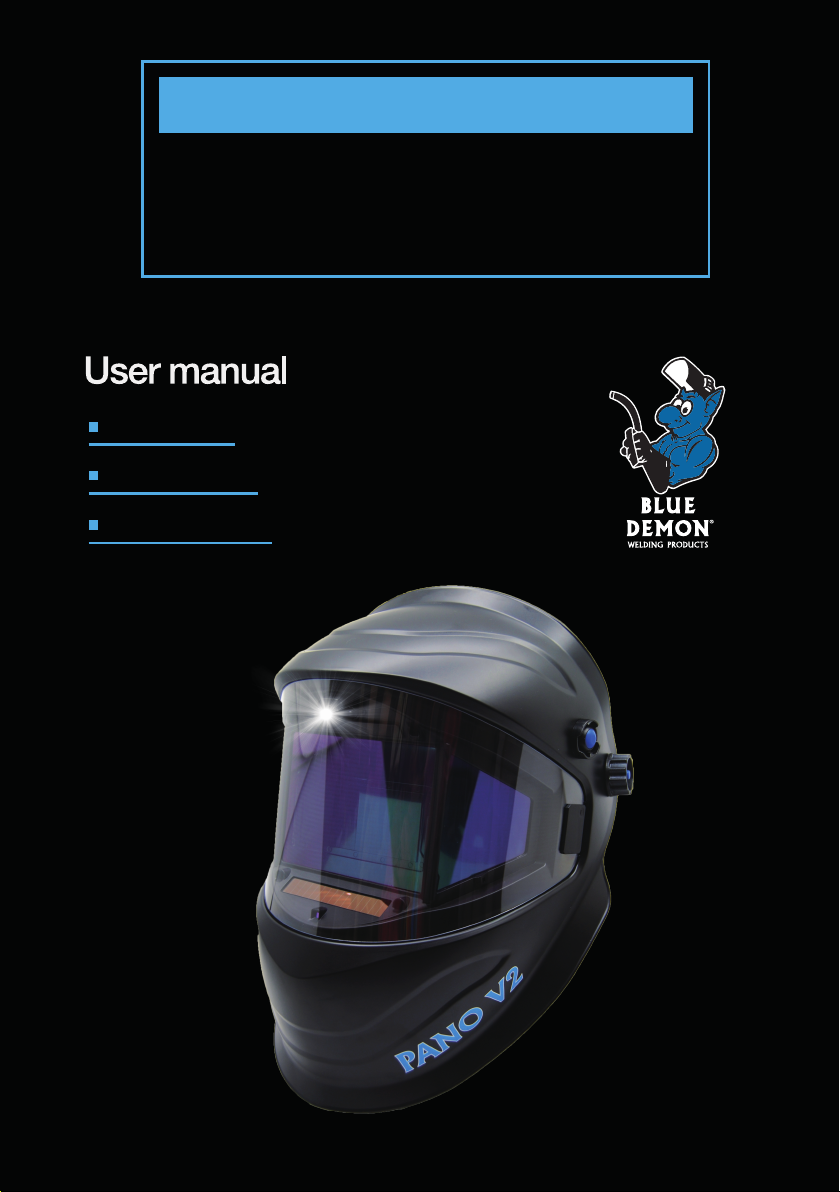

Blue Demon TRUE VIEW PANO V2 User manual

Digital Product

TRUE COLOR

180° SIDE VIEW

AUTO DARKENING WELDING HELMET

PANO V2

TRUE VIEW

2

TRUE VIEW PANO V2

3

4

5

7

8

15

16

18

20

*TRUE COLOR vision on the work piece both prior and during welding, which means

improved quality and higher efficiency.

*Overall-process protection against ultraviolet (UV) and infrared (IR ) radiation. TRUE

VIEW PANO V2 is equipped with lithium battery and solar cells that extends the life of the

battery.

*The product is in full conformity with related ANSI, CE. CSA, AS/NZS safety standards.

INDEX

WARNING

CORRECT USE OF THE WELDING HELMET

OPERATING INSTRUCTIONS

ADJUSTMENT INSTRUCTIONS

TECHNICAL SPECIFICATIONS

ILLUSTRATION

DISASSEMBLY AND ASSEMBLY INSTRUCTIONS

TROUBLESHOOTING

21

RELATED PARTS LIST AND WARRANTY

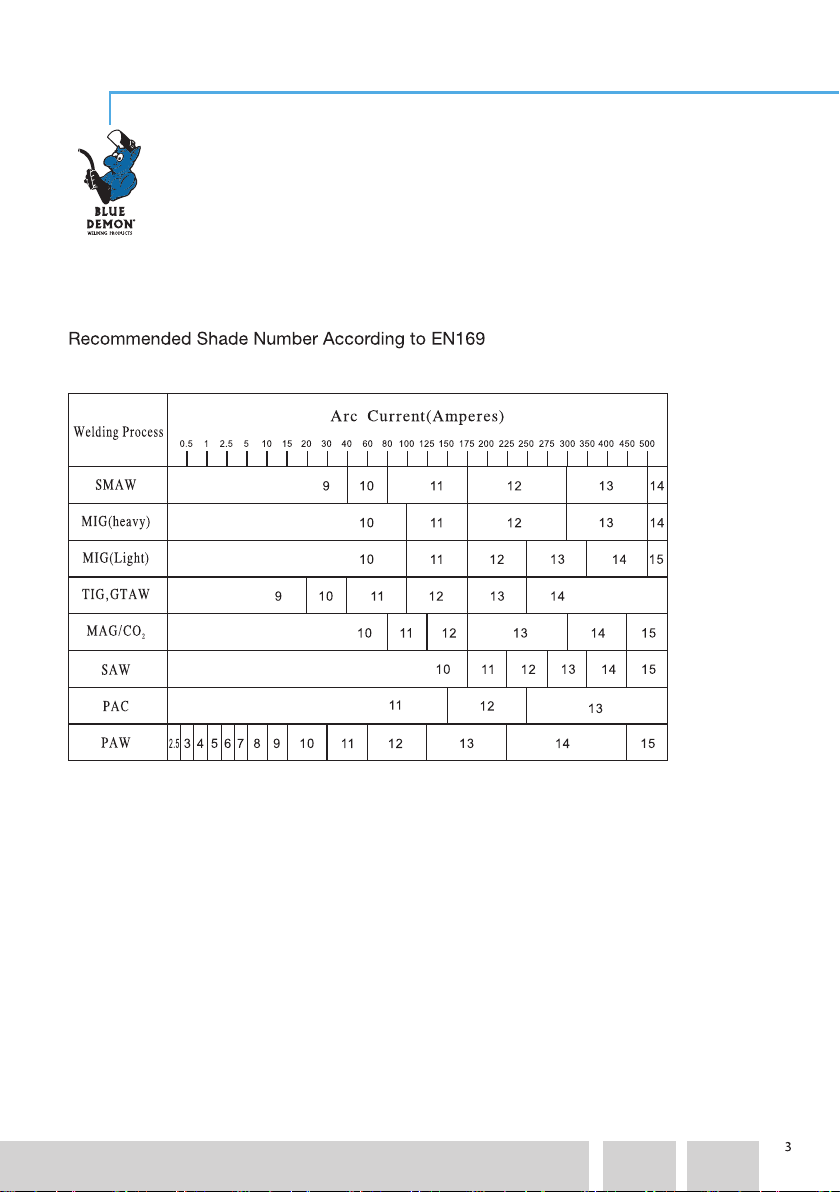

SHADE NUMBER

PAGE

TRUE VIEW PANO V2

Adjust shade pursuant to the field condition.

SHADE NUMBER

4

WARNING

READ CAREFULLY AND UNDERSTAND THESE

INSTRUCTIONS BEFORE USING THE HELMET

If the auto-darkening filter is cracked, stop using the helmet: UV/IR protection may

be compromised, resulting in burns to the eyes and skin.

During the welding process, heat and radiation are released.

• FUMES AND GASES can be dangerous to your health.

• Keep your head out of fumes.

• Use enough ventilation, exhaust at the arc, or both, to keep fumes and gases

away from your breathing zone and general area.

• ARC RAYS can injure eyes and burn skin.

• Before welding, always inspect helmet and filter lens to be sure they are fitted

properly, in good condition and not damaged.

• Check to see that the clear lens is clean and securely attached to the helmet.

• Always wear safety glasses or goggles under the welding helmet and protective

clothing, to protect your skin from radiation, burns and spatter.

• Ensure that optical radiation from other welder’s arcs in the immediate area

does not enter in from behind the helmet and auto-darkening filter.

Welding produces sparks and drops of molten metal that fly in all directions.

• The protective helmet must be worn to avoid potentially serious physical damages.

• Appropriate additional safety clothing must be worn to protect the rest of the body.

TRUE VIEW PANO V2

TRUE VIEW PANO V2 welding helmets are designed to protect the eyes and face

from sparks, spatter and harmful radiation under normal welding conditions. The

welding helmets may only be used for welding and not for other purposes. They

are suitable for use with virtually all welding process, except oxy-acetylene, laser

and gas welding procedures. They will not protect against severe impact hazards,

including fragments from grinding disks, explosive devices or corrosive liquids.

Machine guards and appropriate protection must be used. Avoid work positions

that could expose unprotected areas of the body to sparks spatter, direct and/or

reflected radiation. Use adequate protection if exposure can not be avoided.

5

CORRECT USE OF THE WELDING HELMET

• Before using the helmet, make sure that:

• the front cover lens, and the filter are in the correct position and correctly fixed

in place;

• all the sensors and the cells are not obstructed;

• the protection films on both screens are removed;

• the red light is off, otherwise change the batteries.

•Keep the filter viewing area as close as possible to the eyes during welding.

•When welding for extended periods, occasionally check the helmet and make

sure there are no signs of deformation or deterioration.

•Do not use the helmet without the transparent filter protections (internal and

external): non-observance may cause a safety hazard or irreparable damage to

the filter.

•Subjects with particularly sensitive skin must take extra care: materials that may

come into contact with the skin can cause allergic reactions.

•

MAINTENANCE

•Regularly check the condition of the helmet and change any damaged parts.

•Replace the external/internal transparent filter protection if it is damaged.

•Do not immerse the filter in water or other liquids; do not use solvents to clean the

filter.

•Do not put any heavy tools/objects in or on the helmet in order not to damage the

filter or the protective screens.

• Keep the helmet away from flames.

•Do not drop the helmet.

•Do not place the helmet too close to the welding area.

•Remove batteries when the helmet is not in use for long periods of time.

•Respect the temperature:

• use: -5°C (+23°F) ÷ +55°C (+131°F)

• storage: -20°C (-4°F) ÷ +70°C (+158°F).

TRUE VIEW PANO V2

Check that the protection level matches your welding process. If the helmet

presents operation problems, refer to the “troubleshooting” chapter; if the

problem persists, immediately stop using the helmet and contact the person in

charge or a distributor.

6

•Place the helmet in a way that does not allow its dimension to deform, or the viewing

filter to break.

•Do not allow the filter to come into contact with liquid and dirt.

•Do not open the filter container. Do not use any tools or other sharp objects to remove

any components of filter or helmet.

•

Do not use replacement parts other than those original ones: unauthorized modifications

and replacement parts will void the warranty and expose the operator to the risk of

personal injury.

CLEANING

Keep the filter, the sensor and the solar cell clean.

After using the helmet and before putting it away, it must be checked to verify integrity

and to eliminate any drops of molten metal.

The cartridge and the front cover lens must be cleaned at regular intervals with clean

cotton, a soft cloth or a special rag for lens. Do not use strong cleaning agents or

solvents: clean the inside and the outside of the helmet with a neutral disinfectant

product.

Non-observance of this regulation can expose the operator to health risks

and void warranty.

We will not accept any liability if the welding helmet is used for other

purposes or if these instructions are disregarded.

TRUE VIEW PANO V2

OPERATING INSTRUCTIONS

Check the front cover lens to make sure that they are clean, and that no dirt is covering

the sensors on the front of filter cartridge. Also check the front / rear cover lens and the

front lens retaining snap joint to make sure that they are secure.

7

TRUE VIEW PANO V2

Inspect all operating parts before each use for signs of wear or damage. Any

scratched, cracked, or pitted parts should be replaced immediately before using again

to avoid severe personal injury.

Adjust headband so that the helmet is seated as low as possible on the head and

close to your face. Adjust helmet's angle when in the lowered position by pressing the

side adjustable button.

Do not make any modifications to either the welding lens or helmet, other than those

specified in this manual.

Failure to follow these warnings and/or failure to follow all of the operating instructions

could result in severe personal injury.

8

ADJUSTMENT INSTRUCTIONS

Basic Functional Parameters

GRIND

WELD

SHADE

Parameter

SENS DELAY

3 0 No Display

No Display

10 1~4

Mode

Note:

Note:

Table 2 PANO V2 Side window function parameters of two operation modes

PANO V2 has one main window and two side windows.

The main window and two side windows have independent working modes to

choose from.

The main window has three operating modes: GRIND, WELD and CUT. The

specific function of the three operation modes parameters are shown in table 1.

The side window has two operating modes: GRIND and WELD. The specific function

of the two operation modes parameters are shown in table 2.

1、0 to 9 of the delay time corresponds to 0.06s to 1.0s, 0 is suitable for TAC

welding;

2、In the function of Welding and Cutting modes, sensitivity and delay time

can be set differently.

1、The two side windows have separate modes and parameter settings.

2、In welding mode when sensitivity set to 1, the side window will be

darkening follow the main window. When sensitivity set to 2, the side window

darkening follows the main window with low sensitivity. When sensitivity set to

GRIND

WELD

CUT

SHADE

Parameter

SENS DELAY

3 0 No Display

8~13 1~8

1~8

0~9

0~94~8

Mode

Table 1 PANO V2 Main window function parameters of three operation modes

TRUE VIEW PANO V2

9

Table 3 PANO V2 Main window Optional features of three operation modes

Main window Advanced Function

3, the side window darkening follows the main window with high sensitivity.

When sensitivity set to 4, the side window will stay dark.

PANO V2 in order to improve the convenience and comfort of users, add 4 optional

features and one-button grinding outside: Automatic Shade Number Adjust,

Automatic Sensitivity Adjust, Automatic Delay Time Adjust and Gradual Return. The

optional features of three operation modes of the main window are shown in table 3.

The outside grinding button is a self-recovery button, which can quickly switch the

working mode of the main window to grinding and press it again to return back the

previous working mode. When grinding button switches the working mode of the

main window to grinding, the main window will flash twice, and when the working

modes switches to the previous working mode, the main window will flash once.

GRIND

WELD

CUT

No

No

Yes

No

No

Yes

No

No

Yes

No

Yes

Yes

Automatic Shade

Number Adjust Sensitivity Adjust Delay Time Adjust Return

Automatic Automatic Gradual

Optional

Features

Mode

Function Definition Of The Display Area

Figure 1 is the display area, it has 10 function buttons, LCD display and LED lights,

which is explained next.

Figure 1 Display Area

TRUE VIEW PANO V2

10

(1)Main window Function Buttons

HIGH

HOLD: AUTO

1.Short Press -Increase the sensitivity.

2.Long Press - In the cut or weld mode,

set sensitivity automatically. (In the

process of automatic set sensitivity,

SENS area will be shown“AUTO”,

sensitivity numbers increase from 0

to 8 in turn)

1. Short Press-Press 0.1s to increase

the sensitivity. Release the button and

press again to increase the sensitivity

again.

2.Long Press-Press over 1.5s to set

sensitivity automatically for one time.

MIN

HOLD: AUTO

1.Short Press-Decrease the delay time.

2.Long Press-Enter or exit automatic

delay time function(When automatic

delay time function is enabled, the

screen of DELAY area will show“AUTO”)

1. Short Press-Press 0.1s to decrease

the delay time. Release the button and

press again to decrease the delay time

again.

2. Long Press-Press over 1.5s to enter

automatic delay time function and press

over 1.5s again to exit automatic delay

time function.

Function The usage the ButtonsButtons

MODE

A/M

HOLD: TEST

1.Short Press-Switching Mode:

GRIND—WELD—CUT—GRIND.

1.Short Press-Press 0.1s to switch the

mode. Release the button and press

again to switch mode again.

1.Short Press-In the welding mode

switch automatic or manual setting

the shade number.

2. Long Press-Test Function: Screen

Flashes—Grind—Cut—Weld.

1. Short Press-Short press to switch

automatic or manual setting the shade

number.

2.Long Press-Press over 1.5s to start

the TEST for one time.

LTR

DKR

LOW

1.Short Press-Decrease the shade

number.

2.Long Press-In the welding and

automatic shade number mode,

main window quickly decreases

the shade number.

1.Short Press-Short press to decrease

the shade number. Release the button

and press again to decrease the shade

number again.

2.Long Press-Press over 1.5s to decrease

the shade number quickly.

1.Short Press-Increase the shade

number.

2.2.Long Press-In the welding and

automatic shade number mode,

main window quickly increases the

shade number.

1.Short Press-Short press to increase

the shade number. Release the button

and press again to increase the shade

number again.

2.Long Press-Press over 1.5s to increase

the shade number quickly.

1.Short Press-Decrease the sensitivity.

2.Long Press- Anti-light interference

mode on/off. When Anti-light interference

is on, the sensitivity area displays a bulb

icon.

1.Short Press-Press 0.1s to decrease

the sensitivity. Release the button and

press again to decrease the sensitivity

again.

2.Long Press- Press over 1.5s to turn

on/off the Anti-light interference mode.

TRUE VIEW PANO V2

11

1.Short Press-Increase the delay time.

2.Long Press- In the weld mode, enter

or exit automatic shade number gradual

return.( When gradual return function

is enabled, the screen of DELAY

area will show “G” )

1、Short Press-Press 0.1s to increase

the delay time. Release the button and

press again to increase the delay time

again.

2、Long Press-Press over 1.5s to enter

automatic shade number gradual return

and press over 1.5s again to exit gradual

return.

MAX

HOLD: Gradual

(3)LCD Display

(2)Side window Function Buttons

Function The usage the ButtonsButtons

L

FILTER

R

FILTER

1、Short Press-Setting the left window

and press the button once to increase

the sensitivity. When enter the setting

of left window, the sensitivity area of

screen will display ”L” and left window

will flash. After setting the parameters,

if there is no keystroke, the LCD

screen will be automatically return to

the parameter interface of the main

window after 8 seconds.

2、Long Press-Quickly back to the

main window parameter display

screen.

1、Short Press-Press 0.1s to

increase the sensitivity. Release the

button and press again to increase

the sensitivity again.

2、Long Press- Press over 1.5s to

main window parameter display

screen.

1.Short Press- Setting the left window

and press the button once to increase

the sensitivity. When enter the setting

of right window, the sensitivity area of

screen will display” R” and right

window will flash. After setting the

parameters, if there is no keystroke,

the LCD screen will be automatically

return to the parameter interface of the

main window after 8 seconds.

2.Long Press-Quickly back to the main

window parameter display screen.

1.Short Press-Press 0.1s to increase

the sensitivity. Release the button

and press again to increase the

sensitivity again.

2.Long Press-Press over 1.5s to

main window parameter display

screen.

LCD Display have four parts: Mode, Shade, Sensitivity and Delay time.

1)GRIND, WELD, CUT indicates the current work mode.

TRUE VIEW PANO V2

12

(4)LCD Display

Sleep and wake up

2)Sensitivity: In the WELD or CUT mode, SENS area will be shown the number. 0 for

the grinding. For main window, 1 is the minimum sensitivity, and 8 for the maximum

sensitivity. For side window, 1 is the minimum sensitivity, and 4 for the maximum

sensitivity. The main window has Anti-light interference mode. When working in a strong

light environment turn the Anti-light interference mode on, the bulb icon will be displayed

in the SENS area on the screen. When automatic sensitivity function is enabled, SENS

area will be shown“AUTO”. The sensitivity numbers will increase from 1 to 8 in turn, and

stop at the gear number which is automatically set. Then the system will quit the

automatic sensitivity setting mode.

3)Delay time: DELAY area will be shown current number. When automatic delay time

function is enabled, DELAY area will be shown“AUTO”. The numbers on the screen can

adjust from -9 to +9 . In the weld mode, When gradual return function is enabled, the

screen of DELAY area will show“G”.

4)Low battery : When the battery is low, the screen will display low battery, indicating

that the batteries need to be charged.

There are two kinds of LED Light mode: Flash and always light. Different LED light

indicators are shown in table 4.

Table 4 Different LED light indicators

Note: The main window in the grind mode when the battery is not enough, the LED will

indicate lack of battery.

Operation Condition LED Indicator

Grind

Lack of battery (empty)

Red light for 2s and flash for 0.3s

Red light always on and the

display flashes a low-power icon

every 5s

In order to extend the service life of the battery, auto darkening welding filter under the

condition of environmental light intensity is less than 1lx and without arc for a long time,

need to enter a dormant state and work in low power mode. In a dormant mode, when

TRUE VIEW PANO V2

13

Basic function of the headlamp

the environmental light intensity is more than 1lx, auto darkening welding filter will be

working normally in 10s.

For different welding environments, the lens is integrated with a built-in headlamp.

Headlamps have two levels of brightness, high (100lm) and low (50lm).

1)Function

Headlamp has two working modes: manual and automatic. The headlamp manual mode

is continuously lit at a fixed brightness. In the automatic mode, the headlamp will be

automatically extinguished after the welding arc, and the headlamp will be lit immediately

after the welding arc is extinguished. The main advantage of automatic mode is to extend

the use time of the headlamp.

① Short press to switch the brightness in the manual mode:

Highlight → low light → Off → high light

②Long press to enter the automatic mode, the light will blink twice quickly. Short press at

any time to return to the manual mode. The brightness of the automatic mode is

determined by the brightness of the current manual mode, as shown in the following

table:

2)Charging

When the Low BAT indicator is steady red and the display displays the low charge, the

battery needs to be charged. You can use the standard TYPE-C charging interface to

plug into the TYPE-C interface on the upper part of the lens. When the lens is charging,

the charging indicator will light up. The red light indicates that the lens is charging and the

green light indicates that the charging is completed.

3)Low battery protection

When the battery is low, the headlamp will be forced to automatically turn off to save

power, so as to ensure that the auto darkening welding lens can still work normally for

more than 7 days.

In Manual Mode Highlight Low light Off

Brightness after long press

to enter the automatic mode Highlight Low light Highlight

TRUE VIEW PANO V2

14

The helmet should be adjusted to cover the eyes and face effectively while welding.

The position of the forehead band and rear headband can be manually adjusted to

fit securely. Rotate the gear to adjust the tightness until it feels comfortable.The front

and rear headbands should be adjusted to tightly cover the forehead and the backside

of head. See figure 2a.

Headgear adjustment:

Headgear depth:

The depth of the headgear can be adjusted to the position that the headgear sits above

your brow.Tighten/loosen the two slotted straps to fit the top of your head. See figure 2b.

The distance from the lens can be adjusted by pressing side pins and move sliders

simultaneously. There are 5 distance positions available for adjustment. See figure 2c.

Distance between lens and face:

The ideal helmet position is where your eyes are at 90°angle behind the lens.There

are 7 angle limitation positions available for adjustment. Press side buttons and move

the sliders simultaneously to make the helmet obtain the required angle limitation

position.See figure 2d.

Angle limitation position:

FIGURE 2

ab

cd

As a result of above mechanism action, the welder surely feels more

comfortable than before and are in working with more high proficiency

at any time.

Headgear

TRUE VIEW PANO V2

15

TECHNICAL SPECIFICATIONS

Main Window:

Light state: DIN3

Dark state: DIN 4-8/8-13

Main window viewing area: 114.5x85.5 mm (4.50” x 3.36”)

Side Window:

Light state: DIN3

Dark state: DIN 10

Side window viewing area: 2(pcs)x36.2(Top)/81.8(Bottom)x68.6(Height) mm

(2(pcs)x1.42(Top)” /3.22(Bottom) x2.70(Height)”)

Sensors: 7

Optical class: 1/1/1/1

True color: YES

Tig capability: >2A

Control: Digital

Shade control: Auto / Manual

Shade deviation of auto shade: -2.0 - +2.0

Sensitivity: 1-8, Automatic

Delay: 0.06 - 1.0S

Manual: YES

Auto mode: YES ( -/+9 steps adjustment )

Gradual: YES

TAC welding: YES

Gradual shade return to clear state: YES

Switch time: 1/10000S

Mode: CUT/WELD/GRIND

Power supply:

Auto ON / OFF: YES

Power backup: Solar panel & battery 2*CR2032

Test: YES

UV & IR protection: Up to shade 16

TRUE VIEW PANO V2

16

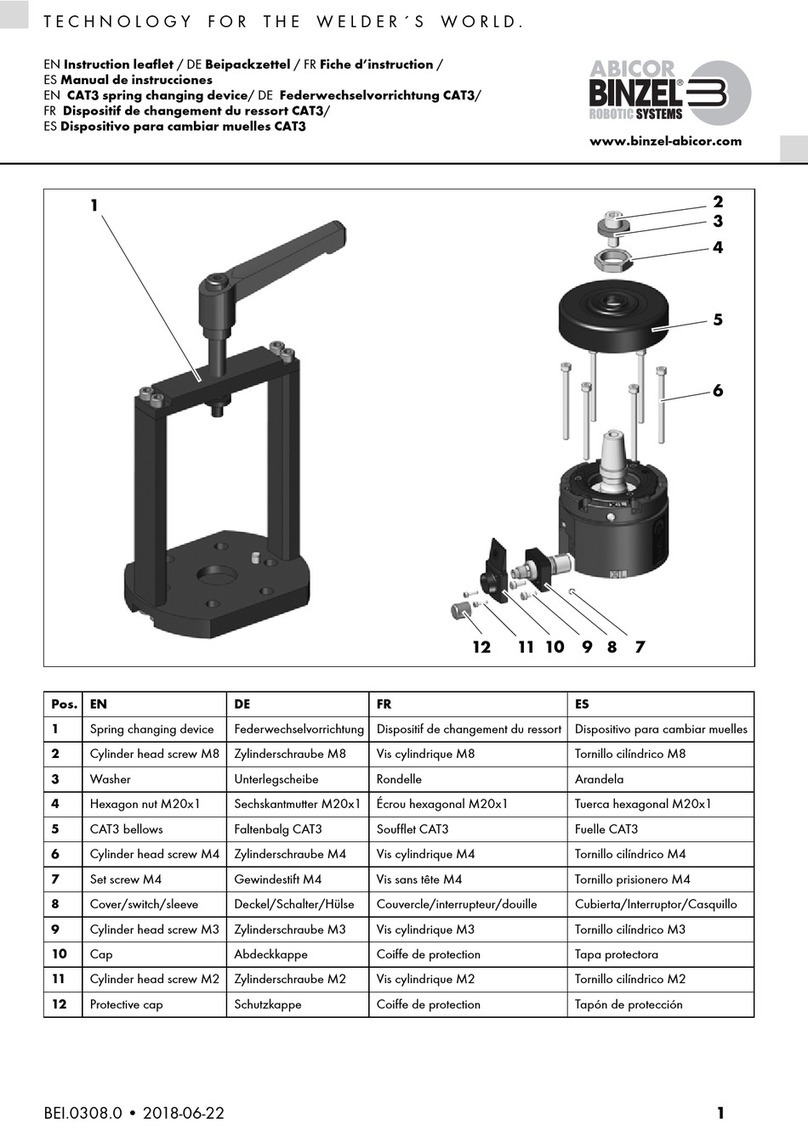

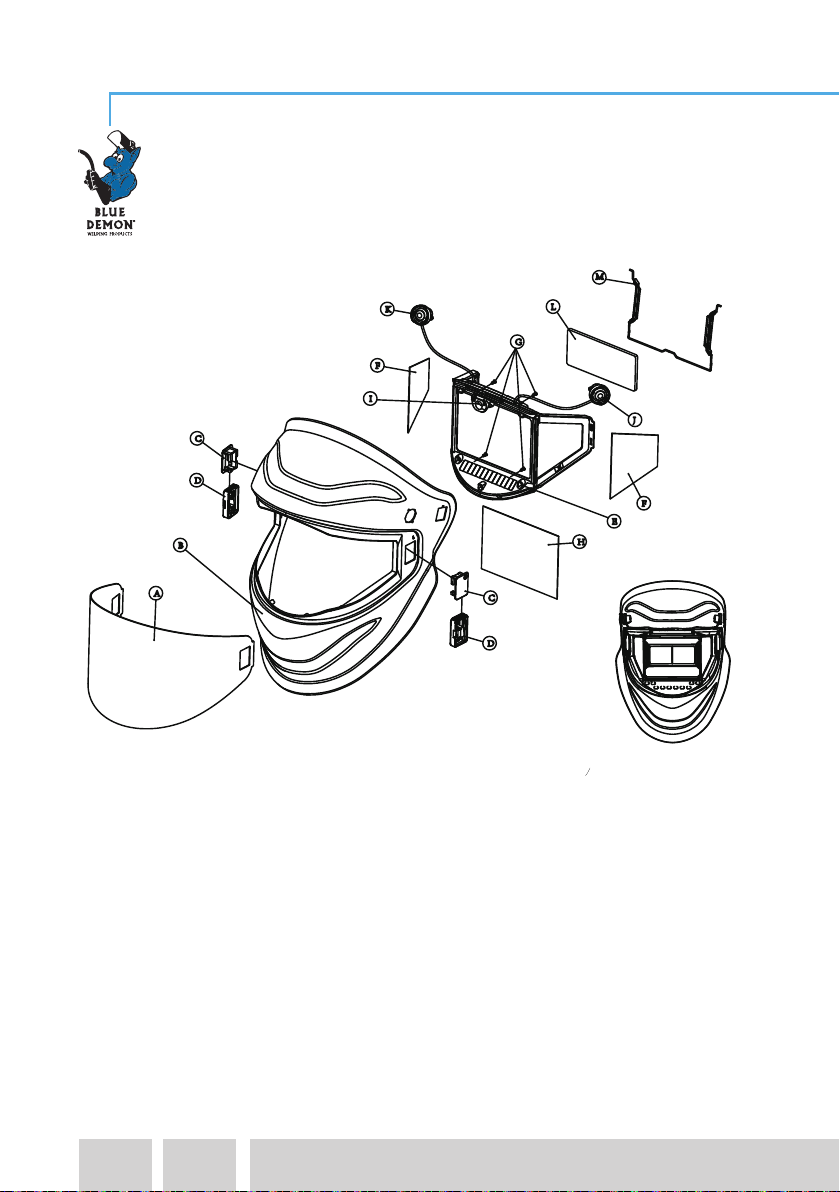

Main Part

ILLUSTRATION

E

A

G

B

Front protection plate

Snap joint for protection plate

Lock for snap joint of protection plate

Helmet shell

C

D

Rear protection plate 01

Auto darkening lens

F

Screw

L

H

I

Rear protection plate 02

Grinding button

Light switch button

light

J

K

Magnifying giass

Magnifying giass

M

Side Window Light Barrier

TRUE VIEW PANO V2

17

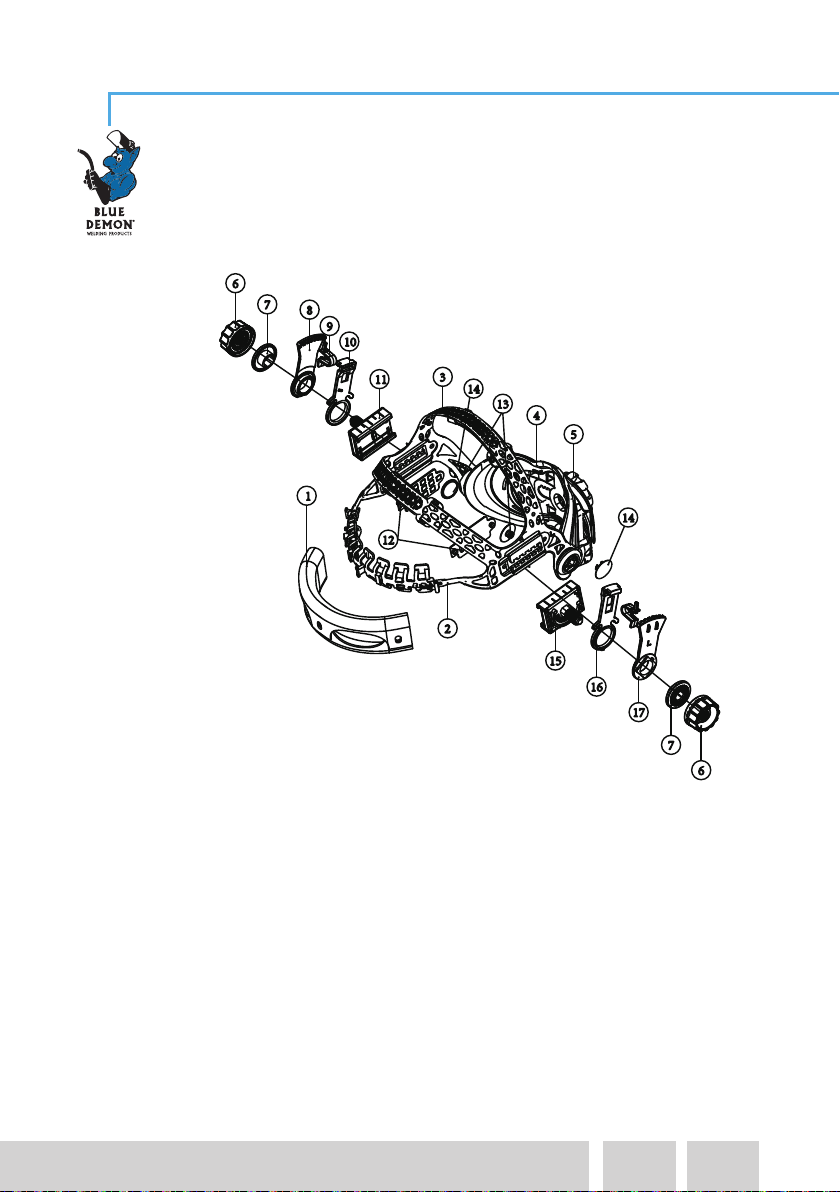

Headgear

5.Occipital pad

7.Washer

8.Right limitation washer

9.Angle pin

10.Right adjustable washer

11.Right slider

12.Side trim

13.Rotating shaft inside trim

14.Rotating shaft outside trim

6.Headband adjusting nut 15.Left slider

16.Left adjustable washer

17.Left limitation washer

1.Sweatband

4.Left belt

3.Right belt

2.Forehead band

TRUE VIEW PANO V2

18

DISASSEMBLY AND ASSEMBLY

INSTRUCTIONS

Protection Plate

1. Unlock the snap joint of protection plate if it is locked (A).

Press the snap joint for protection plate and then take out

the plate (A).

2. Change another protection plate and insert the snap joint

(make sure “a” side close to the helmet) and then lock it

(B).

3. Insert a finger into the semicircular hole and pull out the

inner protection lens (C). Remove protection film from

lens.

Place inside protection lens (C) back into the front of the

helmet by inserting one side of the lens into either side

slot and then bend the lens just enough that it will slip

into the other side slot.

Lock

Insertion

1

A

2

B

Unlock

Press

C

3

a

b

TRUE VIEW PANO V2

I

7

19

DISASSEMBLY AND ASSEMBLY

INSTRUCTIONS

Battery

7. Paste the control panel (I).

5. Peel off the control panel (E).

6. Loose the screw (F) and take out the filter (G) assembly from

the shell.

Tighten the screws (H).

6

4. Using the battery remover to take out the battery (D).

Change the battery and then put them back.

E

F

5

H

G

Filter

D

4

TRUE VIEW PANO V2

The filter does not darken or is

unstable when switching from

light to dark and viceversa

The external transparent protection of the filter is

dirty or damaged

Change the external transparent

protection

The sensors are dirty Clean the sensor surface

The level of the welding current level (sensitivity)

is too low

Increase sensitivity

The batteries are not in good condition or not

properly inserted

Replace the batteries or remove them

and re-insert them properly

Battery terminals and the contact surfaces of the

filter are dirty or oxidized

Clean both

The switch “WELD-GRIND” on the filter is in

position “GRIND”

Place the switch in the “WELD”

Slow switching The operating temperature is too low Do not use at temperatures

under -5°C (+23°F).

The external or/and internal protection of the filter

is/are dirty or damaged

Clean the dirty components and

replace the damaged ones

Not enough light in the surrounding area

The scale number is not set correctly, or the fixed

scale number is not suitable

Where possible, select the correct

number

Filter darkening without arc

being struck

Sensitivity is too high Adjust sensitivity to the right level

Filter remains dark after

completing a weld

Delay set too high

Ambient light is too bright

Adjust delay.

Reduce light level

Weld spatter is damaging

the filter

Missed, damaged, broken, distorted front cover Replace front cover lens

Some common problems listed below, together with their possible solutions, can

arise when using the helmet:

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

ATTENTION! If the described malfunctions cannot be solved, stop using the

helmet immediately and contact Blue Demon Welding Products

Poor visibility

20

TRUE VIEW PANO V2

Table of contents

Other Blue Demon Welding Accessories manuals