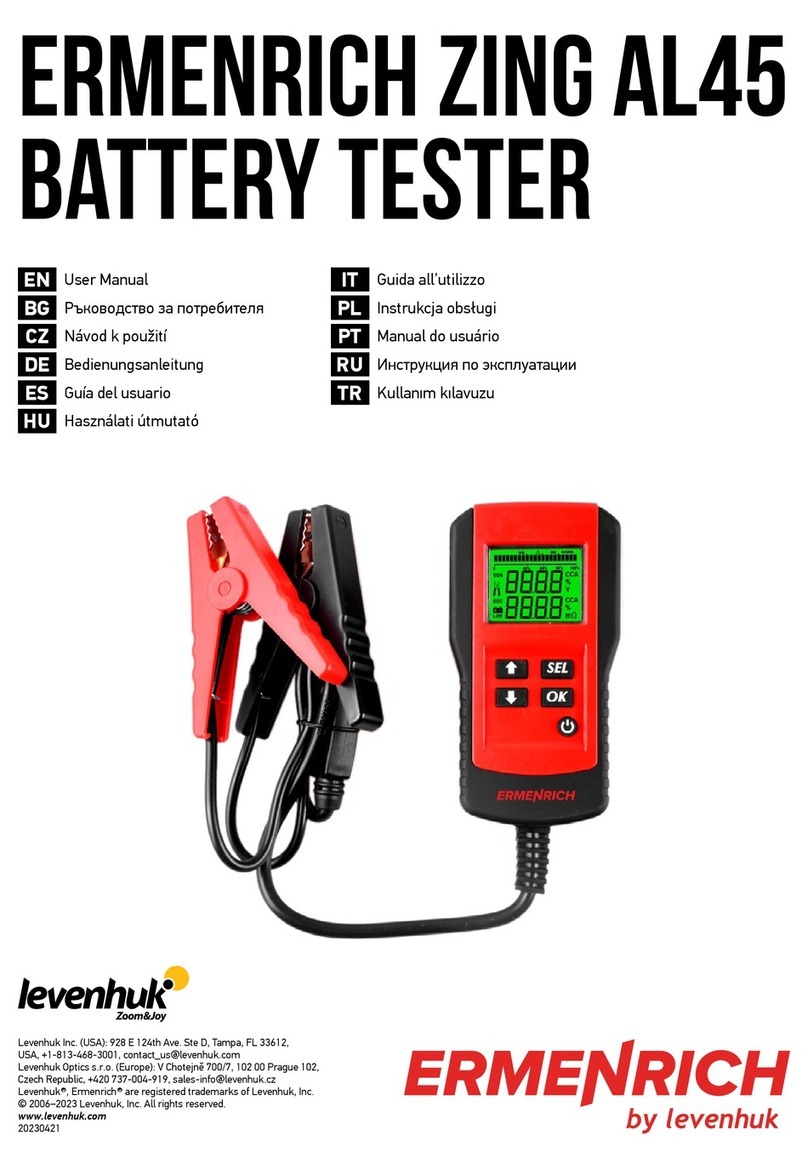

bloom 25 GPM Installation manual

BLOOM 1.5 INSTALLATION AND STARTUP

GUIDE

REFER TO OPERATING MANUAL FOR IMPORTANT SAFETY

INFORMATION

- 2 -

PAGE INTENTIONALLY LEFT BLANK

- 3 -

CONTENTS

GENERAL INFORMATION .........................................................................................................4

LOCATION REQUIREMENTS.....................................................................................................4

PARTS AND ACCESSORIES......................................................................................................5

INSTALLATION GUIDELINES.....................................................................................................6

Installation Parts and Materials..................................................................................................6

Pipe Assembly..............................................................................................................................6

Gas Connection ..........................................................................................................................7

Flooded Suction Installation ......................................................................................................7

Suction Lift Installation.................................................................................................................8

Table 4. Recommended Suction and Discharge Pipe. .................................................................9

Frame Dimensions and Components Descriptions.......................................................................9

Suction Piping Installation..........................................................................................................10

Discharge Piping Installation......................................................................................................11

CIP Valve Installation (Optional) ................................................................................................12

Connect Power to Control Box. ..............................................................................................12

QUICK STARTUP GUIDELINES................................................................................................13

Flooded Suction Applications: Pump Priming Instruction............................................................13

Suction Lift Applications: Pump Priming Instructions...........................................................15

Suction and Discharge Operation............................................................................................17

Operating Parameter Ranges...................................................................................................17

- 4 -

PAGE INTENTIONALLY LEFT BLANK

- 4 -

GENERAL INFORMATION

Read instructions thoroughly prior to assembly and installation.

All Bloom products are factory adjusted for optimal nanobubble production. Do not

adjust factory setpoints.

LOCATION REQUIREMENTS

Carefully select the BLOOM installation location based on the requirements specified in this

section. Locate and secure the BLOOM on a concrete pad or other firm, level surface that is

at least 44 in long x 23 inches wide. Maintain a clearance of at least 30 inches on all sides to

allow access for servicing and maintenance to the front and back of the BLOOM. Select a

sheltered, (weatherproof), well-ventilated area that is protected from excess moisture (i.e.,

rain, splashing, washdown water, etc.), dust and flooding. Use the schematic shown in

Figure 1 for mounting hole placement.

Figure 1. Plan view of BLOOM frame showing mounting hole placement.

The BLOOM power, suction and discharge pipe requirements are summarized in Table 1 and

Table 4 respectively.

Failure to install BLOOM within the limits specified in Tables 1 and 4 may void the

system warranty and result in poor nanobubbles production and pump cavitation.

- 5 -

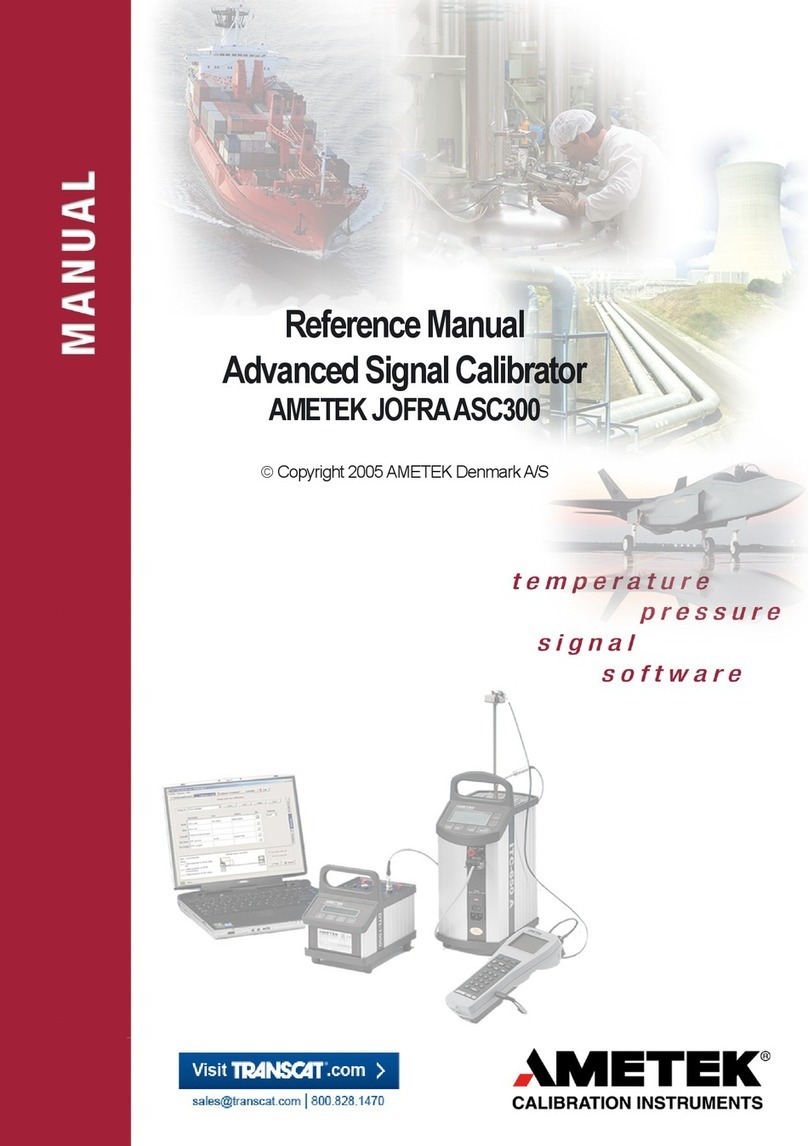

Table 1. Power Requirements

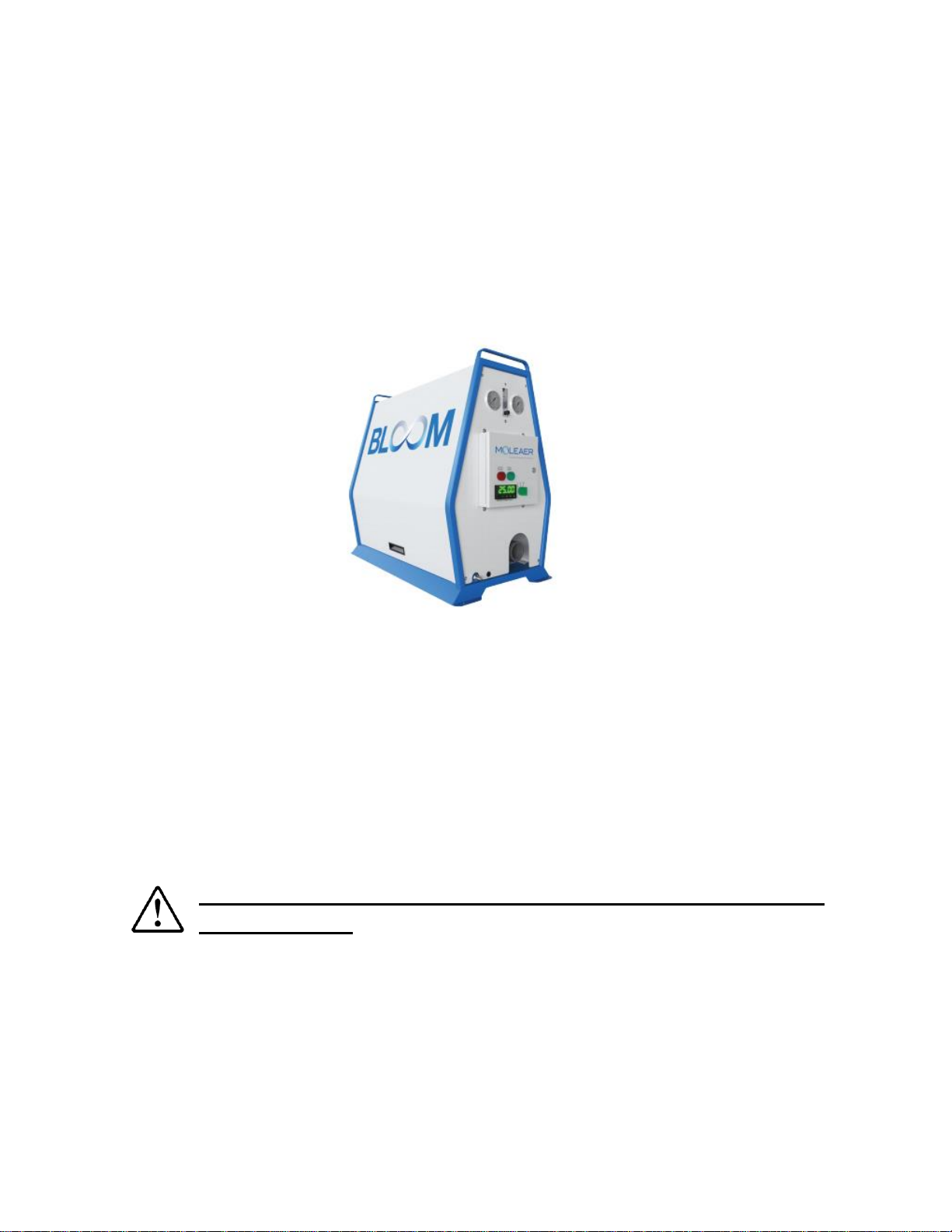

PARTS AND ACCESSORIES

The parts shown in Table 2 are offered as accessories available for purchase with all BLOOM

models.

Table 2. High Pressure Oxygen Regulator Kit Parts List (P/N:99K0-001)

Image

QTY

Part Description

P/N

1

Regulator Oxygen

99J0-050

1

Hose, Welding Gas, Grade R, Green.

99C0-084

Unit

Version

Voltage

Phase

Hz

Amps

Pump Manufacturer

BLOOM 25 GPM

US

115

1

60

10.2

Pentair

US

230

1

60

6.0

Pentair

EU

230

1

50

6.9

Pentair

BLOOM 50 GPM

US

115

1

60

12.7

Pentair

US

230

1

60

6.8

Pentair

EU

230

1

50

16.9

Pentair

US

115

1

60

12.7

DAB

BLOOM 150 GPM

US

230

1

60

15.8

Pentair

EU

230

1

50

16.9

Pentair

- 6 -

NOTE: The parts shown in Table 3 are offered as accessories to the DAB pump and are only

available for purchase with the US BLOOM 50.

Table 3. Power Converter

Image

QTY

Part Description

P/N

1

Step Up- Down Transformer

99E0-235

1

Adapter

99E0-234

INSTALLATION GUIDELINES

The site conditions unique to each irrigation reservoir, irrigation room, or commercial

greenhouse project, etc., should be carefully considered when identifying the BLOOM

installation location. Refer to the Location Requirements section for addition details.

The following guidelines are recommendations for tanks with intake structure submergence.

depths less than15 ft (4.5m).

Upon delivery, unscrew the shipping screws to remove the BLOOM unit from the shipping crate.

Inspect the BLOOM for any damage or loose parts that may have occurred during transport.

Hand tightens any loose parts, make sure don’t over tight.

Installation Parts and Materials

The parts and materials required to install the BLOOM include:

•3/8 in wrench (US models) or 14mm wrench (EU models).

•7/8 in wrench (US models) or 34mm wrench (EU models). Wrench required to install the

regulator kit.

Follow

Pipe Assembly

- 7 -

Use only Schedule 40 or Schedule 80 polyvinyl chloride (PVC) pipe and fittings. Use only PVC

cement formulated for wet condition and fast installation to ensure connection between PVC

pipe to PVC fittings. Follow PVC cement manufacturer’s recommendations on cure time before

wet testing the system. Do not use black, ABS piping or mix ABS pipe with PVC pipe or fittings.

All PVC pipe connections must be airtight and leakproof. Failure to provide airtight suction

pipe connections may negatively impact nanobubble generator performance. Large

bubbles visible at the pump strainer basket are an indication of suction pipe leaks. Difficulty with

pump priming may also be the result of suction pipe leaks.

Gas Connection

For BLOOM models without onboard gas generation, connect a high pressure rated oxygen gas

line to the standard CGA-022 fitting connection. Adjust the oxygen gas regulator on the gas

supply to 100 –120 PSIG.

DO NOT EXCEED 140 PSIG SUPPLY GAS PRESSURE. Excessive pressure may

void warranty and compromise gas seals resulting in a sudden drop in backpressure.

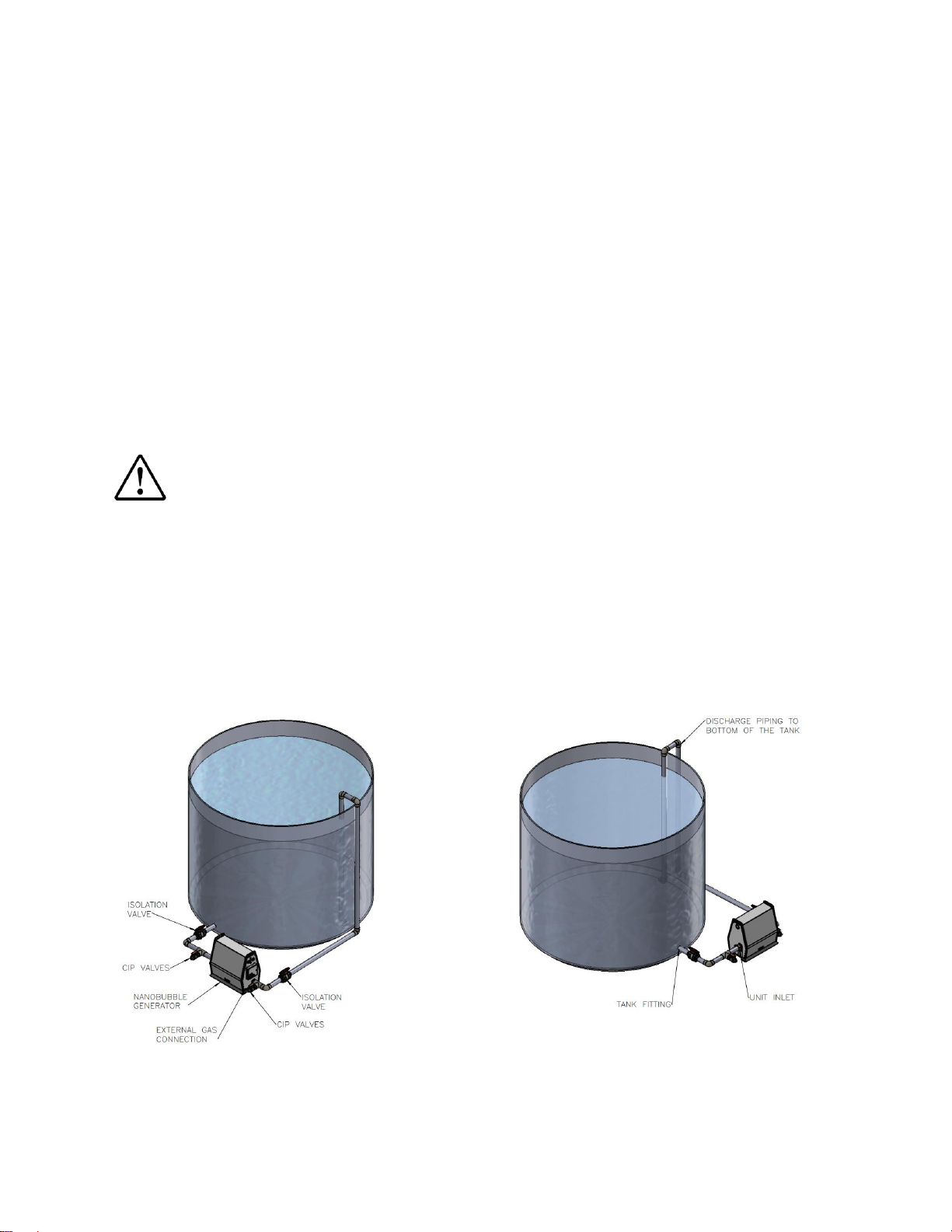

Flooded Suction Installation

Refer to Figures 2 and 3 to determine whether the installation has a flooded suction pipe. A

flooded suction exists when the pipe between the tank and the BLOOM pump completely fills

with water when the pump is off and isolation valves are open (i.e., when the tank water

surface level is above the suction intake and the BLOOM pump). Refer to Figure 7 for BLOOM

enclosure dimensions and suction and discharge fitting locations.

Figure 2. Isometric View a Flooded Suction BLOOM installation.

- 8 -

Figure 3. Plan View of BLOOM Discharge Pipe Orientation in a Tank.

Suction Lift Installation.

Refer to Figures 5 to determine whether the installation has a suction lift pipe. A

suction lift exists when the source of liquid is located below the BLOOM centerline. The suction

pipe leading to the pump and the pump must primed to lift liquid from the tank to the BLOOM.

Figure 4. Isometric View Suction Lift Installation

Do not run the pump dry. Impeller may melt and seize, and the pump will stop running.

See Figure 3 for plan view of BLOOM suction lift pipe orientation in a Tank.

- 9 -

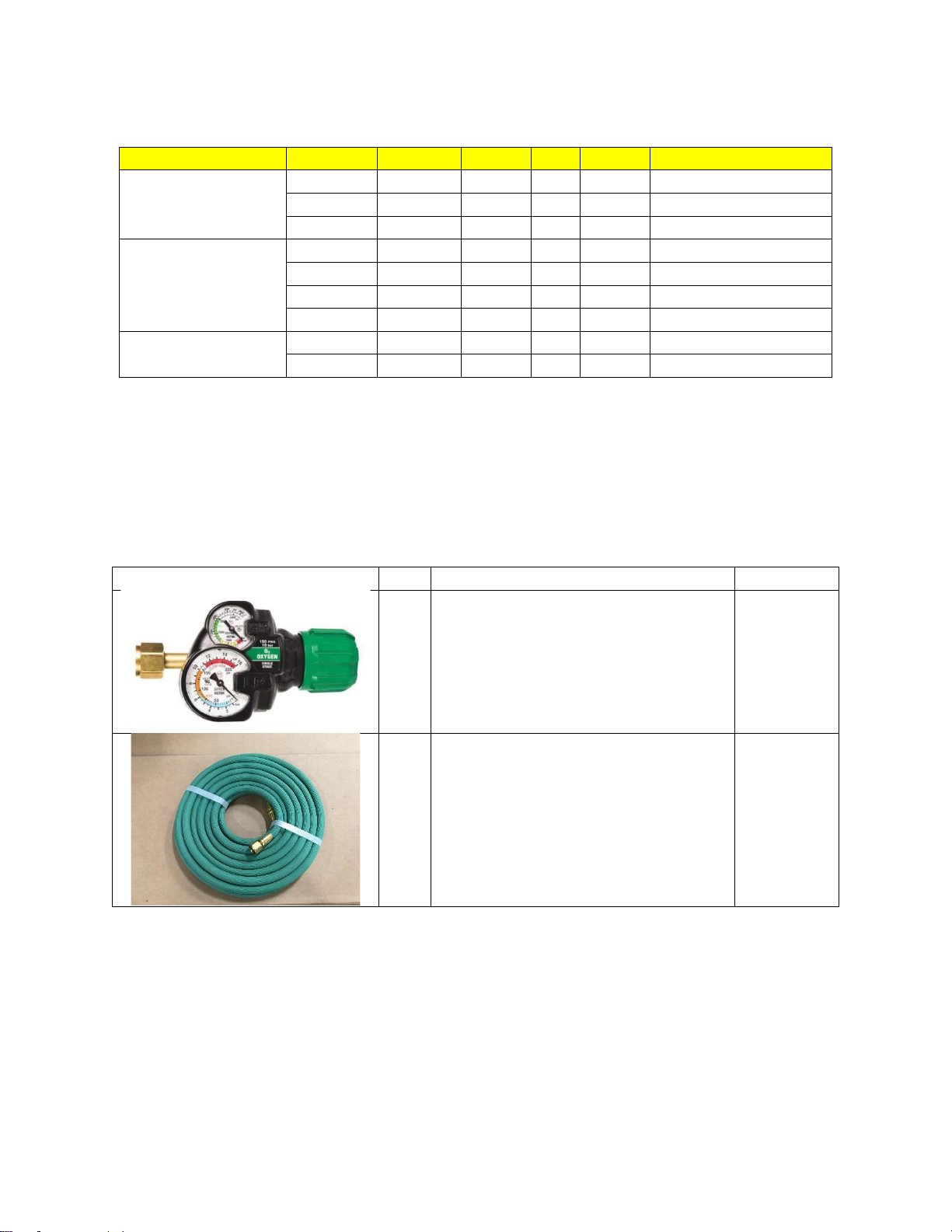

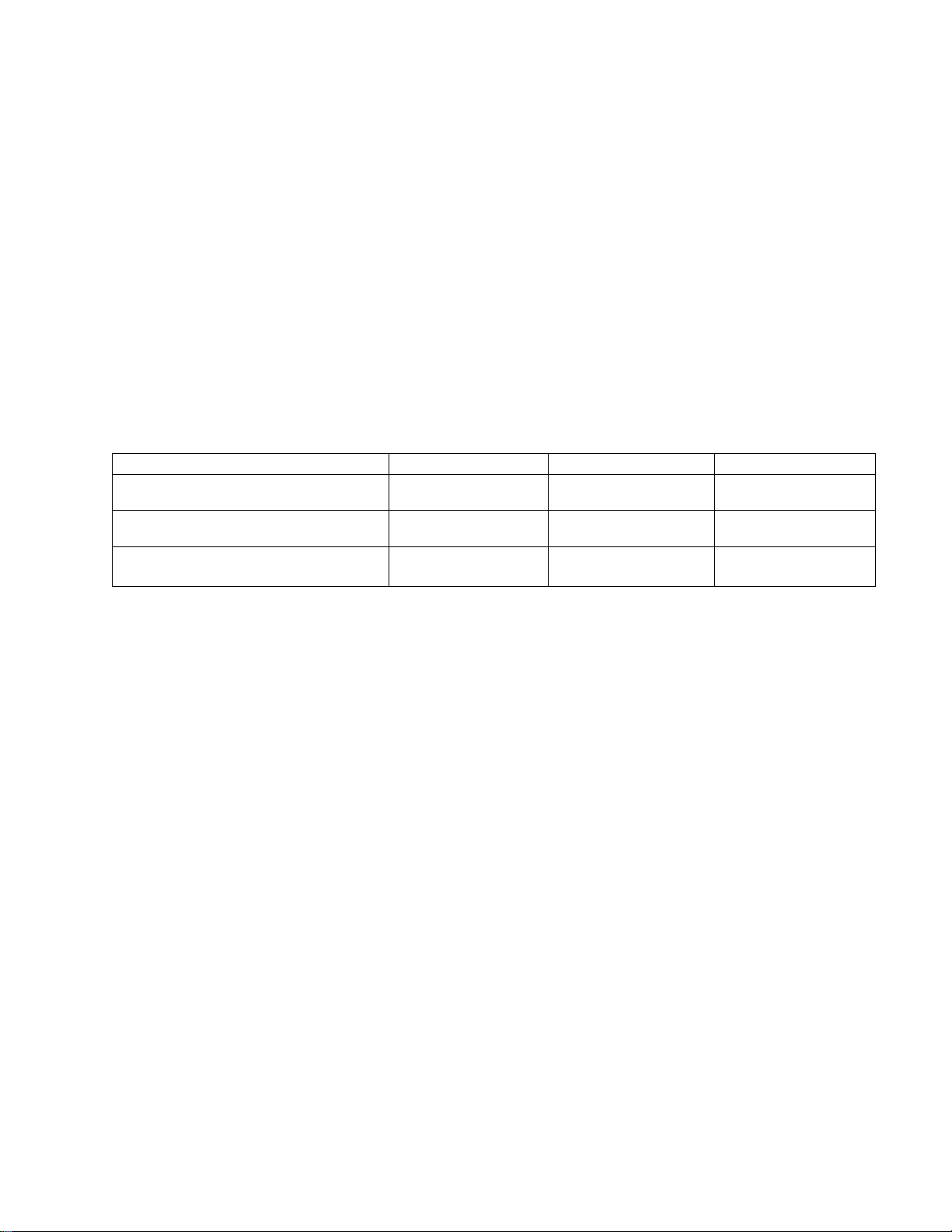

Table 4. Recommended Suction and Discharge Pipe.

UNIT

MAIN PIPE

TANK FITTING

ISO VALVE

CIP VALVE

UNIT INLET

BALL CHECK VALVE

25 BLOOM

2"

2"

2"

1"

2"

2"

50 BLOOM

2"

2"

2"

1"

2"

2"

150 BLOOM

3"

3"

3"

1 - 1/2"

2"

3"

Piping connections for all sizes of BLOOM are provided below. Verify the type of pump provided

with your BLOOM before beginning installation. These materials are not included with a

purchase of a BLOOM, but can be found at most hardware stores.

Frame Dimensions and Components Descriptions.

Figure 5 shows the overall BLOOM frame dimensions and the location of the suction and

discharge ports of the pump in metric and imperial units.

Figure 8 shows the major components of the BLOOM.

Figure 7. BLOOM with suction and discharge connection locations

Figure 5. BLOOM with suction and discharge connection locations

- 10 -

Figure 6. Isometric views of BLOOM with Components Description

Suction Piping Installation

Install piping as close to the water body as possible. Keep pipe length as short as possible

and configure suction piping in a manner that minimizes the number of fittings (bends) and

valves.

Run a length of straight horizontal piping to the suction side of the pump. The length of this pipe

should a minimum of five (5) pipe diameters. Example: If system is to be plumbed with 90mm

(3”) diameter PVC pipe, then a straight section of pipe 38cm (2”) long should be used immediate

to the suction side of the pump.

Locate and install the suction pipe following the recommendations detailed in Figures 3 and 4

for a flooded suction installation. Use fittings as necessary to route the suction piping from the

BLOOM to the tank.

Water flows through a check valve in only one direction as indicated by the flow arrow on the

check valve. The check valve is normally in the closed position and opens in response to the

pump drawing suction from the tank. Ensure the check valve is installed with the flow arrow in

the direction of suction flow so as not to restrict flow from the waterbody to the pump. Check

valve is needed in the flooded lift installations only.

- 11 -

For installations where debris is approximately greater than 1/8” (3 mm) in size are present in

water, install a screen on the intake of the suction pipe to ensure that large solids do not pass

through the BLOOM. Verify that the intake screen is rated for the flow liquid capacity of your

BLOOM and does not restrict the generator’s design liquid flow rate.

Discharge Piping Installation

Locate and install the discharge pipe following the recommendations detailed in Figure 3 for the

installation. Use pipe fittings as necessary to route the discharge piping from the BLOOM

unit to the tank wall. The discharge pipe can be routed over the top of or through the tank wall.

Install discharge pipe at the maximum water submergence depth and connect a 90 –

degree elbow to the end. Angle the discharge tangential to the tank to create a circular current

to assist with mixing.

Figure 7. –BLOOM Discharge Pipe at Maximum Water Submergence Depth.

- 12 -

CIP Valve Installation (Optional)

Two optional shut-off valves can be used to isolate the BLOOM from the rest of the system

for Clean in Place maintenance. See Table 4 for CIP valve sizes recommendations.

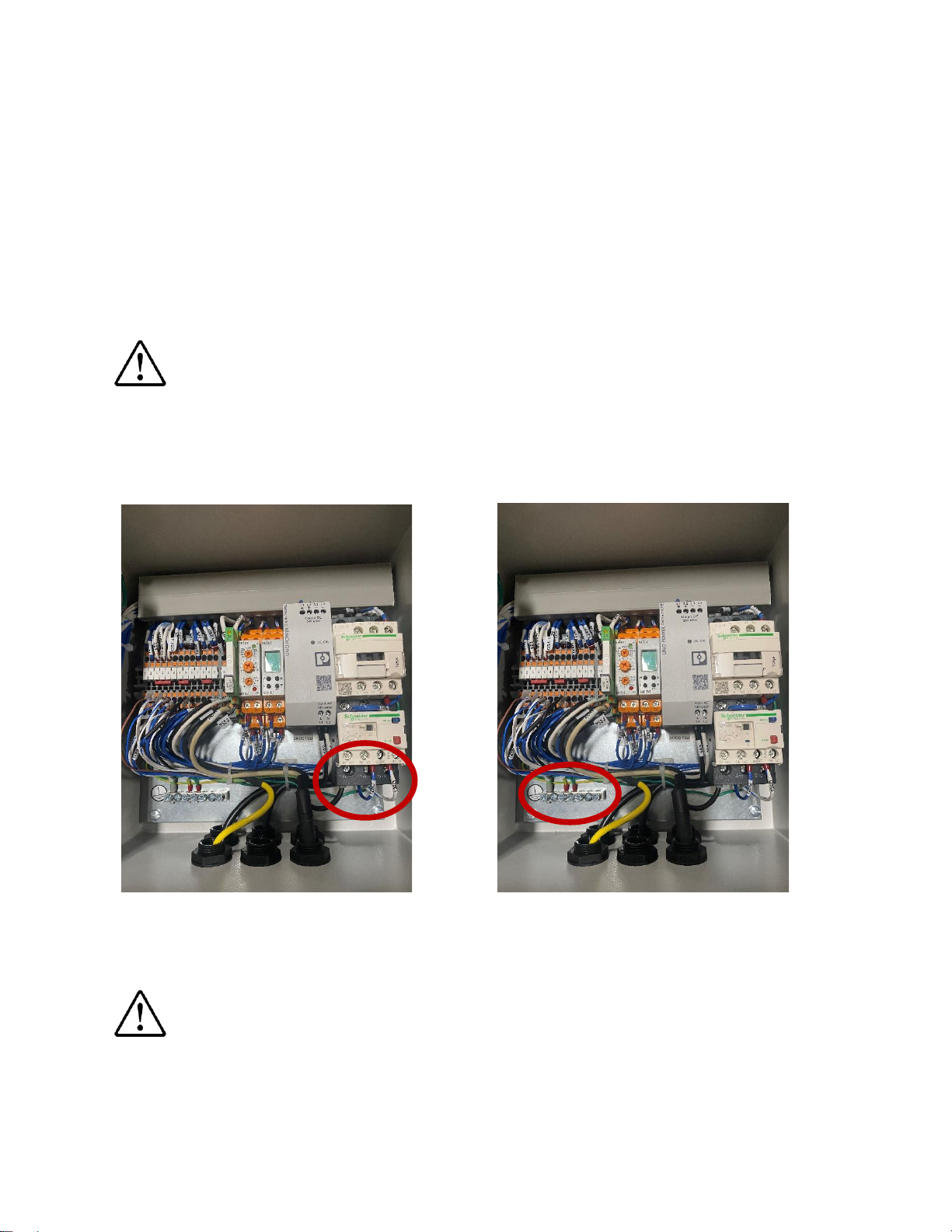

Connect Power to Control Box.

WARNING: Before connecting power, verify the voltage, phase and amps

requirements of your BLOOM. See purchase order for unit details.

All BLOOMS are single-phase model, there will be two wires coming out of the overload relay,

as shown in the red circle photo 1. Photo 2 shows the ground connection.

Photo 1. Output Terminal Connections on Photo 2. Ground

Overload Relay Wired for a Single Phase.

WARNING: Ensure that the ground wire from the power cable is connected to the

grounding bar inside the enclosure.

- 13 -

QUICK STARTUP GUIDELINES

WARNING: Refer to the operating manual for important safety and startup information.

When all piping is installed and pipe glue cure time has been met, connect electricity in

accordance with applicable Local Electrical Code and ordinances. The use of an

extension cord is hazardous and should be avoided.

Flooded Suction Applications: Pump Priming Instruction

Step 1. Open the intake and discharge valves to flood piping.

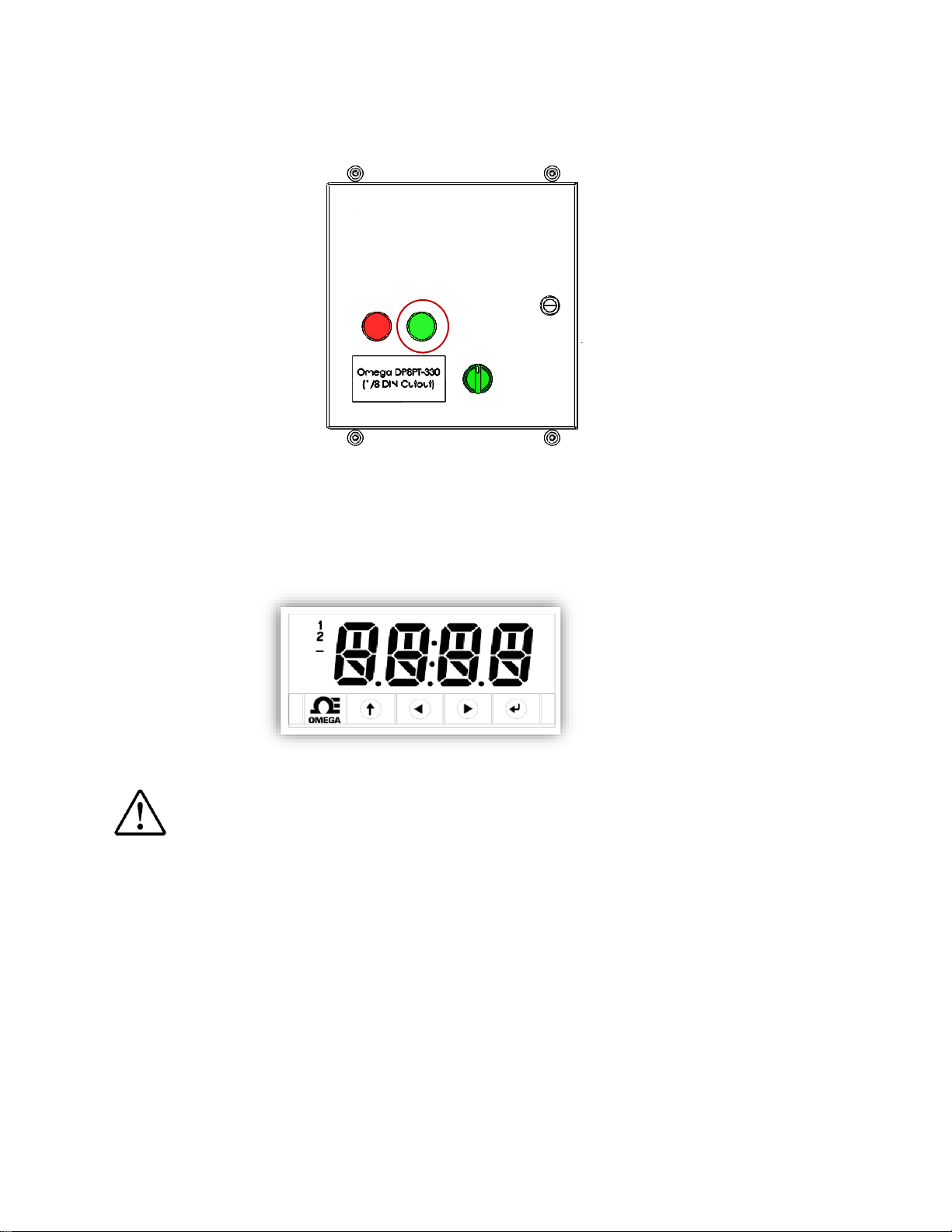

Step 2. Turn on the main power by using the green selector switch.

Intake and discharge valves.

- 14 -

Step 3. Press the green bottom to select “AUTO” position.

Step 4. The four button / LED display interface allows continuous monitoring of

sensor values, as well as for quick changes to LOW and HIGH setpoints.

Refer to the operating manual for more details in how to operate controller.

WARNING: Do not use isolation valves to throttle the pump. This may cause

loss of prime, excessive temperature, and damage of the pump, voiding

warranty.

Step 5. Check piping for visible leaks. If your BLOOM pump is equipped with a pump

strainer, verify through the clear window in the strainer lid that there are no bubbles

entering in through the liquid suction stream.

A large air pocket or large bubbles should not be visible in the strainer basket. If large

bubbles or an air pocket is visible in the strainer basket there is a suction pipe leak.

Turn OFF BLOOM and check suction pipe for leaks and ensure all pipe connections

are airtight.

Refer to the BLOOM Manual to configure the operational mode of the BLOOM.

- 15 -

Suction Lift Applications: Pump Priming Instructions

Step 1. Open the intake and discharge valves to flood piping.

Step 2. Turn on the main power by using the green selector switch.

Intake and discharge valves.

- 16 -

Step 3. Press the green bottom to select “AUTO” position.

Step 4. The four button / LED display interface allows continuous monitoring of

sensor values, as well as for quick changes to LOW and HIGH setpoints.

Refer to the operating manual for more details in how to operate controller.

WARNING: Do not use isolation valves to throttle the pump. This may cause

loss of prime, excessive temperature, and damage of the pump, voiding

warranty.

Step 5. Check piping for visible leaks. If your BLOOM pump is equipped with a pump

strainer, verify through the clear window in the strainer lid that there are no bubbles

entering in through the liquid suction stream.

A large air pocket or large bubbles should not be visible in the strainer basket. If large

bubbles or an air pocket is visible in the strainer basket there is a suction pipe leak.

Turn OFF BLOOM and check suction pipe for leaks and ensure all pipe connections

are airtight.

Refer to the BLOOM Manual to configure the operational mode of the BLOOM.

- 17 -

Suction and Discharge Operation

Turn the BLOOM on and observe the suction and discharge locations in the waterbody.

The intake should not create a vortex at the surface. If a vortex is visible, the suction

intake is not properly submerged. Verify that the suction is at least 2 ft beneath the

minimum water level. The bubble pattern visible at the surface of the water above the

discharge should consist primarily of small bubbles, roughly the size of a pea or smaller.

If bubbles are consistently larger than the size of a small pea, contact a Moleaer technical

service representative at (424) 558-3567.

Operating Parameter Ranges

Normal operating ranges for the BLOOM units are shown in Table 5.

Table 5. BLOOM Normal Operating Ranges

Parameter

BLOOM 25

BLOOM 50

BLOOM 150

Gas Pressure (Gauge)

40-120 psig

40-120 psig

40-120 psig

Liquid Pressure (Gauge)

10-20 psig

10-20 psig

10-20 psig

Gas Flow Rate (Standard)

(US) & (EU) (Rotameter)

0-2.5 CFH

0-5 CFH

0-10 CFH

If the BLOOM unit is consistently operating outside of the ranges shown in Table 4,

contact a Moleaer technical service representative at (424) 558-3567.

This manual suits for next models

2

Table of contents

Other bloom Test Equipment manuals

Popular Test Equipment manuals by other brands

JDS Uniphase

JDS Uniphase Network Device JDSU brochure

Ametek Land

Ametek Land Landcal P1600B2 user guide

Keysight

Keysight 8516A Operating and service manual

Proceq

Proceq Pundit PL-200 manual

TEXIO

TEXIO DCS-1000B SERIES instruction manual

BluePoint MEDICAL

BluePoint MEDICAL AlcoTrue E operating instructions