BLMA Models Cantilever Signal Bridge User manual

Thankyouforpurchasingthisfine-scalemodel! Thisbridgehasbeendesignedforeasy

assembly,exceptionaldurability,andeaseofmounting. Pleasefeelfreetocontactusifyouhave

anycommentsorconcerns.Shouldanissuearise,sparepartsareavailableforpurchase.

!

!

!

!

!

!

Glue: Any medium CA (super) glue. (Super glue accelerator might also come in handy.)

Hobby Knife: A sharp hobby knife is imperative for cutting etched metal pieces from the

frame in which they come. (Be careful with sharp blades; use eye protection while cutting!)

File: To remove any burs left behind when the parts are cut from their etched frame.

Paint: Any flat black paint. We recommend using an air brush to apply the paint. It is easy to

cover the small details with paint applied by brush. Silver & White paint are needed as well.

Toothless Pliers: To aid in bending things such as the ladder supports, signal heads, etc.

*Toothless pliers decrease the risk of causing damage to delicate, etched-metal parts.

Toothpicks: Come in handy when applying glue or small dabs of “touch-up” paint.

Materials/Tools NeededMaterials/Tools Needed

Cantilever Signal Bridge InstructionsCantilever Signal Bridge InstructionsCantilever Signal Bridge Instructions

Please read through all instructions before assembling and painting this structure.

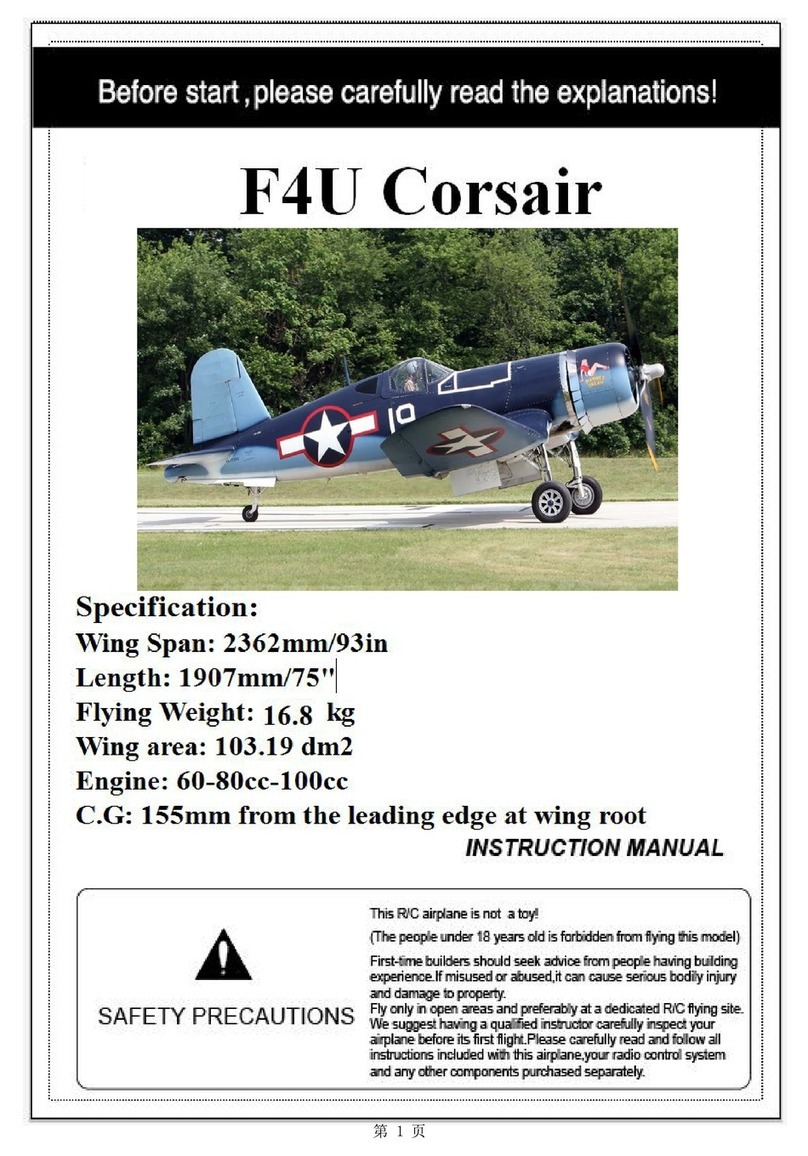

Modeled after a common Santa Fe protoype, this

Cantilever Signal Bridge has been in use all over the

countryforwelloverahalf century. Sturdyconstruction

and a solid design has allowed these bridges to last into

the new millennium. The photos to the right are of the

prototype bridge this kit is modeled after. Replaced on

the 1st of August, 2006, this relic survived long enough

toseeBNSFcometopoweroverSantaFerails.

THE PROTOTYPETHE PROTOTYPE

#4020#4020

THE MODELTHE MODEL

Our HO Scale model of this interesting bridge is an

exact scale replica of the prototype. If you look closely,

you will notice that everything down to the rivet detail is

in place! Because a solid model starts with solid

dimensions and drawings, all of the information used

was taken directly from the prototype. The model

photos to the right were taken at the same angle as the

prototypephotostoshowhowexactthismodelis.

BLMA Models

16623 Pear Blossom Ct.

Whittier, California 90603

Phone: 562-712-7085

#4020 - Signal Bridge Instructions

A. Main Span & Center Base

B. Vertical Posts & Ladder

C. Base

D. Top Handrail

E. Electrical Box (not pictured)

F. Signal Heads (3) (Non-operating - not pictured)

1. Base Assembly

Thebase of theprototypeis an angledconcrete block. LocatepartC and remove

it from it’s etched frame. Notice the half-etched fold lines on the underside of the

etching. Fold all sides so the half-etched lines are facing down. Note: Adding CA glue

fromtheinsidewillhelptopreventthesidesfrompushingoutward.

Please contact us at BLMAmodels.com for any spare part requests.

A B

DC

Bend sides down as shown. Completely assembled and

glued from the inside.

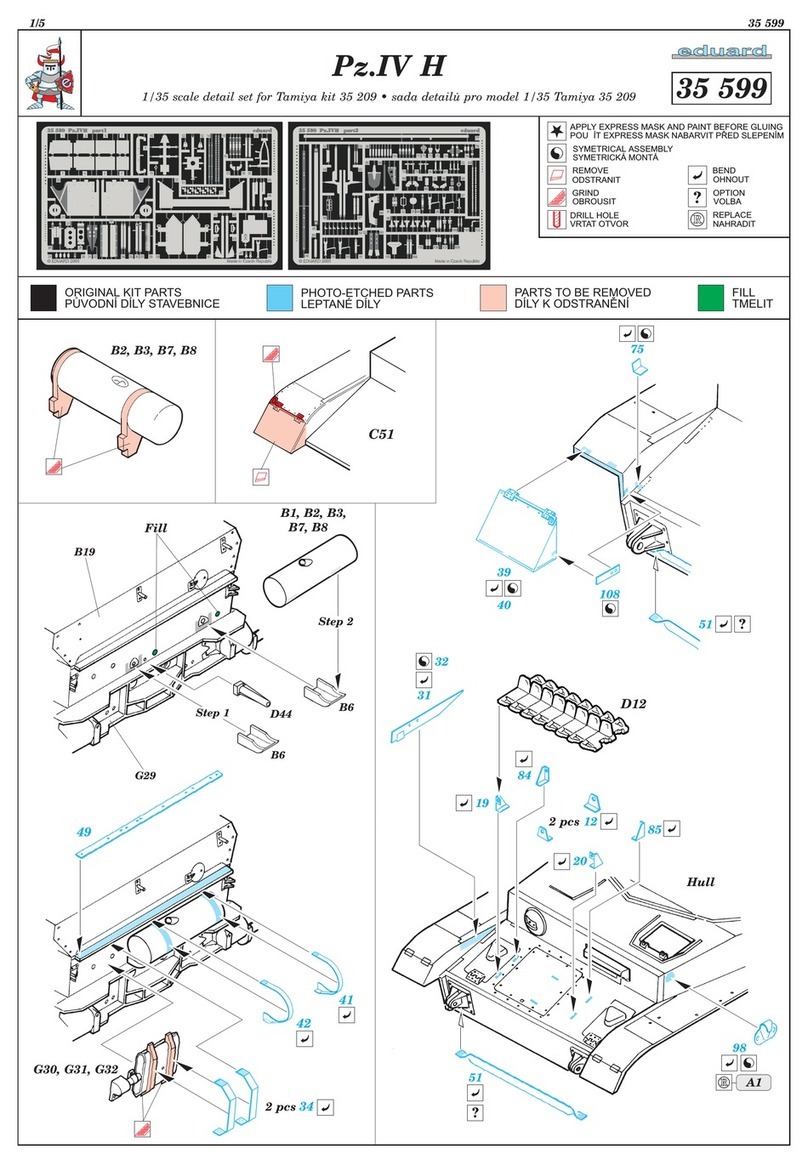

2. Vertical Post Construction

The main vertical post of this model is constructed of four separate

components. Through testing the product, we found this to be the best we to

faithfully recreate the construction methods of the bridge.

Locate and remove the four long posts from etching B. It is extremely

important that these posts remain perfectly flat. Notice that the ends of these four

pieces have short “tabs” protruding from them. These tabs will fit neatly into the

base assembly as well as the top handrail section (more on that later). Furthermore,

notice that the tabs on one end are longer than on the other end. The end with the

longest tabs will fit into the base. Continued on page 3...

AssemblyAssembly

PartsListPartsList

#4020 - Signal Bridge Instructions Page 2

3. Top Base Assembly

Startingwiththetwo solidposts, locatethe endwiththe longtab,dipitin CAand insert

it into the base. Of the entire kit, this is the most crucial part! Make sure that your post is

perfectlyvertical. The post must be completely vertical forthemodel to assemble correctly in

the later steps. The post can lean in toward the center a tad (so the top of it falls directly

above the center hole in the base). Repeat the steps above for the opposite post. Make sure

both posts are perfectly vertical (however, it’s OK for them to lean in toward the center and

ontoeachotheraswehavepicturedFigureB).

Fromthere, locate the other two verticalsupports and glue them into the base with the

long tab end first. These posts might have a tendency to lean out which is perfectly OK (we’ll

adjust them later.). By now, all of your posts should be glued in place and should be the same

height(FigureC). Throughoutthisprocess,makesurethatallpostsstaycompletelyvertical.

Figure A

Perfectly vertical post.

Figure B Figure C

Both solid posts in place. All four posts in place.

Locate and remove the Top Base from etching A. Note that there are half-etched

foldlinesonit’sbottomside. Foldtheendsdownatthehalf-etchedlines.

Locate your Base/Post assembly from step 2 along with your Top Base from the

stepabove;proceedwithsteponeandthentwobelow.

You will need to separate the

four vertical posts in order to easily

mount the Top Base in place.

Simply use your fingers or tweezers

to gently pull the four posts away

from the center. Continue gently

pulling the posts outward until the

space between them is slightly

largerthenthespaceatthebottom.

Step 1. Step 2. Add a dab of glue to the the

tops of the four posts. Carefully,

place the Top Base onto the

assembly so that the longest

side hangs over the only vertical

side of the Base. It is easiest to

insert the double pronged posts

into the bottom of the base and

then bring the single pronged

sidepiecesinward.

The longest end

of the Top Base

extends over

the only vertical

side of the Base.

Note the ends are folded down perpendicular to the center.

#4020 - Signal Bridge Instructions Page 3

4. Top Handrail Assembly

TheTopHandrailportion of this kitisetched in .010”

Stainless Steel for improved handrail durability over the

alternative (brass). Locate part D and remove it from it’s

etched frame. (Be careful whencutting the tie-barsfor the

handrailsasyoudonotwanttobentordistortthem.)

Bend all of the handrails perpendicular to the base.

Notice that the ends also have additional bend lines where

the handrails cross the width of the bridge (at the ends).

You may want to add a small dab of CA to the handrails

wheretheymeetinordertoensurebetterdurability.

Main structure assembly and completely

assembled Top Handrail etching.

Partially formed Top

Handrail etching.

The next step of the kit is gluing the Top Handrail section onto your main

structure. WiththeTopHandrailetchingand yourmainstructureassemblyin hand,test

fittheTopHandrailtoseehowitfitsintothetabsoftheVerticalPosts.

To mount, lay the Top Handrail section upside down so it is supported by the

handrails (do not apply excess pressure or you will crush the handrails!). Next, add a

line of CA down the center of the Top Handrail underside. Place the main structure

(being held upside down) onto the Top Handrail piece so that all of the tab holes align.

During this process, apply pressure to the Top Base so it lays flush with the underside of

theTopHandrail.

The Vertical Posts and Top Handrail should form a perfectly right angle. Adjust any

slight imperfection in the angle by gently pushing the pieces in the proper direction.

The Vertical Posts and horizontal walkway

(Top Handrail piece) should form a right angle.

5. Main Span Assembly

The next step in this kit is to add the Main Span pieces. Locate the two pieces

frometchingAandhavethemreadytogowithyourassembledmainstructure.

Lay the main assembled structure on it’s side. Test fit one of the Main Span

etchings to visualize how thingswill line up. Run a line of gluedown the edge of the Top

BaseontheundersideoftheTopHandrail. Continuedonpage5...

#4020 - Signal Bridge Instructions Page 4

Complete the previous steps for the opposite side of the structure.

Addadditionaldabsofgluefromtheinsidetoensuredurability.

6. Ladder Assembly

Locate the ladder from etching D. As with the other parts, be careful when

cutting the part from the etching as you do not want to distort/bend it. Note that the

tabs extending from the ladder that allow it to mount onto the vertical posts should NOT

beperpendiculartothebridge(theyareataslightangleforareason).

Locate the half-etched fold lines on the tabs extending from the bridge and bend

themtoformaright anglewith thebridge. Iftheladderisperfectlyverticalinyourhand

andyou’reviewing itfromtheside, thetabs shouldangleup slightly. When theladder is

mounted on to the bridge, the tabs will then become perfectly horizontal while the

ladderwilltaperclosertotheverticalpostsasitrisesupthestructure.

Run a line of glue along

dotted line (see arrow). Repeat the same steps to

complete the opposite side.

Fold mounting tabs perpendicular

to the ladder. These should NOT

be perfectly perpendicular

to the ladder.

Add a dab of glue to the ends of

each tab and place on model so

the top, curled over handrails

are just above the walkway.

Make sure the ladder is firmly

glued in place. Bend the two

curled runner tops inward

as shown above.

We’ve included a typical Electrical Box to

compliment the Signal Bridge. To assemble,

simply clean up the castings, glue the doors in

place (line up the hinges for best results), and

affix the cast footings. Like the other cast metal

parts in this kit, the Electrical Box is

manufacturedinconjunctionwithDetailsWest.

ElectricalBoxElectricalBox

#4020 - Signal Bridge Instructions Page 5

The Signal Heads provided in this kit are exact scale

replicasofthecommon, “Searchlight”signal(namedafterit’s

appearance). Although our signal heads are non-operating,

after-marketLED’smaybeinstalledifdesired.

Note: Wehavesuppliedyouwithanextrasignalhead.

Locate parts A and C. Part C

should fit through the center of

part A. Remove burs from part

C if necessary.

AE

D

B

C

A. Etched Target and Hood

B. Signal Head Body

C. Signal Head Insert

D. Signal Head Mount

E. Mounting Rod

1. 2. 3.

Bend the hood around the

provided brass pole to give

it the proper curvature.

It is imperative that the hood be

shaped to the proper curvature so it

will mount correctly onto the

assemblyfromstep2.

Insert the mounting pegs on the

hood through the corresponding

holes on the target. The hood

shouldwrapneatlyaroundpartC.

Once fully inserted, bend the

mounting tabs on the hood toward

theoutsideofthetarget.

6.

5.

4.

7. 8. 9.

12.11.10.

Gluetheassemblyfromstep6into

part B (part C’s narrow end should fit

into the large opening on part B).

Affixwithglue.

Locate part D and bend its sides

perpendicular to the middle portion.

We suggest bending with toothless

pliersasshown.

Once both sides are folded down,

bend the tiny nub at the end of the

part the opposite direction of the

sides.

The small nub bent in figure 9 fits

into the bottom of the signal head

(partB).

Cut down part E so it is the height

of the handrail & glue in place. The

best way to cut brass tube is by

rollingit underasharphobbyknife.

Glue the completed signal head

assembly onto the pole. Vertical

position and the number of signals

dependsontheprototypemodeled.

Our Signal Heads are also sold seperately in a three pack. BLMA #4000

Add a small amount of glue to the

A/Cassembly fromstep 1to secureit

in place. Locate and remove the

“hood”frometchingA.

SignalHeadsSignalHeads

#4020 - Signal Bridge Instructions Page 6

Table of contents

Popular Toy manuals by other brands

LEGO

LEGO CITY 60003 Assembly manual

Destination Science

Destination Science Millennium Starship Directions

Eduard

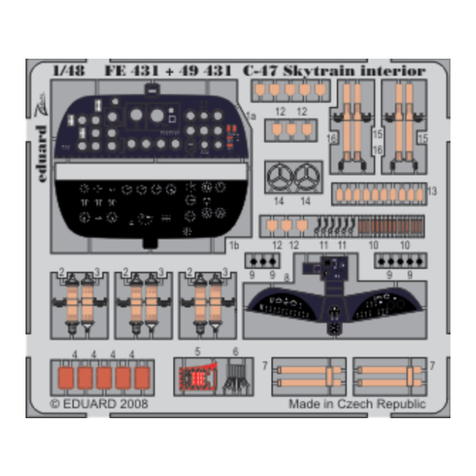

Eduard Zoom C-47 Skytrain interior S.A. Assembly instructions

Horizon Hobby

Horizon Hobby HANGAR 9 Aermacchi MB-339 instruction manual

Hasbro

Hasbro Nerf Rival Zeus MXV-1200 quick start guide

Fisher-Price

Fisher-Price DWR66 owner's manual