Sit 630 Eurosit Technical manual

L

630

EUROSIT

Read the instructions before use. This control must

be

installed

in

accordance with the rules

in

force.

L

English

.-.

T

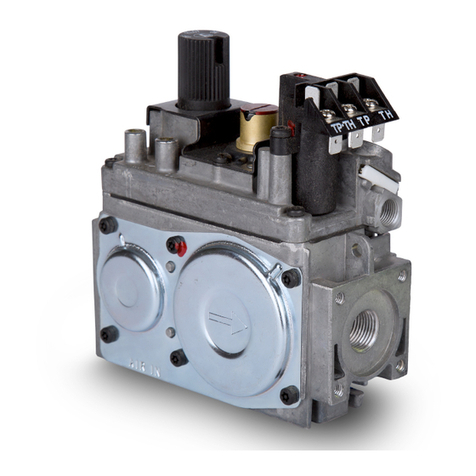

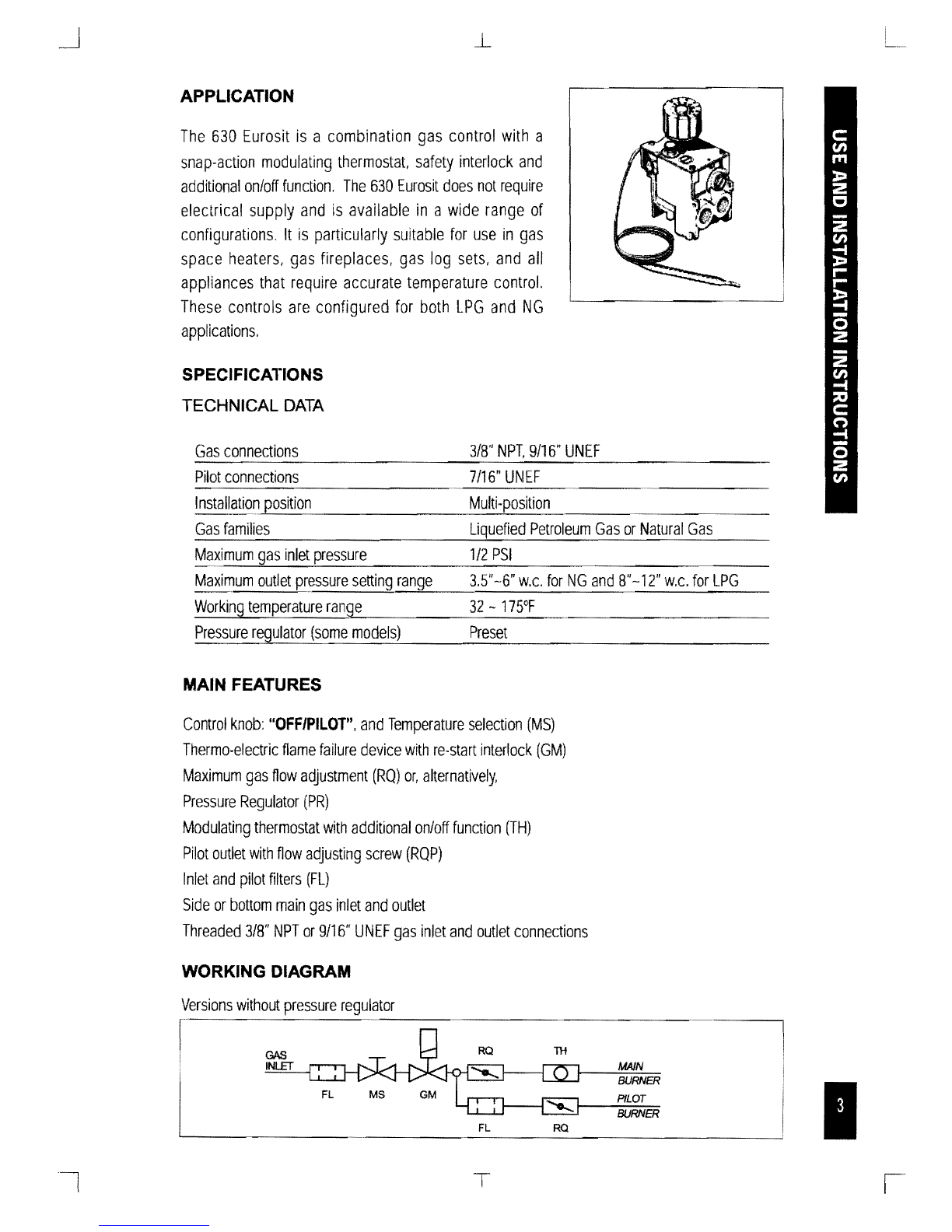

APPLICATION

The

630

Eurosit

is

a

combination

gas

control

with

a

snap-action

modulating

thermostat,

safety

interlock

and

additional

onloff

function.

The

630

Eurosit

does

not

require

electrical

supply

and

is

available

in

a

wide

range

of

configurations.

It

is

particularly

suitable

for

use

in

gas

space

heaters,

gas

fireplaces,

gas

log

sets,

and

all

appliances

that

require

accurate

temperature

control.

These

controls

are

configured

for

both

LPG

and

NG

applications.

SPECIFICATIONS

TECHNICAL

DATA

Gas

connections

3/8"

9/16"

UNEF

Pilot

connections

7/16"

UNEF

Installation

position

Multi-position

~--------------------~-------------------------

Gas

families

Petroleum

Gas

or

Natural

Gas

Maximum

1/2

PSI

Maximum

outlet

pressure

setting

range

3.5"

-6"

w.c.

for

NG

and

8"-12"

w.c.

for

LPG

Working

temperature

range

32

-

175°F

Pressure

regulator

(some

models)

Preset

MAIN FEATURES

Control

knob:

"OFF/PILOT",

and

Temperature

selection

(MS)

Thermo-electric

name

failure

device

with

re-start

interlock

(GM)

Maximum

gas

How

adjustment

(RQ)

or,

alternatively,

Pressure

Regulator

(PR)

Modulating

thermostat

with

additional

onloff

function

(TH)

Pilot

outlet

with

How

adjusting

screw

(RQP)

Inlet

and

pilot

filters

(FL)

Side

or

bottom

main

gas

inlet

and

outlet

Threaded

3/8"

NPT

or

9/16"

lINEF

gas

inlet

and

outlet

connections

WORKING DIAGRAM

Versions

without

pressure

regulator

MAIN

BURNER

PILOT

BURNER

FL

RQ

Versions

with

pressure

regulator

TH

~

MAJN

----:::eu;"='RN"-::'S=R

FL MS GM '0....

t-_....:R~IL~OT~

BURNER

FL

RQ

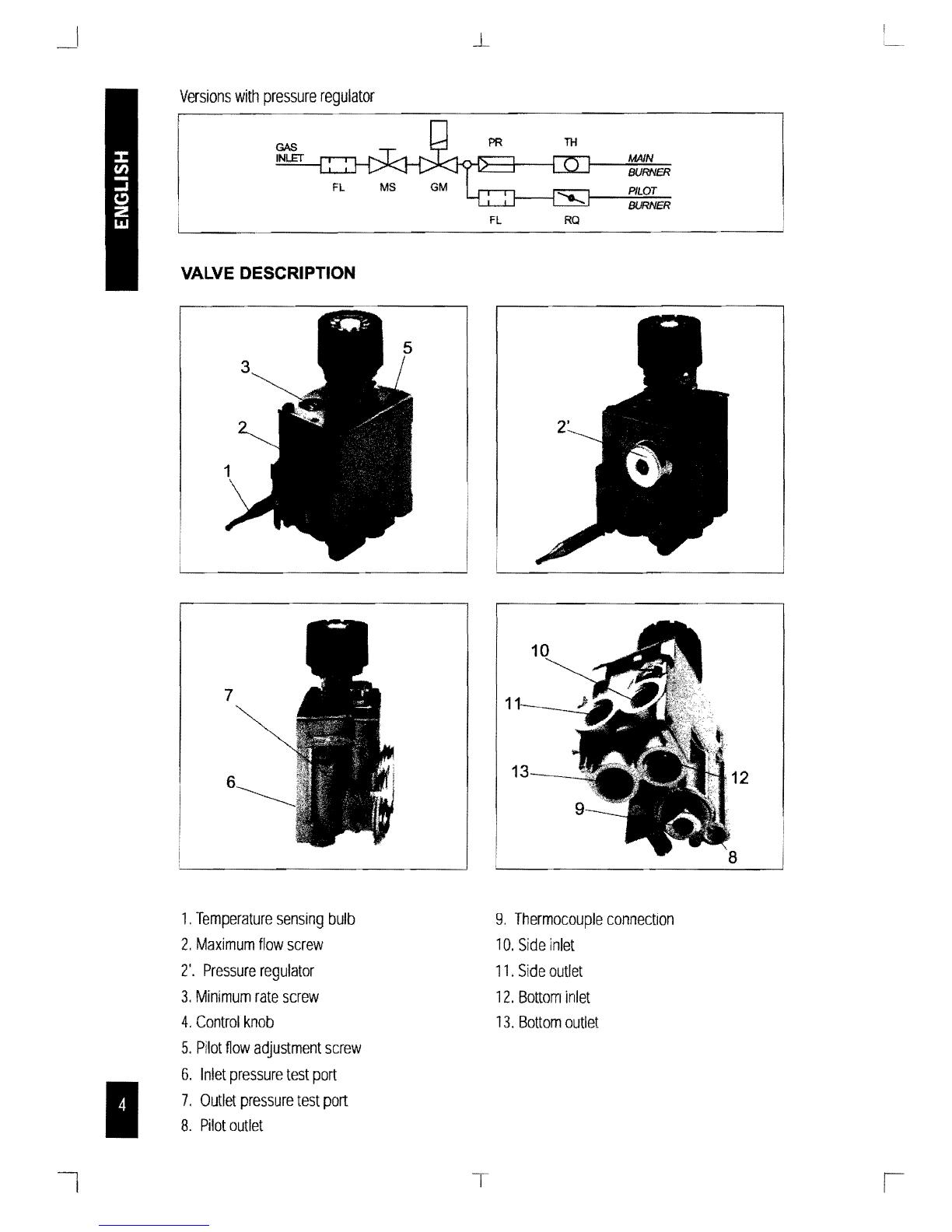

VALVE DESCRIPTION

1.

Temperature

sensing

bulb

2.

Maximum

flow

screw

2'.

Pressure

regulator

3.

Minimum

rate

screw

4.

Control

knob

5.

Pilot

fiow

adjustment

screw

6.

Inlet

pressure

test

port

7.

Outlet

pressure

test

port

8.

Pilot

outlet

9.

Thermocouple

connection

10.

Side

inlet

11.

Side

outlet

12.

Bottom

inlet

13.

Bottom

outlet

L

THERMOSTAT REGULATION SPECIFICATIONS

Thermostat

Features

Thermostatic

Range

55.100

of

55.118

of

a

2.7

4.5

i b c

I

2.7

1.B

4.5

2.7

b

Temperature

c a

eSTOP:

Do

not

install,

replace,

or

in

any

way

modify

the

gas

valve

or

the

appliance,

unless

CERTIFIED

and

QUALIFIED

as

a

Gas

Appliance

Service

Technician

on

the

appliance

this

valve

is

used

on.

READ

AND

FOLLOW

ALL

INSTRUCTIONS,

INSTALLATION

Valve

configuration

inspection

Min

Rate

Screw

The

630

Eurosit

can

have

one

inlet

and

one

outlet

plugged.

Inspect

the

control

to

determine

which

inlet

and

outlet

are

plugged.

The

plugs

use

o·ring

seals

and

are

made

of

brass,

The

replacement

control

must

have

the

same

inlet

and

outlet

plugged

as

the

original

control.

Use

a

5/16"

Allen

key

to

remove

and

tigten

the

plug.

The

replacement

630

Eurosit

has

an

On/Off

modulating

plug

(fig,

A)

installed.

To

achieve

similar

performance

as

the

original

control.

remove

the

plug

in

the

replacement

control

using

a

Flathead

Screwdriver

and

set

aside.

Remove

the

Min

Rate

Screw

(fig.

B)

from

the

original

control

and

install

it

into

the

replacement

control

in

the

same

location.

When

installation

of

this

product

begins."

1.

Read

all

of

these

instructions

carefully.

Failure

to

follow

instructionscould

damage

the

product

or

cause

a

dangerous

condition.

2.

Check

the

ratings

given

in

the

instructions

and

on

the

appliance

to

make

certain

that

the

control

is

suitable

for

your

application,

3.

All

operations

of

installation,

calibration,

conversion

and

regulation

must

be

undertaken

exclusively

by

qualified

personnel

following

the

instruction

speCified

in

this

catalog

and

those

in

the

instruction

manual

of

the

appliance

in

which

the

valve

is

installed.

4,

After

installation

is

complete,

verify

that

the

appliance

operates

as

indicated

in

these

instructions.

T

_I

L

WARNING:

Fire

or

Explosion

Hazard.

Can

cause

property

damage,

severe

iruury

or

death.

Follow

these

instructions

completely.

1.

Turn

off

gas

supply

at

the

appliance

service

valve

before

installation,

and

perform

a

Gas

Leak

Test

after

the

installation

is

completed.

2.

Always

install

the

sediment

trap

in

the

gas

supply

line

to

prevent

contamination

of

the

gas

control.

3.

Do

not

force

the

control

knob.

Use

only

your

hand

to

turn

the

knob.

If

the

knob

does

not

move

by

hand,

the

valve

should

be

replaced

by

a

trained

service

technician.

WARNING:

Oxygen

Depletion

Hazard.

Can

cause

injury

or

death

by

asphyxiation.

00

not

use

valves

for

vented

appliances

on

unvented

or

vent

free

appliances.

00

not

use

valves

for

unvented

or

vent

free

appliances

on

vented

appliances.

&.

CAU'nON

Electrical

shock

or

equipment

damage

hazard.

Can

shock

individuals

or

short

equipment

circuitry.

Make

sure

to

disconnect

all

electrical

supplies

before

beginning

the

installation

process.

IMPORTANT

-

These

gas

controls

are

shipped

with

anti-contamination

seals

over

inlets

and

outlets.

-

Do

not

remove

the

seals

until

ready

for

connection

to

piping.

-

Appliance

manufacturer's

instructions

supercede

any

instructions

listed

in

this

instruction

book.

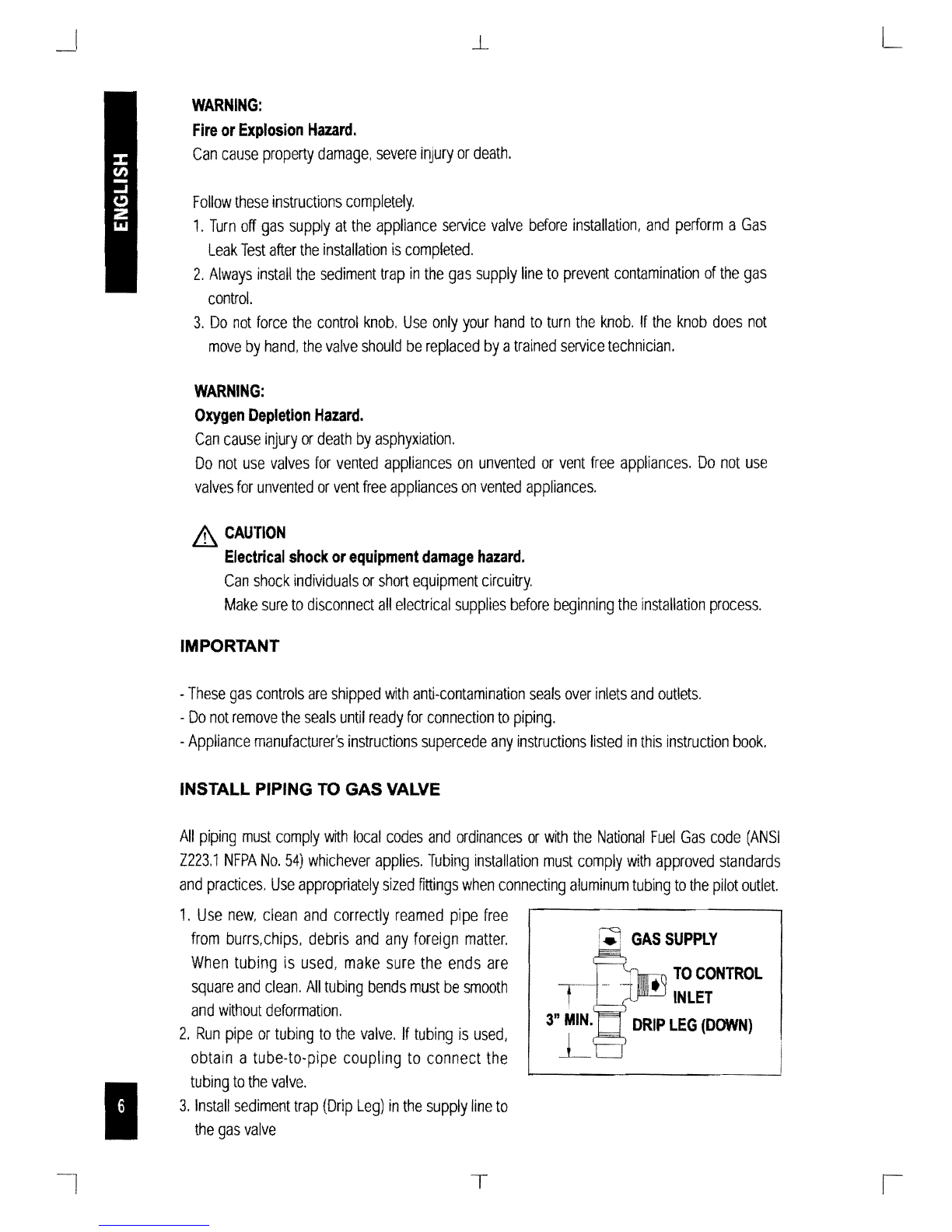

INSTALL PIPING TO

GAS

VALVE

All

piping

must

comply

with

local

codes

and

ordinances

or

with

the

National

Fuel

Gas

code

(ANSI

Z223.1

NFPA

No.

54)

whichever

applies.

Tubing

installation

must

comply

with

approved

standards

and

practices.

Use

appropriately

sized

fittings

when

connecting

aluminum

tubing

to

the

pilot

outlet.

1.

Use

new,

clean

and

correctly

reamed

pipe

free

from

burrs,chips,

debris

and

any

foreign

matter.

When

tUbing

is

used,

make

sure

the

ends

are

square

and

clean.

All

tubing

bends

must

be

smooth

and

without

deformation.

2.

Run

pipe

or

tubing

to

the

valve.

If

tubing

is

used,

obtain

a

tube-to-pipe

coupling

to

connect

the

tubing

to

the

valve.

3.

Install

sediment

trap

(Drip

Leg)

in

the

supply

line

to

the

gas

valve

~

GAS

SUPPLY

INLET

•

TOCONTROL

T

3"

MIN.

DRIP

LEG

(DOWN)

L

T

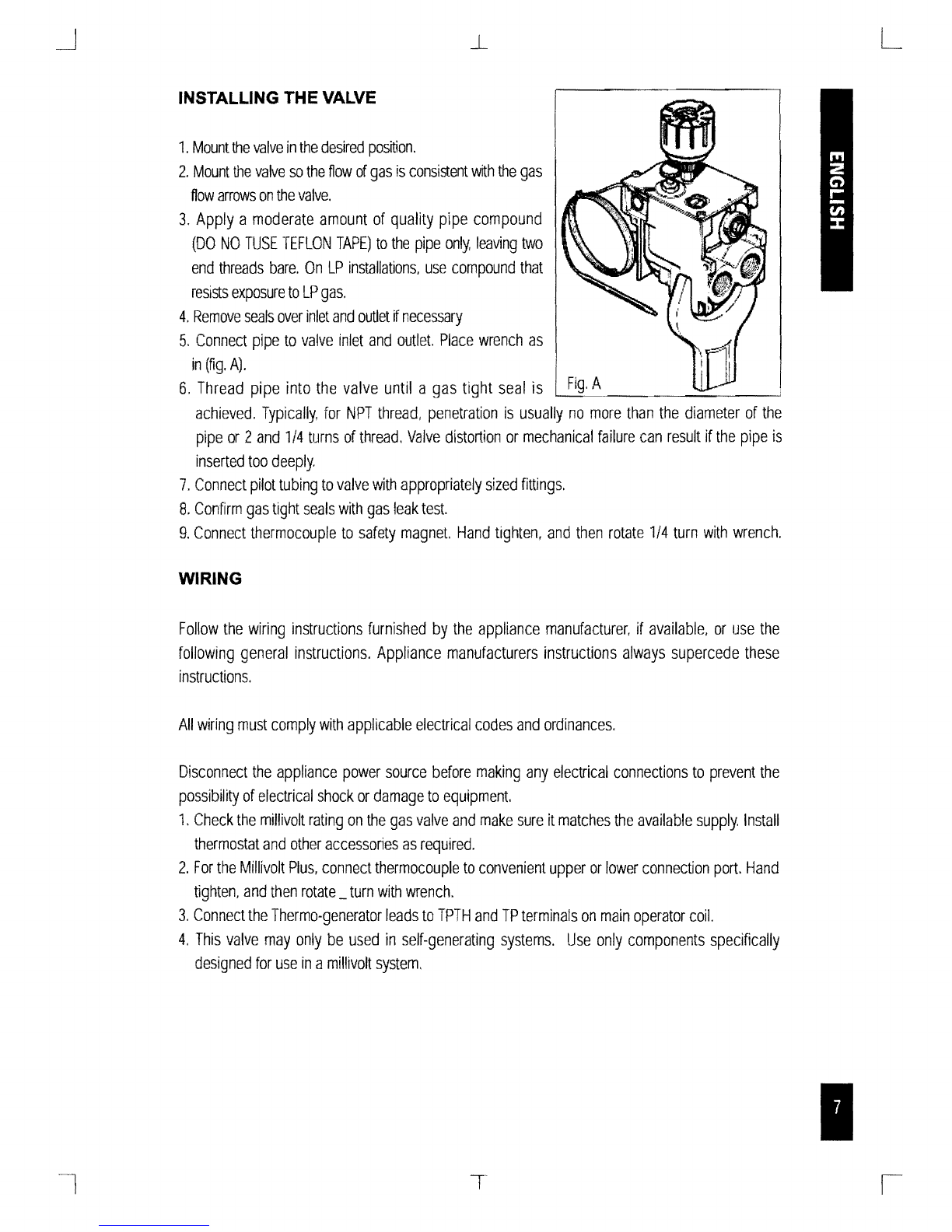

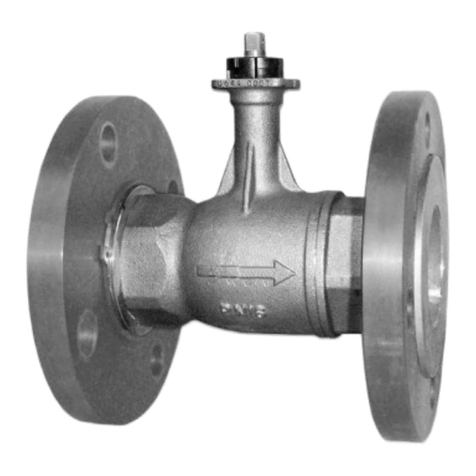

INSTALLING THE VALVE

1.

Mount

the

valve

in

the

desired

position.

2.

Mount

the

valve

so

the

flow

of

gas

is

consistent

with

the

gas

flow

arrows

on

the

valve.

3.

Apply

a

moderate

amount

of

quality

pipe

compound

(DO

NO

TUSE

TEFLON

TAPE)

to

the

pipe

only,

leaving

two

end

threads

bare.

On

LP

installations,

use

compound

that

resists

exposure

to

LP

gas.

4.

Remove

seals

over

inlet

and

outlet

if

necessary

5.

Connect

pipe

to

valve

inlet

and

outlet.

Place

wrench

as

in

(fig.

A).

6.

Thread

pipe

into

the

valve

until

a

gas

tight

seal

is

achieved.

Typically.

for

NPT

thread,

penetration

is

usually

no

more

than

the

diameter

of

the

pipe

or

2

and

1/4

turns

of

thread.

Valve

distortion

or

mechanical

failure

can

result

if

the

pipe

is

inserted

too

deeply.

7.

Connect

pilot

tUbing

to

valve

with

appropriately

sized

fittings.

8.

Confirm

gas

tight

seals

with

gas

leak

test.

g.

Connect

thermocouple

to

safety

magnet.

Hand

tighten,

and

then

rotate

1/4

turn

with

wrench.

WIRING

Follow

the

wiring

instructions

furnished

by

the

appliance

manufacturer,

if

available,

or

use

the

following

general

instructions.

Appliance

manufacturers

instructions

always

supercede

these

instructions.

All

wiring

must

comply

with

applicable

electrical

codes

and

ordinances.

Disconnect

the

appliance

power

source

before

making

any

electrical

connections

to

prevent

the

possibility

of

electrical

shock

or

damage

to

equipment.

1.

Check

the

millivolt

rating

on

the

gas

valve

and

make

sure

it

matches

the

available

supply.

Install

thermostat

and

other

accessories

as

required.

2.

For

the

Millivolt

Plus,

connect

thermocouple

to

convenient

upper

or

lower

connection

port.

Hand

tighten,

and

then

rotate

_

turn

with

wrench.

3.

Connect

the

Thermo-generator

leads

to

TPTH

and

TP

terminals

on

main

operator

coil.

4.

This

valve

may

only

be

used

in

self-generating

systems.

Use

only

components

specifically

designed

for

use

in

a

millivolt

system.

L

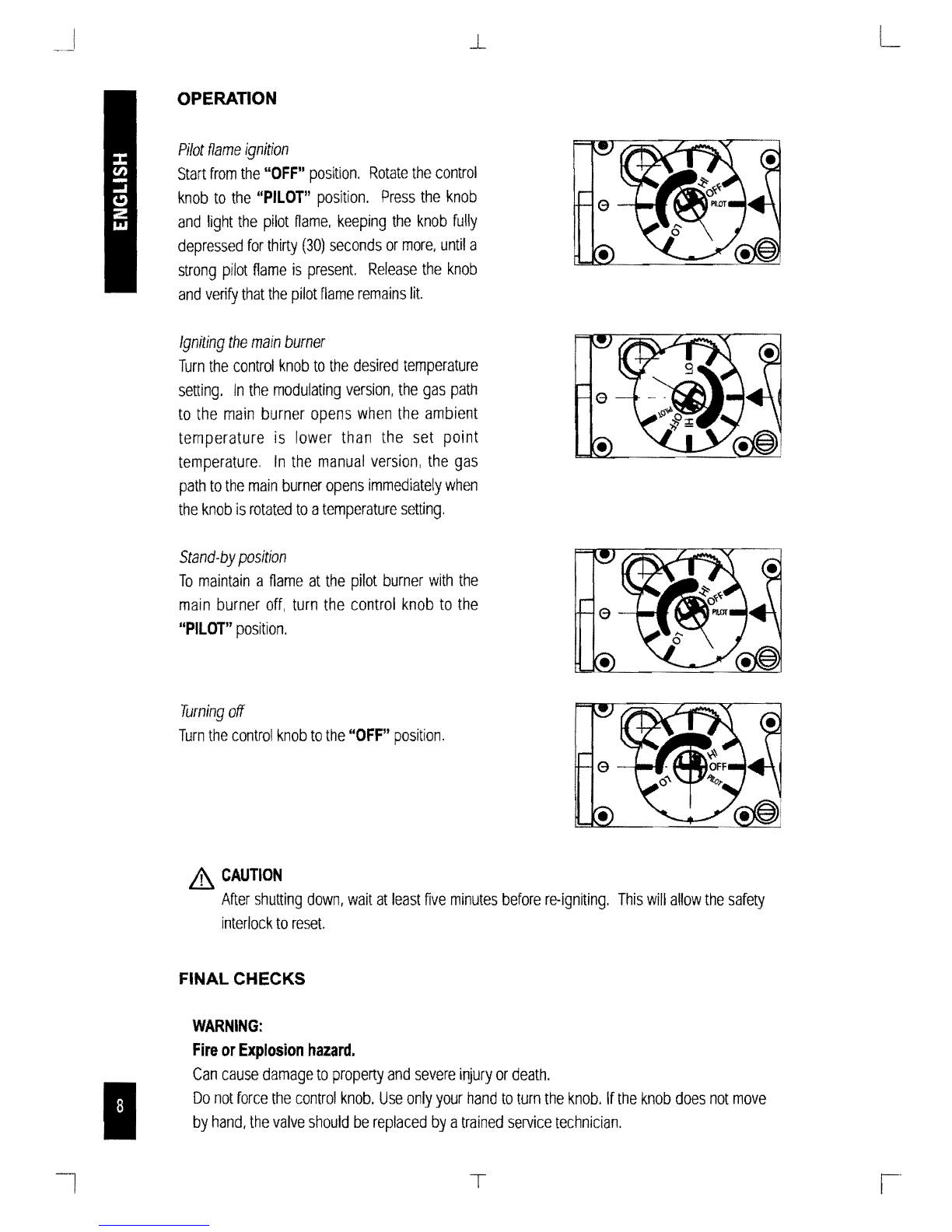

OPERATION

Pilot

flame

ignition

Start

from

the

"OFF"

position.

Rotate

the

control

knob

to

the

"PILOT"

position.

Press

the

knob

and

light

the

pilot

name.

keeping

the

knob

fully

depressed

for

thirty

(30)

seconds

or

more,

until

a

strong

pilot

flame

is

present.

Release

the

knob

and

verify

that

the

pilot

flame

remains

lit.

Igniting

the

main

burner

Turn

the

control

knob

to

the

desired

temperature

setting.

In

the

modulating

version.

the

gas

path

to

the

main

burner

opens

when

the

ambient

temperature

is

lower

than

the

set

point

temperature.

In

the

manual

version,

the

gas

path

to

the

main

burner

opens

immediately

when

the

knob

is

rotated

to

a

temperature

setting.

Stand-by

position

To

maintain

a

flame

at

the

pilot

burner

with

the

main

burner

off.

turn

the

control

knob

to

the

"PILOT"

position.

Turning

off

Turn

the

control

knob

to

the

"OFF"

position.

&

CAUTION

After

shutting

down,

wait

at

least

five

minutes

before

re-igniting.

This

will

allow

the

safety

interlock

to

reset.

FINAL CHECKS

WARNING:

Fire

or

Explosion

hazard.

Can

cause

damage

to

property

and

severe

injury

or

death.

Do

not

force

the

control

knob.

Use

only

your

hand

to

turn

the

knob.

If

the

knob

does

not

move

by

hand,

the

valve

should

be

replaced

by

a

trained

service

technician.

PERFORM GAS LEAK TEST

WARNING:

Stand

away

from

the

main

burner

while

lighting.

Hidden

gas

leaks

can

cause

Hashbacks

in

the

appliance

area.

Check

for

gas

leaks

with

rich

soap

and

water

solution

any

time

work

is

done

on

a

gas

system.

GAS LEAK TEST

o

Using

a

solution

of

soapy

water,

paint

the

piping

connections

which

are

upstream

of

the

control.

The

presence

of

bubbles

indicate

a

gas

leak

is

present.

o

If

a

leak

is

detected,

tighten

the

pipe

connections

and

repeat

leak

test.

o

Light

the

main

burner.

o

With

the

main

burner

in

operation,

paint

all

piping

connections

from

the

valve

with

a

soap

and

water

solution.

o

If

another

leak

is

detected,

tighten

the

connection.

o

If

after

tightening

the

connections

the

leak

is

still

present.

replace

the

leaky

part

and,

or

valve.

Shut

off

the

main

gas

supply

before

attempting

replacement

of

parts

or

the

valve.

o

Using

the

soap

and

water

solution

test

the

pressure

test

ports

and

min

rate

screw

to

verify

that

no

leak

is

present.

o

If

a

leak

is

detected

tighten

the

screw

and

retest.

-

If

after

tightening

the

pressure

test

port

or

min

rate

screw

the

leak

is

still

present

shut

off

main

gas

supply

and

replace

the

valve.

SHUTDOWN PERFORMANCE TEST

WARNING:

Fire

or

Explosion

Hazard.

Can

cause

severe

irtiury

or

death.

Perform

the

safety

shutdown

check

any

time

work

is

done

on

a

gas

system.

1.

Place

the

appliance

in

operation.

The

pilot

and

main

burners

should

be

lit.

2.

Place

gas

control

knob

in

"PILOT"

position.

Main

burner

should

extinguish

and

pilot

should

remain

lit.

3.

Extinguish

pilot

Hame.

Pilot

gas

safety

shutoff

proves

complete

shutdown

due

to

the

fact

the

safety

shutoff

valve

prohibits

main

burner

and

pilot

gas

How.

4.

Wait

at

least

five

minutes

for

the

safety

magnet

to

reset

and

residual

gas

to

clear

from

the

combustion

chamber.

S.

Relight

pilot

burner

and

operate

the

system

through

one

complete

cycle

to

ensure

all

functions

operate

correctly.

MAINTENANCE

This valve

is

not field serviceable. There are

no

replaceable parts.

Do

not

disassemble,

or

attempt replacement of any parts

on

or

in

the valve.

Improper adjustment or tampering with settings can result in severe

injury or death.

ACCESSORIES

3/~sealing

pl~g

fo!

unused

inlets

and

outlets

(Typically

2

per

valve)

0.972.058

for

pilot

burner

connections

for

1/4"

0.958.042

Disc

adaptor

for

remote

control

0.997.209

Other

accessories

available

on

request

T

Other manuals for 630 Eurosit

2

Table of contents

Other Sit Control Unit manuals

Popular Control Unit manuals by other brands

Telcoma

Telcoma T201 Instructions for installing

Watts

Watts AMES 960GD-15-17 Installation, operation and maintenance

jbc

jbc DMU instruction manual

QUNDIS

QUNDIS Q Water 5.5 Mounting and installation instructions

Advantech

Advantech PCM-3347 Series user manual

Azbil

Azbil Actival VY5302C Specifications & instructions