Blichmann Cornical Installation instructions

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 1

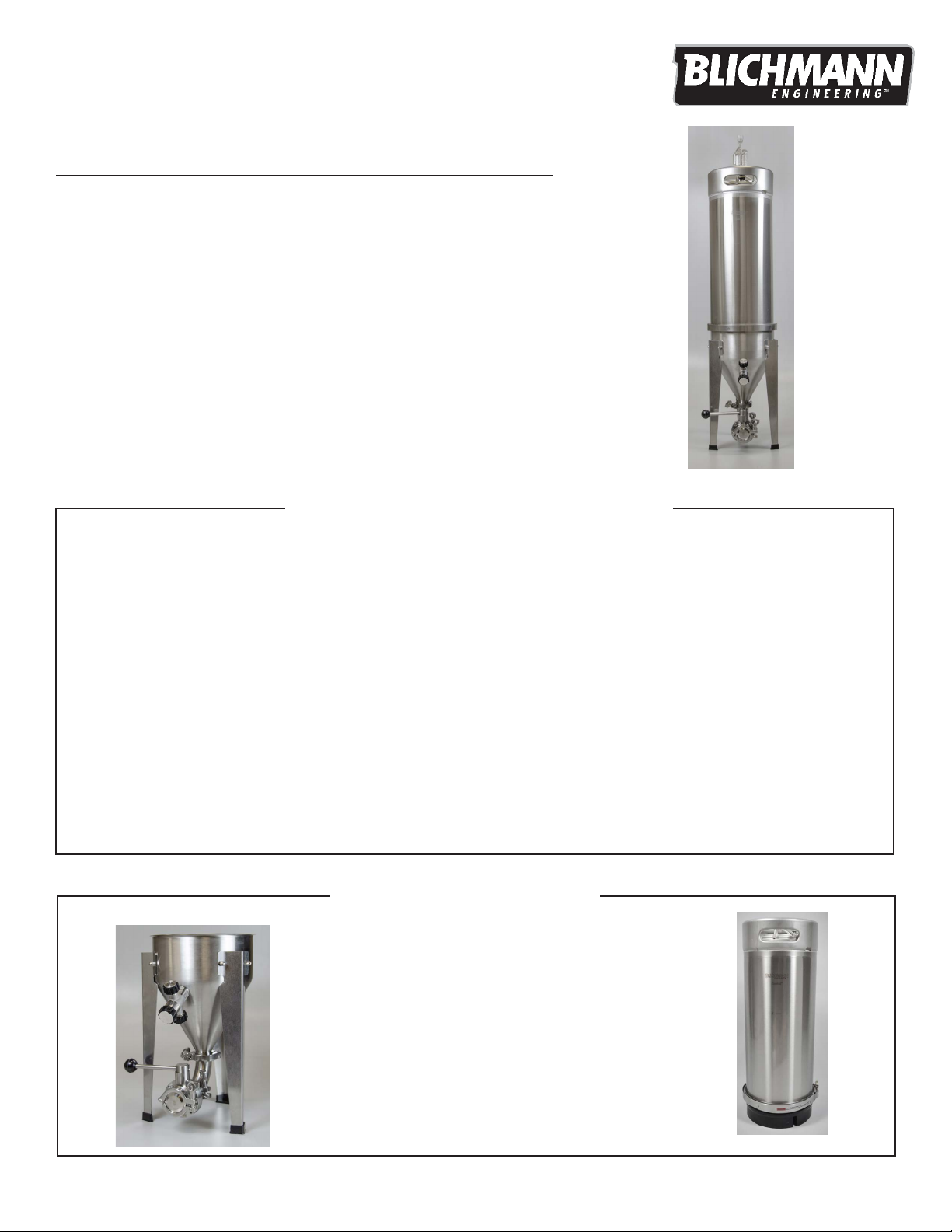

Cornical™

Assembly, Operation, & Maintenance

Congratulations on your purchase, and thank you for selecting the Cornical™ Modular

Keg and/or Conical Fermentor from Blichmann Engineering. We are condent that it will

provide you years of service and many gallons of outstanding beer. This manual will

familiarize you with the assembly, installation procedures, and use of this product.

Sections labeled “Warning” can lead to serious injury or death if not followed. Please thoroughly read these sections and under-

stand them completely before use. If you do not understand them or have any questions, contact your

retailer or Blichmann Engineering (www.BlichmannEngineering.com) before use.

Sections labeled “Caution” can lead to equipment damage or unsatisfactory performance of the equipment. Please read these

sections thoroughly. If you have any questions, contact your retailer or Blichmann Engineering

(www.BlichmannEngineering.com) before use.

Sections labeled “Danger” are critical to follow and understand to reduce risk of serious injury or death. Please read these thor-

oughly and understand them completely before use. If you do not understand them or have any questions, contact your retailer or

Blichmann Engineering (www.BlichmannEngineering.com) before use. Do NOT at ANY time operate the product until you have

thoroughly read and understood these instructions!

WARNING:

CAUTION:

DANGER:

IMPORTANT INFORMATION

PLEASE READ AND THOROUGHLY UNDERSTAND THIS MANUAL PRIOR TO USE

FOR IMPORTANT SAFETY INFORMATION!

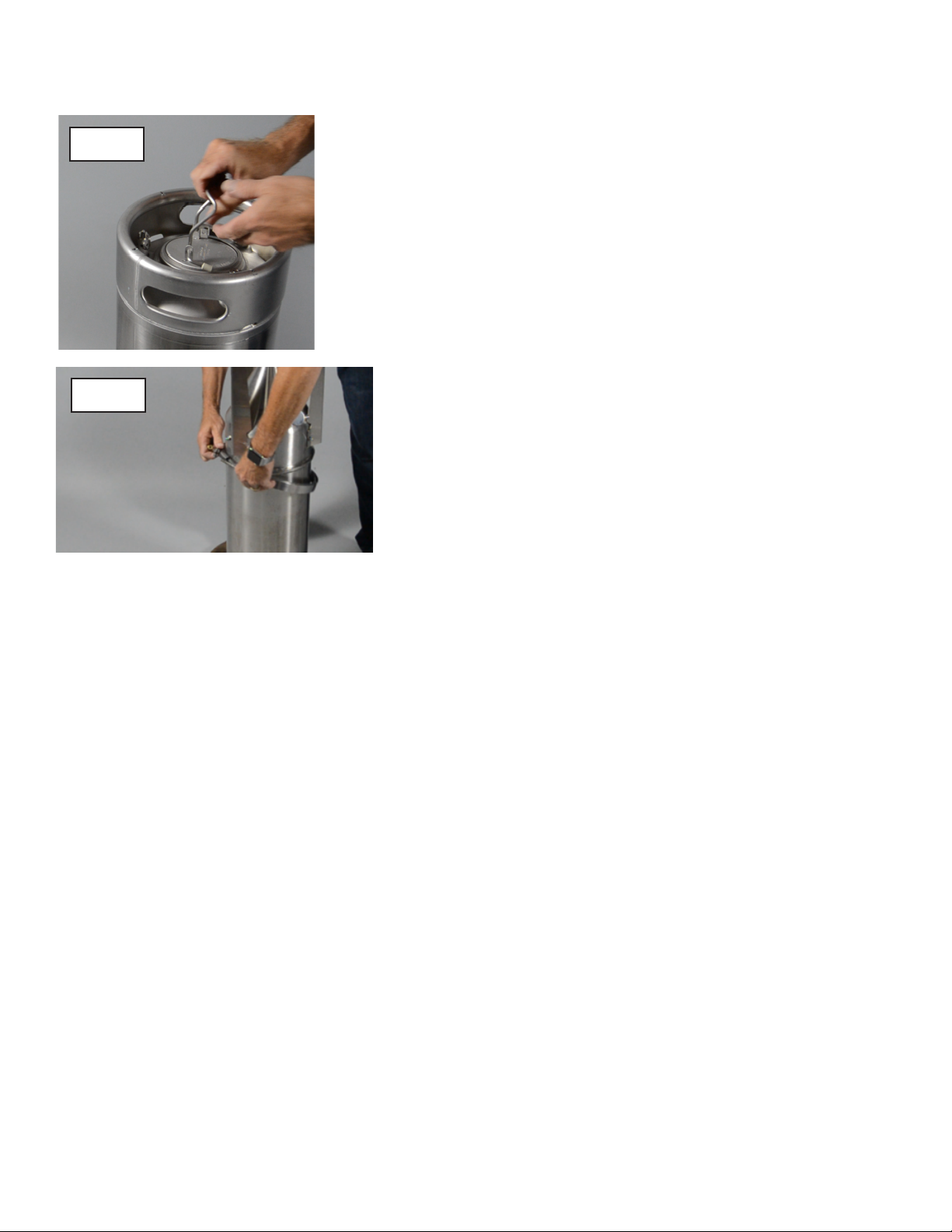

What’s In the Box?

Keg Assembly

Fermentor Assembly

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 2

What’s In the Box?

1. Cone

2. Leg (installed on cone)

3. Acorn nut (installed on cone)

4. Leg cap (installed on legs)

5. Tri-clamp buttery valve (1.5 in)

6. QuickConnect 1/2” Straight

7. Aseptic Valve

8. Racking tube

9. Racking tube nut

10. Racking o-ring

11. Clamp – 1.5”

12. Gasket 1.5”

13. Cap – 1.5”

14. Elbow – 1.5”

15. Barb tting – 1.5” TC X 1” hose

16.

17.

18. QuickConnector nut

19. QuickConnector cap

20. QuickConnector ½” elbow

21. QuickConnector o-ring

22. Hose – ½” blowoff

23. Hose clamp

23. Fermentation lid hatch

23. Airlock

23. Airlock washer

23. 1” ID bottom dump

hose

BE-000547-03

BE-000939-01

BE-000028-00

BE-001022-00

BE-000865-00

aQC_12S

FE-367-01

FE-357-00

FE-376-03

BE-000682-00

BE-000633-00

BE-000868-00

BE-000630-00

BE-000863-00

BE-000627-00

QC-12NUT-01

BE-001017-00

QC-12ELBOW-01

BE-000105-00

BE-000707-00

BE-000374-00

BE-000944-01

BE-500019-00

BE-001018-00

BE-001100-00

Conical Fermentor Kit

10. Racking O-Ring

7. Aseptic Valve

19. QuickConnector™ cap

18. QuickConnector™ nut

20. QuickConnector™ ½” elbow

14. Elbow 1.5”

5. Tri-Clamp Buttery 1.5”

11. Clamp 1.5” 12. Gasket 1.5”

13. Cap 1.5”

24. Fermentation

Lid Hatch

Dump

Assembly

Dump

Assembly

Racking

Assembly

6. QuickConnect™ 1/2” Straight

8. Racking Tube

9. Racking Tube Nut

Fig 3

Assembly of the Keg Kit:

Note: We recommend a trial assembly of your new Cornical™ keg before using it to ferment so you are familiar with the

procedures and are sure you have all the parts. When you are ready to use the fermentor for an actual brewing session,

read the sanitizing procedures before assembling your Cornical™ since many parts are sanitized before assembly.

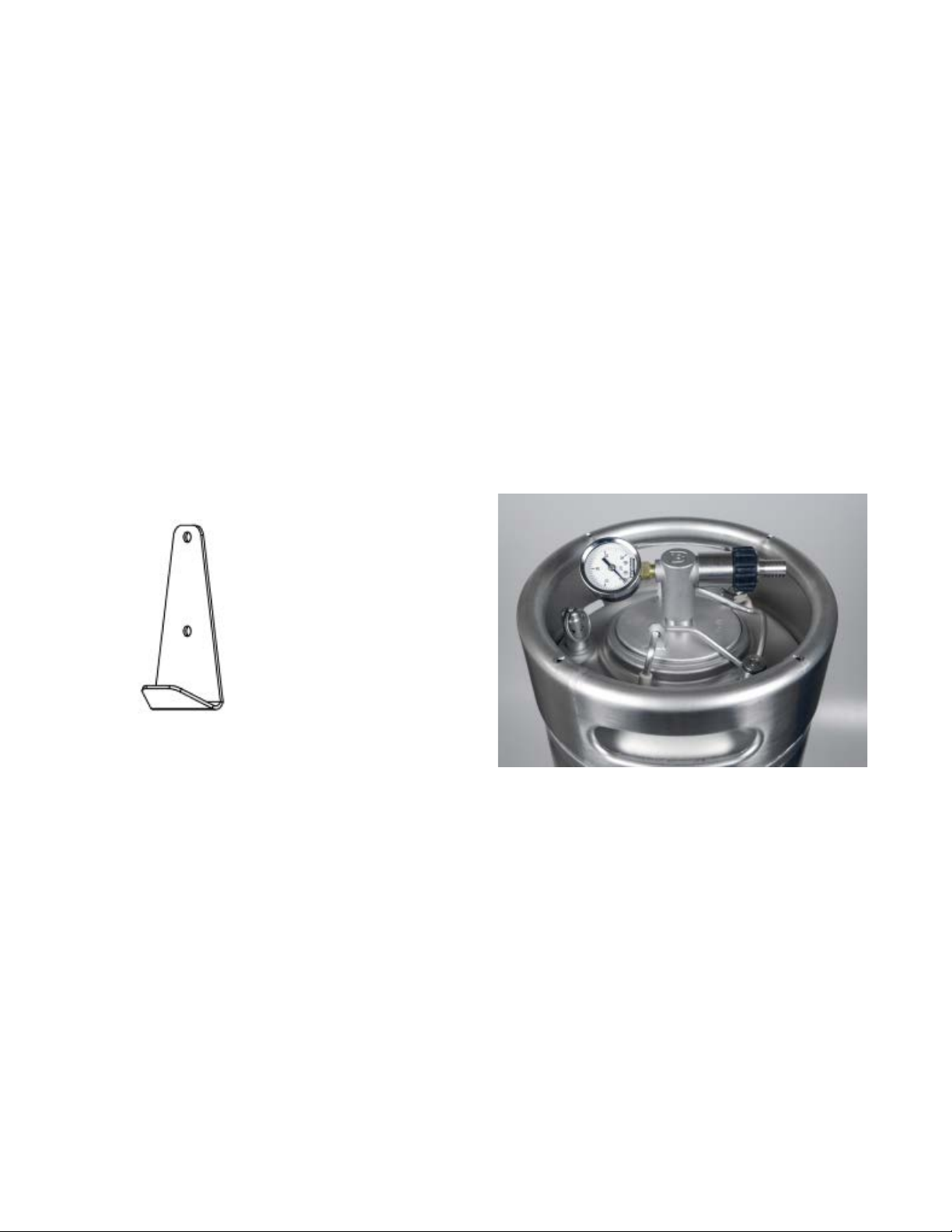

DANGER: ALWAYS release the pressure inside of the keg before

attempting to open the keg or loosening the nut on the v-band clamp! If

this clamp is opened while under pressure serious injury or death may

result! Relieve pressure by pulling the ring on the top of the pressure

relief valve until the hiss of gas completely stops (Fig 4.) Remove the

hatch on top of the keg to ensure all pressure is released (Fig. 5)! At this

time it is safe to remove the v-band clamp from the bottom of the keg

(Fig. 6.)

Fig 4

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 3

DANGER: ALWAYS remove the lid hatch on top of the keg BEFORE removing

the v-band clamp on the bottom of the keg! This ensures that the keg is fully

depressurized.

DANGER: NEVER exceed the 50 PSI (3.3 BAR) rated pressure!

DANGER: Only use the pressure relief valve that is included with this product.

Do not modify or tamper with the relief valve. Using the incorrect parts or

tampering with the pressure relief valve can lead to serious injury or death!

DANGER: DO NOT use any pressure relief valve components or the

lid hatch on any keg other than the Cornical™ or serious injury or

death could result!

DANGER: ALWAYS use a blowoff hose or airlock during fermentation.

Do NOT use the solid lid or cap the NPT tting on the fermentation lid

while the beer is actively fermenting.

Cleaning & Sanitizing the Keg:

DANGER – DEPRESSURIZE KEG BEFORE OPENING OR REMOVING CLAMP: Before opening or removing the

v-band clamp ALWAYS rst relieve ALL internal pressure from the keg by pulling the ring on top of the pressure relief

valve until all hissing stops (Fig. 4.) Then remove the lid hatch on top of the keg (Fig. 5.) Continue to fully

disassemble the keg including the removal of the keg posts and pressure relief valve (PRV). It is not necessary to

disassemble the posts or PRV further.

Soak all parts in a suitable cleaning agent such as PBW (powdered brewery wash) or similar cleaner. Scour the inside

of the keg body and the keg bottom. It is important that ALL parts are free of soil for the sanitizer to work properly.

Rinse all components in hot water and allow to dry thoroughly so that the passive layer forms on the

surface of the stainless steel.

Prepare a 3-4 gal bucket of sanitizer. We recommend StarSan from Five Star products. However, any

non-chlorine based no-rinse sanitizer including Iodophor are acceptable. Soak all ttings in the sanitizer before

assembly. Recommended, but not included, is a long brush for cleaning the inside of the liquid out tube. These are

available at your retailer.

CAUTION: Iodophor CAN be harmful to stainless steel if exposed for long periods of time. Never store a keg with

Iodophor inside. Do not use any cleaner or sanitizer containing chlorine such as bleach. Over time, this will pit and

erode stainless steel. This is not a warrantable failure.

CAUTION: Do not soak the V-band clamp or brass nut in sanitizer. Doing so reduces the life of the threads and may

cause galling (sticking) of the threads. Clean only with warm soapy water if needed. Always place a dab of Vaseline or

keg lube on the threads of the v-band clamp each time before assembly. This helps to increase the life of the threads

and makes assembly easier. Galled, cross-threaded, or other thread damage from failure to use lube or soaking in

sanitizer is not a warrantable failure.

Fig 6

Fig 5

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 4

Fig 8

Fig 7

Place the o-ring on the bottom lip of the keg body as shown in Fig.

7. Place the keg bottom onto the bottom of the keg body making

sure the o-ring is not pinched, then place a dab of Vaseline or keg

lube on the threads of the clamp and then install the band clamp

nger tight. Using a 7/16” wrench (not included) tighten the clamp

fully. When fully tightened, the clamp gap (shown in Fig. 8) will be a

maximum of 3/16”.

DANGER: ALWAYS ensure that the clamp is fully tightened! Failure

to do so can result is serious injury or death!

After removing and sanitizing the CO2 in, and liquid out

tubes, keg posts, and the pressure relief valve, reinstall

them into the keg body. Pour the 3-4 gal of sanitizer from

the bucket into the keg through the keg hatch opening.

Reinstall the keg hatch. Slowly apply 5-10 PSI of pressure

to the keg to check for leaks near the clamp and other

ttings. If you see any leaking, depressurize the keg,

remove the lid, and disassemble the clamp checking for a

pinched seal and also inspect other components for leaks

or missing seals

After 5-10 min, invert the keg to sanitize the top portion of the keg. After another 5-10 minutes depressurize the keg,

remove the hatch on top of the keg, and pour out the sanitizer.

TIP - Purge oxygen from your keg: If you are storing your keg and want it ready to ll at a future date purging it with

CO2 and storing under 10-15 PSI of pressure is highly recommended. Place the keg in an inverted position to let the

sanitizer drain fully. Then return the keg upright and replace the lid hatch. Connect a black LIQUID ball lock on your

CO2 hose. Connect it to the liquid out post. This purges the keg from the bottom up. Pull the pressure relief valve, and

turn it 90 degrees so that it stays in the open position. Turn on your CO2 gas and let the gas run for about 30 seconds to

one minute. Then return the pressure relief valve to the closed position. When the CO2 gas stops owing the keg will be

under pressure. Turn off the gas and remove the ball lock from the post. If you are immediately lling your keg it is not

necessary to pressurize it after purging.

Filling the Keg:

Depressurize your keg and remove the lid hatch on top. Place a sanitized hose on the outlet of your fermentor and place

the other end at the BOTTOM of the keg. This will minimize foaming, splashing, and oxidizing your beer. When the keg

is full, remove the hose and install the lid hatch. Pressurize the keg through the gas post to about 10-15 PSI. Pull the

pressure relief valve to vent the pressure and allow it to re-pressurize. Do this 4 or 5 times to purge any oxygen out of the

head space of the keg. Refrigerate the keg and apply CO2 pressure as needed for proper carbonation. In most cases, the

beer will fully carbonate in 7-10 days. We do not recommend shaking the keg, exceeding the normal dispensing pressure.

Doing so usually results in over-carbonated beer.

TIP: If you are in a hurry to drink your beer, Blichmann Engineering offers our QuickCarb™ in-line carbonator that will

carbonate your beer in about an hour with no chance of over-carbonation.

Note: Contact the factory at

trouble getting a seal.

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 5

Fermentation Kit Assembly and Use:

The fermentation kit is an optional accessory for the Cornical™

modular keg. This kit converts your keg into a full

featured conical fermentor. This allows you to eliminate the transfer

of the beer to a secondary keg for dispensing. Simply invert the

fermentor after fermentation is complete, replace the cone with the

keg bottom, and you’re ready to carbonate and dispense!

Note: It is to be expected that there will be some krausen residue

on the inside of the keg body after fermentation. For full avored

ales and lagers this will not led to detectable off avors. However,

for delicately avored beers, or extended lagering and cellaring

times, it is recommended to transfer the fully fermented beer into a

second clean keg.

Fully disassemble the fermentation kit components and soak in a

cleaning agent similar to the procedure used for

cleaning and sanitizing your keg. Note that it is not necessary or

recommended that you disassemble the large buttery valve. How-

ever, it is recommended that you remove the stem from the racking

valve.

After soaking in a cleaning agent, rinse with hot water and then soak

in a bucket of 4-5 gal of sanitizing solution.

Assemble the bottom dump components (sanitary elbow, gaskets, buttery valve, 1.5” cap, and clamps) as shown in Fig.

3. Assemble the racking arm components (small elbow, nut, ttings, o-ring, gasket, and sampling valve) as shown in Fig.

3. For the racking arm, ensure that the o-ring is in the groove of the racking tting. Then use a wrench on the inside and

outside of the racking arm and tighten rmly.

Note: Do not use Teon sealing tape on the threads of the racking arm. Ensure that the o-ring is on the outside of the

tank and is placed in the groove of the racking arm tting.

TIP: It is recommended that you orient the racking tube and the racking valve outlet tube in the same direction. This will

act as a position indicator of the

racking tube as you begin draining the fermentor.

Install the conical bottom on the keg body using the identical procedure as installing the keg bottom as in Fig. 8. Place

the fermentor upright and ll the fermentor with about 4-5 gal of sanitizer. Replace the keg lid hatch with the fermentation

lid hatch (Fig. 9) and install the nut, cap, and o-ring. Pressurize to 5-10 PSI and check for any leaks. Let soak for 5-10

minutes. Invert the keg and let sit another 5-10 minutes. Place the fermentor upright, release the pressure, remove the

lid hatch and drain the sanitizer back into the bucket. Open the drain valves to expel any remaining sanitizer.

Fig 9

Fig 9.1

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 6

Filling the fermentor: Fill the fermentor through the top lid hatch to a maximum of 5.75 gal for beer (6 gal for wine) to

ensure there is adequate head space to prevent a blow-off of krausen. Reinstall the fermentation lid hatch and install

either the included airlock or the blowoff hose.

Included with your fermentor is an airlock and orange silicone washer that can be used during fermentation (Fig 9.1.)

Remove the o-ring from the QuickConnector nut and insert the washer.

In addition, a ½” 90 degree elbow and ½” hose are also provided to act as a blowoff kit for aggressive fermentations

(Fig. 10.)

TIP: It is highly recommended that you use Fermcap S in the fermentor which signicantly reduces krausen and poten-

tial for blow-off. This product also aids in improving head retention in the nished beer. Fermcap S is available through

your retailer.

Warning for Dry-hopping: Do not use loose whole leaf hops for dry-hopping!

Not only will they possibly clog the pressure relief valve causing a potential dan-

gerous over-pressurization, the leaves tend to clog the racking arm. If you use

whole hops be sure to use a hop bag. Pellet hops can be used with or without a

hop bag. In all cases, using a hop bag will reduce the carry-over of hop particles

in the nished beer and harvested yeast and leave you with more nished beer.

Boiling the bag before placing the hops inside is an easy way to reduce the risk

of introducing bacteria in to the fermentor from the bag. In practice, pre-boiling of

the hops is not needed due to the natural bacterial inhabitation from hops. This

will also preserve the volatile aromatic compounds from being lost.

TIP: Proper aeration of your wort is essential for proper yeast health. An inline oxygenation system is available through

Blichmann Engineering. ANVIL Brewing Equipment™ also offers a high quality oxygenation wand.

Harvesting yeast: If you’re harvesting the yeast for use in a future batch of beer, you’ll need to sanitize the included 1”

hose and the 1” hose barb tting rst. The inside of the valve can easily be sanitized by a spray bottle of sanitizer a few

minutes prior to installing the barbed tting. Slowly open the dump valve and allow the brown colored trub to pass rst

and drain into a pan. Close the valve and direct the 1” hose into a sanitized container. Collect the cream colored yeast

and then close the valve and spray the valve with sanitizer. A wide mouthed Erlenmeyer ask tted with an airlock and

stopper is ideal yeast collection vessel for this application. Purging the ask with CO2 before lling is ideal. With proper

sanitization techniques, yeast can be stored for about 2 weeks and harvested 4-6 times in a homebrew environment.

Since you’ll have plenty of yeast to pitch (reactivate with a small amount of wort if more than one week old) you’ll nd

your ferments starting faster and progressing much more quickly and completely

Rotating Racking Arm Operation

This feature is used for taking wort samples during the fermentation process and for racking the nished beer into

secondary vessels, kegs or a bottling bucket. If you are planning on leaving the beer in the fermentor and switch to the

keg bottom, skip to the next section: Converting to Keg.

Tip: Open the pressure relief valve prior to draining beer/wort from the tank or you will suck the liquid out of the airlock

and into the fermentor! The CO2 from the actively fermenting beer is generally sufcient to purge any ingested air from

the tank. However, if you place a few PSI or pressure on the keg prior to taking a sample there will be no additional air

drawn into the tank. To do this, remove the airlock and install the plug in its place

Fig 10

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 7

Wort sample: Taking a wort sample is as easy as turning the knob on the back of the racking valve and draining it directly

into a container. After taking a sample, spray sanitizer into the outlet of the racking valve. Note that is isn’t necessary to

rotate the valve to take a sample.

Racking nished beer – gravity drain: Spray the barb tting inside and out with sanitizer. Connect the sanitized ½” san-

itized hose and clamp to the barb tting. Hold the valve body to prevent it from rotating, and slowly open the valve, begin

draining it into your keg or bottling bucket. Then slowly rotate the racking arm assembly downward. Stop rotating when

you see a yeast pick-up, then turn it back a bit to keep from picking up additional yeast. DO NOT loosen the tri-clamp

ttings to turn the racking arm and pay close attention that the hex on the rack tting is rotation with the valve assembly. If

it is not, either tighten the assembly or turn the assembly by the hex using a wrench. That’s it! If you never see a yeast

pick-up, leave it in the full down position.

Prior to inverting the keg it is important to drain as much yeast and trub as

possible from the fermentor so that it isn’t left in the nished beer. Remove

the cap from the bottom dump valve. Connect the 1” barb tting and hose to

the bottom dump valve. Open the valve slowly and drain the thick yeast and

trub into a pan. Stop when liquid runs from the hose. Remove the barb and

hose, spray the inside of the valve with sanitizer and reinstall the cap. Wait a

couple days for more yeast to settle and repeat.

TIP: If the yeast has compacted and will not ow from the valve, close the

valve. Install the cap on the lid hatch and pressurize the fermentor to about

5-10 PSI with CO2. Then SLOWLY open the valve and the yeast should

begin to ow.

Converting to Keg

This is one of the most useful features of the Cornical™ features. The ability to invert the fermentor and switch from

the conical bottom to the keg bottom. This completely eliminates the need to clean or rack into a secondary vessel for

dispensing!

Use a hydrometer and check that the specic gravity of the beer has not changed for a period of 3 days to ensure that

fermentation is complete.

5

Aseptic Valve and Rotating Racking Arm

Install a small o-ring into the groove of the flare fitting on the aseptic valve as shown in Figure 11a. Install the 2 QuickConnect™ caps

onto the ends of the aseptic valve. Insert the assembly into the hole in the conical side of the tank (see Figure 11b). Place the flare fitting

nut on the racking tube and thread onto the flare fitting. Tighten the flare nut snugly with a wrench – do not over-tighten or you could

inadvertently bend the tank while tightening. It is not necessary to excessively tighten the fitting to get a good seal. If your wrench it too

thick to fit between the tank and the clamp on the racking assembly, install the racking fitting first, and then clamp the valve to it after

tightening.

Install the tube as directed by the side of the aseptic valve shown in Figure 12. This will allow you to use the handle as a guide to

determine the position of the racking arm when draining the beer or wine. The racking arm should initially be positioned horizontally

(below right).

FIGURE 11a FIGURE 11b FIGURE 12

Fig 13

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 8

Install the keg plain lid hatch as shown in Fig. 5. Pull the pressure relief valve to relieve any pressure and then invert

the keg. Remove the conical bottom and replace it with the keg bottom as per the previous instructions. Reinvert the

keg, connect a CO2 tting on the gas in post and purge the air from the top of the keg as described previously.

Pressurize the keg for carbonation and check for leaks at the band clamp, keg posts, and the lid hatch area. Correct as

needed. That’s it!!

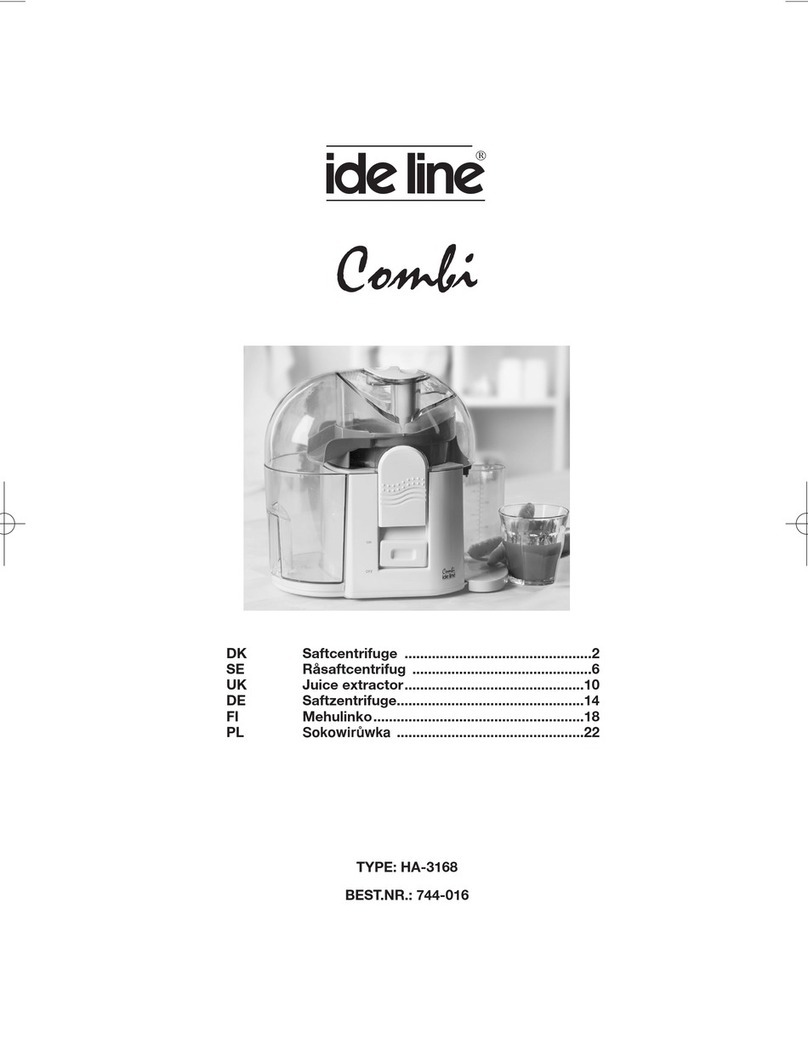

Optional wall hanger (BE-000933-01)

is available and sold separately

Optional NPT Spunding Valve is perfect for the

Blichmann Engineering™ Cornical™ Unitank

Accessories

After ensuring all of the yeast sediment has been expelled from your fermentor, you will need to measure the beer level in

the fermentor to ensure it is less than 5 gal so that it doesn’t spill when you remove the cone bottom. To do this connect the

sanitized ½” hose to the outlet of the racking arm with a clamp. Depressurize the fermentor by pulling the pressure relief

valve and lock it open. Then hold the open end of the hose above the top of the fermentor and slowly open the racking

valve. The beer level will equalize at the level inside of the tank. See Fig. 13. If the beer level is above the 5 gal mark

simply drain some beer from the racking valve hose. Then close both the racking and pressure relief valve and remove the

hose.

Cornical™ - V3 © Blichmann Engineering, LLC 2020

For replacement parts, visit: blichmannengineering.com/genuine-replacement-parts 9

Blichmann Engineering™Product Warranty

A. Limited Warranty

1. Blichmann Engineering warrants to the original purchaser that this product will be free from manufacturing defects in material and workmanship for a period of one (1) year from the date of purchase by the customer. Proof of

purchase is required. Blichmann Engineering’s obligation to repair or replace defective materials or workmanship is the sole obligation of Blichmann Engineering under this limited warranty.

2. This product is for home use only. The limited warranty covers only those defects that arise as a result of normal use of the product and does not cover any other problems, including, but not limited to, those that arise as a

result of:

a. Improper maintenance or modication;

b. Damage due to incorrect voltage or improper wiring by customer;

c. Operation outside of the product’s specications;

d. Carelessness or neglect to operate the product in accordance with instructions provided with the product;

e. Damaging the tamper label on the product;

f. Damage by over-tightening the fasteners;

g. Failure to follow cleaning and / or maintenance procedures; or

h. Exceeding published operational temperatures.

3. Blichmann Engineering reserves the right to request delivery of the defective component for inspection before processing the warranty claim. If Blichmann Engineering receives, during the applicable warranty period, notice

of a defect in any component that is covered by the warranty, Blichmann Engineering shall either repair or replace the defective component with a new or rebuilt component at Blichmann Engineering’s option.

4. Blichmann Engineering must be notied within seven (7) days of the delivery date of any shipping damage. Customer is responsible for shipping damage outside of this time period. Approval for return must be provided by

Blichmann Engineering prior to any return. Customer is responsible for keeping all original packaging material for warranty returns. Blichmann Engineering is not responsible for damage from improperly packaged warranty

returns, and these repair costs will be the sole responsibility of the customer. Shipping costs for warrantee returns are covered only for the contiguous United States.

5. Blichmann Engineering’s limited warranty is valid in any country where the product is distributed.

________________________________________

B. Limitations of Warranty

1. Any implied warranty that is found to arise by way of state or federal law, including any implied warranty of merchantability or any implied warranty of tness, is limited in duration to the terms of this limited warranty and is

limited in scope of coverage to this warranty. Blichmann Engineering disclaims any express or implied warranty, including any implied warranty of tness for a particular purpose or merchantability, on items excluded from

coverage as set forth in this limited warranty.

2. Blichmann Engineering makes no warranty of any nature beyond that contained in this limited warranty. No one has authority to enlarge, amend, or modify this limited warranty, and Blichmann Engineering does not authorize

anyone to create any other obligation for it regarding this product.

3. Blichmann Engineering is not responsible for any representation, promise, or warranty made by any independent dealer or other person beyond what is expressly stated in this limited warranty. Any selling or servicing dealer

is not Blichmann Engineering’s agent, but an independent entity.

________________________________________

C. Limitations of Liability

1. The remedies provided in this warranty are the customer’s sole and exclusive remedies.

2. Except for the obligations specically set forth in this warranty, in no event shall Blichmann Engineering be liable for direct, indirect, special, incidental, or consequential damages, whether based on contract, tort, or any other

legal theory and whether or not advised of the possibility of such damages.

3. This warranty does not cover, and in no event shall Blichmann Engineering be liable for, travel, lodging, or any other expense incurred due to manufacturing defects in material and workmanship, or any other reason.

4. Any performance of repairs after the warranty coverage period has expired or performance of repairs regarding anything excluded from coverage after this limited warranty shall be considered good-will repairs and they will

not alter the terms of this limited warranty, or extend any warranty coverage period.

5. Venue for any legal proceedings relating to or arising out of this warranty shall be in Tippecanoe County, Indiana, United States, which courts will have exclusive jurisdiction.

________________________________________

D. Local Law

1. This warranty gives the customer specic legal rights. The customer may also have other rights that vary from state to state in the United States or other countries.

2. To the extent that this warranty is inconsistent with local law, it shall be deemed modied, only to the extent necessary to be consistent with such local law.

This product uses FDA and/or NSF approved food grade materials anywhere the product touches the beverage.

Warning: This product contains or may contain chemical(s) known to the State of California to cause cancer, birth defects, or other reproductive harm.

Table of contents

Popular Kitchen Appliance manuals by other brands

Ide Line

Ide Line 744-016 user guide

Salton

Salton ELITE SDM051E Instructions and warranty

Culinaire

Culinaire CH.HC.U Specification, installation and operation manual

Whynter Elite

Whynter Elite Spectrum Lightshow BWR-545XS instruction manual

Ritter

Ritter markant 01 operating instructions

Bosch

Bosch MUM58920/05 instruction manual