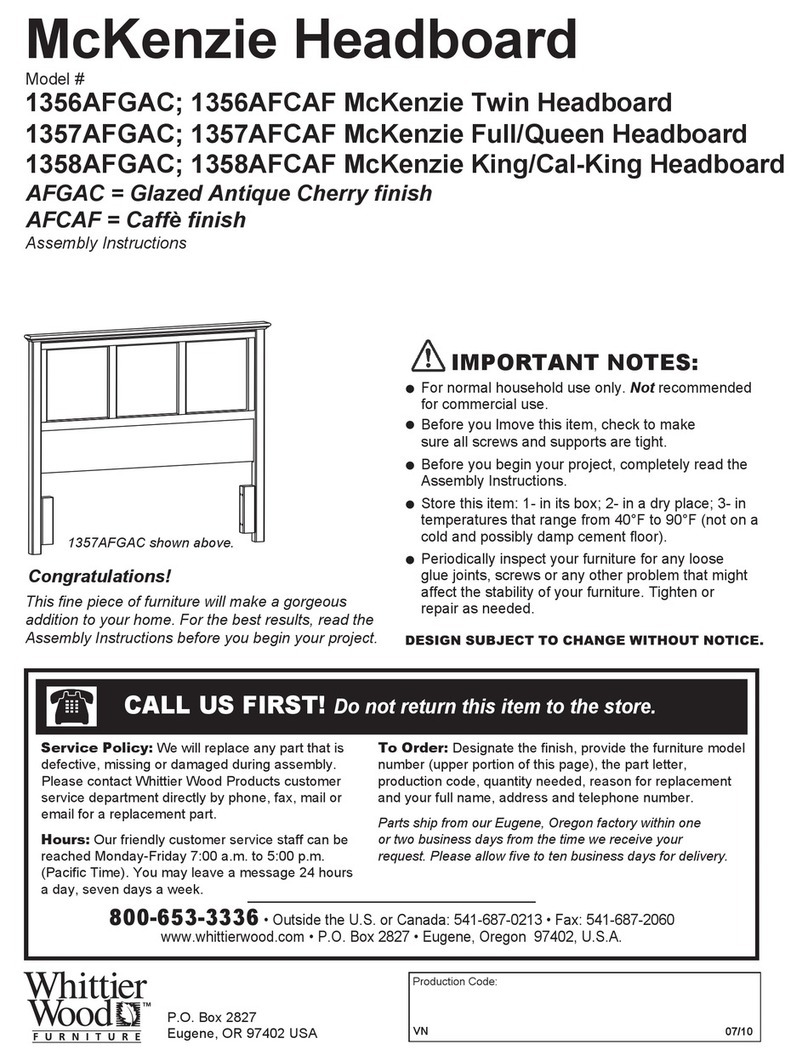

Spacer blocks are used to project

the installation brackets away from

the mounting surface when

additional shade clearance

is needed. Spacer blocks are

usually used when the shade is

mounted above the trim.

Each spacer block increases

clearance by 3/8”; use a maximum

of two per installation bracket.

Check that your installation screws are long enough to securely

attach the installation bracket and the spacer blocks.

Make sure the tops of the installation brackets are perfectly

horizontal and aligned at the same height before tightening

the screws. Please refer back to Section D for details.

With inside mount applications, one installation

screw is used through the top of each

installation bracket into the underside of

the top of the window frame.

If more than two brackets are required,

additional brackets are spaced evenly between

the two end brackets. Please refer back to

Section D for details.

To attach the brackets, the flat surface of the top frame must be at least 1”

deep. If less than 1” deep swivel brackets are required.

GETTING STARTED

A

THE TOOLS

B

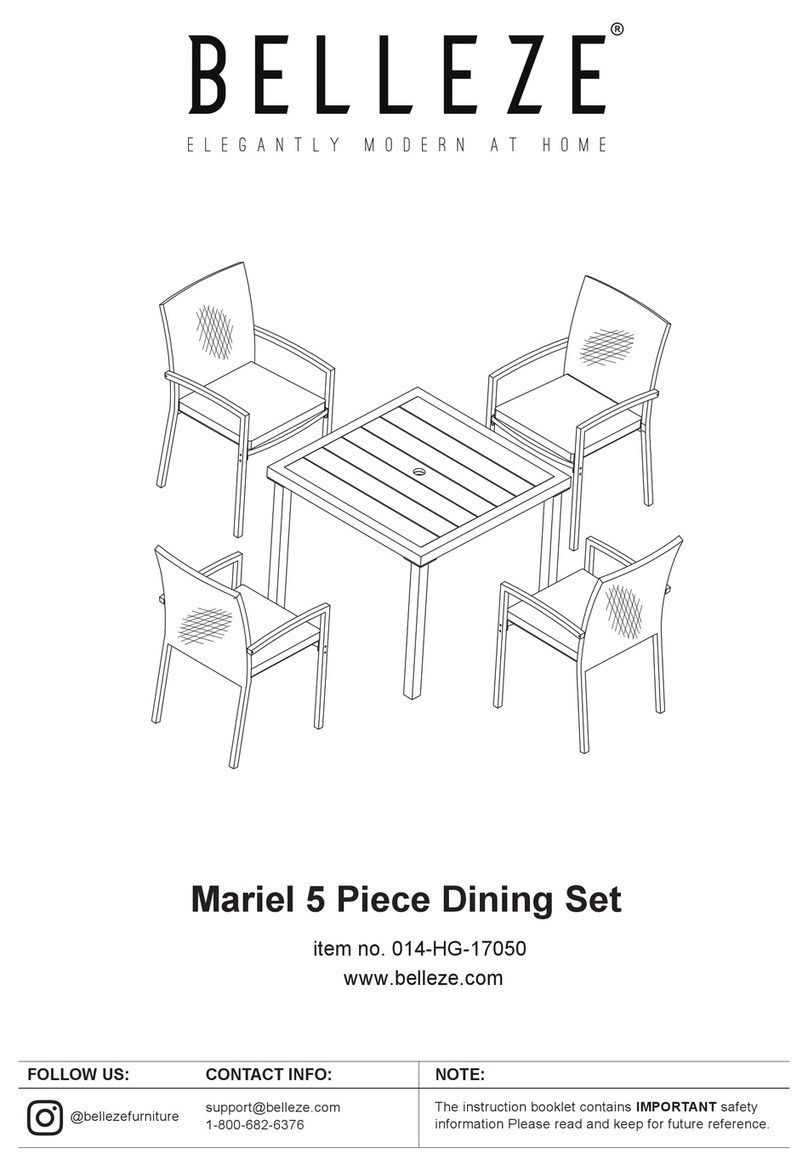

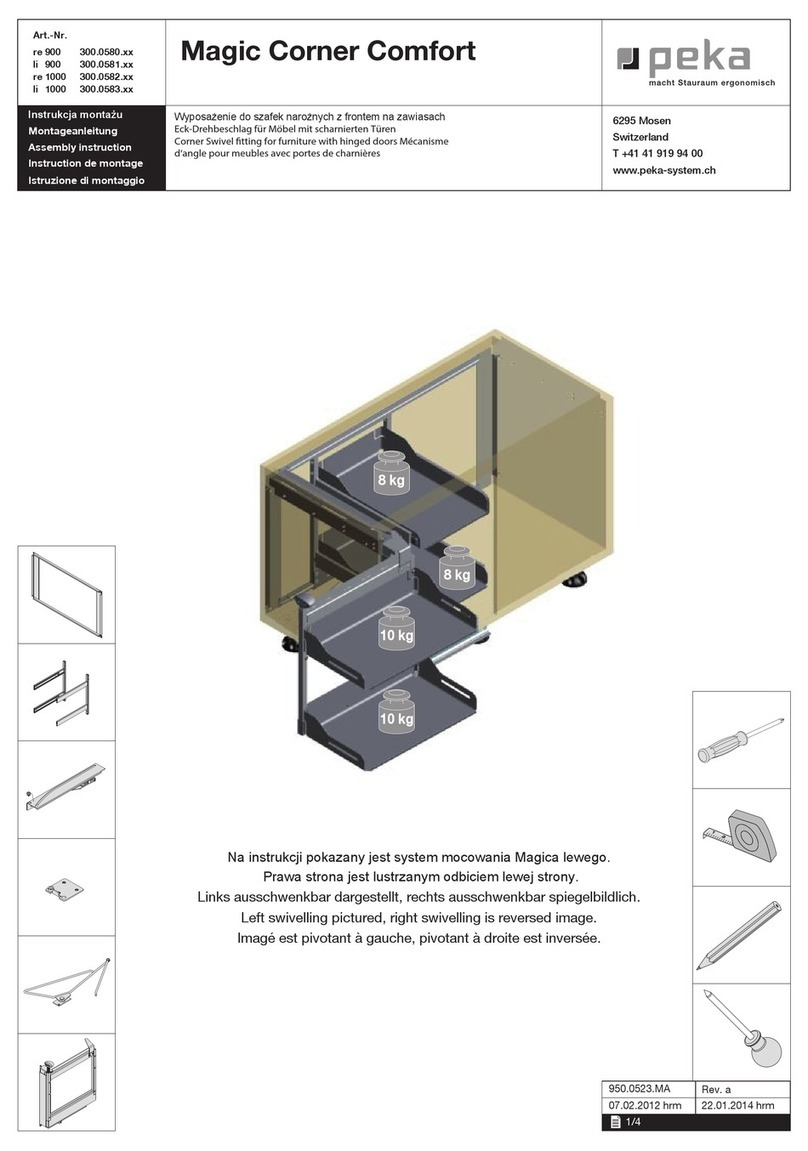

Inside the headrail of your Lift&Lock™Shade there is a sorting label.

On this label you will recognize:

Order size of the shade.

Room location (If not

present, info not given at

time of order).

Whether the shade was

ordered for inside mount (IB),

outside mount (OB), or side mount (EM).

2-Room Location

1-Order Size of Shade

Work Order Number

3-Type of Mount

2.

3.

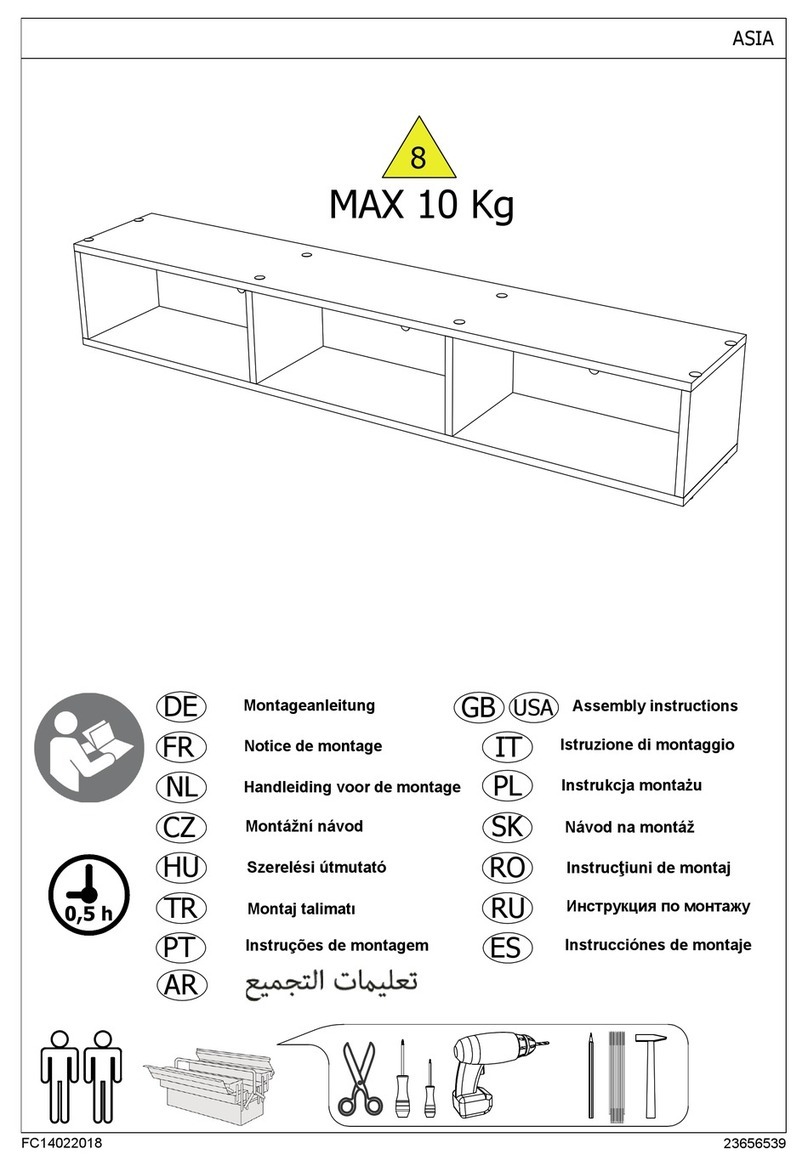

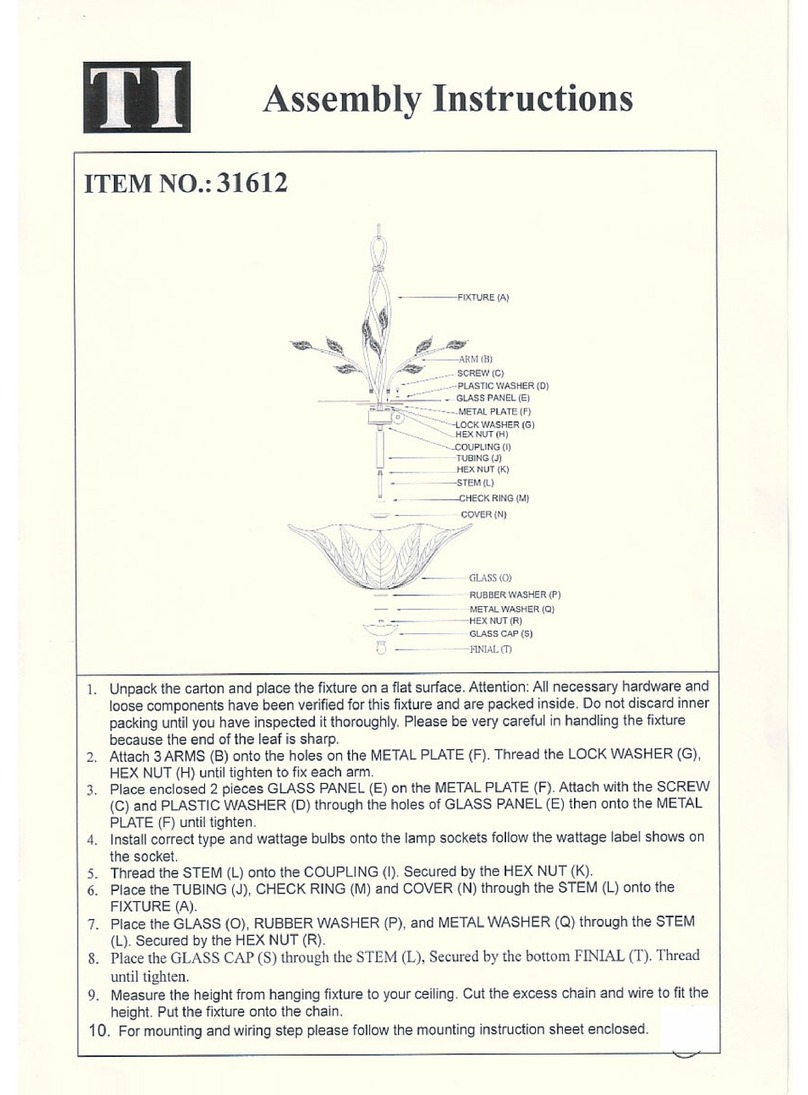

The Parts: Before starting, please remove and identify the following parts

required for the installation of your shades:

1.

To install your Blinds First Lift&Lock™Shade, you will need

a few basic tools:

Important Note:

Screws provided are for installation into wooden frames only. For metal surfaces,

use suitable sheet metal screws and pre-drill holes. For concrete, stone, brick,

or tile, use a carbide drill and appropriate anchors and screws. For wallboard or

plaster, use hollow wall anchors and/or longer screws to reach framing or stud. In

all cases, follow the fastener manufacturer’s recommendations.

• Measuringtape

• Powerdrillwith¼”hexheadattachmentand/or

PhillipsHeadScrewdriver

• Pencil

BRACKET SPACING

D

IF ORDERED AS INSIDE MOUNT (IB)

IF ORDERED AS OUTSIDE MOUNT (OB)

1.With outside mount applications, two installation screws are

used to attach the back of each installation bracket to the flat vertical

surface. In most instances this will be a flat area on the window trim.

In some instances Spacer Blocks may need to be installed to project

the installation brackets away from the mounting surface (typically

when shades are mounted above the trim). If Spacer Blocks are

required, proceed to Section F. Extension brackets can project the

installation brackets up to 2 ½” from mounting surface. If Extension

Brackets are required, proceed to Section G.

Before tightening the screws, check to be sure the tops of all the

installation brackets are perfectly horizontal and aligned at the same

height. Please refer back to Section D for details. (To attach the

brackets, the flat vertical surface must be at least 1/2” high.)

2.

Honeycomb shades

3/4” size & double cell

Honeycomb shades

3/8” size

Honeycomb shades

3/4” size & double cell

Honeycomb shades

all sizes

Honeycomb shades

3/8” size

Honeycomb shades

3/4” size & double cell

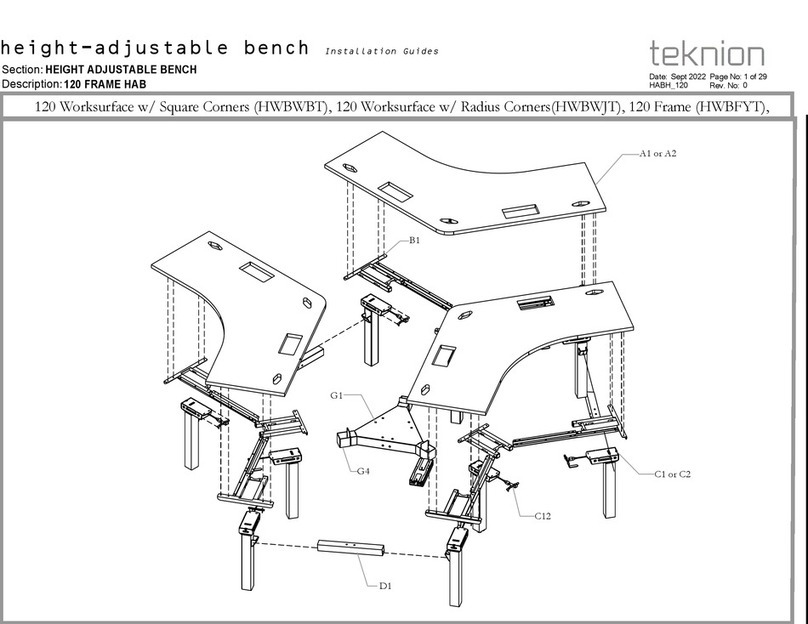

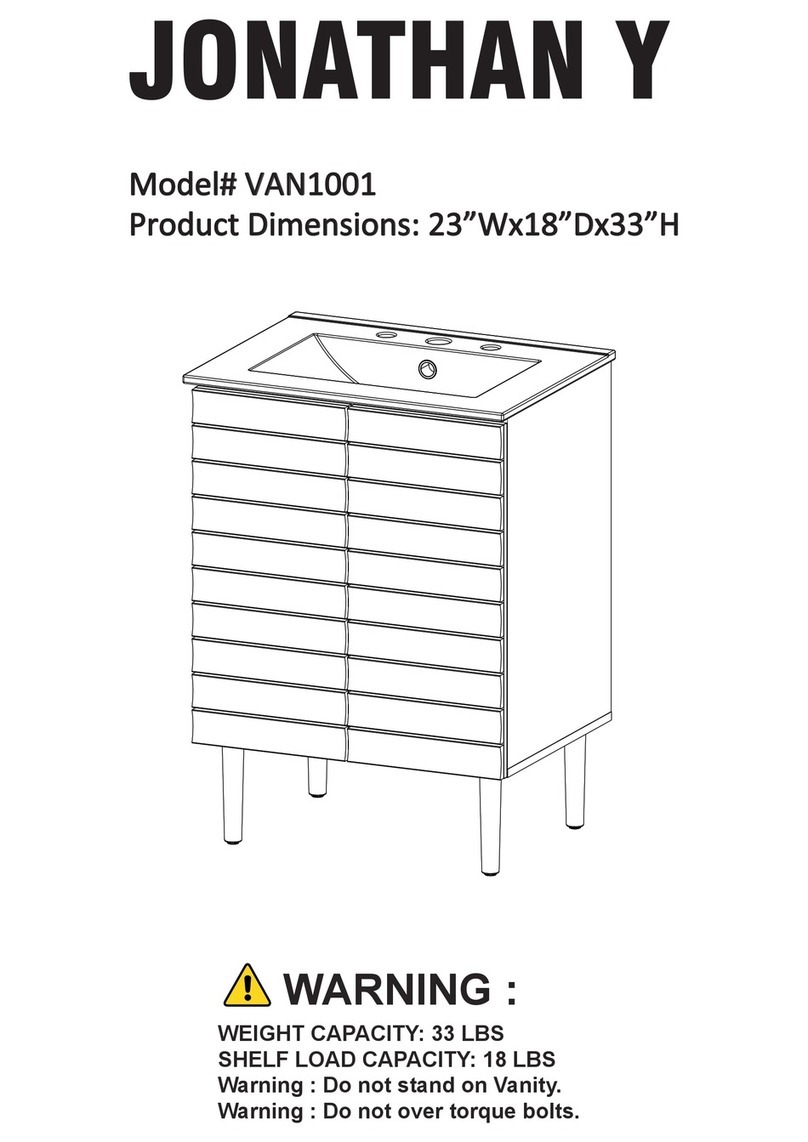

Two installation brackets are positioned on the mounting surface so that

their centerlines will be 2” in from the ends of the shade. If more than two

brackets are required follow instructions shown in the next column.

Shade

Width

Number

of

Brackets

Up to 60”

60 1/8” to 96”

96 1/8”-120”

2

3

4

InstallationBracketSpacingonHeadrail

2” 2”

Space evenlySpace evenly

Installation

Bracket Centerline

Installation

Brackets

Installation

Screws

ExtensionBrackets

(optional)

Swivel

Brackets

(optional)

SpacerBlocks

(optional)

HoldDown

Brackets

forDoors

(optional)

Measureandmarkallbracketcenterlines. Note: For optional swivel

brackets, position the holes (for mounting screws) 3” in from the ends of

the shade.

BRACKET INSTALLATION

E

1.

2.

3.

IF ORDERED AS INSIDE MOUNT SWIVEL (Optional)

Swivel brackets can be used on inside mount (IB) only. One screw is used

to attach each swivel bracket. Swivel brackets require less mounting depth

than standard installation brackets. (Bracket attachment requires a solid

mounting surface only 1/2” deep. Shades will mount securely but will not

fully recess.)

INSTALLING SPACER BLOCKS (Optional)

F

1.

2.

SORTING YOUR SHADES

C