Blue Diamond Multi-Purpose Cutter Guide

Multi-Purpose

Cutter

Operation and Parts manual

3

Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

Pre-Delivery Checklist

The Dealer should inform the Purchaser of this product of the Warranty terms, provisions, and procedures that

are applicable. The Dealer and Purchaser should review the contents of the Operator’s Manual including safety

equipment, safe operation and maintenance, review the Safety Signs on the implement (and tractor if necessary),

and the Purchaser’s responsibility to train their operators in safe operation procedures.

• IMPLEMENTS: I have explained that a Safety Shield should be installed and maintained in good repair. If the

shield is not installed the purchaser accepts responsibility for any personal injury due to not having the shield.

• HYDRAULICS: I have made certain that the hydraulic supply pump, hoses, and motor is in good repair and

fastened securely in place to prevent injuries.

• MOUNTED IMPLEMENTS: I have explained that it is not possible to guard against thrown objects when

the cutter is lifted off the ground or operated in a vertical conguration, and that operator is responsible for

watching out for persons in the work area.

PRE-DELIVERY SERVICE

CHECK AND ADJUST OR LUBRICATE AS REQUIRED

Refer to this Manual for Details

Inspection Performed - Warranty and Safety Procedures Explained - Installation Complete

CUTTER

Make Sure The Pump Motor And Adapter Bolts Are

Properly Tightened

Make Sure The Blade Carrier Bolt Is Properly

Tightened And Cotter Pin Is In Place

Make Sure The Two Blade Bolts Are Tight

Make Sure The Blades Are Installed In Correct

Rotational Direction

Review Procedure To Configure The Cutter In One

Of The Three Possible Configurations

Make Sure All Hardware Is Properly Tightened

Retighten the tapered roller bearing in the pivot

arm after 15 minutes of initial use and again at 30

minutes. Recheck again before the next use.

I have thoroughly instructed the buyer on the above-described equipment. This review included the Operation and

Parts Manual content, equipment care, adjustments, safe operation, and applicable warranty policy.

Date__________________ Dealer Rep. Signature_________________________________________

The above equipment and Operator’s Manual have been received by me (the purchaser), and I have been

thoroughly instructed as to care, adjustments, safe operation, and applicable warranty policy. As the purchaser

I have read, understand, and take responsibility for the use of this attachment. I understand and

accept responsibility for the proper use of this cutter. I acknowledge this cutter is dangerous if not

used correctly or if the safety information is not followed.

Date__________________ Owner’s Signature_________________________________________

LUBRICATION & HYDRAULICS

Make Sure All Grease Joints Are Lubricated.

Check All Hoses And Coupling For Damage Or

Leaks.

CUTTER TO TRACTOR CONNECTIONS

Make Sure The Proper Hydraulic Connections Are

Available On the Tractor

SAFETY ITEMS

Make Sure Safety Shield Is Properly Installed

Make Sure Safety Decals Are Installed

Review This Operator’s Manual

Cut Here to Remove Page or Make Copies of This Page

4Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

Table of Contents

1. INTRODUCTION ........................5

1.1 Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Safe Operation .........................5

1.3 Intended Usage .........................5

1.4 Owner/Operator Manual Storage ...........6

1.5 Operator Orientation .....................6

1.6 Serial Number Location...................6

1.7 Product Improvements ...................6

1.8 Disposal of Equipment at End of Useful Life ...6

1.9 Unanswered Questions ...................6

2. SAFETY................................7

2.1 General ...............................7

2.2 Safety Alert Symbols .....................7

2.3 Safety Icon Nomenclature ................ .8

2.3.1 Personal Protection/Important

Information ...................... 8

2.3.2 Prohibited Actions .................8

2.3.3 Hazard Avoidance .................8

2.4 General Safety Instruction.................9

2.5 Training ..............................10

2.6 OSHA Training Requirements .............10

2.7 Federal Laws and Regulations ............11

2.8 Sign-Off Form .........................12

2.9 Operation Safety .......................13

3. SAFETY SIGNS AND INSTRUCTIONAL

LABELS ..............................14

3.1 General Information. ....................14

3.2 How to Install Replacement Safety Signs ....14

3.3 Safety Signs ..........................15

4. 4. OPERATION ..........................18

4.1 Operating Safety .......................18

4.2 Work Area Safety. ......................18

4.3 Tractor Requirements ...................19

4.4 Attaching to Tractor ....................19

4.5a Mowing Configuration ...................21

4.5b Mowing Configuration ................... 24

4.6 Detaching from Tractor ..................25

4.7 Cutter Checklist .......................25

4.8 Operation Checklist .....................26

4.9 Right of Way (Roadway) Mowing ..........26

5.TRANSPORTING .......................27

5.1 Transporting Safety (Road) ...............27

6.STORAGE .............................28

6.1 Storage Safety. ........................28

6.2 Placing In Storage ......................28

6.3 Removing From Storage ................28

7.SERVICE AND MAINTENANCE ...........29

7.1 Maintenance Safety. ....................29

7.2 Greasing .............................30

7.3 Blade Servicing .......................30

7.3.1 Blade Removal. ..................30

7.3.2 Blade Installation .................30

7.3.3 Blade Sharpening ................30

7.4 Blade Carrier Removal ..................30

7.5 Blade Carrier Installation .................30

7.6 Service Record ........................31

7.7 Welding Repairs .......................31

9. 8. PARTS ..............................32

10. 9. WARRANTY ..........................38

5Blue Diamond Attachments, LLCBrush Cutters

September 2020 888-376-7027

1. INTRODUCTION

1.1 Welcome

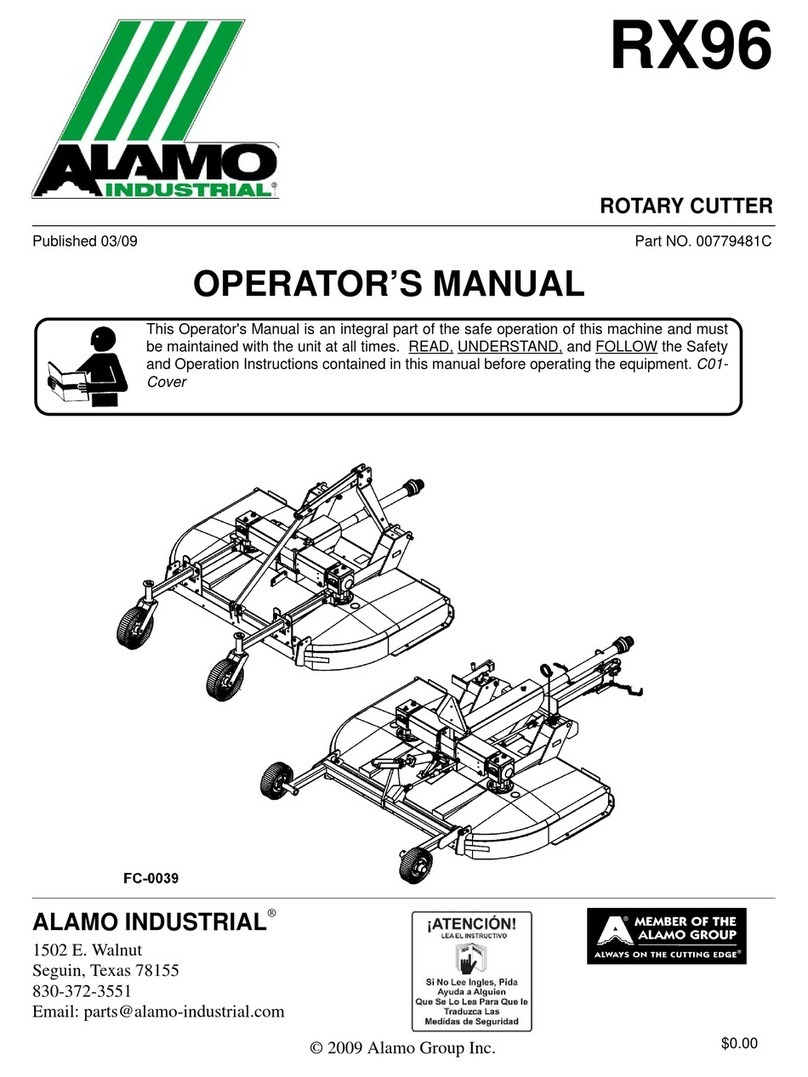

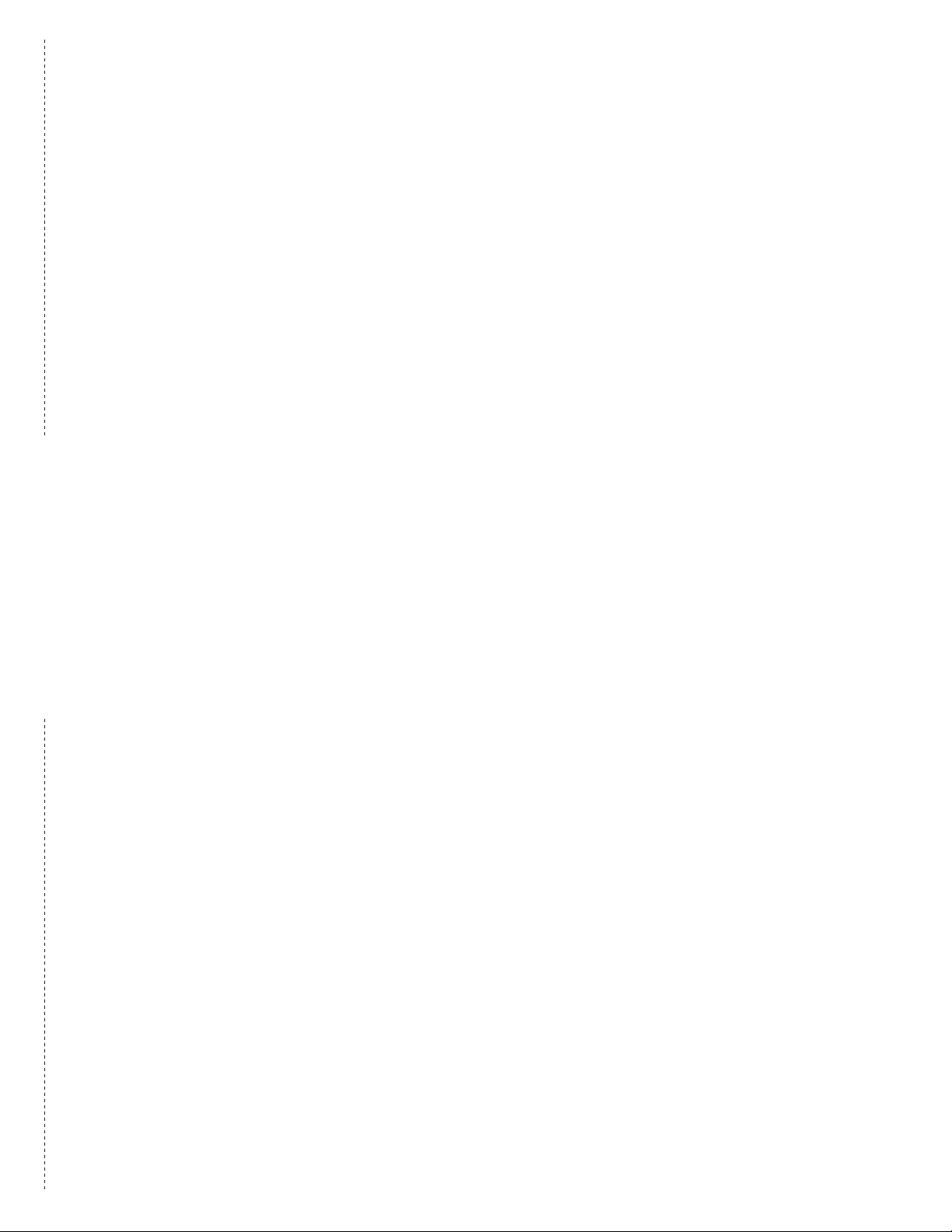

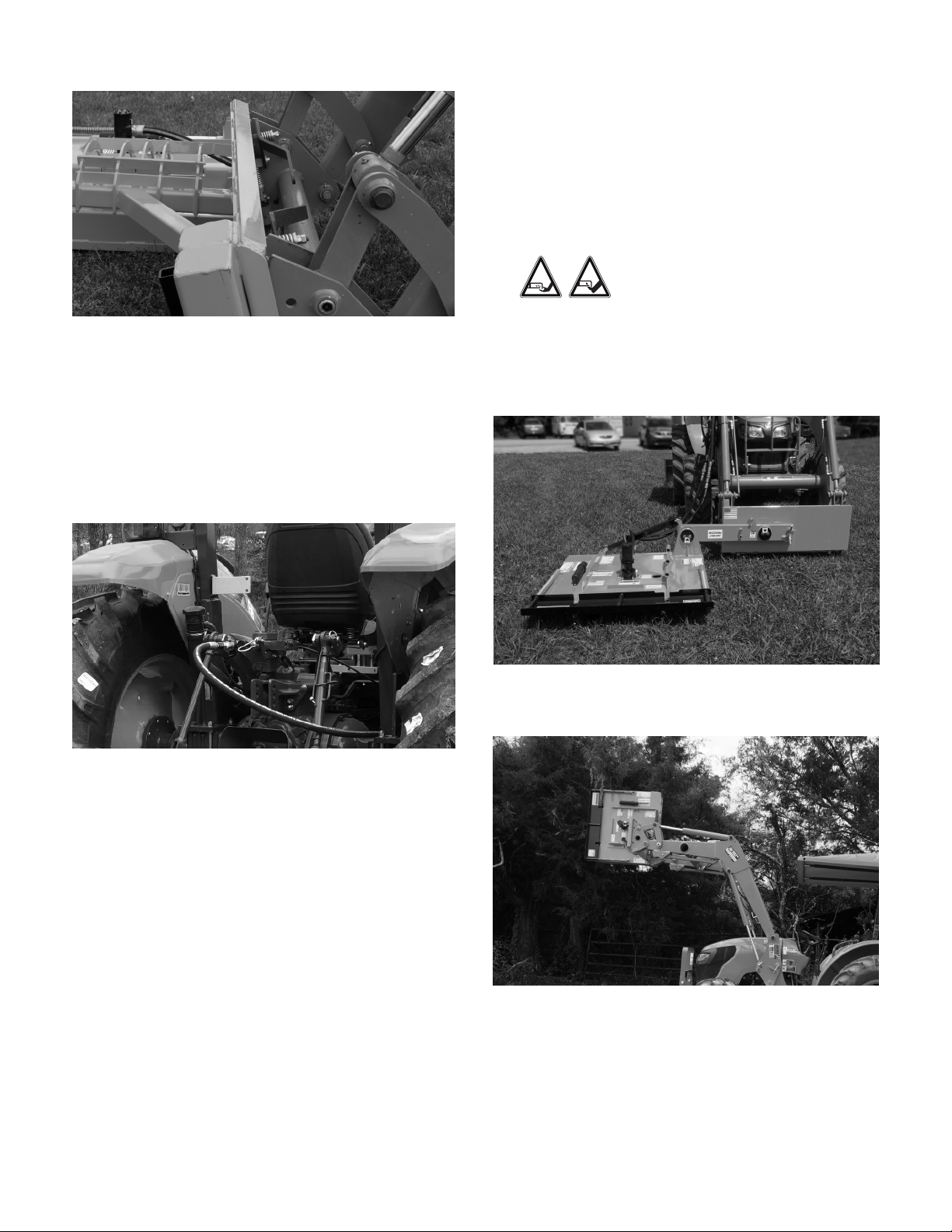

Standard Offset Configuration

Congratulations on your choice of a Blue Diamond

Attachments, LLC Multi-Purpose Cutter. This

equipment has been designed and manufactured to

meet the needs of discerning users.

The Blue Diamond Multi-Purpose Cutter is designed to

cut grass, weeds, and light brush.

Many features incorporated into this Multi-Purpose

Cutter are the result of suggestions made by

customers like you. Read this manual carefully to

learn how to operate the Multi-Purpose Cutter safely

and how to set it to provide maximum cutting

efficiency.

The offset mowers are designed for light-duty

applications such as weed, grass, and light brush up to

3” diameter. The cutters can be used to mow under a

fence line or it can be turned vertically to mow the

sides of hedgerows and tree lines.

The cutter uses a single spindle with two free-swinging

blades, which reduce the shock of impact when a

stationary object is contacted. A shear key in the input

shaft protects the motor from damage.

WARNING

Operating the Multi-Purpose Cutter without

the safety shield can result in physical

injury or death. Make sure the shield is

properly installed and in working condition

before operating the Multi-Purpose Cutter.

By following the operating instructions in conjunction

with a good maintenance program, your Multi-Purpose

cutter will provide many years of trouble-free service.

1.2 Safe Operation

Safe, efficient, and trouble-free operation of your

Multi-Purpose Cutter requires that you, and anyone

else who will be using or maintaining the unit, read

and understand the information contained within the

Owner’s Manual.

Use this manual for frequent reference and to pass on

to new operators or owners.

WARNING

Read And Understand Manual

To prevent personal injury or even death, be

sure you read and understand all of the

instructions in this manual and other related

OEM equipment manuals! The Multi-Purpose

Cutter, if not used and maintained properly, can be

dangerous to users unfamiliar with its operation. Do

not allow operating, maintaining, adjusting, or

cleaning of this Multi-Purpose Cutter until the

user has read this manual and has developed a

thorough understanding of the safety precautions

and functions of the unit.

This Multi-Purpose Cutter is designed for the specific

purpose of cutting grass, weeds, and light brush.

DO NOT modify or use this Multi-Purpose Cutter

for any application other than that for which it was

designed.

Offset mowers maintained or operated

improperly or by untrained personnel can be

dangerous; exposing the user and/or

bystanders to possible serious injury or death.

1.3 Intended Usage

Do not use this Multi-Purpose Cutter for any other

purpose than its intended use; cutting grass, weeds,

and light brush and an in-line or offset application.

6Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

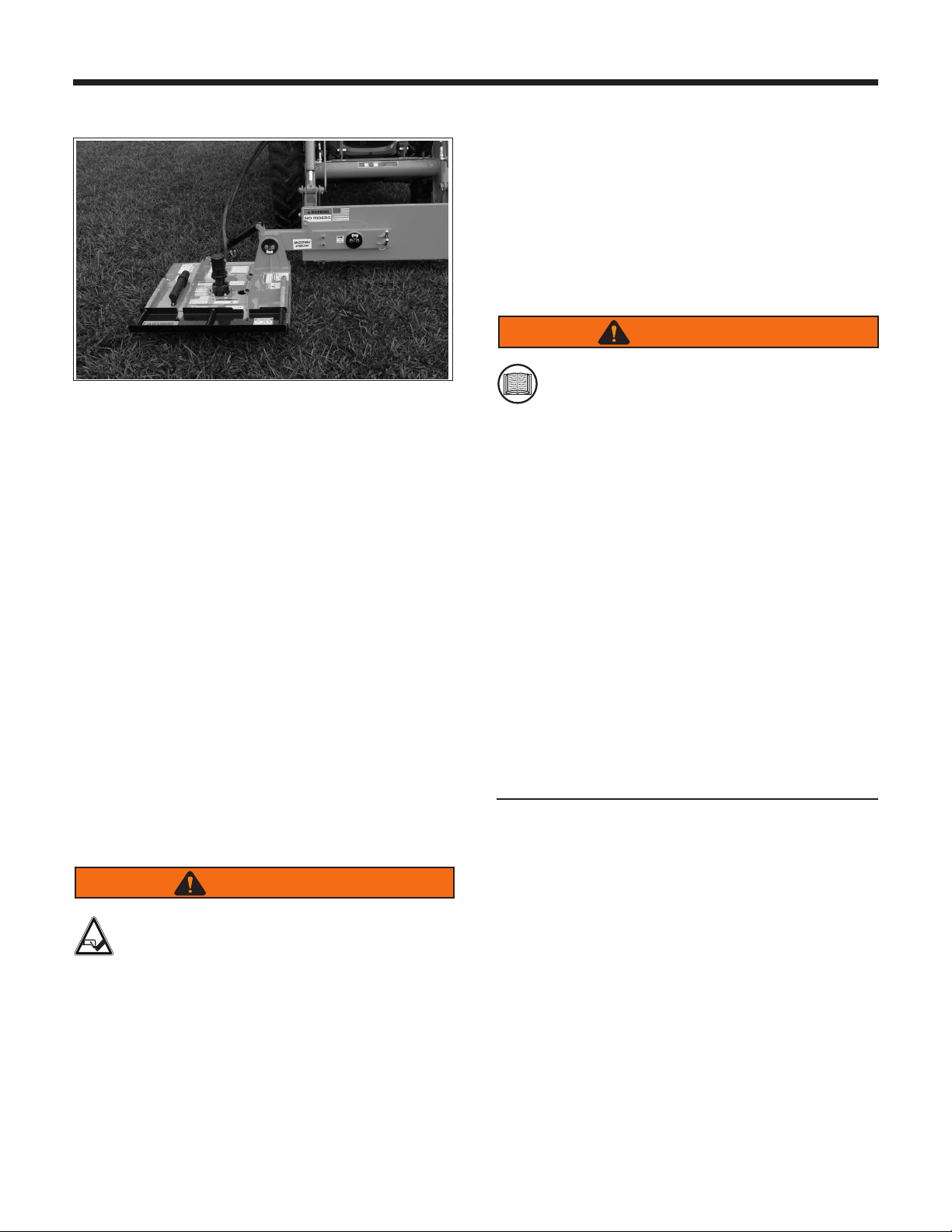

The Multi-Purpose Cutter can also be used in a

vertical configuration for mowing along hedge rows

and tree lines.

This unit WILL NOT work on a skid steer

machine.

WARNING

Using the cutter on a skid steer will void the

warranty and have the potential for serious

injury to the user or bystanders.

1.4 Owner/Operator Manual Storage

Always store the Owner/Operator manual and other

operating materials in the document storage tube.

1.5 Operator Orientation

The directions left, right, front, and rear, as mentioned

throughout this manual, are as seen from the tractor

operator’s seat and facing in the direction of travel.

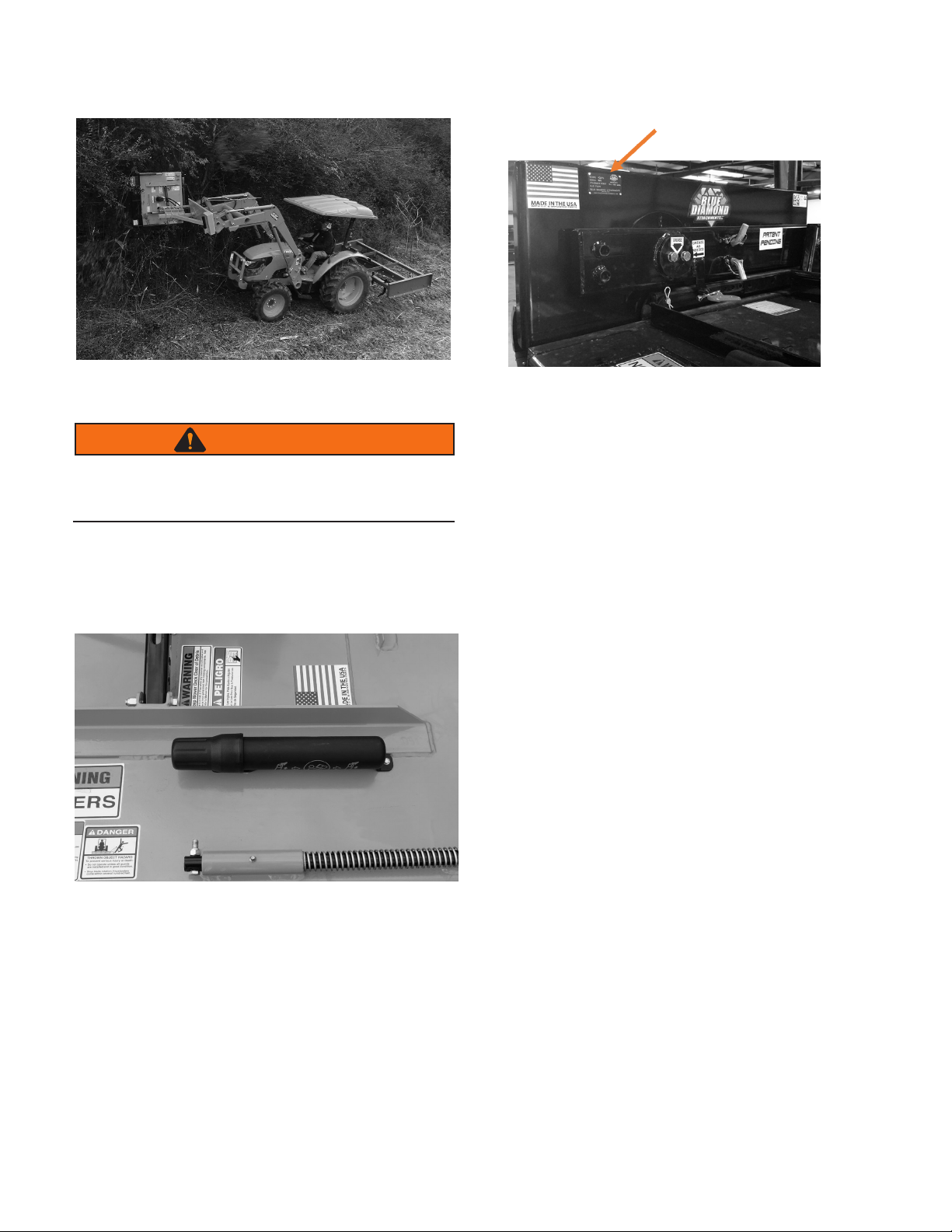

1.6 Serial Number Location

The serial number decal is located on the top left

of the mounting plate.

Model Number ______________________________

Serial Number ______________________________

1.7 Product Improvements

Because Blue Diamond Attachments, LLC maintains

an ongoing program of product improvement, we

reserve the right to make improvements in design or

changes in specifications without incurring any

obligation to install them on units previously sold.

1.8 Disposal of Equipment at End of Useful

Life

The Blue Diamond Attachments, LLC Multi-Purpose

Cutter has been designed for the specific purpose of

cutting grass, weeds, and light brush. When this unit is

no longer capable of doing its designed purpose, it

should be dismantled and scrapped. Do not use any

materials or components from this unit for any other

purpose.

1.9 Unanswered Questions

If you have any questions not answered in this manual

or require additional copies or the manual is damaged,

please contact your dealer or:

Blue Diamond Attachments, LLC.

4512 Anderson Road

Knoxville, TN 37918

Phone: (888) 376-2027

Fax: (865) 246-2007

7Blue Diamond Attachments, LLC

888-376-7027

2. Safety

2.1 General

Safety of the operator and bystanders is one of the

main concerns in designing and developing a new

piece of equipment. Designers and manufacturers

build in as many safety features as possible. However,

every year many accidents occur which could have

been avoided by a few seconds of thought and a more

careful approach to handling the equipment.

Most work-related accidents are caused by failure to

observe basic safety rules or precautions. An accident

can often be avoided by recognizing potentially

hazardous situations before an accident occurs. As you

assemble, operate, or maintain the Multi-Purpose Cutter

(unit), you must be alert to potential hazards. You

should also have the necessary training, skills, and tools

to perform any assembly or maintenance procedures.

Improper operation and maintenance of this unit could

result in a dangerous situation that could cause injury

or death.

If you have any questions not answered in this manual

or require additional copies or the manual is damaged,

please contact your dealer or:

Blue Diamond Attachments, LLC.

4512 Anderson Road

Knoxville, TN 37918

Phone: 888-376-7027

Fax: 423-405-5904

WARNING

Do not assemble, operate, or maintain the

unit until you read and understand the

information contained in this manual.

Safety precautions and warnings are provided

in this manual and on the unit. If these hazard

warnings are not heeded, bodily injury or

death could occur to you or to other persons.

Blue Diamond Attachments, LLC cannot anticipate

every possible circumstance that might involve a

potential hazard. The warnings in this manual and on

the

unit are, therefore, not all-inclusive. If a method of

assembly, operation, or maintenance not specifically

recommended by us is used, you must satisfy yourself

that it is safe for you and for others. You should also

ensure that the unit will not be damaged or be made

unsafe by the methods that you choose.

The information, specifications, and illustrations in

this manual are based on the information that was

available at the time this material was written and can

change at any time without notice.

2.2 Safety Alert Symbols

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

This manual contains DANGERS, SAFETY

INSTRUCTIONS, CAUTIONS, IMPORTANT NOTICES,

and NOTES which must be followed to prevent

the possibility of improper service, damage to the

equipment, personal injury, or death. The following

keywords call the readers’ attention to potential

hazards.

Hazards are identied by the “Safety Alert Symbol”

and followed by a signal word such as “DANGER”,

“WARNING”, or “CAUTION”.

DANGER

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme

situations.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

NOTICE

Indicates that equipment or property damage can result

if instructions are not followed.

SAFETY INSTRUCTIONS

Safety instructions (or equivalent) signs indicate

specic safety-related instructions or procedures.

Note: Contains additional information important to a

procedure.

Brush cutters

September 2020

8Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

2.3 Safety Icon Nomenclature

Pictorial icons signal a type of

hazard and warn of personal

protection issues, prohibited actions,

and hazard avoidance.

2.3.1 Personal Protection/

Important Information

Read the manual

Maintenance procedure

N

I

NG

AR

Damaged hazard label

Eye protection

Fire extinguisher

First aid kit

Hand protection

Head protection

Hearing protection

Inspect equipment

OEM

OEM parts only

Protective shoes

Remove key

Set parking brake

STOP Stop engine

THINK

SAFETY! Think safety

Transmission in park

Use proper support

Use proper tools

Use two people when

lifting heavy objects

Visibility

Rollover protection

Wear seat belt

Weight rating

Chemical flushing kit

2.3.2 Prohibited Actions

Do not alter or modify

Use proper tools

Do not weld

No alcohol

No drugs

No smoking

No young children

No riders

2.3.3 Hazard Avoidance

Crush hazard

Crush hazard (chock

wheels)

Crush hazard (foot)

Defective or broken part

Entanglement hazard

Explosive force hazard

Explosive separation

hazard

Fall hazard

Fire hazard

Cutter blade contact

hazard (hand)

Cutter blade contact

hazard (foot)

Lifting hazard

Cutting hazard

Pinch point hazard

Projectile hazard

Rollover protection

Safety alert symbol

Safety shields

Sharp object hazard

Slipping injury

0Tire pressure

Tripping injury

9Blue Diamond Attachments, LLC

Brush Cutters

September 2020 888-376-7027

2.4 General Safety Instruction

The owner/operator is responsible for the SAFE use

and maintenance of the Multi-Purpose Cutter. Make

sure anyone who is operating, maintaining, or working

around the Multi-Purpose Cutter is familiar with the

operating and maintenance procedures and related

SAFETY information contained in this manual. This

manual will take you step-by-step through your

working day and alerts you to all good safety practices

that should be used while using the Multi-Purpose

Cutter.

In addition to the design features of the Multi-Purpose

Cutter, including safety signs, accident prevention is

dependent upon the awareness, concern, prudence,

and proper training of the people involved in the

operation, maintenance, and storage of the Multi-

Purpose Cutter.

In addition to this safety section, refer also to safety

messages and instructions in each of the appropriate

sections of the Multi-Purpose Cutter manual.

These general safety instructions apply to the overall

use and maintenance of the Multi-Purpose Cutter.

More specific instructions on safety are found in the

operation, maintenance, and storage sections of this

manual. Refer to these sections before performing

any of these tasks.

WARNING

Failure to comply with the following safety

instructions can and will result in serious injury and

possibly even death if they are not understood and

followed.

Read and Understand Manual

To prevent personal injury or even

death, be sure you read and understand

all of the instructions in this manual and other

related OEM equipment manuals! The

Trailblazer Multi-Purpose Cutter, if not used and

maintained properly, can be dangerous to

users unfamiliar with its operation. Do not

allow operating, maintaining, adjusting, or

cleaning of this Multi-Purpose Cutter until the user

has read this manual and has developed a

thorough understanding of the safety precautions

and functions of the unit.

This Multi-Purpose Cutter is designed for the

specific purpose of cutting grass, weeds, and

light brush. DO NOT modify or use this Multi-

Purpose Cutter for any application other than

that for which it was designed.

Brush cutters maintained or operated improperly,

or by untrained personnel, can be dangerous;

exposing the user and/or bystanders to

possible serious injury or death.

WARNING

Provide User with Literature Trailblazer

Multi-Purpose Cutter owners must provide

operator instructions to anyone using the

Multi-Purpose Cutter before use, and at least

annually thereafter. Refer to “2.6 OSHA

Training Requirements” on page 13.

Stay Clear: Clear the area of people,

especially small children, before using

the Multi-Purpose Cutter. Under no

circumstances should young children be allowed

to work with or around the Multi-Purpose Cutter.

Impaired User Hazard : Do not

attempt to assemble, operate, or

maintain this Multi-Purpose Cutter

under the influence of drugs or alcohol. Consult

your doctor before using this Multi-Purpose

Cutter while taking prescription medications.

Crush Hazard

Do not allow anyone to ride on the

tractor or the Multi-Purpose Cutter.

Falling or crushing hazards can result in severe

injuries or death.

Falling Hazard

Do not allow riders on the hitch,

tractor, or cutter at any time.

Falling can result in severe injuries or death.

No Unauthorized Modi ications Do

not modify the Multi-Purpose Cutter

or safety devices. Do not weld on the

Unauthorized modifications may impair its function

and safety. Personal injury or death can result

from unauthorized modifications.

If the Multi-Purpose Cutter has been altered in any

way from the original design, Trailblazer does not

accept any liability for injury or warranty.

Damaged Parts Hazard: Do not use the

Multi-Purpose Cutter if any parts are

damaged. If the Multi-Purpose Cutter has a

defect, immediately stop using it and remedy the

problem before continuing.

Thrown Objects Hazard: The Multi-

Purpose Cutter can throw objects up to

300 feet. To avoid serious injury or death:

Keep all thrown object shielding in place.

Inspect area for potential thrown objects before

cutting.

Do not operate the Multi-Purpose Cutter with

the deck raised.

10Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

CAUTION

The following safety instructions are provided to

help prevent potential injury. Not following these

instructions may lead to injury.

Personal Protection Equipment

When using this Multi-Purpose Cutter, wear

appropriate personal protective equipment.

This list may include, but is not limited to:

• Protective shoes with slip resistant soles

• Protective goggles, glasses, or face shield

• Protective clothing and gloves

• Safety vest (when operating near roads)

• Hearing protection

Ear Protection

Wear suitable ear protection during prolonged

exposure to excessive noise.

Hearing Loss

Prolonged Exposure To Loud Noise May

Cause Permanent Hearing Loss!

Working environments with noise-producing

equipment can cause partial to permanent hearing

loss. We recommend using hearing protection any

time noise levels exceed 80 decibels (dB). Noise

levels over 85 dB, on a long-term basis, can cause

severe hearing loss. Noise levels over 90 dB over a

period of time can cause permanent and even total

hearing loss.

Hearing loss from loud noise is cumulative over a

lifetime without hope of natural recovery.

Crush Hazard

The tractor should be equipped with a

Roll Over Protective Structure (ROPS)

and a seat belt. A crushing hazard can occur if the

driver is ejected from the seat while the tractor is in

motion. Fasten the seat belt whenever the tractor is

moving.

SAFETY INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit equipment damage.

N

I

NG

AR Safety Signs

Replace any missing or hard-to-read safety

signs or instructional labels. Use care when

washing or cleaning the Multi-Purpose Cutter.

Replacement safety sign locations and part numbers

are provided in this manual and are available from

an authorized dealer parts department or the factory.

First Aid Kit

Have a rst aid kit available for use should

the need arise and know how to use it.

Fire Extinguisher

Have a re extinguisher available for use

should the need arise and know how to use it.

THINK

SAFETY! Think SAFETY!

Work SAFELY!

2.5 Training

Anyone who will be using and/or maintaining the

cutter must read, clearly understand, and follow ALL

safety, operation, and maintenance information

presented in this manual, other related OEM manuals,

and the safety signs

If you do not understand any information in this

manual, see your dealer or contact Blue Diamond

Attachments, LLC before proceeding.

Do not use or allow anyone else to use this cutter until

all information has been reviewed. Annually review

this manual before the season start-up.

Make periodic reviews of SAFETY and OPERATION

of the cutter a standard practice. An untrained

operator is not qualified to use this cutter.

2.6 OSHA Training Requirements

The following training requirements have been taken

from Title 29, Code of Federal Regulations Part

1928.57 (a) (6). www.osha.gov.

Operator instructions. At the time of initial assignment

and at least annually thereafter, the employer shall

instruct every employee who operates an agricultural

tractor and implements in the safe operating practices

and servicing of equipment with which they are or will

be involved, and of any other practices dictated by the

work environment.

11Blue Diamond Attachments, LLCBrush Cutters

September 2020 888-376-7027

2.7 Federal Laws and Regulations

IMPORTANT FEDERAL LAWS AND REGULATIONS

CONCERNING EMPLOYERS, EMPLOYEES AND OPERATORS

This sections is intended to explain in broad terms the concept and effect of the following federal laws and

regulations. It is not intended as a legal interpretation of the laws and should not be considered as such.

U.S. PUBLIC LAW 91-596 (The Williams-Steiger Occupational Safety and Health Act of 1970) OSHA

This Act Seeks:

“ ... to assure so far as possible every working man and woman in the nation safe and healthful working conditions and to

preserve our human resources ... “

DUTIES

Sec. 5(a) Each Employer -

(1) shall furnish to each of its employees employment and a place of employment which are free from

recognized hazards that are causing or are likely to cause death or serious physical harm to its

employees.

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards

and all rules, regulations, and orders issued pursuant to this Act which are

applicable to his or her own actions and conduct.

OSHA Regulations

Current OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter, the

employer shall instruct every employee in the safe operation and servicing of all equipment with which the

employee is, or will be involved.” These will include (but are not limited to) instructions to:

Keep all guards in place when the machine is in operation;

Permit no riders on equipment;

Stop engine, disconnect the power source, and wait for all machine movement to stop before servicing,

adjusting, cleaning, or unclogging the equipment, except where the machine must be running to be

properly serviced or maintained, in which case the employer shall instruct employees as to all steps and

procedures which are necessary to safely service or maintain equipment.

Make sure no one is within 300 feet of machinery before starting the engine, engaging power,

or operating the machine.

EMPLOYEE TRACTOR OPERATING INSTRUCTIONS:

1. Securely fasten your seat belt if the tractor has a ROPS.

2. Where possible, avoid operating the tractor near ditches, embankments, and holes.

3. Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4. Stay off slopes too steep for safe operation.

5. Watch where you are going, especially at row ends, on roads, and around trees.

6. Do not permit others to ride.

7. Operate the tractor smoothly - no jerky turns, starts, or stops.

8. Hitch only to the drawbar and hitch points recommended by tractor manufacturers.

9. When tractor is stopped, set brakes securely and use park lock if available.

Child Labor Under 16 Years Old

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility to

know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment Standard

Administration, Wage & Home Division, Child Labor Bulletin #102).

12Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

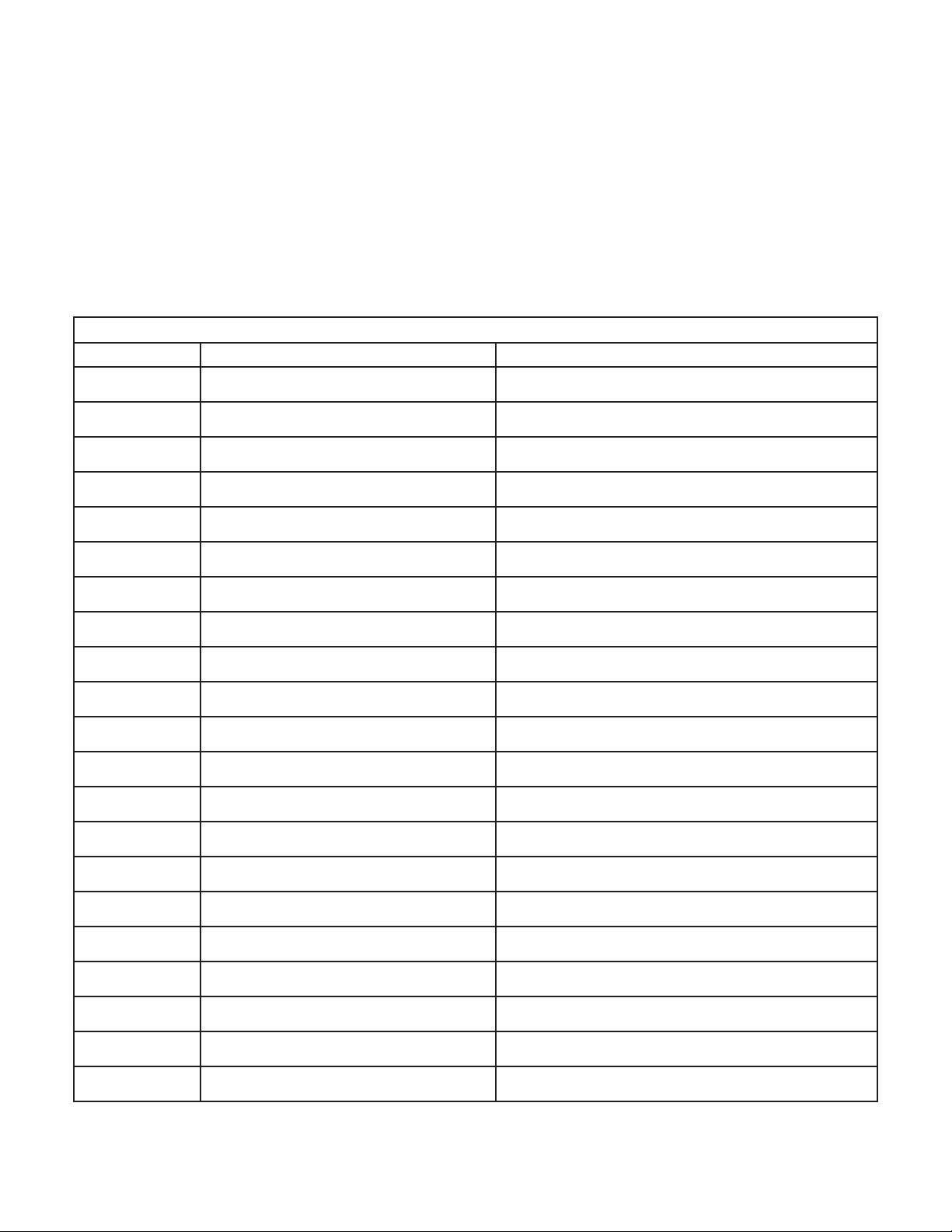

2.8 Sign-Off Form

Blue Diamond Attachments, LLC follows the

general Safety Standards specified by the Farm

Equipment Manufacturers Association (FEMA), and

the American National Standards Institute (ANSI).

Anyone who will be using and/or maintaining the

cutter must read and clearly understand ALL

safety, operation and maintenance information

presented in this manual.

Do not use or allow anyone else to use this cutter

until all information has been reviewed. Annually

review this manual before the season start-up.

Sign-Off Form

Date User’s Signature Owner’s Signature

Make periodic reviews of SAFETY and OPERATION of

the cutter a standard practice. An untrained operator is

not qualified to use this cutter.

This sign-off sheet is provided for your record keeping

to show that all personnel who will be working with the

equipment have read and understand the information in

this Operator’s Manual and Parts Book and have been

instructed in the operation of the equipment.

13Blue Diamond Attachments, LLCBrush Cutters

September 2020 888-376-7027

2.9 Operation Safety

Refer to the Operation section for safety

recommendations related to using the cutter. All

applicable safety recommendations in other sections

should also be followed.

The safety shield found on all multi-purpose cutters is

designed to reduce the risk of thrown objects;

however the cutter deck and safety shield cannot

prevent all objects from escaping the blade enclosure

in every mowing condition, especially in the vertical

configuration.

It is possible for objects to ricochet and escape,

traveling as much as 300 feet. Inspect safety shield

each day of operation and replace any broken or

missing chains, as required.

2.10 Transporting Safety

Refer to the Transporting section for safety

recommendations related to transporting the cutter. All

applicable safety recommendations in other sections

should also be followed.

2.11 Storage Safety

Refer to the Storage section for safety

recommendations related to storing the cutter. All

applicable safety recommendations in other sections

should also be followed.

2.12 Maintenance Safety

Refer to the Service and Maintenance section for

safety recommendations related to maintaining the

cutter. All applicable safety recommendations in other

sections should also be followed.

14Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

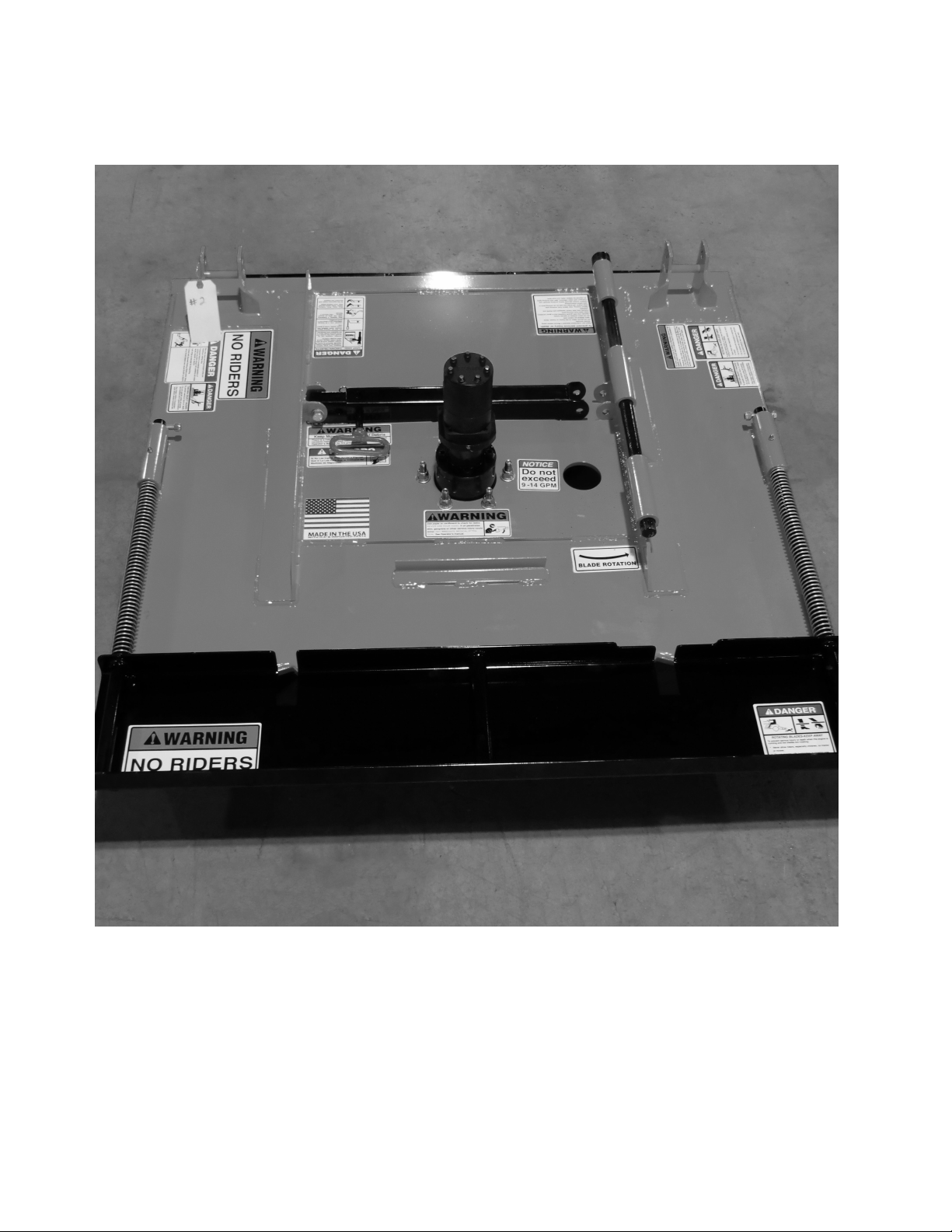

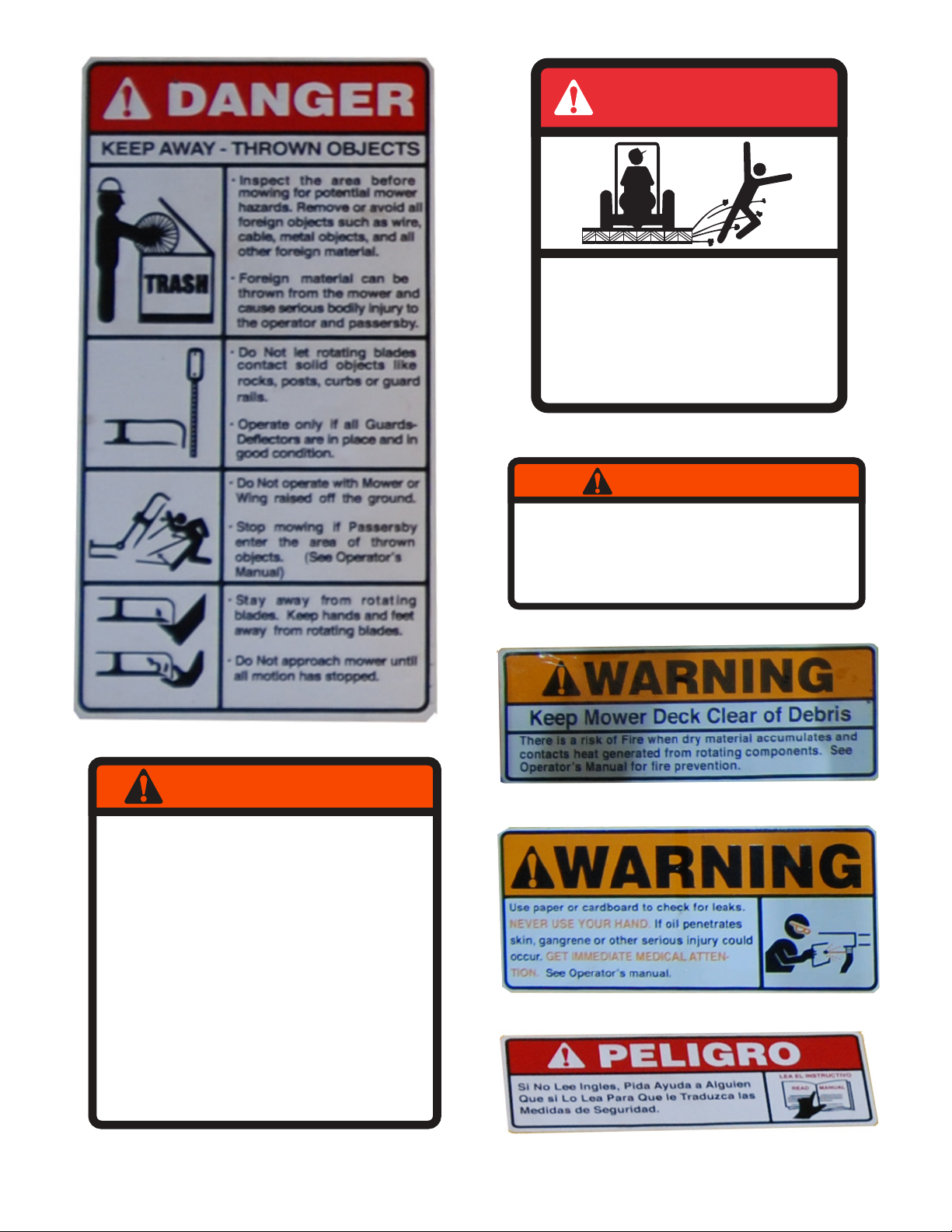

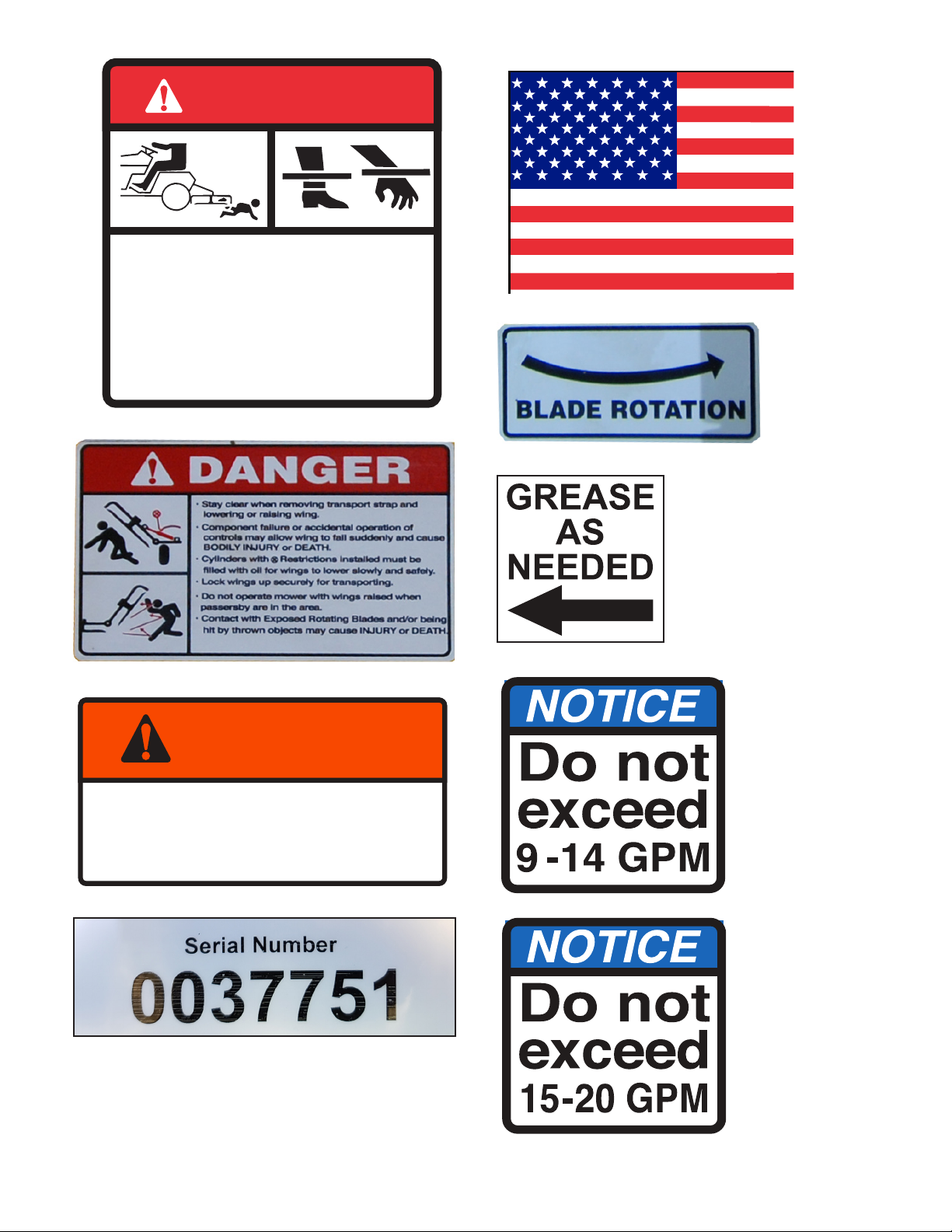

3. SAFETY SIGNS AND INSTRUCTIONAL LABELS

3.1 General Information

The types of safety signs (hazard labels) and

instructional labels, along with their locations on the

equipment, are shown in the following illustrations.

Good safety practices require that you familiarize

yourself with the various safety signs, the type of

warning, and the area or particular operation related to

that area that requires your SAFETY AWARENESS.

THINK

SAFETY!

Think SAFETY!

Work SAFELY!

Pay close attention to the safety signs and

instructional labels attached to the tractor and the

cutter. Duplicate safety signs, which are attached to

the cutter, can also be found in this section. If the

cutter is missing a label or one is unreadable, replace

the label before using the cutter.

SAFETY INSTRUCTIONS

N

I

NG

AR

Safety Signs and Instructional Labels

1. Keep safety signs or instructional labels clean

and legible at all times. Use a clean, damp cloth

to clean safety decals.

2. Replace any missing or hard-to-read safety signs

or instructional labels.

3. Use care when washing or cleaning the equipment

not to remove or damage the labels. When using

a pressure washer to clean the cutter, avoid

spraying too close to decals; high-pressure water

can enter through very small scratches or under

edges of decals causing them to peel or come

off.

4. Locations for the labels and replacement part

numbers are shown in this section.

5. Replacement parts must have replacement labels

attached during installation and/or before the

cutter is used.

6. Labels are available from your authorized dealer

or from Trailblazer at no charge.

3.2 How to Install Replacement Safety Signs

1. Clean and dry the installation area.

Note: Do not install the signs if the temperature is

below 50°F (10°C).

2. Determine the exact position before you remove the

backing paper.

3. Remove the backing paper.

4. Align the sign over the specied area and carefully

press the sign to the part/frame.

Note: Small air pockets can be pierced with a pin and

smoothed out using the piece of backing paper.

15Blue Diamond Attachments, LLCBrush Cutters

September 2020 888-376-7027

3.3 Safety Signs

16Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

TI-00005

To prevent serious injury or death:

Read and understand Operator’s Manual before using.

Review annually.

Do not permit riders on the tractor or mower. Never

carry children on tractor seat.

Do not allow children to operate mower.

Operate only with guards installed and in good condition.

Keep away from moving parts.

Operate only with tractor equipped with ROPS and

seatbelts.

Before mowing, clear debris from mowing area.

Do not operate in the raised position.

Stop engine, set brake and wait for all moving parts to

stop before dismounting.

Support mower securely before working beneath unit.

Transport with clean reflectors, SMV and working lights

as required by federal, state, and local laws.

WARNING

•

•

•

•

•

•

•

•

•

•

•

TI-00006

THROWN OBJECT HAZARD

To prevent serious injury or death:

Do not operate unless all guards

are installed and in good condition.

Stop blade rotation if bystanders

come within several hundred feet.

•

•

DANGER

TI-00075

All rotary cutters have the ability to discharge objects at high

speeds, which could result in serious injury to bystanders or

passers-by.

Therefore, this cutter is not to be operated along highways or

in any area where people may be present unless all sides of the

unit are enclosed by permanent bands, safety chains, or other

factory approved safety shields that are in good repair.

WARNING

17 Blue Diamond Attachments, LLCBrush Cutters

September 2020 888-376-7027

TI-00007

DANGER

ROTATING BLADES-KEEP AWAY

To prevent serious injury or death when the engine is

running and the blades are rotating:

•

Never allow riders, especially children, on tractor

or mower.

•

Do not operate with bystanders in mowing area.

•

Do not operate with deflectors/guards removed.

•

Do not place hands or feet under deck.

TI-00074

WARNING

NO RIDERS

TI-00008

WITH U.S. & IMPORTED PARTS

MADE IN THE USA

18Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

4. Operation

4.1 Operating Safety

WARNING

Crush Hazard

The tractor should be equipped with

a Roll Over Protective Structure

(ROPS) and a seat belt. A crushing hazard can occur

if the driver is ejected from the seat while the tractor

is in motion. Fasten the seat belt whenever the

tractor is moving.

STOP

Roll Away Hazard

Before leaving the

tractor seat, make sure

the engine is stopped, the transmission is placed in

park, the key is removed, and the parking brake is

set.

The weight of the tractor, plus the

cutter if it rolls onto a person, can cause

serious crushing injury or death.

Thrown Object Hazard

Cutters can throw objects up to 300 feet.

To avoid serious injury or death:

1) Keep all thrown object shielding in place.

2) Inspect area for potential thrown objects

before cutting.

3) Do not operate cutter with the deck raised.

Thrown Object Hazard

For non-agricultural use, OSHA, ASAE, SAE,

and ANSI standards require the use of chain

guards or other protective guards at all times.

Stay Clear

Clear the work area of all unnecessary people

and obstructions to prevent personal injury.

Blade Contact Hazard (hand)

To avoid serious injury or death, keep away

from rotating blades. Do not put hands

under cutter deck.

Blade Contact Hazard (foot)

To avoid serious injury or death, keep away

from rotating blades. Do not put feet under

cutter deck.

SAFETY INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit equipment damage.

THINK

SAFETY! Train Unfamiliar Users

It is the cutter owner’s

responsibility to make sure any

person using the cutter, especially if it is loaned

or rented, has been thoroughly trained on its

proper and safe use.

Train all new users and review instructions annually

with existing users.

Be certain only physically-able persons will use the

cutter.

Users who have not read and understood all

operating and safety instructions are not qualified

to use the cutter.

Untrained users expose themselves and bystanders

to possible serious injury or death.

If the elderly are assisting with the work, their

physical limitations need to be recognized and

accommodated.

Never allow children to operate equipment.

4.2 Work Area Safety

SAFETY INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit equipment damage.

Never operate the cutter in darkness or foggy

conditions where you cannot clearly see at least 300

feet in front and to the sides of the tractor and

cutter.

Make sure that you can clearly see and

identify passersby, steep slopes, ditches,

drop-offs, overhead obstructions, power lines,

debris, and foreign objects. If you are unable to

clearly see these type of items, stop operating the

cutter.

Do not operate the cutter, or drive the tractor into

material that is burning, or areas that recently

burnt and may contain hot embers. Burning material,

sparks, and coals could be thrown from the

cutter to areas of vegetation that might ignite.

19 Blue Diamond Attachments, LLC

Brush Cutters

September 2020 888-376-7027

SAFETY INSTRUCTIONS

The following safety instructions are provided to

help prevent injury or limit equipment damage.

Carry a fire extinguisher on the tractor at all

times to extinguish possible fires encountered.

Do not operate the cutter on a tractor with an

under-frame exhaust.

Before turning, slightly raise the cutter off

the ground.

After the cutter is hydraulically disengaged,

the motor can free-wheel for several minutes.

Stay clear of the blades until they come to

complete stop.

Large, dense, or wet vegetation may need to be

cut in two or more passes to achieve a uniform

cut.

Stay alert and watch for trees, low hanging

limbs, power lines, and other overhead

obstacles as well as solid ground objects. Avoid

cutting in reverse.

4.3Tractor Requirements

WARNING

Tractor Owner/Operator Manual

Always refer to the tractor owner’s manual to

ensure compatibility and maximum safety.

The tractor used to operate the cutter must have the

power capacity to lift, push, and hydraulically operate

the cutter.

Depending on the model the tractor will need either

9 to 14 gpm of oil ow

15 to 20 gpm of oil ow

The recommended tractor is a 3000 pound tractor with

rear ballast (such as a cutter deck) to offset the weight

on the front of the tractor. Also, recommended is

tractor tires that are “filled” or solid to prevent

puncture from brush.

This unit WILL NOT work on a skid steer

machine.

WARNING

Using the cutter on a skid steer will void the

warranty and have potential for serious injury to

the user or bystanders.

Operating the cutter with a tractor that does not meet

the following requirements may cause tractor or cutter

damage and be a potential danger to the operator and

passersby.

Always review the “controls” section of the tractor

operator’s manual to be familiar with the location,

settings, and function of the tractor controls. Be

familiar with all controls before using this equipment.

• Approved Roll-Over Protective Structure (ROPS)

or ROPS cab and seat belt.

• Tractor Safety Devices; Slow Moving Vehicle

(SMV) emblem, lighting.

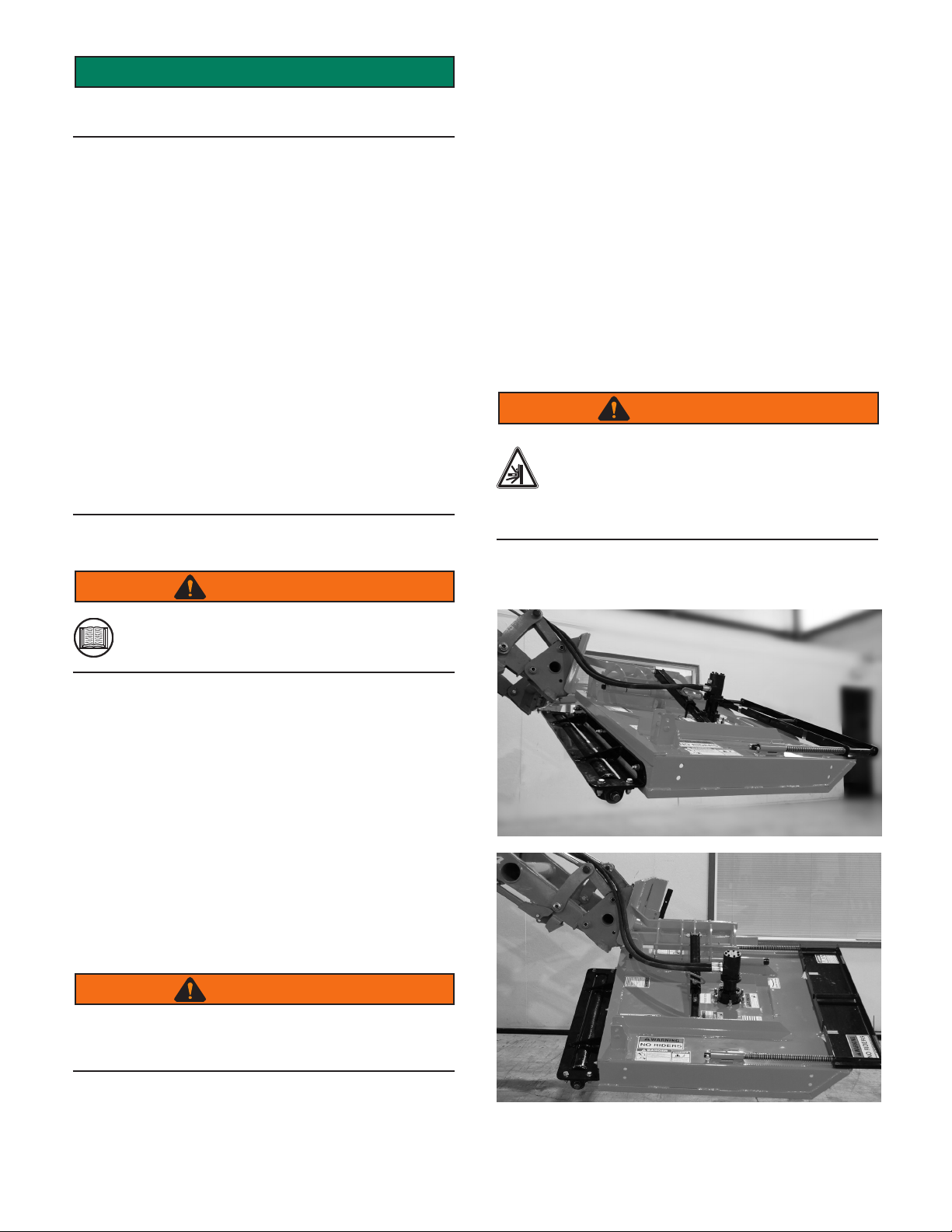

4.4 Attaching to Tractor

Use caution when connecting the cutter to the tractor.

The cutter should be securely resting at ground level or

setting on blocks. Keep hands and feet from under the

deck and clear of pinch points between the tractor

hitch arms and cutter hitch pins.

WARNING

Crush Hazard

Crush hazard between loader’s quick

attachment plate and cutter. Do not allow

anyone to stand between the loader and

implement during hook-up operations.

1. Connect the cutter to the loader arms.

20Brush Cutters

888-376-7027

Blue Diamond Attachments, LLC

September 2020

2. Lock the cutter to the lift arms.

3. Turn OFF the tractor engine and dismount.

4. Connect a user-supplied hydraulic supply hose from

the tractor supply manifold valve to the hose routed

to the right port of the hydraulic motor. The pump

port conguration is from tractor’s viewpoint.

The hose MUST be 5/8 inch diameter. DO NOT

use smaller or larger diameter hoses.

5. Connect the left return port on the motor to a user

supplied hose (5/8 inch diameter) routed to the

tractor’s reservoir.

The return hose must have free-ow back into

the pump reservoir and not be ported through the

tractor’s manifold valve. DO NOT connect into the

tractor’s rear remote return valve.

Note: An optional Hose Kit is available consisting

of two male QD couplings, two female QD

couplings, two 5/8” diameter hoses, and two

pump ttings.

6. Start the cutter and check for rotation. Make sure the

pump is turning in the correct rotation. Hooking up the

hoses to the wrong port will make the cutters operate in

a reverse direction.

Do not put hands or feet under

the cutter deck while the blades

are rotating.

7. Place the cutter in the desired cutting configuration.

a. Horizontal offset mowing configuration.

b. Vertical mowing configuration.

Table of contents

Other Blue Diamond Cutter manuals