmann Engineering prior to any return. Customer is responsible for keeping all original packaging material for warranty returns. Blichmann Engineering is not responsible for damage from improperly packaged warranty

returns, and these repair costs will be the sole responsibility of the customer. Shipping costs for warrantee returns are covered only for the contiguous United States.

5. Blichmann Engineering’s limited warranty is valid in any country where the product is distributed.

________________________________________

B. Limitations ofWarranty

1. Any implied warranty that is found to arise by way of state or federal law, including any implied warranty of merchantability or any implied warranty of fitness, is limited in duration to the terms of this limited warranty and is

limited in scope of coverage to this warranty. Blichmann Engineering disclaims any express or implied warranty, including any implied warranty of fitness for a particular purpose or merchantability, on items excluded from

coverage as set forth in this limited warranty.

2. Blichmann Engineering makes no warranty of any nature beyond that contained in this limited warranty. No one has authority to enlarge, amend, or modify this limited warranty, and Blichmann Engineering does not authorize

anyone to create any other obligation for it regarding this product.

3. Blichmann Engineering is not responsible for any representation, promise, or warranty made by any independent dealer or other person beyond what is expressly stated in this limited warranty. Any selling or servicing dealer

is not Blichmann Engineering’s agent, but an independent entity.

________________________________________

C. Limitations of Liability

1. The remedies provided in this warranty are the customer’s sole and exclusive remedies.

2. Except for the obligations specifically set forth in this warranty, in no event shall Blichmann Engineering be liable for direct, indirect, special, incidental, or consequential damages, whether based on contract, tort, or any other

legal theory and whether or not advised of the possibility of such damages.

3. This warranty does not cover, and in no event shall Blichmann Engineering be liable for, travel, lodging, or any other expense incurred due to manufacturing defects in material and workmanship, or any other reason.

4. Any performance of repairs after the warranty coverage period has expired or performance of repairs regarding anything excluded from coverage after this limited warranty shall be considered good-will repairs and they will

not alter the terms of this limited warranty, or extend any warranty coverage period.

5. Venue for any legal proceedings relating to or arising out of this warranty shall be in Tippecanoe County, Indiana, United States, which courts will have exclusive jurisdiction.

________________________________________

D. Local Law

1. This warranty gives the customer specific legal rights.The customer may also have other rights that vary from state to state in the United States or other countries.

2. To the extent that this warranty is inconsistent with local law, it shall be deemed modified, only to the extent necessary to be consistent with such local law.

This product uses FDA and/or NSF approved food grade materials anywhere the product touches the beverage.

Warning:This product contains or may contain chemical(s) known to the State of California to cause cancer, birth defects, or other reproductive harm.

Other manuals for BrewCommander

1

Table of contents

Other Blichmann Controllers manuals

Popular Controllers manuals by other brands

Conrad

Conrad Wii Motion Plus Controller operating instructions

Asentria

Asentria Teleboss 850 user manual

Balmar

Balmar BRS-2T-24 operating instructions

RESEARCH CONCEPTS

RESEARCH CONCEPTS RC2000C manual

Banner

Banner Sure Cross Performance P15E Node Series manual

Blueprint Controllers

Blueprint Controllers BDTC-1 manual