Blindleistungsregler TSM-AT User manual

Dynamic Power Factor Correction

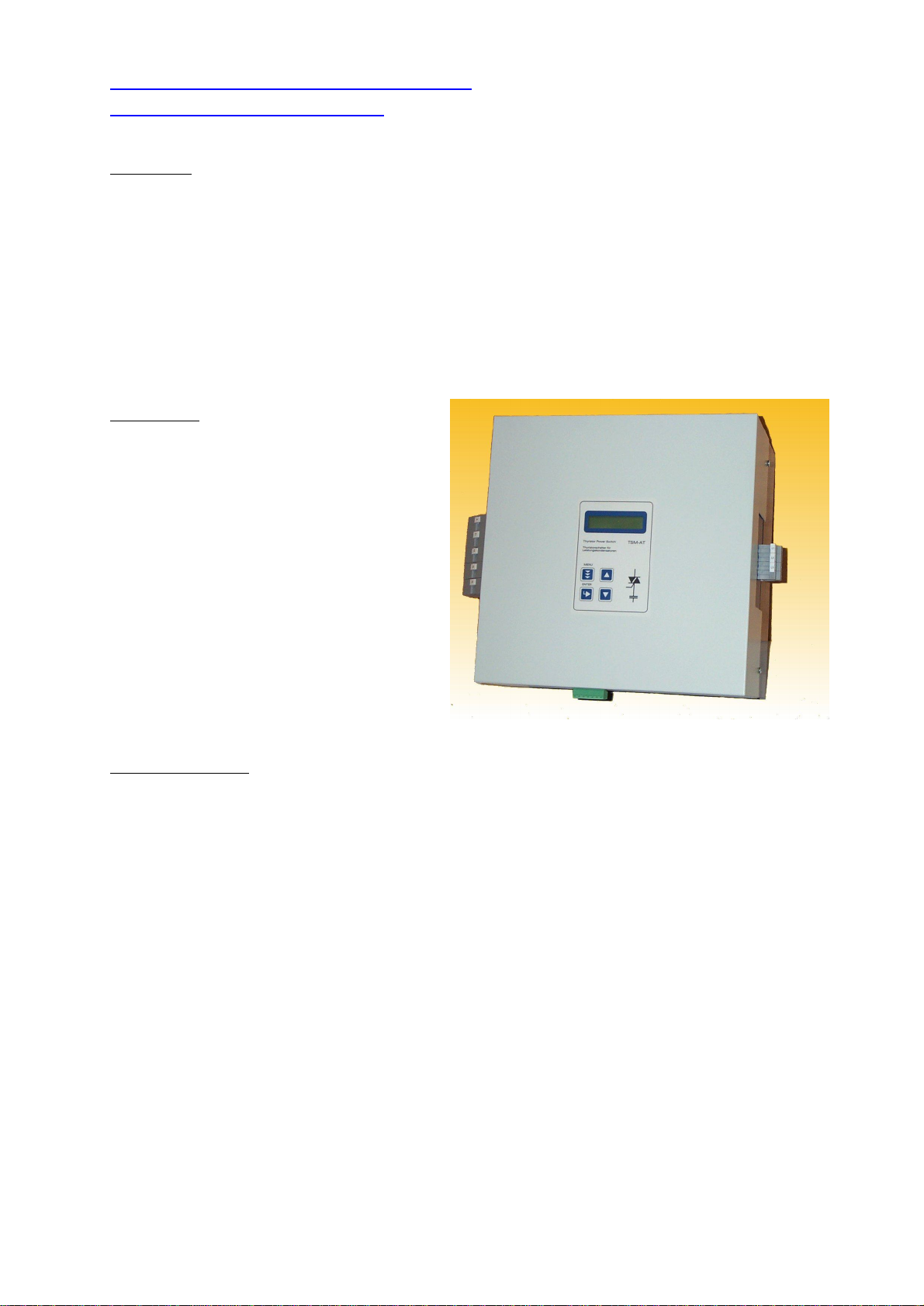

Thyristor Module TSM-AT

General:

Conventional systems for power factor correction are used to optimize the power factor and

reduce the level of harmonics in the net. The usage of new technologies in modern industry has

negative impacts on electrical power quality of the main supply networks, eg. frequent high load

fluctuations and harmonic oscillation. Excessive currents, increased losses and flickering will not

only influence the supply capacity but will also have a significant impact on the operation of

sensitive electronic devices. The solution for this are dynamic power factor correction systems.

With the TSM-AT module we provide the main component – „electronic switch“ – for dynamic

power factor correction. The TSM-AT is a fast electronically controlled, self-observing thyristor

switch for capacitive loads up to 100 kVAr, which is capable to switch PFC capacitors within a few

milliseconds as often as required.

Features:

-Real 3-phase switching

(usage only with single-phase capacitors

L-N)

-Output up to 120 kVAr at 690 V

-Usage for PFC-systems with and without

reactors (programmable)

-Connected load (output) programmable

-Easy programming for the individual

application via multi-lingual plain

language display

-Indication of all relevant parameters of

the grid

(voltage, current, temperature...)

-Alarm output and error message storage

.

Technical Data

Voltage max. 690V ( 3 x 400V L-N )

Max.power up to 120 kVAr at 690 V

up to 100 kVAr at 525 V

Parameter setting nominal voltage, degree of detuning, overcurrent, alarm temperature,

via display frequency, error message storage, delay time during cascading

Control features permanent monitoring of net voltage, phasing, capacitor current,

module temperature. Malfunction shown in plain language and evaluated;

former errors are stored in an error message storage

Display 3-phase indication of net voltage and capacitor current

temperature values and all parameters programmed can be retrieved

Controlling 10-24 VDC , internally DC-insulated; manual operation possible

Power circuit connection: three-pole via clamp (25qmm)

Losses Pv(in W)= 3.0 * I (in A) at 690V / 100 kVAr approx. 240W)

Fuses electronic fuse „superfast“ 160 A (NH00)

Dimensions 300 x 300 x 200 mm (w x h x d)

Description

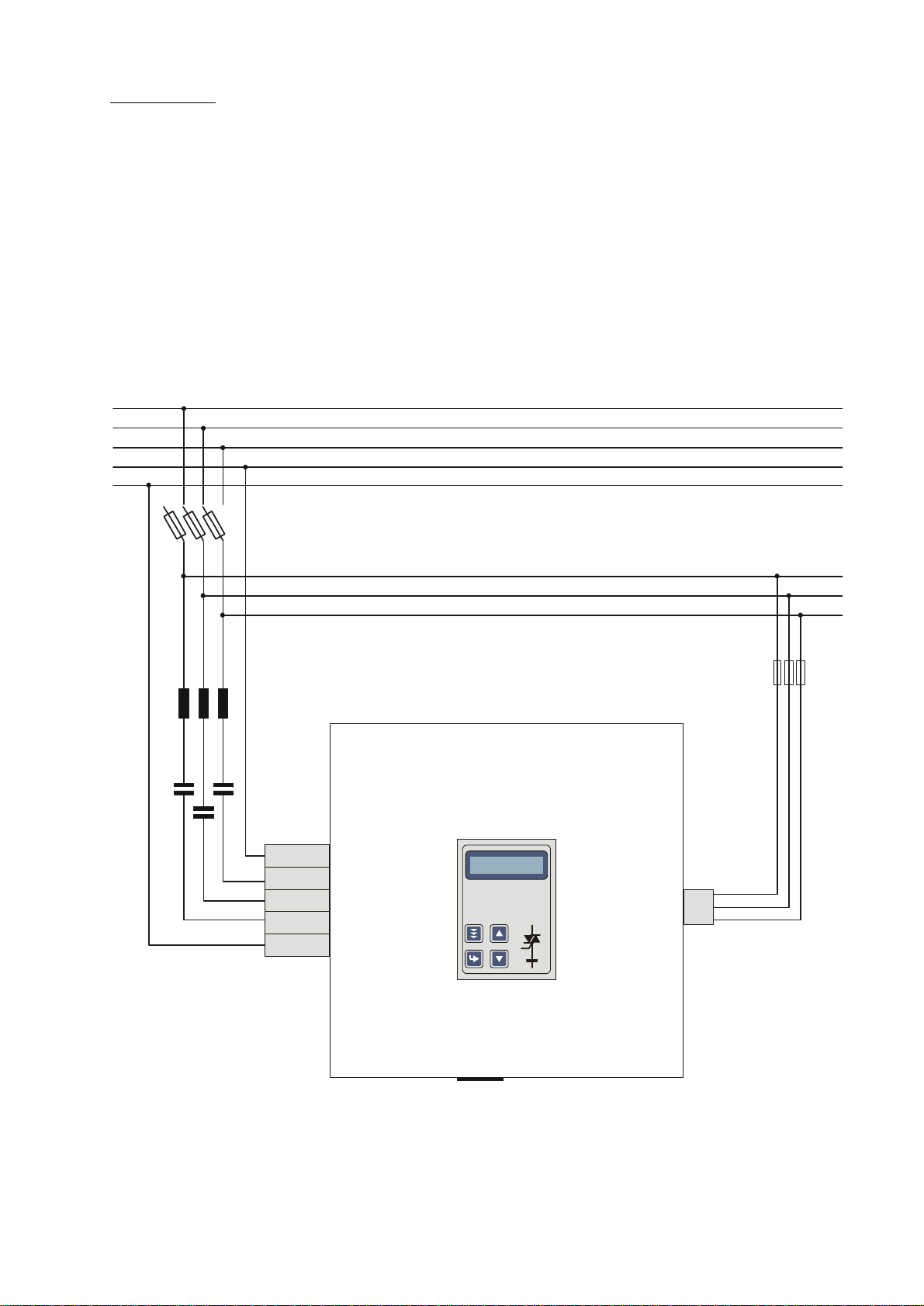

TSM-AT Thyristor-switches are used for dynamic PFC equipment. The connection is

made via three phases according to picture 1. Take care for a correct phase sequence!

(If the phase-sequence is not correct, the module will be blocked.)

Main-fuses have to be electronic-fuses (superfast) for protection of the semiconductor

components. Please observe the correct fuse rating.

Activation of the modules is done by a 10-24 VDC signal (by a dynamic reactive power

regulator) which is connected to terminals X3:1 and 2.

For cascading of several modules (for increase of the kVAr-output) parallel-connection is

possible. For additional modules, programming of delay time is possible.

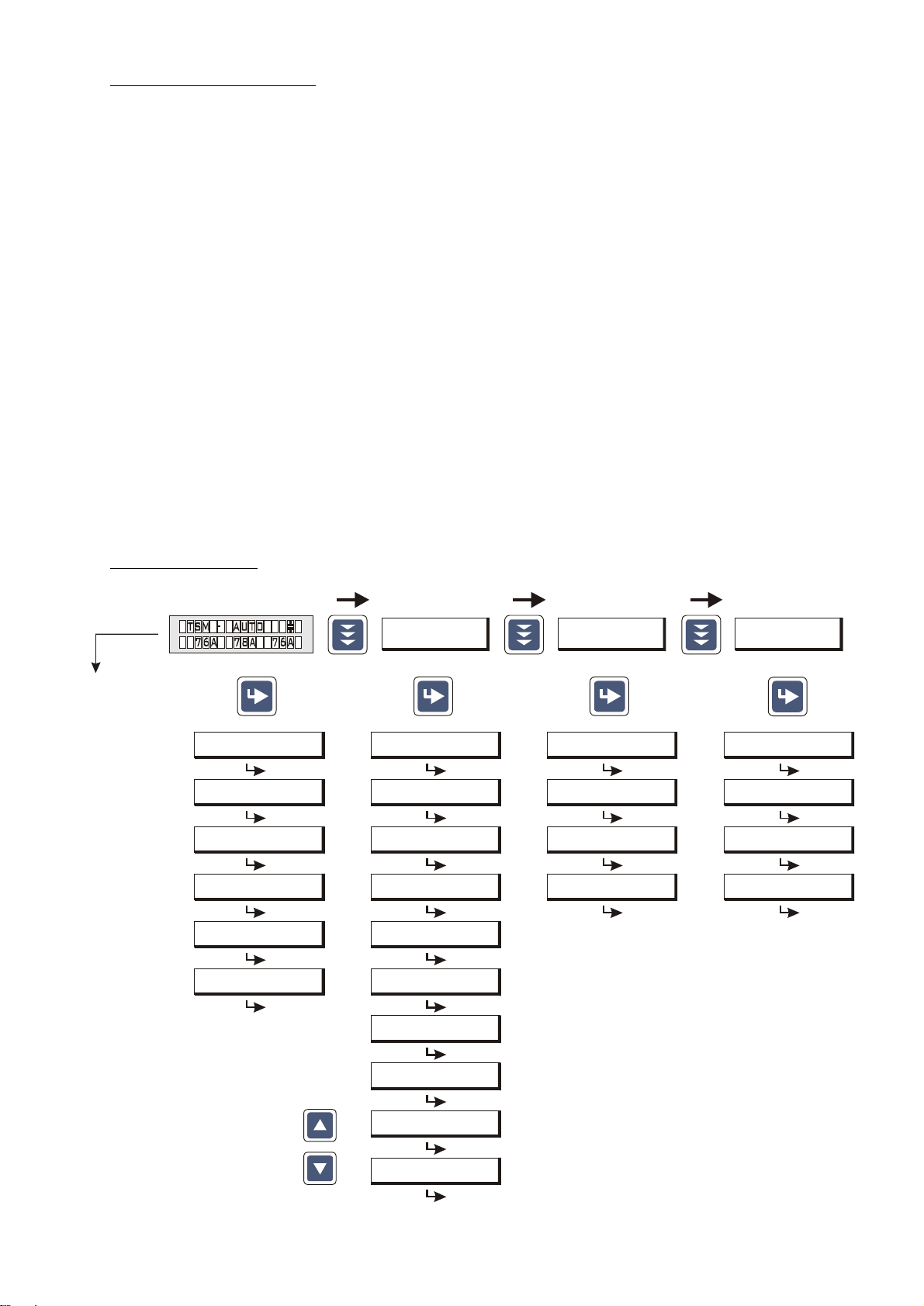

Pic. 1

C3

C2

C1

3x4AT

Control-Input:

1 activation signal - 12V

2 activation signal +12V

3 and 4 alarm output (zero-potential) max 250V,6A

5 and 6 n.c.

Ausschnitt

65x20 mm

T hy ris tor Po wer Swi tch

for capa citors

T hy ris torsch alte r für

Leistungskondensa toren

TSM-AT

ENTER

Display

Program

Service

1 2 3 4 5 6 7

L1

L2

L3

N

SL

Thyristor-switch TSM-AT

here: for 690V grid

3xC - star-connection

Fuses for power supply

NH00, superfast

Fuse for

controlvoltage

N

C3

C2

C1

SL

L1

L2

L3

Putting into operation

After connection of the module according to above instructions, it can put into

operation.

After applying up of net voltage (inserting of the branch fuse) the module is ready for

operation. No triggering signal should be connected! Charging of the capacitors is

indicated in the display by a momentarily blinking diode-symbol. The permanent diode-

symbol indicates the operational readiness of the TSM-AT. (In case a triggering signal is

active at the input of the TSM, this is indicated by the letter “X” in the display next to

the diode-symbol.

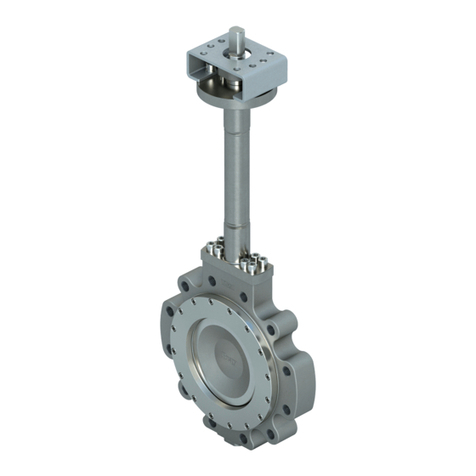

The menu item “programming” is activated via the menu-button. The parameterizing of

the module is done here (see operation diagram). Change of values is done via the

arrow buttons ; safe with “ENTER”. After entry of all parameters, the module is

ready for operation (automatic operation).

During automatic operation, the module can be turned ON and OFF via arrow buttons

manually (manual operation). The operation mode is indicated in the display

(AUTO/HAND).

The ON-mode of the module is indicated in the display by a capacitor-symbol.

Operating diagram

Programming Expert mode

Fault memory

1 PASSWORD ????

( 0*** )

2 BASIC SETTINGS NEW

[ NO ]

3 PROGRAM LOCK

[ NO ]

4 SWITCHING ON-DELAY

[ 0 ] PERIODS

1 VOLTAGE

400V 400V 400V

2 TEMPERATURE

45°C

3 MODUL ADRESS

1

4 MODUL-VOLTAGE

5 CURRENT

SOFTWARE VERSION

TSM VE 1.0

1 LANGUAGE

[ ENGLISH ] 1. ERROR L1 L2 L3

UNDERVOLTAGE

2. ERROR

up to. 16 ERRORs

Delete ERROR ?

[ NO ]

2 MODUL ADRESS

[ 1 ]

8 ALARM RELAY

[ ERROR ]

CONTRAST

**** 9 ****

BASIC SETTINGS

[ NO ]

Programming:

Changing of

values by

buttons

bei Störung erfolgt

Anzeige “TSM-ERROR”

4 VERDROSSELUNG

[ 7 ] %

5 OVERCURRENT

[ 30 ] %

7 FREQUENCY

[ 50 ] Hz

6 TEMP-ALERT

[ 80 ] °C

3 POWER

[ 50 ] kvar

BACK TO 2

BACK TO 1

Automatikbetrieb

BACK TO 1

BACK TO 1

Following ERROR-messages are possible:

- UNDERVOLTAGE

- OVERVOLTAGE

- OVERCURRENT

- UNDERCURRENT

- THYRISTOR FAULT

- TEMPERATURE FAULT (Sensor)

- OVERTEMPERATUR

Control functions / Alarm messages

The TSM-AT observes permanently:

- voltage (availability & value)

- phase sequence

- capacitor rated current

- temperature of the power switches

When voltage, current or temperature-problems occur, the TSM turns-off and shows the

Error at the display.

At the same time, the error-description is stored in the error storage register (max. 16).

In the menu item “Error storage” the errors can be read out. So it is possible to

recognize also short-term malfunctions afterwards.

By supervising the capacitor current it is possible to identify dangerous operating

conditions, such as harmonic distortion. High current harmonics may cause the

destruction of the connected PFC capacitor. Over currents are measured by an

integrated measuring system. The module turns-off as long as the overload exists.

The highly advanced measuring circuit for self-observing of the thyristor switch protects

the capacitor and the application as well.

The alarm-signal of the temperature trigger switches-off the corresponding capacitor

branch. After disconnection the thyristor switch will cool down again. If the temperature

drops below the preset threshold value, the module will reconnect.

Errors are indicated via relay contact and visualized via Display.

All error messages are summarized as a centralized error message and the output

occurs via a relay contact. In the programming menu it can be selected if this output

should be stored or whether it should only be displayed during the malfunction.

NOTE THE FOLLOWING INSTRUCTIONS !

The power capacitors are permanent on high voltage ( up to 1500 VDC )

EVEN IF THE TSM-AT IS SWITCHED OFF !!

Please follow the instructions:

Don’t touch live parts in the PFC equipment !!

Warning signs in the equipment required!!

Wait 10 minutes after the main switch is turned off – until the voltage in the

system is down to an uncritical value.

In systems (690V grid) you need single-phase capacitors with a min. voltage of

440V! All capacitors have to switch in star-circuit. (L-N)

In systems (525V grid) you need single-phase capacitors with a min. voltage of

380V ! All capacitors have to switch in star-circuit. (L-N)

In dynamical PFC systems discharge reactors cannot be used!

( this would be a shortcut of the high-voltage DC )

In PFC systems without filter circuit reactors current limiting reactors are required (

e.g. BD-100 ) for the TSM.

For short circuit protection superfast electronic fuses for protection of the thyristor

are required, standard HRC fuses are not suitable

Popular Control Unit manuals by other brands

Bray

Bray McCANNALOK Series Installation, operation and maintenance manual

Siemens

Siemens SIRIUS ACT 3SU18 N Series Original operating instructions

King gates

King gates Star 2230 instruction manual

Long Range Systems

Long Range Systems Butler II Quick setup & operation

Hayward

Hayward GLX-PCB-PRO Replacement manual

Danfoss

Danfoss VLT HVAC Drive FC 102 instruction manual