Operating Instructions And Parts Manual

7

Notes

system is reset).

Functionally, the liquid in the basin

rises and trips the first float, but the

pumps do not turn ON. As the liquid

level rises, it trips the second float,

activating one of the pumps. Once the

liquid level recedes and no longer trips

the second float, the pump will turn

OFF. If the second float is tripped

again, the other pump will turn ON.

If for some reason the liquid level

increases past the second float and

trips the third float, both pumps turn

ON and trips the alarm.

Under normal circumstances, the first

pump will handle the flow after the

second float is tripped. In those cases,

the liquid level will recede until it

drops the lower float. This action turns

the pump OFF. The next time that the

liquid level rises, the other pump turns

ON. This alternates the pumps; this

prevents lock-up and extends the lifer

of both pumps.

Available Controls

For 115 volt only, a wide angle float

switch can be supplied with a plug-

thru series plug.

For 230 volt Simplex units, a NEMA 1

Simplex Controller with a hand-off-

auto switch and run light can be

supplied. This is supplied with a wide-

angle switch for automatic operation.

For 230 volt Duplex units, a NEMA 1

control panel can be supplied with a

hand-off-auto switches, run lights,

pump alternator, and an alarm bell.

This is supplied with a three float

switch system for automatic operation.

General Information

Sewage Pump Systems:

Simplex System

A simplex system consists of one pump,

its control switch, and one basin. It is

used in applications where less than six

toilets (units) are discharged into a

basin. The simplex unit is generally

operated with a contactor to turn the

pump ON and OFF. The contactor is

activated by a single pole float switch.

The float switch is a wide-angle

differential switch that rises with the

liquid level and turns the pump ON. As

the liquid level decreases, the float

lowers and turns the pump OFF. The

switch differential is 120º.

Sewage Pump Systems:

Duplex System

A duplex system is used in applications

where more than six toilets (units) are

discharged into a basin. However, each

pump should be sized to handle the

entire flow in case one pump fails. The

duplex unit is controlled by a NEMA 1

control panel that has an automatic

alternator, run lights, hand-off-auto

switches, and an alarm bell. The duplex

control panel is supplied with three

float switches. The floats are to be

positioned so that the lower float

turns the pumps OFF. The second float

alternates turning first one pump ON

and then the other pump ON. The

third float will turn BOTH pumps ON in

case one pump cannot handle the

flow. The third float will also sound

the alarm (which remains on until the

2

Operating Instructions And Parts Manual

Installation

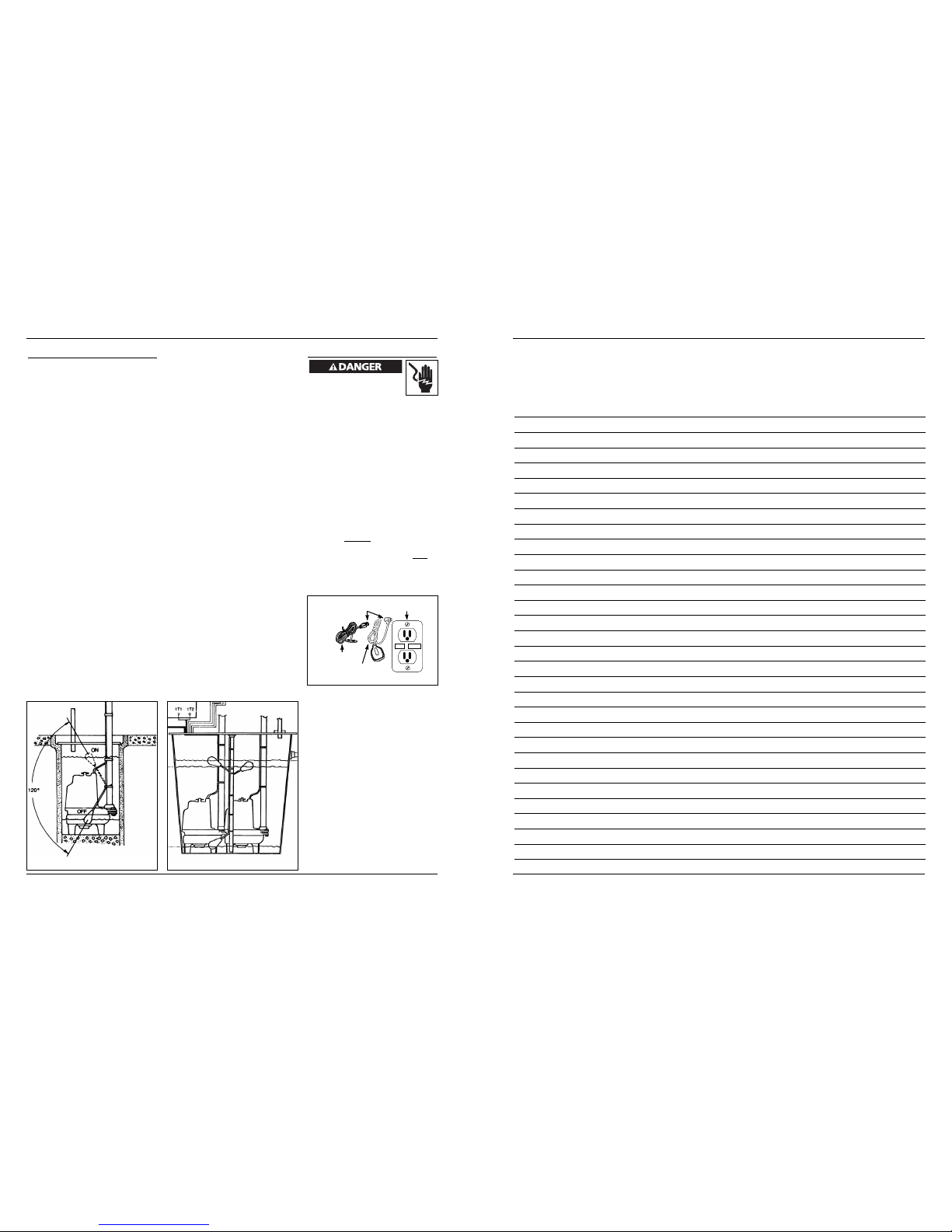

Always disconnect the power

source before attempting to

install, service, relocate or

maintain the pump. Never touch sump

pump, pump motor, water or discharge

piping when pump is connected to

electrical power. Never handle a pump

or pump motor with wet hands or when

standing on wet or damp surface or in

water. Fatal electrical shock could occur.

Some models of this product include a

grounded plug for quick installation

anywhere a grounded outlet is

accessible. Some models must be

incorporated into the building’s

electrical system. Models without plugs

must be connected to a grounded

circuit. The circuit should be equipped

with a ground fault interrupter device.

All models without plug-in power

cords systems must be installed by a

qualified electrician. All models with a

plug-in power cords system should still

have a qualified electrician inspect the

outlet being used to ensure proper

wiring.

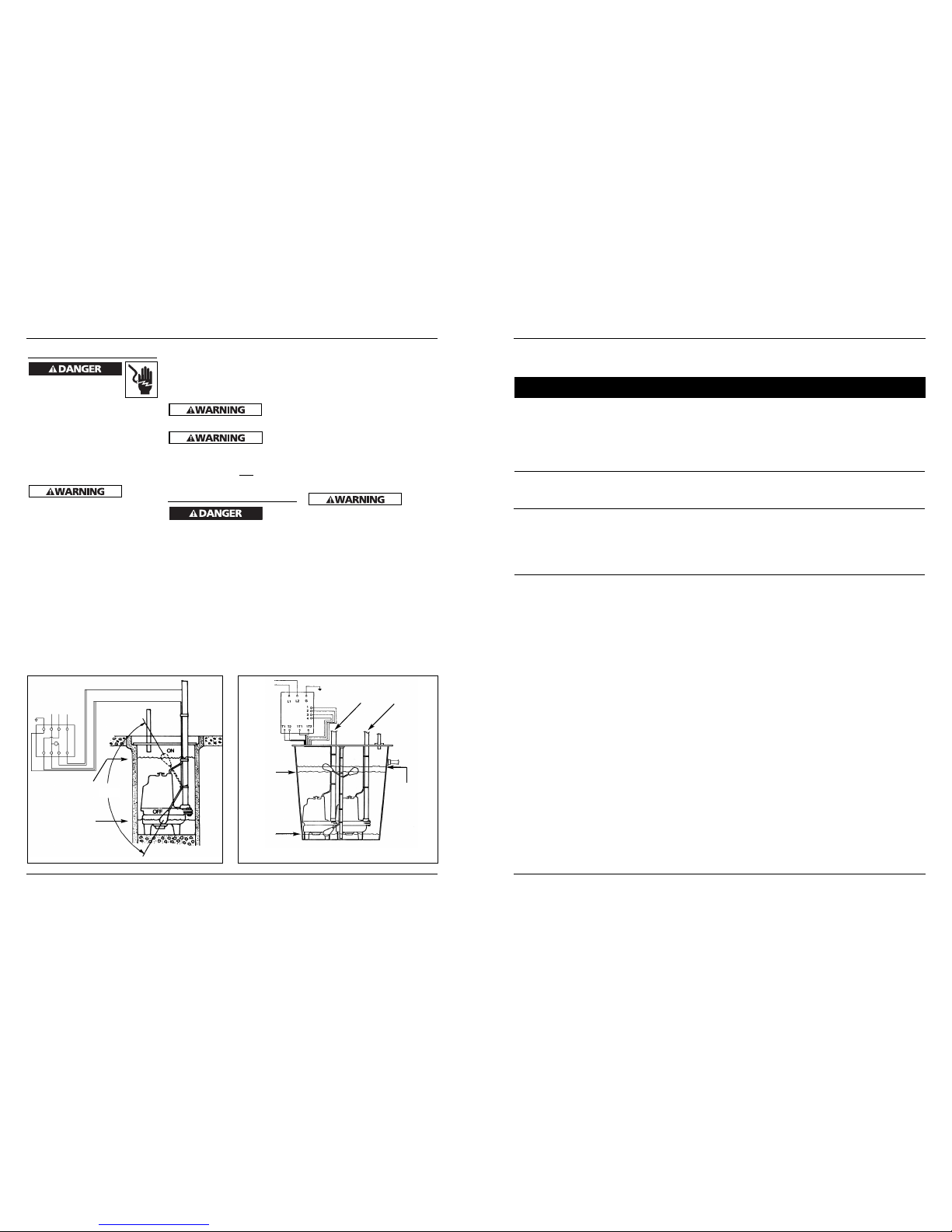

The control switch is a wide-angle

system which prevents short cycling of

the pump motor and the

consequential problems that short

cycling can cause. The switch can be

mounted on the discharge pipe (just

above the pump discharge flange). See

illustrations for switch mounting

arrangements.