Blue Diamond Extreme Duty 2 Series User manual

1

Extreme Duty Series 2 Augers Operators Manual May2020

Blue Diamond® Attachments

Extreme Duty Series 2 Augers

Owner's Manual

2

Extreme Duty Series 2 Augers Operators Manual May2020

1 CRITICAL INFORMATION -SERVICE INTERVALS

CRITICAL -DO NOT CONNECT OR OPERATE YOUR DRIVE UNIT

WITHOUT FIRST HAVING READ AND UNDERSTOOD THIS STATEMENT

Your Blue Diamond® Extreme Duty Series 2 Augerx is a high performance attachment that is designed

for Drilling, Screw Anchoring (Pier) installation, Core Barreling and other extreme

applications where it is seeing high levels of torque. To avoid premature wear and failure, and to fulfill

your terms of warranty please read this statement.

All Blue Diamond® Extreme Duty Series 2 Augers must have a first oil change within the first 30hrs

(extreme use) or 50hrs (Moderate use) or 3mths (which ever comes first) of use to ensure the bed

in of the drive unit. For more detailed information please read pages 43 -- 46

If the first oil change is not performed within this period excessive wear within the gearboxx will occur

that will cause premature failure. All Warranty will be void.

Oil must then be changed thereafter every 300/500hrs and a full service every 12mths must be

performed by an authorized service agent to ensure Warranty requirements are met.

In the event of a failure under the warranty period:

•Contact Blue Diamond® immediately, DO-NOT DISASSEMBLE YOUR DRIVE without first

obtaining written permission and instructions from Blue Diamond®.

•Proof of service must be provided in hard copy form of both operational and service history

(in-cluding serial number of gearbox and hydraulic motor) records. Service must be performed

by an authorized Blue Diamond® service agent.

3

4 Auger Drives Operators Manual May2020

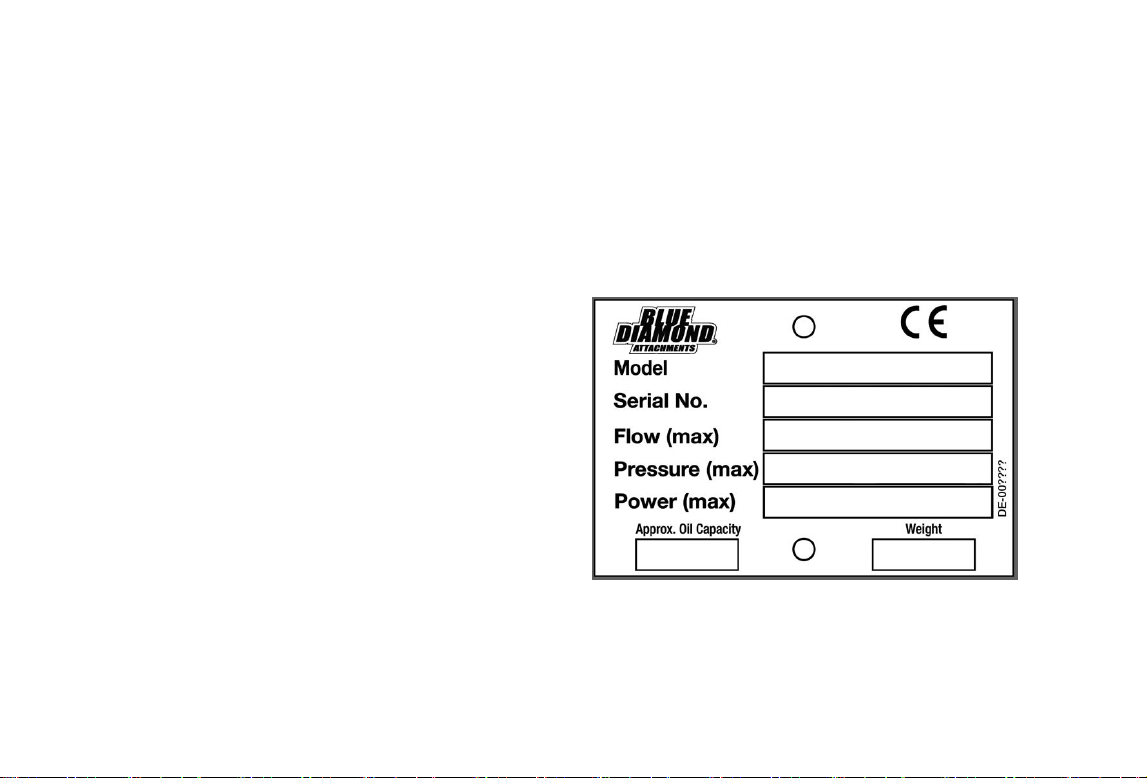

3 TO THE PURCHASER

THANK YOU

Congratulations on the purchase of your new High Performance Blue Diamond® Extreme Duty Series 2 Auger. This product was

carefully designed and manufactured to give you years of dependable service. It is mandatory that oil changes are performed at the

specified interval to keep it in top working condition (maintenance - chapter 12).

The complete manual must be read and understood before connecting and operating. Be sure to observe all safety precautions and

maintenance procedures as described in this manual.

Optional Extras are available for special applications or extreme conditions: these are noted throughout the manual. Contact your

Blue Diamond® dealer for any further information pertaining to this product or for further information on other products available in

the Blue Diamond® range.

ABOUT THIS MANUAL

This manual has been designed to help you do a better,

safer job. Read this manual carefully and

become familiar with its contents before

connecting and operating.

Remember; never let anyone operate this unit without

reading the "Safety Precautions" and "Operating

Instructions" sections of this manual. Unless noted

otherwise, right and left sides are determined from the

position of the machine operator when facing forward.

SAFETY ALERT SYMBOL

AThis is the "Safety Alert Symbol" used by this industry. This symbol is used to warn

of possible injury. Be sure to read all warnings carefully. They are included for your

safety and for the safety of others working with you.

5

Your Blue Diamond Extreme Duty Series 2 Auger is a user non serviceable part. Unauthorized

disassembly will void warranty. All service and warranty must be performed by an authorized Blue

Diamond® dealer. Contact your local Blue Diamond® dealer for details.

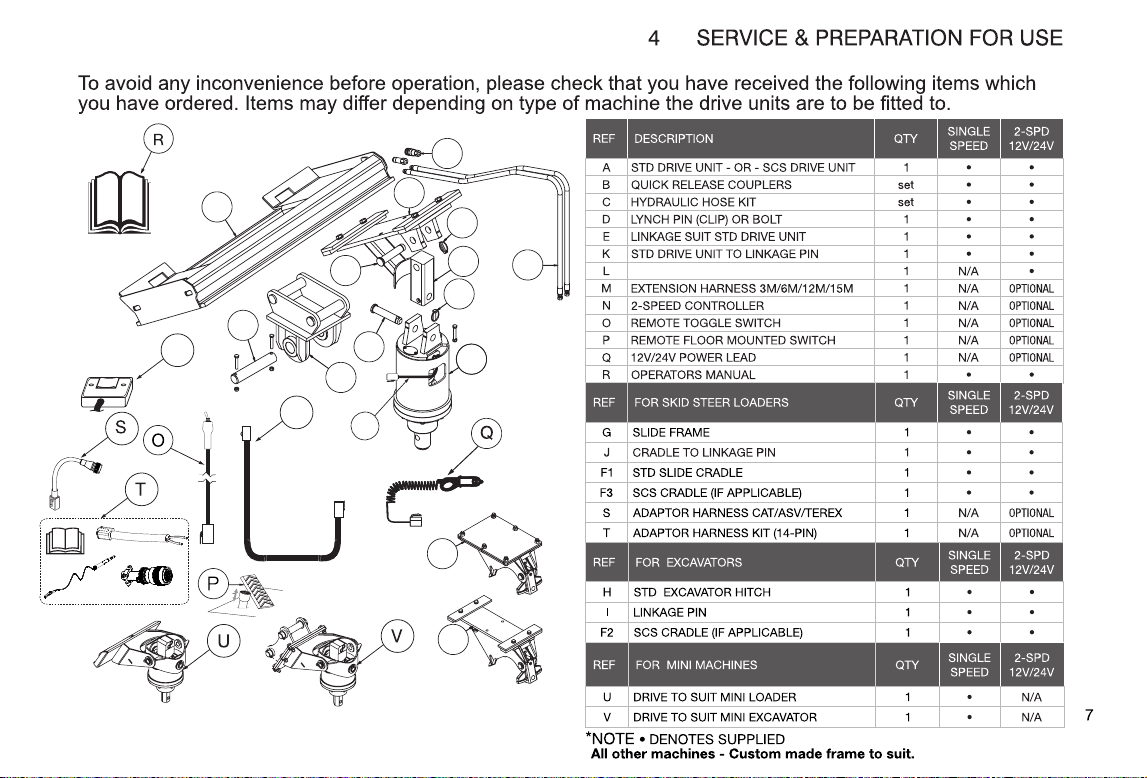

DRILLING DRIVES ANCHOR DRIVES 2-SPEED DRIVES

EX1, EX2, EX3, EX4,

EX4HF, EX5HF,

EX6HF, EX7HF,

EX9HF, EX12HF,

EX13HF, EX16HF,

EX20HF, EX25HF,

EX30HF, EX7LP,

EX9LP, EX12LP,

EX13LP, EX16LP,

EX20LP, EX25LP

AEX5HF, AEX6HF,

AEX7HF, AEX7LP,

AEX9HF, AEX9LP,

AEX 12HF,

AEX12LP, AEX13HF,

AEX13LP, AEX16HF,

AEX16LP, AEX20HF,

AEX20LP, AEX25HF,

AEX25LP, AEX30HF

2EX5HF, 2EX6HF, 2EX7HF,

2EX9HF, 2EX12HF, 2EX13HF,

2EX16HF, 2EX20HF, 2EX25HF,

2EX30HF, 2EX7LP, 2EX9LP,

2EX12LP, 2EX13LP, 2EX16LP,

2EX20LP, 2EX30LP, 2AEX5HF,

2AEX6HF, 2AEX7HF, 2AEX9HF,

2AEX12HF, 2AEX13HF,

2AEX16HF, 2AEX20HF,

2AEX25HF, 2AEX30HF,

2AEX7LP, 2AEX13LP, 2AEX9LP,

2AEX12LP, 2AEX16LP,

2AEX20LP, 2AEX25LP

G

B

F-1

C

E

J

D

H

I

A

OR

K

D

F-2

F-3

L

M

N

BDA MOTOR CONTROL HARNESS

5 SAFETY PRECAUTIONS - GENERAL INFORMATION

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL IS USED TO CALL YOUR ATTENTION TO

INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY OR OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS: ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS: Note the use of signal words DANGER, WARNING, and CAUTION with the safety messages. The appropriate signal

word for each has been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation, which if not avoided, will result in death or serious injury. This signal word is to be

limited to the most extreme situations, typically for machine components which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation, which if not avoided, could result in death or serious injury, and includes hazards

that are exposed when guards are removed. It may also be used to alert against unsafe practices and indicate potential failure or damage

to equipment.

CAUTION: Indicates a potentially hazardous situation, which if not avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

This section is composed of various warnings and safety tips. Read and learn all the information in this section before you attempt

to use your attachment. Also read your machines owner's manual before using your equipment. This knowledge will help you operate

your unit safely. Do not take this information lightly, it is presented for your benefit and for the benefit of others working around

you.

The "Safety Alert Symbol" A will be used throughout this manual. It will appear with the word DANGER, WARNING, or CAUTION, and

a safety message pertaining to the specific topic being covered. Take the time to read these messages as you come across them.

8 Extreme Duty Series 2 Augers Operators Manual May 2020

WARNING

A

WARNING

A

WARNING

A

WARNING

A

KNOW WHERE UTILITIES ARE

5 SAFETY PRECAUTIONS -GENERAL INFORMATION

Observe overhead electrical and other utility lines. Be sure equipment will clear them. When digging, call or your local

UTILITIES location service provider for location of buried utility lines, gas, water, and sewer, as well as any other

hazard you may encounter.

EXPOSURE TO RESPIRABLE CRYSTALLINE SILICA DUST ALONG WITH OTHER HAZARDOUS DUSTS MAY

CAUSE SERIOUS OR FATAL RESPIRATORY DISEASE.

It is recommended to use dust suppression, dust collection and if necessary personal protective equipment during the

operation of any attachment that may cause high levels of dust.

REMOVE PAINT BEFORE WELDING OR HEATING

Hazardous fumes/dust can be generated when paint is heated by welding, soldering or using a torch. Do all work

outside or in a well ventilated area and dispose of paint and solvent properly. Remove paint before welding or heating.

When sanding or grinding paint, avoid breathing the dust. Wear an approved respirator. If you use solvent or paint

stripper, remove stripper with soap and water before welding. Remove solvent or paint stripper containers and other

flammable material from area. Allow fumes to disperse at least 15 minutes before welding or heating.

END OF LIFE DISPOSAL

At the completion of the useful life of the unit, drain all fluids and dismantle by separating the different materials (rubber,

steel, plastic, etc.). Follow all federal, state and local regulations for recycling and disposal of the fluid and components.

9

5 SAFETY PRECAUTIONS - GENERAL INFORMATION

WARNING

A

WARNING

A

WARNING

A

OPERATING THE PLANETARY DRIVE

•An operator must not use drugs or alcohol, which can change his or her alertness or coordination. An operator taking

prescription or over-the-counter drugs should seek medical advice on whether or not he or she can safely operate

equipment.

•All bystanders should be kept a minimum of 20 feet away from the working area of the drive.

•Do not allow site workers to climb or ride on a drill mast, planetary drive, auger bits or auger extension at any time,

including while stationary, in operation or being moved or rotated.

•Operate only from the operator's station.

•Avoid steep hillside operation which could cause the machine to overturn. Consult your machines operator's and safety

manuals for maximum incline allowable.

•Reduce speed when driving over rough terrain, on a slope, or turning, to avoid overturning the vehicle.

Travel only with the planetary drive in a safe transport position to prevent uncontrolled movement. Drive slowly over

rough ground and on slopes.

•Tether any auger, anchor or extensions connected to the drive with a chain if necessary, to prevent uncontrolled swing-

ing of the attachments when moving from position to position.

•Do not drive close to ditches, excavations, etc., cave in could result.

•Before exiting the machine, lower the attachment to the ground, apply the parking brakes, turn off the prime mover's

engine, and remove the key.

•Flow and pressure gauges, fittings, and hoses must have a continuous operating pressure rating of at least 25%%

higher than highest pressures of the system.

•Do not smoke when refueling the prime mover. Allow room in the fuel tank for expansion. Wipe up any spilled fuel.

Secure cap tightly when done.

•Remove the auger drive from the prime mover before transporting to and from the jjob site.

•Planetary Drives shall be used only for their designed intent and shall not be loaded beyond their rated capacity. Over-

loading or exceeding the manufacturers specifications will void all warranty.

10

Extreme Duty Series 2 Augers Operators Manual May 2020

WARNING

A

WARNING

A

5 SAFETY PRECAUTIONS- GENERAL INFORMATION

OPERATING THE PLANETARY DRIVE CONT ....

•Drill stem rotation must be stopped before adding or removing sections, or making adjustments to the drill

stem or sampling equipment.

•Augers shall be cleaned only when the rotating mechanism is in neutral and the auger stopped; long-handled

shovels shall be used to move cuttings from the auger. Materials heavier than 22Ibs must be moved

mechanically or by using at least two people.

•Drilling operations must be stopped in the event of local thunderstorm, or lightning activity. During operation,

weather conditions shall be monitored: operations shall cease during electrical storms or when electrical storms

are imminent.

•Open bore holes must be capped and flagged.

STORAGE OF THE PLANETARY DRIVE

Seal hydraulic quick couplers from contaminants and secure all hydraulic hoses off the ground to help prevent

damage.

Clean the unit thoroughly, removing all mud, dirt, and grease.

Inspect for visible signs of wear, breakage, or damage. Order any parts required and make the necessary re-

pairs to avoid delays upon removal from storage.

Check that drive unit motor and hoses are full of clean oil and planetary is full.

Coat liberally with grease the output shaft and collar, extension shaft and collar, and all connecting pins to pre-

vent rust and reduce wear.

Tighten loose nuts, capscrews and hydraulic connections.

Replace decals that are damaged or in unreadable condition.

Store unit in a dry and protected place. Leaving the unit outside will materially shorten its life.

11

5 SAFETY PRECAUTIONS -GENERAL INFORMATION

WARNING

A

WARNING

A

WARNING

A

WARNING

A

GROUND PERSONNEL AND BYSTANDERS

•Be alert to others in the work area. Be sure others know when and where you will be working. Make sure no

one is behind equipment or within 20 feet of it operating.

•Loose fitting clothing, long hair, jewellery and equipment which might become entangled in moving equipment

are prohibited while working near Auger Drills or Anchoring equipment.

•Operators, helpers, and other personnel working near Auger Drills or screw piling equipment must wear steel-

toe safety shoes, safety glasses, and hard hats as a minimum. Hearing protection, respirators, and personnel

protective clothing will be specified in the site-specific Health and Safety Plan.

MAINTAINING THE PLANETARY DRIVE

•Before performing maintenance, lower the attachment to the ground, apply the parking brakes, turn off the

engine, and remove the key.

•Drill rigs must be shut down and properly locked-out and tagged before repairs or maintenance is per-formed.

Only properly trained and qualified individuals are permitted to perform repairs and maintenance.

•Never adjust a relief valve for pressure higher than recommended by the machine's manufacturer.

TRANSPORTING

Follow all local government regulations that may apply along with recommended tie down points and any equipment

safety precautions at the front of this handbook when transporting your attachment.

TIE DOWN POINTS

•Tie down points are identified by tie down decals where required. Securing to trailer at other points is unsafe and

can damage attachment.

•Do not attach tie down accessories around cylinders or in any way that may damage hoses or hydraulic

components.

•Attach tie down accessories to unit as recommended.

•Check unit stability before transporting.

Verify that all tie down accessories (chains, slings, ropes, shackles and etc.) are capable of maintaining attachment

stability during transporting and are attached in such a way to prevent unintended disengagement or shifting of the

unit. Failure to do so could result in serious personal injury or death.

12 Extreme Duty Series 2 Augers Operators Manual May 2020

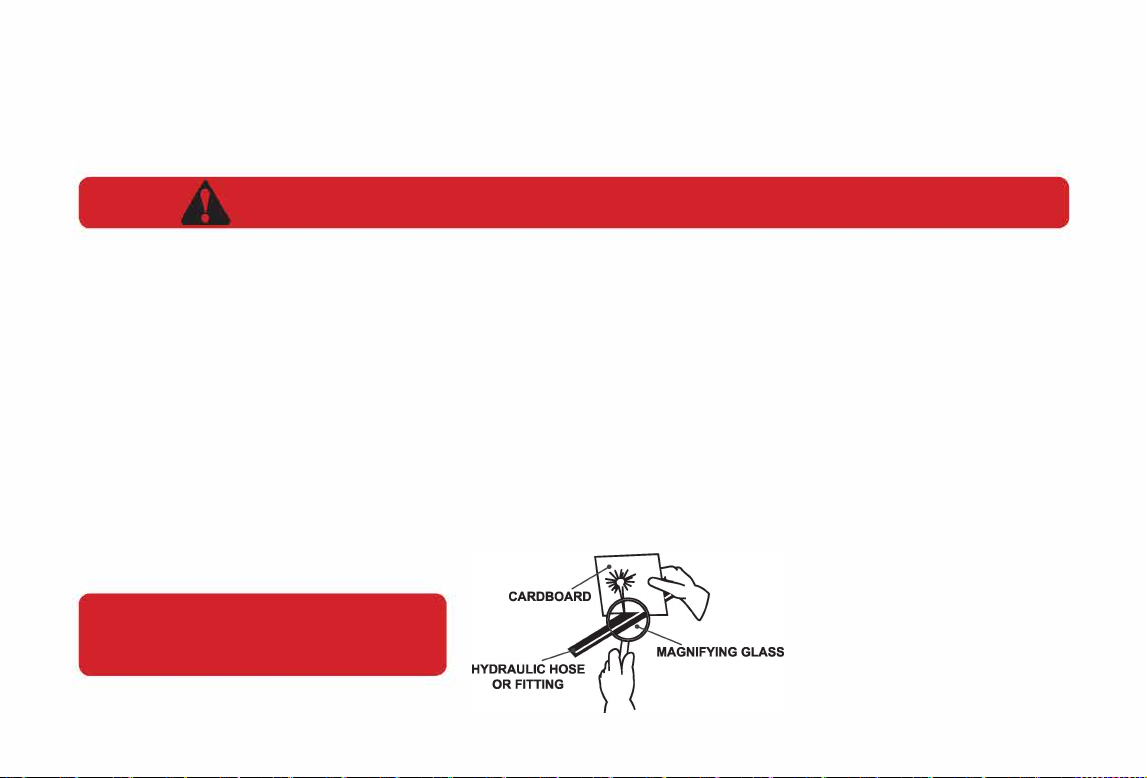

6 SAFETY -WORKING WITH THE ATTACHMENT

WHEN DEALING WITH HYDRAULICS DURING ANY TYPE OF ASSEMBLY,

OPERATION, MAINTENANCE, OR OTHER WORK ON OR NEAR THIS PRODUCT

•Hydraulic fluid under pressure can penetrate the skin and cause serious injury or death. Hydraulic leaks under pressure

may not be visible!

•If any fluid penetrates the skin, GET IMMEDIATE MEDICAL ATTENTION!!

•Wear safety glasses, protective clothing, and use a sound piece of cardboard or wood when searching for hydraulic leaks.

DO NOT USE YOUR HANDS!

•Before connecting or disconnecting hydraulic hoses, read your machine or power unit's operator's manual for detailed

instructions on connecting and disconnecting hydraulic attachments.

•Make certain that all parts meet the specifications for this product when installing or replacing hydraulic hoses or fittings.

•After connecting hydraulic lines:

oSlowly and carefully raise the loaders arm/s and cycle the rollback/ dump cylinders to check hose clearances and to

check for any interference.

oOperate the hydraulics on this product to ascertain forward and reverse.

oMake certain that the hoses cannot interfere with or actuate the quick-attach mechanism.

oMake certain that hoses will not be pinched, or get tangled, in any equipment.

•Do not lock the auxiliary hydraulics of your power unit in the "ON" position.

•Refer to your power unit's operator's manual and this manual for procedures and intervals, then inspect and maintain the

entire hydraulic system to insure that the fluid remains clean, that all devices function properly, and that there are no fluid

leaks.

14

Extreme Duty Series 2 Augers Operators Manual May 2020

6 SAFETY -WORKING WITH THE ATTACHMENT

WHEN MOUNTING THIS PRODUCT TO YOUR MACHINE

•Refer to the operator's manuals of your machine, and your quick-attach for special or detailed mounting instructions.

•This product should fit onto the quick-attach Frame or Hitch (Machine Mount).

•If this product does not fit properly, contact your Blue Diamond® Dealer before operating.

•Never place any part of your body into the mounting plate, frame, hitch or loader holes. A slight movement of the power

unit and this product could cause serious injury.

•Where 'Dead Man' connections are connected or installed, do not disengage, tamper with or remove them.

WHEN ADJUSTING, SERVICING OR REPAIRING THIS PRODUCT

•Make no modifications to your Drive Unit.

•When making repairs use only authorized Blue Diamond® service agents, use only genuine Blue Diamond® parts for

the gearboxx. For fasteners, hydraulic hoses, or hydraulic fittings, use only properly rated parts.

•Replacement parts must also have safety signs attached.

15

6 SAFETY - DECAL LOCATION

GENERAL INFORMATION

The following decals are reductions of the actual decals

used on auger drives. Use this information to order

replacements for lost or damaged decals. Be sure you

understand all decals before operating the attachment. They

contain information you need to know for attachment safety.

IMPORTANT

Keep all safety decals clean and legible. Replace all

missing, or damaged safety decals. When replacing parts

with safety decals attached, the safety decals must also be

replaced.

REPLACING SAFETY DECALS

Clean the area of application with a nonflammable solvent,

then wash the same area with soap and water. Allow the

surface to dry. Remove the backing from the safety decal,

exposing the adhesive surface. Apply the safety decal to the

position shown in the diagram, and smooth out any bubbles.

DECAL LOCATION

Safety

I

Warning decals should be placed on each side of

the drive unit facing any bystanders.

ORDERING NEW DECALS

Contact your local Blue Diamod® Attachments dealer to

obtain new safety decals as well as logo and model decals.

16 Extreme Duty Series 2 Augers Operators Manual May 2020

&CAUTION

&

HIGH-PRESSURE

FLUID HAZARD

To prevent serious injury:

Relieve pressure on system

before repairing, adjusting or

disconnecting.

Wear proper hand and eye

protection when searching

for leaks. Use wood or

cardboard Instead of hands.

Entanglement with rotating

parts can cause lnfury.

Keep onlookers 20 ft. {Sm)

clear of all moving parts.

Read operator's manual

before operation.

NOTICE

Keep all components In

®good repair.

Change the gear oil after

6 months or 60 hours of

moderate operation, then

every 500 hours or

12 months. Whichever

comes first.

Do not rapidly engage

forward/reverse to clear

spoil from auger.

xj

!FORWARD

FORI/VAAO STOP

·, REVERSE ·, FO=

O

,. ; ,. ;

\... \"

;

,

;

,

ft.Clarion clarlorw.a .com IXDX

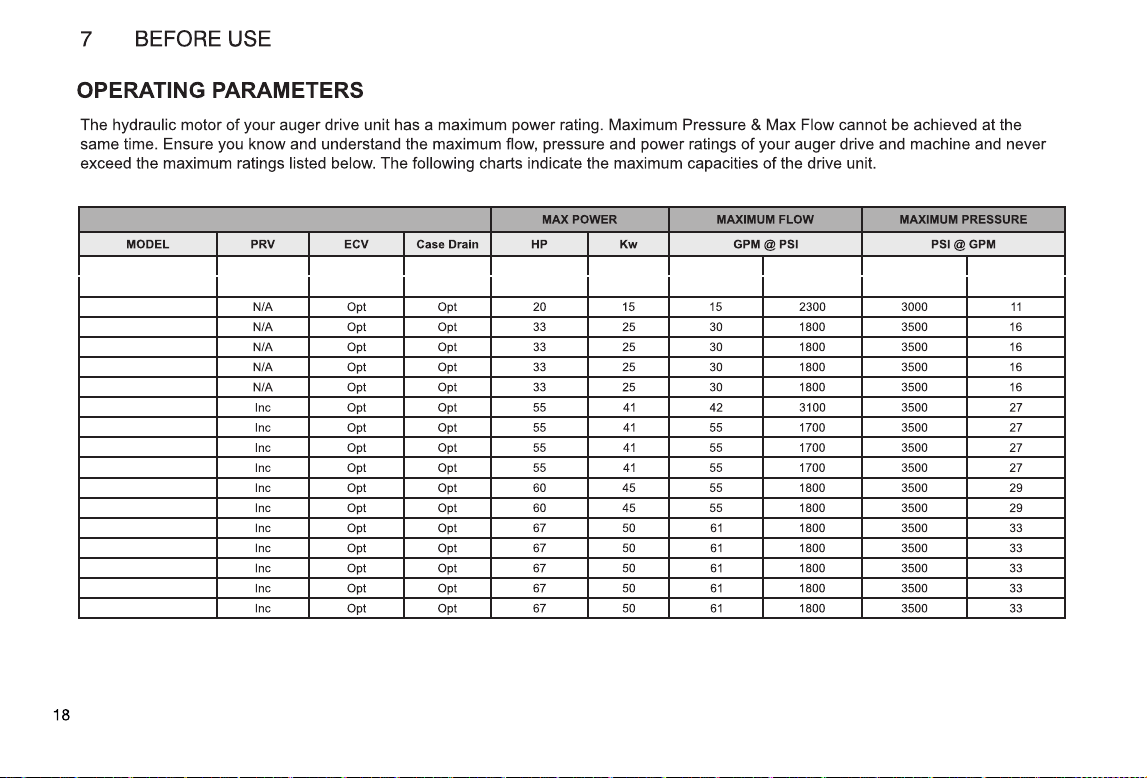

7 BEFORE USE

The key feature of your Blue Diamond® Attachments Auger Drive is low maintenance, regular oil changes only are required. It contains no

user serviceable parts, unauthorized disassembly will void warranty. WRITTEN PERMISSION FROM BLUE DIAMOND®

ATTACHMENTS MUST BE OBTAINED before performing any disassembly.

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS

BEFORE BEGINNING ANY DRIVE UNIT MAINTENANCE.

BEFORE FIRST USE

•Inspect the attachment for shipping damage. If damage does exist, do not operate until the damaged parts have

been replaced or repaired.

BEFORE EACH USE

•Make sure that all nuts and bolts are in place and properly tightened.

•Make sure that all other fasteners are in place and are performing their specified function.

•Make sure that all hydraulic fittings are tightened and that there are no leaks in any fittings or hoses.

•Make sure that all safety signs are in place, are clean, and are legible. (SEE THE SAFETY SIGN SECTION)

•Check for any oil leaks.

•Wear and tear on pins, linkages, clips, bushes and hood.

•Ensure any damage or excessively worn parts are replaced.

•Always wear safety goggles or glasses when inspecting equipment.

WARNING!

If injured by injected fluid, see a doctor at

once. If your doctor is not familiar with this

type of injury, ask him to research it

immediately to determine proper treatment.

Escaping fluid under pressure can have

sufficient force to penetrate the skin

causing serious personal injury. Fluid

escaping from a very small hole can

be almost invisible. Use a piece of

cardboard or wood, rather than hands

to search for suspected leaks. Keep

unprotected body parts, such as

face, eyes, and arms as far away as

possible from a suspected leak. Flesh

injected with hydraulic fluid may develop

gangrene or other permanent disabilities.

17

Auger Drives Operators Manual May 2020

MS1

EX1

EX2

EX3

EX4

EX4HF

EX5HF

EX6HF

EX7HF

EX9HF

EX12HF

EX13HF

EX16HF

EX20HF

EX25HF

EX30HF

POWER

MODEL PRV ECV Case Drain HP Kw

2 SPEED DRIVE UNITS -LOW PRESSURE (3000PSI)

2EX7LP&2AEX7LP Inc

2EXLP Opt/2AEXLP Inc

Inc 55 41

2EX9LP&2AEX9LP Inc Inc 60 45

2 EX12LP &2AEX12LP Inc Inc 60 45

2EX16LP &2AEX16LP Inc Inc 67 50

2EX20LP &2AEX20LP Inc Inc 80 60

2EX25LP &2AEX25LP Inc Inc 80 60

2 SPEED DRIVE UNITS • STANDARD PRESSURE (3500PSI)

2EX5HF &2AEX5HF Inc DDT Opt/ADT Inc Inc 55 41

2EX6HF & 2AEX6HF Inc

2EXHF Opt/2AEXHF Inc

Inc 55 41

2EX7HF&2AEX7HF Inc Inc 55 41

2EX9FH &2AEX9HF Inc Inc 60 45

2EX12HF &2AEX12HF Inc Inc 60 45

2EX13HF & 2AEX13HF Inc Inc 67 50

2EX16HF & 2AEX16HF Inc Inc 67 50

2EX20HF &2AEX20HF Inc Inc 80 60

2EX25HF & 2AEX25HF Inc Inc 80 60

2EX30HF &2AE30HF Inc Inc 80 60

MAXIMUM FLOW

GPM@PSI

53 1800

53 1950

53 1950

53 2200

53 2600

53 2600

53 1800

53 1800

53 1800

53 1950

53 1950

53 2200

53 2200

53 2600

53 2600

53 2600

7 BEFORE USE

MAXIMUM PRESSURE

PSl@GPM

3000 27

3000 29

3000 29

3000 33

3000 39

3000 39

3500 27

3500 27

3500 27

3500 29

3500 29

3500 33

3500 33

3500 39

3500 39

3500 39

19

2EXLP Opt/2AEXLP Inc

2EXLP Opt/2AEXLP Inc

2EXLP Opt/2AEXLP Inc

2EXLP Opt/2AEXLP Inc

2EXHF Opt/2AEXHF Inc

2EXHF Opt/2AEXHF Inc

2EXHF Opt/2AEXHF Inc

2EXHF Opt/2AEXHF Inc

2EXHF Opt/2AEXHF Inc

2EXHF Opt/2AEXHF Inc

2EXHF Opt/2AEXHF Inc

8 COMMISIONING PROCEDURE

NOTE: BEFORE THE DRIVE UNIT IS EVEN CONNECTED TO THE MACHINE ENSURE THAT

THE DRIVE IS FULL OF HYDRAULIC OIL AND THE GEARBOX IS FULL OF GEAR OIL.

All Blue Diamond® Attachments planetary drive units are dispatched from the

factory full of fluids

(hydraulic and gearbox oil) unless this warning decal is attached.

The decal is only applied in special circumstances, for example if a drive unit

needs to be air-freighted to the customer. Air transportation regulation prohibits

certain fluids from being air-freighted.

If there are no fluids in the drive unit at the time of dispatching, then the decal

will be applied to the drive unit.

,.. "

WARNING -

THIS UNIT HAS BEEN SHIPPED WITHOUT OIL -

FILL BEFORE USE

1. Once you have determined if the drive unit has gearbox oil in or requires oil, ensure that the correct grade and quantity

of oil is used. DO NOT RUN THE DRIVE UNIT WITHOUT OIL. Connect the hydraulic hoses and if required, optional 2

speed electrical harness to the machine. If the customer has ordered the optional Pressure Differential Kit and the align

Kit, then there will be 2 additional electrical harness to connect.

20 Extreme Duty Series 2 Augers Operators Manual May 2020

Other manuals for Extreme Duty 2 Series

2

This manual suits for next models

73

Table of contents

Other Blue Diamond Construction Equipment manuals