4FIBT-1310 SERIES

User Manual

SECTION 1 – GENERAL & SAFETY INSTRUCTIONS

This product is designated for use in restricted locations. It is strongly advised that you always follow these safety

instructions to help ensure against injury to yourself and damage to your equipment.

åALWAYS read the product data sheet and the laser safety label before

powering the product. Note the operating wavelength, optical output power,

and safety classifications.

åIf safety goggles or other eye protection are used, be certain that the protection

is effective at the wavelength(s) emitted by the device under test BEFORE

applying power.

åALWAYS connect a fiber to the output of the device BEFORE power is applied.

Power should never be applied without an attached fiber output. If the device

has a fiber output, a connector should be attached that is connected to a

fiber. This ensures that all light is confined within the fiber waveguide, virtually

eliminating all potential hazard.

åNEVER look in the end of a fiber to see if light is coming out. NEVER! Most

fiber optic laser wavelengths (1310 nm and 1550 nm) are totally invisible to the

unaided eye and will cause permanent damage. Shorter wavelength lasers (e.g.

780 nm) are visible and are very damaging. Always use instruments, such as an

optical power meter, to verify light output.

åNEVER, NEVER, NEVER look into the end of a fiber on a power device with

1.2 LASER SAFETY PROCEDURES

ANY sort of magnifying device. This includes microscopes, eye loupes, and

magnifying glasses. This WILL cause permanent, irreversible burn on your

retina.

åALWAYS double check that power is disconnected before using such devices. If

possible, completely disconnect the unit from any power source.

åIf you have questions about laser safety procedures, please call Blonder Tongue

before powering your product.

åDo not attempt to service the unit yourself, as opening or removing covers may

expose you to dangerous voltage and will void the warranty. Refer all servicing

to authorized service personnel.

åUnplug the unit from the wall outlet and refer servicing to authorized service

personnel whenever the following occurs:

oThe power supply cord or plug is damaged;

oLiquid has been spilled, or objects have fallen into the unit;

oThe unit has been exposed to rain or water;

oThe unit has been dropped or the chassis has been damaged;

oThe unit exhibits a distinct change in performance.

1.1 SAFETY PRECAUTIONS

åThe optical emissions from the units are laser-based Class IIIb, and may present eye hazards if improperly used. NEVER USE ANY KIND OF OPTICAL INSTRUMENT

TO VIEW THE OPTICAL OUTPUT OF THE UNIT.

åAs always, be careful when working with optical fibers. Fibers can cause painful injury if they penetrate the skin.

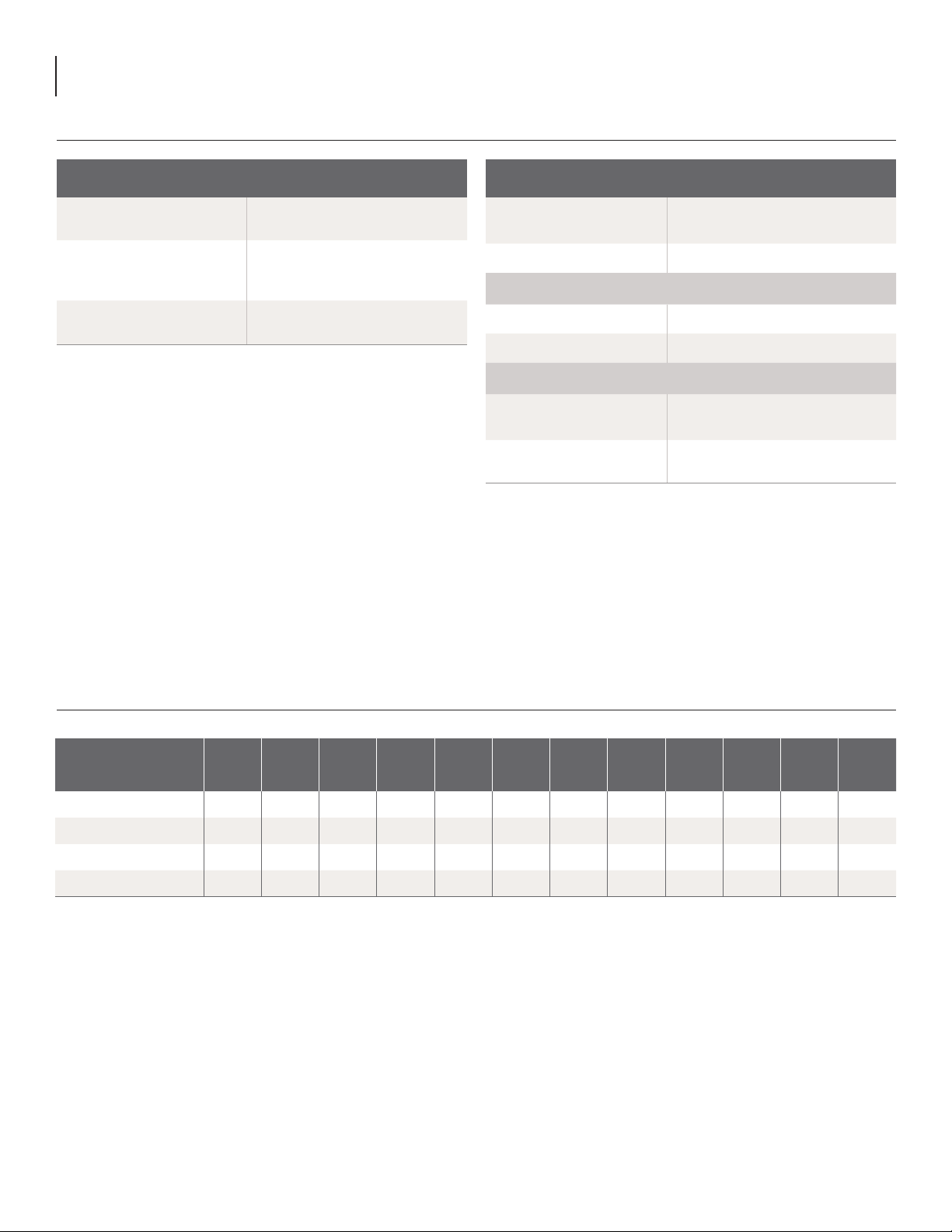

Class 1 Laser Product IEC 60825-1: 2014

Wavelength: 1.31µm Max Output: 31mW

WARNING

INVISIBLE LASER RADIATION

AVOID DIRECT EYE EXPOSURE TO BEAM

ATTENTION

LASER RADIATION INVISIBLE EVITER

UNE EXPOSITION DIRECTE DES YEUX AU FAISCEAU

HAZARD

LEVEL 1

IEC 60825-2:2004

The STOP sign symbol is intended to alert you to the

presence of REQUIRED operating and maintenance

(servicing) instructions that if not followed, may result in

product failure or destruction.

The YIELD sign symbol is intended to alert you to the

presence of RECOMMENDED operating and maintenance

(servicing) instructions.

The LIGHTNING flash symbol is intended to alert you

to the presence of uninsulated “dangerous voltage”

within the product's enclosure that may be of sufficient

magnitude to constitute a risk of electrical shock.

TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE COVER

FROM THIS UNIT.

NO USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

WARNING: TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS

UNITTO RAIN OR MOISTURE

NOTE TO CATV SYSTEM INSTALLER

This reminder is provided to call the CATV System Installer’s attention to

Article 820-40 of the NEC that provides guidelines for proper grounding and, in

particular, species that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entry as practical.

WARNING:

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure. The optical emissions from the units are laser-based and present eye hazards.

Avoid Exposure and follow all safety precautions.