TITAN Technologies International, Inc.®

9001 Jameel Street, Suite 180 • Houston, TX 77040

Toll-Free:

866.345.8484

•

Phone:

281.449.9994

•

Fa

x: 281.449.9996 • Email:[email protected] http://www.titanti.com

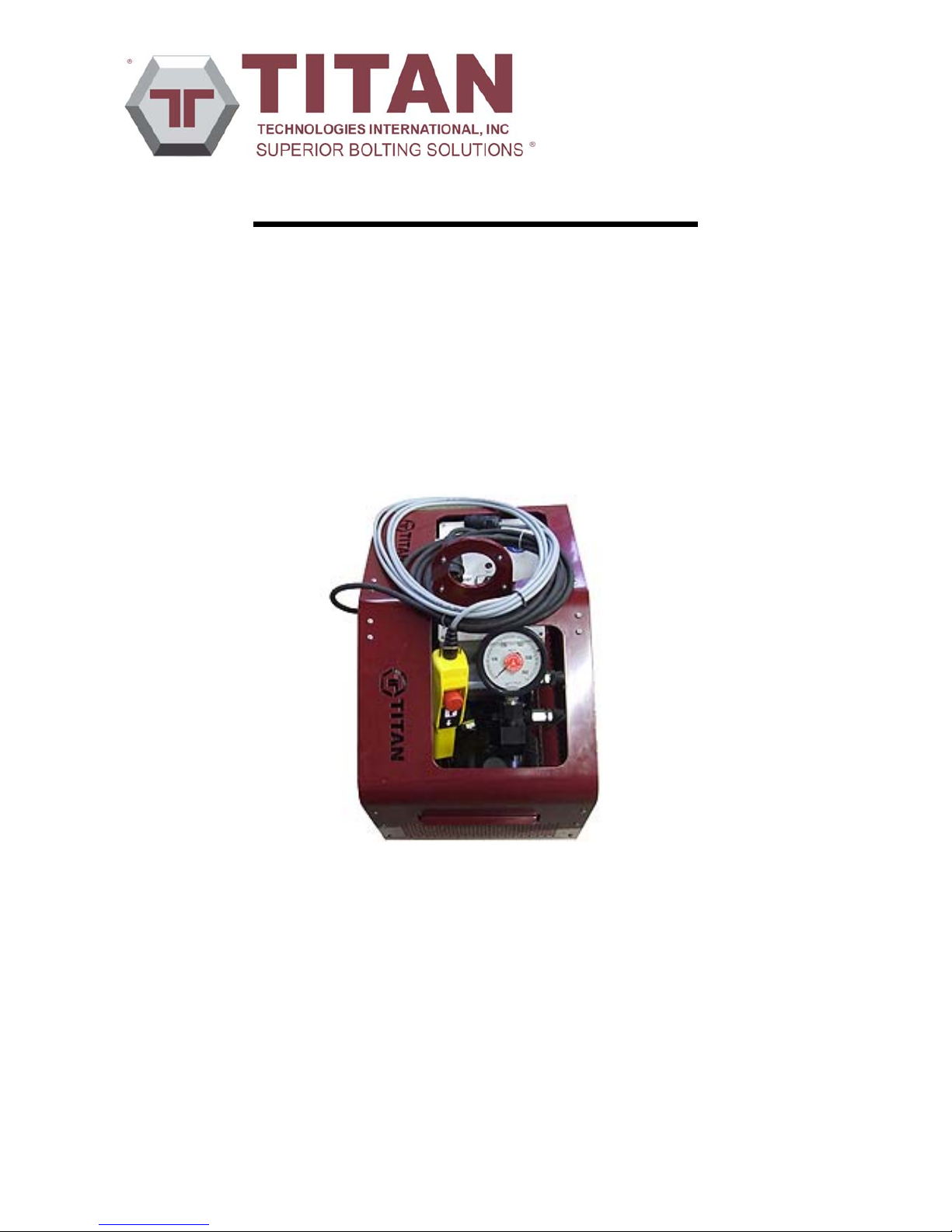

Starting

Note: The TITAN®WindMaster™ 2010 Pump produces extremely high

hydraulic pressure. Extreme care must be taken to ensure safety.

Failure to do so may result in severe injury or death.

Before starting the work, please make sure that the oil level in the pump tank is

correct. The oil gauges should be filled with oil. Filling the tank approximately 1

cm under the tank caps is allowed. In some cases it can be necessary to refill the

device with oil.

Use only hydraulic oil and never aggressive oil, because it can results in

damaging your seals.

NOTE: CHECK AND ENSURE THAT THE APPLICATION AND ITS

THREADED FASTERNERS ARE SUITABLE FOR THE MAXIMUM

OPERATING PRESSURE.

HINT: ALSO, ONLY HOSES AND CONNECTIONS WITH SUITABLE

OPERATING PRESSURE RATINGAND SAFETY FACTORS SHOULD BE

USED. CHECK ALL HOSES FOR KINKING AND IF FOUND, REPLACE

PRIOR TO PRESSURIZING. FOR BEST RESULTS AND OPTIMUM SAFETY,

USE ONLY TITAN®SUPPLIED HOSES, CONNECTIONS AND ACCESSORIES.

ATTENTION: NEVER USE THE HOSES AS A CARRING HANDLE.

The high-pressure hose must be shifted as straight-lined and directly as possible,

in each case never exceed the minimum bending radius. The hose should not be

overdriven or loaded. Sharp edged parts can damage the hose. Pay attention

particularly to the suitable threaded connections.

For tightening the threaded bolt or stud connection we recommend normal

spanners without extension, in order to avoid overloading at the threads. For the

hose connectors only use the threaded bolt or stud connections specified in our

catalogue under accessories.

Dirt particles in the hydraulic system can lead to damages at the cylinder faces

and at the valve seats, therefore replace dirty hydraulic fluid before starting.

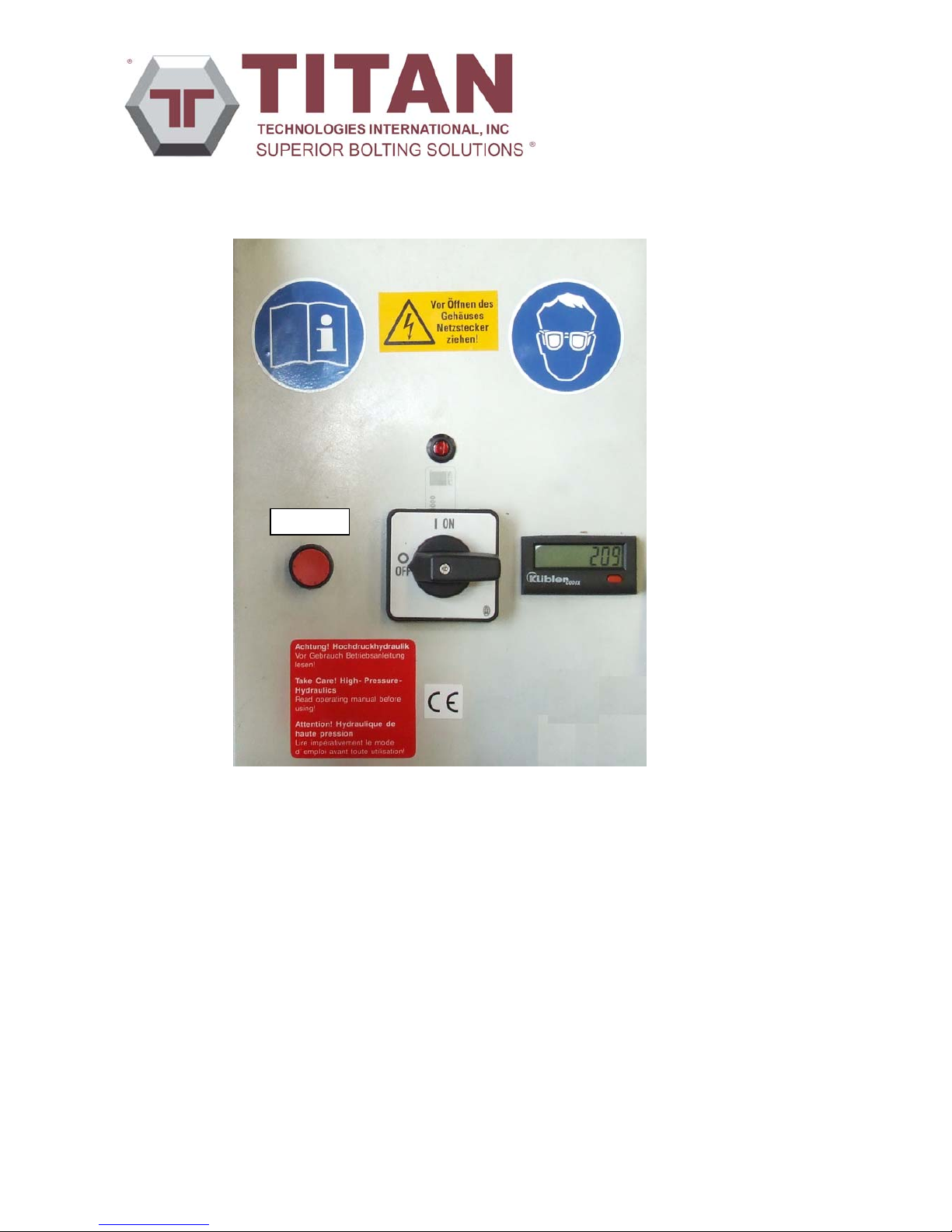

After all components are examined for the structural integrity necessary for the

desired pressure, the device can be plugged in to the electricity supply. Turn the

main switch to the pos.1 to start the pump.